Abstract

A furfuryl ester-terminated butylene succinate oligomer (FBSO) with Mn 1800 and Mw 2800 was synthesized by the condensation of furfuryl alcohol with a carboxyl-terminated butylene succinate oligomer. The reaction of FBSO and 1,1′-(methylenedi-4,1-phenylene)bismaleimide (BMI) in chloroform at 60 °C for 48 h yielded an exo-rich Diels–Alder (DA) adduct ((P(FBSO-BMI)) with Mn 9000 and Mw 15 500. The gel permeation chromatography analysis of the products of heating a reaction mixture of P(FBSO-BMI) in dimethylformamide (DMF) at 120 °C for 1 h revealed that FBSO and BMI are quantitatively recovered by the retro DA reaction. Maleimide/phenyl-substituted oligomeric silsesquioxane (MPOSS) was synthesized by the reaction of maleimidemethyl 3-(triethoxysilyl)propylcarbamate and triethoxyphenylsilane in the presence of hydrochloric acid. The DA reaction of FBSO and MPOSS in DMF at 60 °C for 48 h gave a partially crosslinked hybrid composite insoluble in general organic solvents. When the hybrid composite was heated in DMF at 140 °C, the retro DA reaction proceeded smoothly. The hybrid film prepared by casting a DMF solution of FBSO and MPOSS and subsequently heating at 60 °C for 48 h had a much higher flexural strength than FBSO did.

Similar content being viewed by others

Introduction

Recently, biodegradable polymers derived from renewable agricultural and biomass feedstocks have been receiving considerable attention as sustainable and eco-efficient replacements for polymer products based exclusively on petroleum feedstocks.1, 2, 3, 4, 5 For example, polylactide is a biodegradable polyester produced from starch by the fermentation of glucose via L-lactic acid.6, 7 Poly(butylene succinate) (PBS) is an industrially available biodegradable and potentially bio-based aliphatic polyester.8, 9, 10 However, these aliphatic polyesters are inferior in mechanical and thermal properties to the conventional petroleum-based polymers. As environmentally benign reinforcing materials for bio-based and biodegradable polyesters, layered silicate nanocomposites have been the subject of many recent publications.11, 12, 13, 14, 15 These nanocomposites often exhibit properties superior to those of conventional composites, including greater stiffness, thermal stability, improved barrier properties and enhanced flame retardant behavior. However, the influence of layered silicates on the biodegradability of the polyesters is still controversial,11, 12, 13 and the environmental and toxicological implications of such nano-sized fillers are not fully understood.15 We had already reported the crosslinking reaction of tung oil or dehydrated castor oil with BMI,16, 17 and the reaction of itaconate unit-containing PBS with methacryl-substituted polysilsesquioxane18 as an effective reinforcement method for C=C unsaturated group-containing bio-based resins. However, the incorporation of the rigid phenyl maleimide and silsesquioxane units causes the retardation of biodegradation, which is an important characteristic of the bio-based materials. Recyclability is another important property for such high-performance bio-based materials. The process and kinetics of chemical recycling via thermo-reversible Diels–Alder (DA) reactions between furan and maleimide (MI) have been widely studied.19, 20, 21, 22, 23, 24, 25 Yoshie and co-workers reported the synthesis of a readily recyclable DA adduct of telechelic furfurylamide-terminated PBS and 1,2-bis(maleimide)ethane.24 Chujo and co-workers reported the synthesis of organic-inorganic polymer hybrids by the sol-gel reaction of tetraethoxysilane in the presence of poly(furfuryloxymethylstyrene-co-styrene) and maleimidemethyl 3-(triethoxysilyl)propylcarbamate (MTES).20

The present study describes the reinforcement of a bio-based furfuryl ester-terminated butylene succinate oligomer (FBSO) with BMI and a maleimide/phenyl-substituted oligomeric silsesquioxane (MPOSS) by the use of a thermo-reversible DA reaction. Our attention is focused on the mechanical and thermal properties of the hybrid materials and the thermo-reversibility of the DA process.

