Abstract

Hyperbranched polycarbonates (HBPCs) with Mn=2.1–7.1 × 103 were synthesized by A2+B3 polymerization using di-tert-butyl tricarbonate as the A2 monomer and 1,1,1-tris(4-hydroxyphenyl)ethane as the B3 monomer. A2+B3 polymerization with different feed ratios was achieved, controlling the degree of branching (DB) and the ratio of terminal functional groups. The DB of the HBPCs is 0.5–0.7. The Boc-terminated PC was prepared by either a 1-pot or a 2-pot synthesis. In contrast, PC with terminal phenol groups was prepared by deprotection of Boc-terminated PC.

Similar content being viewed by others

Introduction

Polycarbonate (PC) with a Bisphenol A skeleton is one of the most widely used engineering plastics because it combines excellent physical, electrical and mechanical properties, including transparency, and heat-distortion resistance toughness.1, 2 However, PC has a potential problem in both synthesis and processes. Two currently used commercial methods for the synthesis of PC are interfacial polycondensation of Bisphenol A with phosgene and transesterification of diphenyl carbonate with Bisphenol A.3 In recent years, there has been an increasing demand for a safe and environmentally friendly process to synthesize PC.4, 5, 6, 7, 8, 9 PC has the disadvantage of having a high melt viscosity (low liquidity) and significant orientational birefringence caused by the Bisphenol-A backbone in the main chain. To solve these problems, there are a few applicable approaches, such as using relatively low molecular weight PC, introducing a different backbone into PC10 and making a polymer alloy or blends with additives that cancel the intrinsic birefringence of PC.1, 2 These PCs have properties that are more suitable for applications. However, these modifications do not reduce the fundamental resolution of PC synthesis and its process.

In general, hyperbranched polymers are good candidates for overcoming the disadvantageous optical properties of PCs because of the fact that they possess low viscosity and high solvent solubility arising from their three-dimensional globular architecture with many branch structures.11, 12, 13 Hyperbranched polycarbonates (HBPCs) have been reported,14, 15, 16, 17, 18 but until now, only a few papers describing HBPCs derived from phenolic structures have been reported.19, 20 Hyperbranched aryl PC from AB2 or A2B condensation has been reported by Wooly et al.20 Compared with AB2 or A2B approaches, monomers used for A2+B3 polymerization are easily prepared or purchased in cases in which the polymer structure can be controlled using different monomer structures. We recently developed an A2+B3 polymerization method for the synthesis of HBPC that uses the reaction between Bisphenol-A-bis(chloroformate) and 1,1,1-tris(4-hydroxyphenyl)ethane (THPE).21 This HBPC showed a lower birefringence change than the corresponding linear PC under a 1% drawn condition (T Nishikubo et al., unpublished data).

Herein, we describe a relatively easy synthesis of HBPC using di-tert-butyl tricarbonate (DBTC) instead of Bisphenol-A-bis(chloroformate) as a novel A2 monomer and THPE as a B3 monomer. HBPCs with both terminal Boc groups and phenol groups were easily prepared by a 1-pot synthesis and by treatment with acid of Boc-protected hyperbranched polymer, respectively.

Experimental procedure

Materials

Tetrahydrofuran (THF) (Wako Chemical, Osaka, Japan, 99%) and pyridine (Kanto Chemical, Tokyo, Japan, 99.5%) were distilled over sodium wire before use. Other materials were used without any purification.

Measurements

1H NMR spectra (500 and 600 MHz) were obtained using JEOL JNM-ECA-600 and JEOL JNM-ECA-500 spectrometers (JEOL, Tokyo, Japan) using chloroform-d (CDCl3) or dimethylsulfoxide (DMSO)-d6 ((CD3)2SO) as a solvent. The chemical shift references were as follows: chloroform-h, 7.26 p.p.m.; DMSO-d5, 2.50 p.p.m.; (13C) CDCl3, 77.0 p.p.m. (CDCl3); and DMSO-d6, 39.5 p.p.m. (DMSO-d6). Typical 1D FID was subjected to exponential multiplication with an exponent of 0.1 Hz (for 1H) and 1.0–2.0 Hz (for 13C).

Fourier transform infrared spectra were obtained using a Nicolet Avatar 380 Fourier transform infrared instrument (Thermo Scientific K. K., Kanagawa, Japan). A few drops of the compound in CH2Cl2 or CHCl3 were applied to the surface of KRS or KBr. After the solvent evaporated, the spectrum was acquired (128 scans, 4-cm−1 resolution).

