Abstract

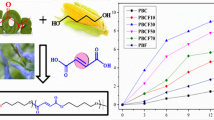

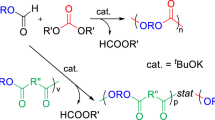

Aliphatic polycarbonate-based polyurethanes were successfully synthesized using two aliphatic polycarbonate polyols and hexamethylene diisocyanate (HDI) with 1,4-butanediol (1,4-BD) as the chain extender. One of the aliphatic polycarbonate polyols, named PBC-diol, was prepared from dimethyl carbonate (DMC) and 1,4-BD, while the other, named PCHC-diol, was derived by reacting DMC with 1,4-cyclohexanedimethanol (CHDM). The results of the thermogravimetric analysis (TGA) indicated that the cyclic structure improved the thermal stability of the polyurethanes. In addition, the differential scanning calorimetry (DSC) curves showed that the cyclic structure increased the glass transition temperature (Tg) of the polyurethanes but slowed their crystallization. Furthermore, the mechanical properties of the polyurethanes with different cyclic structure contents were analyzed using Instron. Although the elongation at break decreased, the tensile strength increased from 32.6 to 844.0 MPa when the PBC-diol was replaced with PCHC-diol in the polyurethanes. Finally, Fourier transform infrared (FTIR) analysis was conducted to investigate the formation of hydrogen bonds. The relationship between the hydrogen bonds and cyclic structure content was also shown in this study.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Ugarte L, Calvo-Correas T, Gonzalez-Gurrutxaga I, Peña-Rodriguez C, Etxeberria O, Corcuera MA, et al. Towards Circular Economy: different Strategies for Polyurethane Waste Recycling and the Obtaining of New Products. Proc. 2018;2:1490.

Choi J, Moon DS, Jang JU, Yin WB, Lee B, Lee KJ. Synthesis of highly functionalized thermoplastic polyurethanes and their potential applications. Polymer. 2017;116:287–94.

Solanki A, Das M, Thakore S. A review on carbohydrate embedded polyurethanes: an emerging area in the scope of biomedical applications. Carbohydr Polym. 2018;181:1003–16.

Bahrami S, Solouk A, Mirzadeh H, Seifalian AM. Electroconductive polyurethane/graphene nanocomposite for biomedical applications. Compos B Eng. 2019;168:421–31.

Fortman DJ, Sheppard DT, Dichtel WR. Reprocessing Cross-Linked Polyurethanes by Catalyzing Carbamate Exchange. Macromolecules. 2019;52:6330–5.

Gunatillake PA, Dandeniyage LS, Adhikari R, Bown M, Shanks R, Adhikari B. Advancements in the Development of Biostable Polyurethanes. Polym Rev. 2018;59:391–417.

Joseph J, Patel RM, Wenham A, Smith JR. Biomedical applications of polyurethane materials and coatings. Trans Imf. 2018;96:121–9.

Akindoyo JO, Beg MDH, Ghazali S, Islam MR, Jeyaratnam N, Yuvaraj AR. Polyurethane types, synthesis and applications – a review. RSC Adv. 2016;6:114453–82.

Kausar A. Polyurethane Composite Foams in High-Performance Applications: a Review. Polym Plast Technol Eng. 2017;57:346–69.

Cakić SM, Špírková M, Ristić IS, B-Simendić JK, M-Cincović M, Poręba R. The waterborne polyurethane dispersions based on polycarbonate diol: effect of ionic content. Mater Chem Phys. 2013;138:277–85.

Špírková M, Poręba R, Pavličević J, Kobera L, Baldrian J, Pekárek M. Aliphatic polycarbonate-based polyurethane elastomers and nanocomposites I The influence of hard-segment content and macrodiol-constitution on bottom-up self-assembly. J Appl Polym Sci. 2012;126:1016–30.

Dongdong P, Hengshui T. Polycarbonate polyurethane elastomers synthesized via a solvent-free and nonisocyanate melt transesterification process. J Appl Polym Sci. 2015;132:41377. https://doi.org/10.1002/app.41377.

Eceiza A, Martin MD, de la Caba K, Kortaberria G, Gabilondo N, Corcuera MA, et al. Thermoplastic polyurethane elastomers based on polycarbonate diols with different soft segment molecular weight and chemical structure: Mechanical and thermal properties. Polym Eng Sci. 2008;48:297–306.

Sobczak M, Dębek C, Olędzka E, Nałęcz-Jawecki G, Kołodziejski WL, Rajkiewicz M. Segmented polyurethane elastomers derived from aliphatic polycarbonate and poly(ester-carbonate) soft segments for biomedical applications.J Polym Sci Part A: Polym Chem. 2012;50:3904–13.

Rosu D, Rosu L, Cascaval CN. IR-change and yellowing of polyurethane as a result of UV irradiation. Polym Degrad Stab. 2009;94:591–6.