Experimental procedure

Materials

MTES was synthesized by the reaction of 3-isocyanatopropyltriethoxysilane and N-methylolmaleimide (MMI) prepared from MI and formalin as described in the literatures.20, 26 Other reagents were commercially available with guaranteed purity and were used without further purification.

Synthesis of carboxy-terminated butylene succinate oligomer

A solution of succinic acid (70.85 g, 0.6000 mol), 1,4-butanediol (45.06 g, 0.5000 mol) and titanium tetra-n-butoxide (0.748 g, 2.20 mmol) in toluene (165 ml) was refluxed at 110 °C for 24 h, and then cooled to room temperature under a nitrogen atmosphere. The generated water was distilled off azeotropically during the reaction using a Dean-Stark trap. The product was precipitated with excess methanol and filtered. The collected precipitate was dissolved into chloroform (500 ml), and the solution was concentrated to ca 80 ml on a rotary evaporator. After the concentrate was poured into excess diethyl ether, the precipitate was filtered, washed with diethyl ether and dried in vacuo to give carboxy-terminated butylene succinate oligomer (CBSO) as a white powder. The yield was 57.8 g (52%). GPC: Mn=1100, Mw/Mn=1.82, proton nuclear magnetic resonance (1H NMR; CDCl3, δ, p.p.m.) 1.70 (s, 28H, –OCH2CH2–), 2.64 (s, 32H, –C(=O)CH2–), 4.12 (s, 28H, –OCH2CH2–). The SA/BA unit ratio of CBSO calculated from the integral values of the 1H signals was 7.0/8.0. The Mn (1323) calculated from the unit ratio was used for the calculation of feed amount of the next reaction.

Synthesis of FBSO

A solution of CBSO (33.08 g, 25.0 mmol), furfuryl alcohol (19.62 g, 200.0 mmol), N,N′-diisopropylcarbodiimide (12.62 g, 100.0 mmol) and 4-dimethylaminopyridine (6.11 g, 50.0 mmol) in dichloromethane (300 ml) was stirred at room temperature for 24 h. The resulting solution was concentrated to ca 150 ml on a rotary evaporator and then poured into diethyl ether (2000 ml). The formed precipitate was filtered, dissolved into chloroform (300 ml) and concentrated to ca 150 ml on a rotary evaporator. After the concentrate was poured into methanol (2000 ml), the precipitate was filtered, washed with diethyl ether and dried in vacuo to give FBSO as a yellowish brown solid. The yield was 32.2 g (87%). GPC: Mn=1800, Mw/Mn=1.51, 1H NMR (CDCl3, δ, p.p.m.) 1.71 (s, 40.8H, –OCH2CH2–), 2.63 (s, 44.8H, –C(=O)CH2–), 4.11 (s, 40.8H, –OCH2CH2–), 5.08 (s, 4H), 6.36 (d, 2H), 6.41 (d, 2H), 7.43 (s, 2H). The SA/BA/FA unit ratio of FBSO calculated from the integral values of the 1H signals was 11.2/10.2/2.0. The Mn (2035) calculated from the unit ratio was used for the calculation of feed amount of the next reaction.

Synthesis of MPOSS

A solution of MTES (22.48 g, 60.00 mmol), triethoxyphenylsilane (TEPS, 7.21 g, 30.0 mmol) and 37% hydrochloric acid (0.498 g, 15.1 mmol) in a mixed solvent (117 ml) of water/ethanol (v/v 1/3) was stirred at room temperature for 10 days. After the resulting solution was concentrated on a rotary evaporator, the product was precipitated with diethyl ether, filtered and dried in vacuo to give MPOSS21 as pale brown powder. The yield was 18.7 g (95.2%). GPC: Mn=1300, Mw/Mn=2.22, 1H NMR (d6-DMSO, δ, p.p.m.) 0.54 (bs, –SiCH2–), 1.45 (bs, –SiCH2CH2–), 2.94 (bs, –CH2NH–), 5.34 (s, –OCH2–), 7.13(s, MI-H), 7.2 ∼7.9 (bm, phenyl-H).