The number-average molecular weight (Mn) and molecular weight distribution (weight-average molecular weight/number-average molecular weight (Mw/Mn)) of the polymers were estimated on a TOSOH size exclusion chromatography system (HLC-8220; TOSOH, Tokyo, Japan) equipped with two consecutive polystyrene gel columns (TSK gels: SuperHZM-M × 2; TOSOH), a refractive-index detector (RI-8022; TOSOH) and an ultraviolet detector (UV-8020; TOSOH) at 40 °C. The system was operated at a flow rate of 0.35 ml min−1 with THF as an eluent. The Mn and Mw/Mn values of HBPC-OH were estimated on a TOSOH size exclusion chromatography system (HLC-8220; TOSOH) equipped with four consecutive polystyrene gel columns (Shodex gels: GF-1G 7B, GF310-HQ × 2 and GF510-HQ; TOSOH), a refractive-index detector (RI-8022; TOSOH) and an ultraviolet detector (UV-8020; TOSOH) at 40 °C. The system was operated at a flow rate of 0.60 ml min−1 with a N,N-dimethyl formamide solution (20 mM LiBr and 20 mM phosphoric acid) as an eluent. In these size exclusion chromatography (SEC) systems, polystyrene standards were used for calibration.

Differential scanning calorimetry: Glass transition temperature (Tg) was measured with an EXSTAR 6000/DSC6200 (SEIKO Instruments, Chiba, Japan) at a heating rate of 10 °C min−1 under a nitrogen atmosphere (monitoring range: −30 to 220 °C).

Thermogravimetric analysis–differential thermal analysis (TG-DTA). Thermal decomposition temperature (Td) was measured with an EXSTAR 6000/TG/DTA6200 (SEIKO Instruments) at a heating rate of 10 °C min−1 under a nitrogen atmosphere (monitoring range: 50–600 °C).

Synthesis

Synthesis of DBTC

DBTC was prepared with a 59% yield according to a previously described method.22, 23, 24

Synthesis of linear PC

The mixture of DBTC (131.1 mg, 0.5 mmol) and ((4,4′-α-methylbenzylidene)bisphenol) (145.2 mg, 0.5 mmol) in THF (0.5 ml) was stirred at 30 °C for 10 h. Thereafter, pyridine (42 μl, ∼1.05 equivalent against DBTC) was added to the reaction mixture. The reaction mixture was poured into methanol/H2O (7/3, v/v) to precipitate the corresponding polymer. The precipitate was collected and dried under vacuum for 24 h yielding a white solid (150.9 mg, 91%). Mn=3.3 × 103 (Mw/Mn=1.78). 1H NMR (600 MHz, DMSO-d6): δ=9.318 (s, 1 H, terminal phenol), 7.38–7.15 (m, 44 H, phenyl), 7.13–7.03 (m, 41 H, phenyl), 6.85–6.81 (m, 2 H, terminal phenyl), 6.70–6.65 (m, 2 H, terminal phenyl), 2.146 (s, 16.8 H, CH3), 2.073 (s, 3.2 H, terminal CH3), 1.468 (s, 7.1 H, t-Bu). Infrared (IR) (film, cm−1): 3450 (νO–H), 2978, 2871 (νC–H), 1775 (νArO-(C=O)-OAr).

Synthesis of HBPC-Boc-OH

A typical procedure for the synthesis of HBPC (HBPC-Boc-OH) was as follows. The mixture of DBTC (131.1 mg, 500 μmol) and THPE (102.1 mg, 333 μmol) in THF (1.0 ml) was stirred at 30 °C for 2 h. Thereafter, pyridine (84 μl, ∼1.05 equivalent against DBTC) was added to the reaction mixture. The reaction mixture was poured into methanol/H2O (7/3, v/v) to precipitate the corresponding polymer, and the precipitate was collected and dried under vacuum for 24 h to yield a white solid (107 mg, 82%). Mn=7.1 × 103 (Mw/Mn=5.95). 1H NMR (600 MHz, DMSO-d6): δ=9.355 (br s, 0.38 H, phenol), 9.280 (m, 0.57 H, phenol), 7.35–7.22 (m, 4.86 H, phenyl), 7.19–7.04 (m, 4.86 H, phenyl), 6.87–6.77 (m, 1.16 H, phenyl), 6.73–6.63 (m, 1.16 H, phenyl), 2.152 (br s, 1.50 H, CH3), 2.090 (br s, 1.20 H, CH3), 2.032 (br s, 0.30 H, CH3), 1.483 (s, 8.9 H, t-Bu). IR (film, cm−1): 3267 (νO–H), 2980, 2875 (νC–H), 1776 (νArO-(C=O)-OAr), 1759 (νArO-(C=O)-O-t-Bu).

Instead of using methanol/H2O (7/3, v/v) solution for precipitation, pyridine/H2O (1/3, v/v) was applied. Similar results were obtained using this procedure.

