Abstract

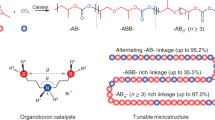

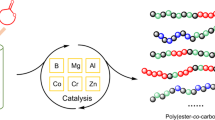

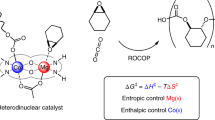

Terpolymerization of carbon dioxide (CO2), propylene oxide (PO), and epoxide with bulky side groups (styrene oxide (SO), cyclohexylethylene oxide (CyEO), tert-butylethylene oxide (tBuEO), or 1-adamantylethylene oxide (AdEO)) was conducted by using a tetraphenylporphyrinatocobalt(III) chloride ((TPP)CoCl)/4-dimethylamino pyridine (DMAP) catalyst system. Compared with the copolymerizations of CO2 and epoxides with bulky side groups, it took less than half (AdEO) or even one-third (CyEO and tBuEO) of the polymerization time to synthesize polycarbonates with degrees of polymerization of 100 or above. In this (TPP)CoCl/DMAP system, a highly random terpolymer of CO2, PO, and SO was realized for the first time, which has not been observed in other catalyst systems, such as cobalt salen complex systems. In contrast, gradient terpolymers were formed in the cases of CyEO, tBuEO, and AdEO. The glass transition temperatures (Tgs) of these terpolymers are tunable between that of the copolymer of CO2 with PO (34 °C) and that of the copolymer of CO2 with the corresponding epoxide with bulky side groups by changing the initial ratio of PO to epoxide with bulky side groups.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Aresta M, Dibenedetto A, Quaranta E. State of the art and perspectives in catalytic processes for CO2 conversion into chemicals and fuels: the distinctive contribution of chemical catalysis and biotechnology. J Catal. 2016;343:2–45.

Sakakura T, Choi JC, Yasuda H. Transformation of carbon dioxide. Chem Rev. 2007;107:2365–87.

Podrojková N, Sans V, Oriňak A, Oriňaková R. Recent developments in the modelling of heterogeneous catalysts for CO2 conversion to chemicals. ChemCatChem. 2020;12:1802–25.

Daza YA, Kuhn JN. CO2 conversion by reverse water gas shift catalysis: comparison of catalysts, mechanisms and their consequences for CO2 conversion to liquid fuels. RSC Adv. 2016;6:49675–91.

Inoue S, Koinuma H, Tsuruta T. Copolymerization of carbon dioxide and epoxide. J Polym Sci Part B Polym Lett. 1969;7:287–92.

Inoue S, Koinuma H, Tsuruta T. Copolymerization of carbon dioxide and epoxide with organometallic compounds. Makromol Chem. 1969;130:210–20.

Huang J, Worch JC, Dove AP, Coulembier O. Update and challenges in carbon dioxide-based polycarbonate synthesis. ChemSusChem. 2020;13:469–87.

Darensbourg DJ. Chain transfer agents utilized in epoxide and CO2 copolymerization processes. Green Chem. 2019;21:2214–23.

Cui S, Borgemenke J, Liu Z, Li Y. Recent advances of “soft” bio-polycarbonate plastics from carbon dioxide and renewable bio-feedstocks via straightforward and innovative routes. J CO2 Util. 2019;34:40–52.

Kozak CM, Ambrose K, Anderson TS. Copolymerization of carbon dioxide and epoxides by metal coordination complexes. Coord Chem Rev. 2018;376:565–87.

Wang Y, Darensbourg DJ. Carbon dioxide-based functional polycarbonates: metal catalyzed copolymerization of CO2 and epoxides. Coord Chem Rev. 2018;372:85–100.

Darensbourg DJ. Comments on the depolymerization of polycarbonates derived from epoxides and carbon dioxide: a mini review. Polym Degrad Stab. 2018;149:45–51.

Scharfenberg M, Hilf J, Frey H. Functional polycarbonates from carbon dioxide and tailored epoxide monomers: degradable materials and their application potential. Adv Funct Mater. 2018;28:1704302.

Liu S, Wang X. Polymers from carbon dioxide: polycarbonates, polyurethanes. Curr Opin Green Sustain Chem. 2017;3:61–6.

Ang RR, Sin LT, Bee ST, Tee TT, Kadhum AAH, Rahmat AR, et al. A review of copolymerization of green house gas carbon dioxide and oxiranes to produce polycarbonate. J Clean Prod. 2015;102:1–17.

Trott G, Saini PK, Williams CK. Catalysts for CO2/epoxide ring-opening copolymerization. Philos Trans R Soc A. 2015;374:20150085.

Darensbourg DJ, Chung WC. Availability of other aliphatic polycarbonates derived from geometric isomers of butene oxide and carbon dioxide coupling reactions. Macromolecules. 2014;47:4943–8.

Taherimehr M, Pescarmona PP. Green polycarbonates prepared by the copolymerization of CO2 with epoxides. J Appl Polym Sci. 2014;131:41141.

Lu XB, Ren WM, Wu GP. CO2 copolymers from epoxides: catalyst activity, product selectivity, and stereochemistry control. ACC Chem Res. 2012;45:1721–35.

Klaus S, Lehenmeier MW, Anderson CE, Rieger B. Recent advances in CO2/epoxide copolymerization—new strategies and cooperative mechanisms. Coord Chem Rev. 2011;255:1460–79.