Similarly, the reaction of MTES (18.72 g, 50.00 mmol) and TEPS (12.01 g, 50.00 mmol) in the presence of 37% hydrochloric acid (1.656 g, 16.81 mmol) afforded MPOSS11 as pale red powder (16.3 g, 82.3%). GPC: Mn=1200, Mw/Mn=2.20, 1H NMR (d6-DMSO, δ, p.p.m.) 0.54 (bs, –SiCH2–), 1.45 (bs, –SiCH2CH2–), 2.94 (bs, –CH2NH–), 5.34 (s, –OCH2–), 7.13(s, MI-H), 7.2–7.9 (bm, phenyl-H).

As a comparison, the reaction of TEPS (28.84 g, 120.0 mmol) in the presence of 37% hydrochloric acid (1.98 g, 20.09 mmol) afforded MPOSS01 as white powder (14.5 g, 93.7%). GPC: Mn=880, Mw/Mn=1.44, 1H NMR (d6-DMSO, δ, p.p.m.) 7.2–7.9 (bm, phenyl-H).

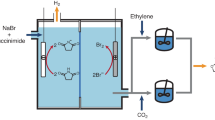

DA polymerization of FBSO and BMI

A solution of FBSO (10.18 g, 5.00 mmol), BMI (1.79 g, 5.00 mmol) and 2,6-di-tert-butyl-4-methylphenol (0.22 g, 1.00 mmol) in chloroform (50 ml) was stirred at 60 °C for 48 h under a nitrogen atmosphere and then cooled to room temperature. The product was precipitated with excess methanol, filtered, washed with acetone and then dissolved into chloroform (25 ml). After the solution was poured into diethyl ether (250 ml), the formed precipitate was filtered, washed with ether and dried in vacuo to give P(FBSO-BMI) as a pale brown solid. The yield was 9.7 g (81%). GPC: Mn=9000, Mw/Mn=1.72. 1H NMR (CDCl3, δ, p.p.m.) 1.71 (s, –OCH2CH2–), 2.65 (s, –C(=O)CH2–), 3.07 and 3.15 (d, exo He,f), 3.55 and 3.82 (bm, endo He,f), 4.05 (bs, Hi), –OCH2CH2–), 4.10 (s, –OCH2CH2–), 4.53 and 5.03 (d, exo Hd), 4.67 and 4.93 (d, endo Hd), 5.40 (s, Ha), 6.49 and 6.62 (s, Hb,c), 7.04 and 7.28 (bd, endo Hg,h), 7.20 and 7.29 (bd, exo Hg,h).

Alternatively, FBSO (10.18 g, 5.00 mmol), BMI (1.79 g, 5.00 mmol) and 2,6-di-tert-butyl-4-methylphenol (0.22 g, 1.00 mmol) were mixed in a mortar with a pestle. The resulting mixture was heated at 140 °C for 2 h and then allowed to stand for 48 h at 60 °C to give a P(FBSO-BMI) film by the melt mixing method. GPC: Mn=6300, Mw/Mn=2.99.

Retro DA reaction of P(FBSO-BMI)

A solution of P(FBSO-BMI) (1.80 g, 0.20 mmol) in N,N-dimethylformamide (DMF, 20 ml) was stirred at 120 °C for 2 h. After the resulting solution was poured into acetonitrile (60 ml), the formed precipitate was filtered, washed with acetonitrile and dried in vacuo to give FBSO as a yellowish brown solid. The yield was 1.44 g (94.0%). The retro DA reaction was monitored on GPC using the DMF solution sampled from another batch of the same reaction.

Model DA reaction of FA and MMI

FA (1.96 g, 20.0 mmol) and MMI (2.54 g, 20.0 mmol) were mixed and heated at 60 °C for 48 h under a nitrogen atmosphere. The obtained DA adduct (FA-MMI) was dissolved in d6-DMSO, and the 1H NMR was measured. 1H NMR (d6-DMSO, δ, p.p.m) 2.91 and 3.08 (d, exo He,f), 3.41 and 3.68 (d, endo He,f), 3.72 and 4.07 (dd, exo Hd), 3.93 and 4.05 (dd, endo Hd), 4.70 (d, Hg), 4.95(bs, Hh), 5.10 (s, Ha), 6.36 (bs, Hi), 6.51 (s, Hb,c).