Synthesis of Boc-protected HBPC (HBPC-Boc) by 2-stage reaction

HBPC-Boc-OH (Mn=4.0 × 103, Mw/Mn=2.98) (105 mg) in THF/pyridine (1.0 ml/113 μml) was reacted with tert-butyldicarbonate (BDC) (323 μl) at room temperature for 6 h. The reaction mixture was poured into n-hexane to precipitate the corresponding polymer. The precipitate was collected and dried under vacuum for 24 h to yield a white solid (110 mg). Mn=6.2 × 103 (Mw/Mn=2.48). 1H NMR (600 MHz, DMSO-d6): δ=7.31–7.08 (m, 12 H, phenyl), 2.18–2.14 (m, 2.9 H, CH3), 1.48 (s, 10.8 H, t-Bu). IR (film, cm−1): 2981, 2937, 2874 (νC–H), 1776 (νO-(C=O)-O), 1759 (νO-(C=O)-O-t-Bu).

Synthesis of HBPC-Boc by 1 pot, 2 stage

The mixture of DBTC (524.5 mg, 2.0 mmol) and THPE (306.3 mg, 1.0 mmol) in THF (1.5 ml) was stirred at room temperature for 2 h. Thereafter, pyridine (1.0 ml) and BDC (1.0 ml, 4.5 mmol) were added to the reaction mixture, and it was stirred at room temperature for another 6 h. The reaction mixture was poured into n-hexane to precipitate the corresponding polymer, and the precipitate was collected and dried under vacuum for 24 h to yield a white solid (415 mg, 92%). Mn=4.3 × 103 (Mw/Mn=2.8). Tg=119 °C. 1H NMR (600 MHz, DMSO-d6): δ=7.33–7.08 (m, 12 H, phenyl), 2.18–2.14 (m, 3 H, CH3), 1.48 (s, 12.5 H, t-Bu). IR (cm−1): 2981, 2937, 2874 (νC–H), 1776 (νArO-(C=O)-OAr), 1759 (νO-(C=O)-O-t-Bu).

Model compound synthesis and NMR study

The compound 1,1,1-tris(4-tert-butoxycarbonyloxyphenyl)ethane (branching unit) was synthesized as described25 using less equivalent (2.2 equivalent against THPE, 306 mg, 1 mmol) di-tert-butyl dicarbonate (480 mg, 2.2 mmol) to obtain mono and disubstituted compounds. Purification with column chromatography (silica, chloroform or chloroform/methanol=9:1) or PTLC (chloroform) resulted in three fractions: F1, 1,1,1-tris(4-tert-butoxycarbonyloxyphenyl)ethane (Rf (chloroform)=∼0.78); F2, 1-(4′-hydroxyphenyl)-1,1-bis(4-tert-butoxycarbonyloxyphenyl)ethane (Rf (chloroform/methanol=9:1)=∼0.7); and F3, 1,1-bis-(4′-hydroxyphenyl)-1-(4-tert-butoxycarbonyloxyphenyl)ethane (Rf (chloroform/methanol=9:1)=∼0.4).

1,1,1-Tris(4-tert-butoxycarbonyloxyphenyl)ethane (F1; branching unit): Yield=14%. 1H NMR (600 MHz, CDCl3): δ=7.080 (d, J=9.0, 6 H, phenyl), 7.051 (d, J=9.0, 6 H, phenyl), 2.130 (s, 3.0 H, CH3), 1.555 (s, 27 H, t-Bu). 1H NMR (600 MHz, DMSO-d6): δ=7.130 (d, J=7.2, 6 H, phenyl), 7.077 (d, J=7.2, 6 H, phenyl), 2.132 (s, 3.0 H, CH3), 1.482 (s, 27 H, t-Bu). 13C{1H} NMR (150 MHz, CDCl3): δ=aromatic region, 152.0, 149.3, 146.0, 129.6, 120.7, aliphatic region, 83.6, 51.6, 30.9, 27.7. 13C{1H} NMR (150 MHz, DMSO-d6): δ=aromatic region, 151.3, 148.8, 145.9, 129.3, 121.0, aliphatic region, 83.2, 51.2, 30.2, 27.2. Melting point 162–163 °C. IR (cm−1): 2980, 2935, 2882 (νC–H), 1758 (νO-(C=O)-O-t-Bu).