Sugimoto H, Inoue S. Recent progress in the synthesis of polymers based on carbon dioxide. Pure Appl Chem. 2006;78:1823–34.

Sugimoto H, Inoue S. Copolymerization of carbon dioxide and epoxide. J Polym Sci Part A Polym Chem. 2004;42:5561–73.

Coates GW, Moore DR. Discrete metal-based catalysts for the copolymerization of co2 and epoxides: discovery, reactivity, optimization, and mechanism. Angew Chem Int Ed. 2004;43:6618–39.

Empower Materials Inc. QPAC poly(alkylene carbonate) copolymers (2010). http://www.empowermaterials.com. Accessed 1 June 2020.

Arai R, Seto K, Bell A, Sugimoto H. Synthesis of CO2-derived polycarbonates with high glass transition temperatures. Polym J. 2018;50:301–7.

Li XH, Meng YZ, Chen GQ, Li RKY. Thermal properties and rheological behavior of biodegradable aliphatic polycarbonate derived from carbon dioxide and propylene oxide. J Appl Polym Sci. 2004;94:711–6.

Nakano K, Hashimoto S, Nakamura M, Kamada T, Nozaki K. Stereocomplex of poly(propylene carbonate): synthesis of stereogradient poly(propylene carbonate) by regio and enantioselective copolymerization of propylene oxide with carbon dioxide. Angew Chem Int Ed. 2011;50:4868–71.

Lu XB, Shi L, Wnag YM, Zhang R, Zhang YJ, Peng XJ, et al. Design of highly active binary catalyst systems for CO2/epoxide copolymerization: polymer selectivity, enantioselectivity, and stereochemistry Control. J Am Chem Soc. 2006;128:1664–74.

Qin Y, Wang X, Zhang S, Zhao X, Wang F. Fixation of carbon dioxide into aliphatic polycarbonate, cobalt porphyrin catalyzed regio-specific poly(propylene carbonate) with high molecular weight. J Polym Sci Part A Polym Chem. 2008;46:5959–67.

Ren WM, Liu Y, Wu GP, Liu J, Lu XB. Stereoregular polycarbonatesynthesis: alternating copolymerization of CO2 with aliphatic terminal epoxides catalyzed by multichiral cobalt(III) complexes. J Polym Sci Part A Polym Chem. 2011;49:4894–901.

Yoshida A, Honda S, Goto H, Sugimoto H. Synthesis of H-shaped carbon-dioxide-derived poly(propylene carbonate) for topologybased reduction of the glass transition temperature. Polym Chem. 2014;5:1883–90.

Honda S, Sugimoto H. Polymer cyclization inhibits thermal decomposition of carbon-dioxide-derived poly(propylene carbonate)s. J Polym Sci Part A Polym Chem. 2016;54:3336–42.

Darensbourg DJ. Making plastics from carbon dioxide: salen metal complexes as catalysts for the production of polycarbonates from epoxides and CO2. Chem Rev. 2007;107:2388–410.

Lamb JR, Jung Y, Coates GW. Meinwald-type rearrangement of monosubstituted epoxides to methyl ketones using an (Al porphyrin)+(Co(CO)4)− catalyst. Org Chem Front. 2015;2:346–9.

Sugimoto H, Kuroda K. The cobalt porphyrin-lewis base system: a highly selective catalyst for alternating copolymerization of CO2 and epoxide under mild conditions. Macromolecules. 2008;41:312–7.

Sugimoto H, Ohtsuka H, Inoue S. Alternating copolymerization of carbon dioxide and epoxide catalyzed by an aluminum Schiff base-ammonium salt system. J Polym Sci Part A Polym Chem. 2005;43:4172–86.

Wu GP, Xu PX, Zu YP, Ren WM, Lu XB. Cobalt(III)-complex-mediated terpolymerization of CO2, styrene oxide, and epoxides with an electron-donating group. J Polym Sci Part A Polym Chem. 2013;51:874–9.

Zhang XH, Wei RJ, Zhang YY, Du BY, Fan ZQ. Carbon dioxide/epoxide copolymerization via a nanosized zinc-cobalt(III) double metal cyanide complex: substituent effects of epoxides on polycarbonate selectivity, regioselectivity and glass transition temperatures. Macromolecules. 2015;48:536–44.

Fox TG. Influence of diluent and copolymer composition on the glass temperature of a polymer system. Bull Am Phys Soc. 1956;1:123–8.

Acknowledgements

This research paper is dedicated to Prof. Shohei Inoue, a great Japanese polymer chemist who pioneered polymer synthesis from CO2 and passed away on March 19, 2020. This work was partly supported by JSPS KAKENHI Grant Number JP19H02757. We thank our former collaborators, Dr. Hidetoshi Goto and Messrs. Kunitaka Kuroda, Isamu Esashika, Takayuki, Shimozaki, and Yuya Ohshima, for their active collaborations.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Honda, M., Ebihara, T., Ohkawa, T. et al. Alternating terpolymerization of carbon dioxide, propylene oxide, and various epoxides with bulky side groups for the tuning of thermal properties. Polym J 53, 121–127 (2021). https://doi.org/10.1038/s41428-020-00412-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-020-00412-8

This article is cited by

-

Special issue: CO2: capture of, utilization of, and degradation into

Polymer Journal (2021)