DA polymerization of FBSO and MPOSS21 in solution

A solution of FBSO (1.80 g, 0.885 mmol) and MPOSS21 (0.684 g, 0.432 mmol) in DMF (14 ml) was stirred at 60 °C for 48 h under a nitrogen atmosphere and then cooled to room temperature. The product was precipitated with excess diethyl ether, filtered, washed with diethyl ether and then dried in vacuo to give P(FBSO-MPOSS21) as a pale brown solid. The yield of P(FBSO-MPOSS21) by the solution precipitation method was 2.03 g (79%).

Alternatively, a solution of FBSO (2.85 g, 1.40 mmol) and MPOSS21 (1.08 g, 0.683 mmol) in DMF (22 ml) was cast on a polytetrafluoroethylene plate, dried at 60 °C for 48 h in an electric oven, and further dried at 60 °C for 48 h in vacuo to give a P(FBSO-MPOSS21) film by the solution casting method.

DA polymerization of FBSO and MPOSS by the melt mixing method

FBSO (3.61 g, 1.77 mmol) and MPOSS21 (1.37 g, 0.863 mmol) were mixed in a mortar with a pestle. The resulting mixture was heated at 140 °C for 2 h and then allowed to stand for 48 h at 60 °C to give a P(FBSO-MPOSS21) film by the melt mixing method. In a similar manner, the reaction of FBSO (3.61 g, 1.77 mmol) and MPOSS11 (1.66 g, 1.14 mmol) afforded a P(FBSO-MPOSS11) film by the melt mixing method. As a comparison, a FBSO/MPOSS01 composite was prepared from FBSO (3.61 g, 1.77 mmol) and MPOSS01 (1.37 g, 1.33 mmol) by the melt mixing method.

Retro DA reaction of P(FBSO-MPOSS21)

A suspension of P(FBSO-MPOSS21) (0.80 g) in DMF (10 ml) was heated at 140 °C for 30 min. The suspension gradually changed to a homogeneous solution during the retro DA reaction. After the resulting solution was precipitated with chloroform (60 ml), the formed precipitate was filtered, washed with chloroform and dried in vacuo to give MPOSS21 (0.20 g, 91%) as a brown solid. The Mn's measured by GPC analysis of the isolated MPOSS21 and the filtrate containing FBSO were 1300 and 1800, respectively, in accordance with those of the original compounds, MPOSS21 and FBSO.

Measurements

1H NMR spectra were recorded on a Bruker AV-400 (400 MHz; Bruker, Madison, WI, USA). GPC was carried out at 40 °C on a Shodex GPC analysis apparatus (Showa Denko KK, Tokyo, Japan) equipped with two SB-806M HQ GPC columns (Showa Denko KK) and a refractive index detector. DMF was used as an eluent at a flow rate of 0.5 ml min−1. Polystyrene standards with a narrow distribution of molecular weights (Mw: 580–377 400) were used for molecular weight calibrations. Differential scanning calorimetry was performed on a Perkin Elmer Pyris 1 differential scanning calorimeter (PerkinElmer Japan, Yokohama, Japan) under a nitrogen atmosphere. The differential scanning calorimetry sample was weighed (∼10 mg) on a small aluminum pan, after which the pan was sealed. The sample was heated from 100 to 150 °C at a heating rate of 20 °C min−1. Dynamic mechanical analysis (DMA) of a rectangular specimen (30 × 7 × 2 mm3) was performed on a Rheolograph Solid (Toyo Seiki, Tokyo, Japan) with a chuck distance of 20 mm, a frequency of 1 Hz, and a heating rate of 20 °C min−1, based on ISO 6721-4:1994 (Plastics-Determination of dynamic mechanical properties, Part 4: Tensile vibrationNon-resonance method). The 5% weight loss temperature was measured on a Perkin Elmer TGA 7 thermogravimetric analyzer (PerkinElmer) in a nitrogen atmosphere at a heating rate of 20 °C min−1. Flexural testing of the rectangular specimen (30 × 7 × 2 mm3) was performed using an Autograph EZ-S (Shimadzu, Kyoto, Japan). The span length was 20 mm, and the testing speed was 1 mm min−1. Three specimens were tested for each set of samples, and the mean values were calculated. Solubility was tested after a mixture of the sample (10 mg) and solvent (1.0 ml) was sonicated for 5 min and then allowed to stand for 24 h at room temperature.