1-(4′-Hydroxyphenyl)-1,1-bis(4-tert-butoxycarbonyloxyphenyl)ethane (F2; linear unit): Yield=32%. 1H NMR (600 MHz, DMSO-d6): δ=9.342 (s, 1 H, OH), 7.097 (d, J=8.0, 4 H, phenyl), 7.051 (d, J=8.0, 4 H, phenyl), 6.833 (d, J=9.0, 2 H, phenyl), 6.689 (d, J=9.0, 2 H, phenyl), 2.071 (s, 3.0 H, CH3), 1.481 (s, 18 H, t-Bu). 13C{1H} NMR (150 MHz, DMSO-d6): δ=aromatic region, 155.5, 151.3, 148.6, 146.7, 138.5, 129.23, 129.12, 120.7, 114.7, aliphatic region, 83.1, 50.8, 30.3, 27.2. IR (cm−1): 3447 (νO–H), 2981, 2937 (νC–H), 1758 (νO-(C=O)-O-t-Bu), 1734 (νO-(C=O)-O-t-Bu).

1,1-Bis-(4′-hydroxyphenyl)-1-(4-tert-butoxycarbonyloxyphenyl)ethane (F3; terminal unit): Yield=11%. 1H NMR (600 MHz, DMSO-d6): δ=9.281 (s, 2 H, OH), 7.061 (d, J=9.0, 2 H, phenyl), 7.026(d, J=9.0, 2 H, phenyl), 6.807 (d, J=9.0, 4 H, phenyl), 6.658 (d, J=9.0, 4 H, phenyl), 2.012 (s, 3.0 H, CH3), 1.480 (s, 9 H, t-Bu). 13C{1H} NMR (150 MHz, DMSO-d6): δ=aromatic region, 155.3, 151.4, 148.4, 147.5, 139.3, 129.2, 129.1, 120.5, 114.5, aliphatic region, 83.1, 50.3, 30.4, 27.2. IR (cm−1): 3409 (νO–H), 2981, 2936, (νC–H), 1757 (νO-(C=O)-O-t-Bu), 1728 (νO-(C=O)-O-t-Bu).

Direct monitoring of the model reaction

The reaction between DBTC (264 mg, 1 mmol) and THPE (102.1 mg, 0.3 mmol) in THF-d8 (0.75 ml) was followed by 1H NMR spectroscopy.

Synthesis of HBPC-BDC

The mixture of DBTC (813.2 mg, 3.1 mmol) and THPE (306.3 mg, 1.0 mmol) in THF (1.0 ml) was stirred at room temperature for 12 h. The reaction mixture was poured into n-hexane to precipitate the corresponding polymer, and the precipitate was collected and dried under vacuum to yield a white solid (573.7 mg, 77%). Mn=1.7 × 103 (Mw/Mn=1.4). 1H NMR (600 MHz, CDCl3): δ=7.20–7.08 (m, 11.9 H, phenyl), 2.18–2.16 (m, 3.0 H, CH3), 1.57 (s, 9.3 H, t-Bu). 13C{1H} NMR (150 MHz, CDCl3): δ=aromatic region, 149.30, 149.28, 148.86, 148.84, 147.57, 146.7, 146.6, 146.2, 145.6, 129.82, 129.80, 129.73, 129.71, 120.40, 120.37, 120.4, 120.21, 120.20, aliphatic region, 86.6, 51.7, 30.8, 27.4. IR (film, cm−1): 2982, 2840 (νC–H), 1832 (νC=O, carbonate), 1778 (νC=O, carbonate).

Synthesis of HBPC-Boc from the decomposition of the BDC group

HBPC-DBC (0.3 g) in THF (1.5 ml) and pyridine (10 μl, 0.2 mmol) was stirred at room temperature for 12 h. The reaction mixture was poured into n-hexane to precipitate the corresponding polymer, and the precipitate was collected and dried under vacuum for 24 h to yield a white solid (253 mg). Mn=1.4 × 103 (Mw/Mn=1.4). 1H NMR (600 MHz, CDCl3): δ=7.16–7.08 (m, 11.9 H, phenyl), 2.17–2.14 (m, 3 H, CH3), 1.48 (s, 12.5 H, t-Bu). IR (cm−1): 2980, 2934, 2874 (νC–H), 1758 (νO-(C=O)-O), 1754 (νO-(C=O)-O-t-Bu).