Singh R, Tomer NS, Bhadraiah SV. Photo-oxidation studies on polyurethane coating: effect of additives on yellowing of polyurethane. Polym Degrad Stab. 2001;73:443–6.

Irusta L, Fernandez-Berridi M. Photooxidative behaviour of segmented aliphatic polyurethanes. Polym Degrad Stab. 1999;63:113–9.

Zhang J, Tu W, Dai Z. Synthesis and characterization of transparent and high impact resistance polyurethane coatings based on polyester polyols and isocyanate trimers. Prog Org Coat. 2012;75:579–83.

Kim YD, Kim SC. Effect of chemical structure on the biodegradation of polyurethanes under composting conditions. Polym Degrad Stab. 1998;62:343–52.

Zheng Y, Yanful EK, Bassi AS. A review of plastic waste biodegradation. Crit Rev Biotechnol. 2005;25:243–50.

Xu W, Zhou L, Sun W, Zhang J, Tu W. Effect of difunctional acids on the physicochemical, thermal, and mechanical properties of polyester polyol-based polyurethane coatings. J Appl Polym Sci. 2015;132:41246. https://doi.org/10.1002/app.41246.

Zhang J, Tu W, Dai Z. Transparent polyester polyol-based polyurethane coatings: the effect of alcohols. J Coat Technol Res. 2013;10:887–95.

Kucinska-Lipka J, Gubanska I, Strankowski M, Cieslinski H, Filipowicz N, Janik H. Synthesis and characterization of cycloaliphatic hydrophilic polyurethanes, modified with l-ascorbic acid, as materials for soft tissue regeneration. Mater Sci Eng C. 2017;75:671–81.

Javni I, Hong DP, Petrović ZS. Polyurethanes from soybean oil, aromatic, and cycloaliphatic diamines by nonisocyanate route. J Appl Polym Sci. 2013;128:566–71.

Awasthi S, Agarwal D. Influence of cycloaliphatic compounds on the properties of polyurethane coatings. J Coat Technol Res. 2007;4:67–73.

Ni H, Daum JL, Thiltgen PR, Soucek MD, Simonsick WJ Jr, Zhong W, et al. Cycloaliphatic polyester-based high-solids polyurethane coatings: II The effect of difunctional acid. Prog Org Coat. 2002;45:49–58.

Ni H, Daum JL, Soucek MD, Simonsick WJ. Cycloaliphatic polyester based high solids polyurethane coatings: I The effect of difunctional alcohols. J Coat Technol. 2002;74:49–56.

Javni I, Zhang W, Petrović ZS. Effect of different isocyanates on the properties of soy‐based polyurethanes. J Appl Polym Sci. 2003;88:2912–6.

Gu L, Cui B, Wu Q-Y, Yu H. Bio-based polyurethanes with shape memory behavior at body temperature: effect of different chain extenders. RSC Adv. 2016;6:17888–95.

Lee DK, Tsai HB. Properties of segmented polyurethanes derived from different diisocyanates. J Appl Polym Sci. 2000;75:167–74.

Ping P, Wang W, Chen X, Jing X. The influence of hard segments on two phase structure and shape memory properties of PCL based segmented polyurethanes. J Polym Sci, Part B: Polym Phys. 2007;45:557–70.

Wang W, Ping P, Chen X, Jing X. Shape memory effect of poly (L-lactide) based polyurethanes with different hard segments. Polym Int. 2007;56:840–6.

Chattopadhyay DK, Webster DC. Thermal stability and flame retardancy of polyurethanes. Prog Polym Sci. 2009;34:1068–133.

Ferguson J, Petrovic Z. Thermal stability of segmented polyurethanes. Eur Polym J. 1976;12:177–81.

Madhavan K, Reddy B. Synthesis and characterization of poly (dimethylsiloxane urethane) elastomers: Effect of hard segments of polyurethane on morphological and mechanical properties. J Polym Sci Part A: Polym Chem. 2006;44:2980–9.

Petrović ZS, Zavargo Z, Flyn JH, Macknight WJ. Thermal degradation of segmented polyurethanes. J Appl Polym Sci. 1994;51:1087–95.

Acknowledgements

The financial support from the Ministry of Science and Technology of the Republic of China (MOST 108-2221-E-006-001) is gratefully acknowledged. The authors also gratefully acknowledge the Instrument Center of National Cheng Kung University for letting them use the Bruker Avance 600 NMR spectrometer.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no competing financial interests or personal relationships that could have influenced the work reported in this paper.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Wu, YH., Wang, CC. & Chen, CY. Effect of the cyclic structure content on aliphatic polycarbonate-based polyurethane. Polym J 53, 695–702 (2021). https://doi.org/10.1038/s41428-021-00462-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-021-00462-6

This article is cited by

-

Development of bio-based polyester-urethane-acrylate (PUA) from citric acid for UV-curable coatings

Journal of Coatings Technology and Research (2023)