Results and Discussion

Characterization of FBSO

The polycondensation reaction of SA/BD in the presence of tetrabutoxy titanium at the feed molar ratio of 6/5 (theo. Mn: 979) afforded a telechelic carboxyl-terminated oligomer, CBSO (Figure 1). The incorporated SA/BD unit ratio of CBSO measured by the 1H NMR method was 8.0/7.0. The Mn calculated from the SA/BD unit ratio for CBSO was 1323, which was in agreement with the Mn (1100) relative to polystyrene standards measured by GPC. A telechelic furfuryl ester oligomer, FBSO, was synthesized by the esterification reaction of CBSO with FA using diisopropylcarbodiimide (Figure 1). The 1H NMR spectrum of FBSO in CDCl3 is shown in Figure 2. The SA/BD/FA unit ratio of FBSO determined from the 1H NMR spectrum was 11.2/10.2/2.0. The Mn calculated from the SA/BD/FA unit ratio for FBSO was 2035, which was in agreement with the Mn (1800) measured by GPC. The fact that observed Mn was higher than theoretical Mn at each reaction step indicates that an ester oligomer with a lower molecular weight was removed during the precipitation of the final product for purification.

DA and retro DA reactions of FBSO and BMI

The DA reaction of equimolar amounts of FBSO and BMI in chloroform at 60 °C for 48 h gave P(FBSO-BMI) with Mn 9000 and Mw 15 500 (Figure 3). When DMF was used as a solvent in the DA reaction, a product with a lower molecular weight (Mn 3800 and Mw 9800) was obtained. It is well known that endo and exo adducts are formed in the DA reactions of furan and MI derivatives. The endo adduct is kinetically favored because of the overlapping of orbitals between the furan and MI moieties, whereas the exo adduct is thermodynamically favored. Therefore, a prolonged reaction at a higher temperature causes an increase in the formation of the exo adduct. In the 1H NMR spectrum of P(FBSO-BMI), the 1H signals of He and Hf of the exo adduct are observed at 3.07 p.p.m. (d) and 3.15 p.p.m. (d) and those of endo adduct are at 3.55 p.p.m. (bm) and 3.82 p.p.m. (bm), respectively (Figure 2). Also, the 1H signals of Hd of the exo adduct are observed at 4.53 p.p.m. (d) and 5.03 p.p.m. (d) and those of the endo adduct are at 4.67 p.p.m. (d) and 4.93 p.p.m. (d), respectively. The endo/exo ratio was estimated to be 26:74 from the integral value of each 1H signal, suggesting that the thermodynamically favored exo-rich adduct was obtained in the reaction at 60 °C for 48 h. The 1H signals of the unreacted furan moiety were observed at 5.08 p.p.m. (s), 6.36 p.p.m. (d) and 6.41 p.p.m. (d). The reacted/unreacted furan ratio was estimated to be 75:25 from the 1H signals. Alternatively, the mixture of FBSO and BMI was heated at 140 °C for 2 h and then allowed to stand for 48 h at 60 °C to give a P(FBSO-BMI) film by the melt mixing method. The P(FBSO-BMI) film produced by the melt mixing method showed a higher DA reaction conversion rate (reacted/unreacted furan ratio 92:8) and contained more exo-rich adduct (endo/exo ratio 16:84) than the P(FBSO-BMI) produced by the solution precipitation method. The former P(FBSO-BMI) had a higher polydispersity (Mw/Mn 2.99) than the latter (1.72).

The DA reaction of FBSO and BMI in chloroform at 60 °C was monitored by GPC (Figure 4a). The average molecular weight of the reaction products gradually increased and became almost constant (Mn 9000 and Mw 15 500) at a reaction time of ∼12 h. The retro DA reaction of P(FBSO-BMI) in DMF was also monitored by GPC (Figure 4b). The average molecular weight started to decrease at around 80 °C. When the reaction temperature reached 120 °C, two peaks corresponding to FBSO and BMI appeared. When the retro DA reaction was allowed to continue for 2 h at 120 °C, FBSO and BMI were almost completely regenerated. From the solution obtained after the retro DA reaction, FBSO was quantitatively recovered by precipitation with acetonitrile because BMI is soluble in acetonitrile, but FBSO is insoluble.