Synthesis of HBPC-OH from the cleavage of the Boc group

HBPC-Boc-OH (40.4 mg, Mn=5.9 × 103, Mw/Mn=2.4) in THF (1.0 ml) and HCl (100 μl, ∼1 mmol) was stirred under reflux for 3 h. The usual aqueous extraction with ethyl acetate yielded crude viscous oil as a product. The resulting oil was dissolved in ethyl acetate and then poured into n-hexane to precipitate the corresponding polymer. The precipitate was collected and dried under vacuum for 24 h to yield a white solid (37.5 mg). Mn=2.9 × 103 (Mw/Mn=3.0, from SEC (eluent/THF)). Tg=188 °C. 1H NMR (600 MHz, DMSO-d6): δ=9.355 (s, 1.0 H, phenol), 9.280 (s, 1.11 H, phenol), 7.35–7.20 (m, 7.94 H, phenyl), 7.18–7.05 (m, 7.84 H, phenyl), 6.87–6.76 (m, 4.36 H, phenyl), 6.72–6.63 (m, 4.31 H, phenyl), 2.177 (br s, 1.33 H, branching unit CH3), 2.100 (br s, 2.84 H, linear unit CH3), 2.025 (br s, 1.86 H, terminal unit CH3). IR (cm−1): 3267 (νO–H), 2980, 2875 (νC–H), 1776 (νO-(C=O)-O).

Results and Discussion

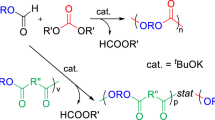

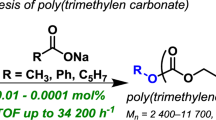

Synthesis of LPC

First, we applied the procedure to the synthesis of linear PC (LPC) (Scheme 1). The reaction between DBTC and ((4,4′-α-methylbenzylidene)bisphenol) was carried out at 30 °C for 2–10 h. The reaction proceeded smoothly, even at around room temperature, to yield the corresponding LPC with Mn=1.4–3.3 × 103 and Mw/Mn=1.5–1.8 in 82–90% yield. The IR spectrum of this LPC showed characteristic absorptions assigned to phenol (νO–H=3450 cm−1) and carbonyl (νC=O=1775 cm−1) groups. 1H NMR in DMSO-d6 also showed phenol and terminal tert-butyl protons at 9.318 and 1.468 p.p.m., respectively.

Synthesis of HBPC-Boc-OH

The reaction of DBTC and THPE was performed in THF at 30 °C in certain feed ratios. The reaction was quenched with pyridine. The products were then precipitated in methanol/H2O to yield the corresponding HBPC (Scheme 2) at ∼80%. The conditions and results are summarized in Table 1. All of these obtained polymers are soluble in common organic solvents.

When the feed ratio of DBTC/THPE was 1.5, HBPC-Boc-OH with the highest Mn (7.1 × 103) and relatively broad Mw/Mn (=6.0) was obtained (Run 6 in Table 1). When a shorter reaction time was used in this polymerization (Runs 4 and 5 in Table 1), the yield, Mn and Mw/Mn were decreased. On the other hand, the longer reaction gave a significant amount of gel product. When the feed ratio of DBTC/THPE was increased to 2, the corresponding HBPC-Boc-OH had significant amounts of the Boc group on the terminus. The terminal ratio of Boc and phenol groups in this polymerization increased with the feed ratio of DBTC, except in the case of a short reaction time (Run 4 in Table 1). In this polymerization, the terminus of the HBPC consisted of both Boc and phenol groups.

The degree of branching (DB) was determined by an 1H NMR spectrum by three different 1H NMR chemical shifts for the three different methyl groups and two different phenolic protons. A detailed investigation of the DB of hyperbranched aryl PC, from AB2 or A2B condensation, was reported by Wooly et al.20 To confirm methyl and phenolic protons, which were assigned from linear, branching and chain end units, we studied and evaluated DB using a model compound prepared from the reaction between DBTC and THPE. The reaction progress was followed up by direct monitoring using 1H NMR spectroscopy in THF-d8. The reaction of DBTC and THPE yields three different products, mono (terminal), di (linear) and trisubstituted (branching) structures (Scheme 3), showing an 1H NMR spectrum with three singlets around 8 p.p.m. assigned to the phenol group and with four singlets around 2 p.p.m. assigned to the methyl group in the early stage. According to the integration value, the compounds showed the characteristic resonance for methyl protons at 2.179, 2.116 and 2.057 p.p.m. for branching, linear and terminal units, respectively, whereas linear and terminal units also had distinct phenolic protons at 9.290 and 9.193, respectively. The methyl and phenolic chemical shifts were shifted downfield according to the substitution number.

Each model compound (Scheme 3), which was synthesized separately, was also investigated by 1H NMR in DMSO-d6 and showed a similar resonance for the methyl protons at 2.132, 2.071 and 2.012 p.p.m. for branching, linear and terminal units, respectively. Notably, the resonances were very similar to the corresponding HBPC and were 2.152, 2.090 and 2.032 p.p.m. for branching, linear and terminal units, respectively (see Figure 1a). This result allows us to estimate DB using 1H NMR in the following Equation26

Using 1H NMR analysis, a DB of 0.5–0.6 was calculated for the HBPC. DB was clearly correlated with the feed ratio of monomers (see Table 1). In other words, the extent of branching increases when the ratio of DTBC increases. This may be explained as follows: the higher feed ratio of DTBC amplifies the formation of branching units.

Synthesis of HBPC-Boc by a 2-stage reaction

HBPC-Boc-OH (Mn=4.0 × 103, DB=0.55, Run 2 in Table 1) was subjected to a reaction with (Boc)2O to obtain HBPC-Boc (Scheme 4). The characteristic absorption of IR and 1H NMR that is ascribed to phenolic protons disappeared completely, and the 1H NMR spectrum showed a unique unresolved singlet (multiplet) around 2.4 p.p.m. that was ascribed to a methyl proton (Figure 1b). In the IR spectra, by increasing the contents of the Boc group, the carbonyl vibration (νC=O) at 1759 cm−1 became more intense than that at 1776 cm−1 (Figure 2). These absorptions at 1759 and 1776 cm−1 were assigned to tert-butoxycarbonyl and diphenyl carbonate, respectively, which is supported by the other IR spectra of HBPC-Boc-OH with a different feed ratio. A shift of the SEC profile toward a higher molecular weight range (Mn=6.2 × 103) was observed after the introduction of a Boc group at the terminal. The shape of the profile was the same as that of the precursor’s. However, the molecular weight distribution of the obtained polymer (Mw/Mn=2.48) was narrow compared with that of the initial polymer (Mw/Mn=2.98), which indicates that the solubility of HBPC-Boc in n-hexane seems to be better than that for HBPC-Boc-OH.

Infrared spectra of (a) hyperbranched polycarbonate (HBPC)-Boc-OH (from Run 2 in Table 1) and (b) HBPC-Boc.

Synthesis of HBPC-Boc by 1 pot, 2 stage

Another simple approach for the synthesis of HBPC-Boc was also examined using direct addition of (Boc)2O into the reaction mixture after a certain time (1 pot, 2 stage in Scheme 5). No phenolic protons were observed in the 1H NMR and IR spectra, both of which were coincident with the HBPC-Boc obtained in the previous section.

Synthesis of HBPC-Boc from the decomposition of a BDC group

During the investigation of HBPC-Boc synthesis, we found that an excess of DBTC, without pyridine quenching, produces the corresponding polymer after precipitation from n-hexane. The IR spectrum was significantly different for HBPC-Boc-OH. Two distinctly different carbonyl absorptions at 1832 and 1778 cm−1 (Figure 3a) were seen. These unique split absorptions have been observed in carboxylic anhydride. The 13C NMR spectrum between 145 and 150 p.p.m. also produced more resonances than the corresponding HBPC-Boc. From this evidence, we concluded that the polymer obtained from this preparation was protected with the BDC group. Additional reaction of HBPC-BDC with pyridine in THF and precipitation from THF to n-hexane yielded the corresponding HBPC-Boc (Scheme 6). The characteristic absorption at 1832 cm−1 in the IR spectrum disappeared, and the exact same spectrum with HBPC-Boc was observed (Figure 3b). This indicates that this polymerization system always included the BDC group as an intermediate. Judging from these results, a relatively high ratio of Boc and phenol in a short polymerization (Run 4 in Table 1) was associated with the formation of a significant amount of oligomeric BDC in the early stages.

Thermal properties of HBPC derivatives

Thermal decomposition temperature (Td) was measured by Thermogravimetric analysis–differential thermal analysis. A higher initial decomposition temperature and a larger weight loss were observed with increasing Boc content (Boc content increased from (b) to (e)). Notably, the thermal weight loss was in good agreement with the calculated Boc content in HBPC. The preliminary thermal deprotection reaction was examined in the film state (sample was the same as in Figure 4c) on KBr using a heating stage. This reaction progress was monitored by Fourier transform infrared. On heating at 110 °C for 0.5 h, the absorption areas of the phenol and tert-butyl groups decreased initially (<2 min). In contrast, the absorption of diphenyl carbonate (νC=O=1776 cm−1) increased, which indicates that the Boc and phenol groups reacted when they were heated to form diphenyl carbonate. However, no further progress was observed under the same temperature conditions. After changing the temperature from 110 to 160 °C, all absorptions dramatically changed; that is, the tert-butyl and tert-butoxycarbonyl groups significantly decreased. In contrast, thermal deprotection produced a phenol group that corresponded to increasing phenol absorption. The thermal stability of HBPC-OH was located just above curve (b) in Figure 4 and showed the good agreement we described above.

Thermogravimetric analysis profiles of hyperbranched polycarbonate (HBPC) derivatives: (a) HBPC-OH, (b) Run 2, (c) Run 6, (d) Run 7 in Table 1, and (e) HBPC-Boc (from 1 pot, 2 stage). Inset: expansion between 120 and 220 °C.