Characterization of MPOSS

The reaction of MTES/TEPS in the molar ratio of 0:1, 1:1 and 2:1 in the presence of hydrochloric acid gave MPOSS01, MPOSS11 and MPOSS21, respectively (Figure 5). Figure 6 shows the 1H NMR spectrum of MPOSS21 as compared with those of MTES and TEPS in d6-DMSO. The 1H signals of ethoxysilyl groups were observed at 1.13 and 3.70 p.p.m. for MTES and at 1.27 and 3.90 p.p.m. for TEPS. In the spectrum of MPOSS21, although 1H signals of the diethyl ether used for precipitation appeared at 1.1 and 3.4 p.p.m., no signals appeared in the region where ethoxysilyl protons should be observed, suggesting that the hydrolysis and condensation reaction of MTES and TEPS proceeded to completion. The 1H signals of methylene and the olefinic protons of the maleimidemethyl group of MPOSS21 were observed at 5.34 and 7.13 p.p.m., respectively, and those of the phenyl group were observed at 7.2–7.9 p.p.m.. The molar ratio of MI/phenyl for MPOSS21 was estimated to be 51:49 from the integral values of their 1H signals. The MI/phenyl ratio of MPOSS11 was similarly estimated to be 39:61. When the fully condensed T38 cubic polyhedral oligomeric silsesquioxane (POSS) structure is assumed for MPOSS21 and MPOSS11, the functionality of the MI groups is estimated to be 4.1 and 3.1, respectively.

The Mn values measured by GPC using polystyrene standards for MPOSS01, MPOSS11 and MPOSS21 were 880, 1200 and 1300, respectively. Their molecular weights are consistent with the theoretical molecular weights (1034, 1449 and 1583) of MPOSS01, MPOSS11 and MPOSS21, based on the assumption that all of the MPOSSs have cubic POSS structures. Actually, the Fourier-transform infrared spectrum of MPOSS01 is almost the same as that of an octaphenyl polyhedral oligomeric silsesquioxane (Ocp-POSS) reported in the literature (Figure 7).27, 28 Brown et al.29 reported that caged POSS's give only one Si–O–Si band at 1120–1130 cm−1, whereas polysilsesquioxanes containing open cages and perhaps some ladder structures exhibit two bands at 1135–1150 and 1045–1060 cm−1. Although MPOSS01 showed one Si–O–Si band at ∼1130 cm−1, MPOSS21 and MPOSS11 had two broad bands at 1134 and 1031 cm−1 ascribed to the symmetric and asymmetric Si–O–Si stretching vibrations. These results suggest that MPOSS11 and MPOSS21 have primarily caged POSS structures and that incomplete cages and some ladder structures are also present as minor components.

DA and retro DA reaction of FBSO and MPOSS

The DA reaction of FBSO and MPOSS21 were conducted with a furan/MI ratio of 1:1 (Figure 8), on the basis of their theoretical molecular weights (2035 and 1034) and the composition estimated from the 1H NMR data. DMF was used as a reaction solvent because MPOSS21 was insoluble in chloroform. When FBSO and MPOSS21 were heated in DMF at 60 °C for 48 h, the precipitate was not identified in the solution. After the solution was precipitated with diethyl ether, P(FBSO-MPOSS21) was obtained as a powder that was insoluble in general organic solvents and swelled slightly in DMF and DMSO. These observations suggest that the conversion of the DA reaction is low and that a partially crosslinked product is formed. As a comparison, the model reaction of MMI and FA at 60 °C for 48 h proceeded smoothly, as is evident from the 1H NMR spectrum (Figure 9). The endo/exo ratio of FA-MMI was estimated to be 16:84. The olefinic 1H signal of unreacted MMI was observed at 7.05 p.p.m. (s). The reacted/unreacted MI ratio was estimated to be 94:6 from their 1H signals. In the reaction mixture of FBSO and MPOSS21, 1H signals of Hd (exo) at 4.5 and 4.9 p.p.m. appeared, indicating that an exo-rich product was obtained in a similar manner to the model reaction. However, a considerable number of 1H signals related to unreacted furan and MI moieties were observed for P(FBSO-MPOSS21), suggesting that the reactivity of FBSO and MPOSS21 is relatively low. As the elevation of reaction temperatures above 60 °C caused the occurrence of a retro DA reaction, we could not improve the conversion of the DA reaction. When the isolated P(FBSO-MPOSS21) was heated in DMF at 140 °C for 0.5 h, a heterogeneous mixture of swollen P(FBSO-MPOSS21) and DMF changed to a homogeneous solution of FBSO and MPOSS21. The powdered sample of MPOSS21 was recovered by precipitation with excess chloroform from the solution.