Synthesis of HBPC-OH

HBPC-Boc-OH (Mn=5.9 × 103, Mw/Mn=2.39, DB=0.54, Run 3 in Table 1) was reacted with HCl/THF at room temperature or under reflux conditions for 3 h to obtain an HBPC with terminal phenol groups (Scheme 7). After precipitation from n-hexane, a significant decrease of t-Bu groups was observed in 1H NMR, which almost disappeared under reflux conditions. The IR spectrum also gave a weaker absorption at 1758 cm−1 (shoulder) associated with the tert-butoxycarbonyl group. The main absorption at 1776 cm−1 was only observed after Boc deprotection. However, the SEC profile of HBPC-OH in THF shifted to the lower molecular side (Mn=2.9 × 103, Mw/Mn=3.02, DB=0.53). The polarity of the polymer increased because of the deprotection of Boc, compared with the partially protected HBPC-Boc-OH. This polarity change might affect the elution time. In the case of SEC (dimethyl formamide), Mn values of HBPC-Boc-OH and HBPC-OH were 1.5 × 104 (Mw/Mn=3.32) and 1.3 × 104 (Mw/Mn=2.70), respectively. Even though the low molecular fraction increased slightly, the SEC profiles from dimethyl formamide did not change dramatically compared with the SEC from THF. The Tg of HBPC-OH was around 188 °C, which is lower than that previously reported19 (Tg=205 °C) because of lower molecular weight. However, in comparison with HBPC-Boc (Tg=119 °C), the Tg was significantly higher because of an increase in the number of phenol groups. These results indicate that the deprotection of Boc occurred smoothly and yielded the corresponding HBPC-OH. In contrast, HBPC-Boc-OH exhibited no Tg in the first scan. However, subsequent measurements showed Tg as an endothermic peak around 185 °C. This Tg was similar to the one for HBPC-OH, giving more evidence that thermal deprotection forms the corresponding HBPC-OH under heating.

Conclusion

In this study, we demonstrated easy synthesis of linear and HPBC using DBTC as the A2 monomer and revealed that DB could be controlled simply by changing the feed ratio. We obtained terminal functionalized HBPC with Boc and phenol using 1-pot and 2-pot syntheses. We also observed that polymerization progressed with tert-butyl dicarbonate as an intermediate functional group; it was then transferred to the Boc and phenol groups during reaction quenching or precipitation. In this regard, it is suggested that we are able to introduce other substituents easily using an electrophile in the second stage of this polymerization. The investigations of mechanical and optical properties of HBPCs, especially birefringence, are now in progress. This HBPC-Boc could be useful for high performance KrF resist in the near future.

Synthesis of linear polycarbonate.

Synthesis of hyperbranched polycarbonates.

Three model compounds (chemical shift in dimethylsulfoxide-d6).

Synthesis of hyperbranched polycarbonate (HBPC)-Boc.

Synthesis of hyperbranched polycarbonate (HBPC)-Boc by 1 pot, 2 stage.

Synthesis of hyperbranched polycarbonate (HBPC)-Boc from the decomposition of HBPC-tert-butyldicarbonate (BDC).

Synthesis of hyperbranched polycarbonate (HBPC)-OH.

References

Freitag, D., Grica, U., Muller, P. R. & Nourvertne, W. in Encyclopedia of Polymer Science and Engineering (eds Mark, H. F., et al.) Vol. 11, 648–718 (Wiley, New York, 1987).

Freitag, D., Fengler, D. & Morbitzer, L. Routes to new aromatic polycarbonated with special material properties. Angew. Chem. Int. Ed. Eng. 30, 1598 (1991).

Clagett, D. C. & Shafer, S. J. in Comprehensive Polymer Science (eds. Allen, G., Bevington, J. C.) Vol. 5, 345–356 (Pergamon Press, Oxford, 1989).

Ono, Y. Dimethyl carbonate for environmentally benign reaction. Pure Appl. Chem. 68, 367 (1996).

Kim, W. B., Joshi, U. A. & Lee, J. S. Making polycarbpnates without employing phosgene: an overview on catalytic chemistry of intermidediate and precursor syntheses for polycarbonate. Ind. Eng. Chem. Res. 43, 1897 (2004).

Kim, W. B. & Lee, J. S. Comparison of polycarbonate precursors synthesized from catalytic reactions of bisphenol-A with diphenyl carbonate, dimethyl carbonate, or carbon monoxide. J. Appl. Polym. Sci. 86, 937 (2002).

Ishii, H., Goyal, M., Ueda, M., Takeuchi, K. & Asai, M. Direct synthesis of polycarbonate from carbon monoxide and Bisphenol A using efficient Pd complex catalyst system. Macromol. Rapid Commun. 22, 376 (2001).

Haba, O., Itakura, I., Ueda, M. & Kuze, S. Synthesis of polycarbonate from dimethyl carbonate and Bisphenol-A through a non-phosgene process. J. Polym. Sci. Part A: Polym. Chem. 37, 2087 (1999).

Yahiro, T., Matsushima, K., Kameyama, A. & Nishikubo, T. A novel synthesis of polyaddition of Bis(epoxide)s with diphenyl carbonate. Macromolecules 34, 3205 (2001).

Kawasaki, S., Yamada, M., Kobori, K., Sakamoto, H., Kondo, Y., Jin, F. & Takata, T. Preparation of novel alloy composed of fluorene-based polyester and polycarbonate and their properties for the optical uses. J. Appl. Polym. Sci. 111, 461 (2009).

Voit, B. New developments in hyperbranched polymers. J. Polym. Sci. Part A: Polym. Chem. 38, 2505 (2000).

Kim, H. M. Hyperbranched polymers 10 years after. J. Polym. Sci. Part A: Polym. Chem. 36, 1685 (1998).

Gao, C. & Yan, D. Hyperbranched polymers: from synthesis to applications. Prog. Polym. Sci. 29, 183 (2004).

Parzuchowski, P. G., Jaroch, M., Tryznowski, M. & Rokicki, G. Synthesis of new glycerol-based hyperbranched polycarbonates. Macromolecules 41, 3859 (2008).

Stumpe, K., Eichhorn, K.- J. & Voit, B. Characterization of thin composite films from hyperbranched polyphenylene and thermolabile hyperbranched polycarbonate. Macromol. Chem. Phys. 209, 1787 (2008).

Scheel, A., Komber, H. & Voit, B. Hyperbranched thermolabile polycarbonates derived from a A2+B3 monomer system. Macromol. Symp. 210, 101 (2004).

Reisch, A., Komber, H. & Voiy, B. Kinetic analysis of two hyperbranched A2+B3 polycondensation reaction by NMR spectroscopy. Macromolecules 40, 6846–6858 (2007).

Fan, Z., Lederer, A. & Voit, B. Synthesis and characterization of A2+B3-type hyperbranched aromatic polyesters with phenolic end groups. Polymer 50, 3431 (2009).

Bolton, D. H. & Wooley, K. L. Synthesis and characterization of hyperbranched polycarbonates. Macromolecules 30, 1890 (1997).

Bolton, D. H. & Wooley, K. L. Hyperbranched Aryl polycarbonates derived from A2B monomers versus AB2 mnomers. J. Polym. Sci. Part A: Polym. Chem. 40, 823 (2002).

Maruyama, K., Takazoe, T., Kudo, H. & Nishikubo, T. Synthesis of photo-curable hyperbranched polycarbonates with terminal methacryloyl groups and their photo-curing reaction. Kobunshi Ronbunshu. 66, 36 (2009).

Nagai, A., Sato, D., Ishikawa, J., Ochiai, B., Kudo, H. & Endo, T. A facile synthesis of N-caroxyanhydrides and poly(α-amino acid) using di-tert-butyltricarbonate. Macromolecules 37, 2332 (2004).

Dean, C. S., Tarbell, D. S. & Friederang, A. W. Synthesis and kinetics of decomposition of di-tert-butyl tricarbonate, di-tert-butyl dithioltricarbonate, and the related dicarbonates. J. Org. Chem. 35, 3393 (1970).

Yamamoto, Y., Tarbell, D. S., Fehlner, J. R. & Pope, B. M. Reactions of tert-Butyl trimethylsilyl carbonate and of bistrialkylsilyl carbonates with amino acids. Carbon-13 chemical shifts in carbonates and Silyl carbonate derivatives. J. Org. Chem. 38, 2521 (1973).

Ogura, T. & Ueda, M. Photosensitive polybenzoxazole based on a poly(o-hydroxy amide), a dissolution inhibitor, and a photoacid generator. J. Polym. Sci. Part A: Polym. Chem. 45, 661 (2007).

Hawker, C. J., Lee, R. & Fréchet, J. M. J. One-step synthesis of hyperbranched dendritic polyesters. J. Am. Chem. Soc. 113, 4583 (1991).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Miyasaka, M., Takazoe, T., Kudo, H. et al. Synthesis of hyperbranched polycarbonate by novel polymerization of di-tert-butyl tricarbonate with 1,1,1-tris(4-hydroxyphenyl)ethane. Polym J 42, 852–859 (2010). https://doi.org/10.1038/pj.2010.82

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2010.82