Proton nuclear magnetic resonance spectra of FA-N-methylolmaleimide (MMI) in d6-DMSO and the reaction mixture of furfuryl ester-terminated butylene succinate oligomer (FBSO) and MPOSS21 in d7-dimethylformamide at 60 °C for 48 h. DMSO, dimethyl sulfoxide; MPOSS, maleimide/phenyl-substituted oligomeric silsesquioxane.

Thermal and mechanical properties of P(FBSO-BMI) and P(FBSO-MPOSS)

To obtain a sample of P(FBSO-MPOSS21) film, a DMF solution of FBSO and MPOSS21 was cast on a poly(tetrafluoroethylene) plate, dried at 60 °C for 24 h in an electric oven, and then dried at 60 °C for 24 h in vacuo. A relatively tough P(FBSO-MPOSS21) film was obtained by the solution casting method. Also, we were able to prepare P(FBSO-MPOSS21) films in a similar manner to the P(FBSO-BMI) film prepared by the melt mixing method. Figure 10 shows the flexural properties of these films. The P(FBSO-MPOSS21) film prepared by the solvent casting method showed the highest flexural strength and bending flexure rate, suggesting that the partially crosslinked structure of the film caused the improvement in the toughness. However, the flexural modulus of the film was reduced because of a relatively low crosslinking density. The P(FBSO-MPOSS11) and P(FBSO-MPOSS21) films prepared by the melt mixing method also had relatively low tensile strengths and moduli, suggesting that the conversion rates of the DA reactions were low because the lack of solvent. The fact that these films had higher flexural strengths than the FBSO/MPOSS01 composite indicates that some DA reaction occurs for the former films. The P(FBSO-BMI) prepared by the melt mixing method showed the highest flexural modulus, indicating that the conversion rate of the DA reaction is much higher than in the case of P(FBSO-MPOSS). The flexural modulus (1300 MPa) of the P(FBSO-BMI) was higher than that of industrially available PBS (700 MPa, Showa high polymer Bionolle #1020).

Flexural properties of (a) furfuryl ester-terminated butylene succinate oligomer (FBSO), (b) melt mixing FBSO/MPOSS01, (c) melt mixing P(FBSO-MPOSS11), (d) melt mixing P(FBSO-MPOSS21), (e) solution cast P(FBSO-MPOSS21), (f) melt mixing P(FBSO-BMI). BMI, bismaleimide; MPOSS, maleimide/phenyl-substituted oligomeric silsesquioxane.

Figure 11 shows the DMA curves of P(FBSO-MPOSS) films. In accordance with the flexural modulus trend, the order of storage modulus from highest to lowest at 20 °C was solution cast P(FBSO-MPOSS21) > melt mixed P(FBSO-MPOSS11) > melt mixed P(FBSO-MPOSS21). The fact that melt mixed P(FBSO-MPOSS11) had a higher flexural and storage modulus than P(FBSO-MPOSS21) should be related to the fact that the former (9.0 wt%) has a higher SiO content than the latter (7.2 wt%). Regarding tan δ peak temperature, P(FBSO-MPOSS21) prepared by the solution casting method showed a higher value (8.2 °C) than P(FBSO-MPOSS11) and P(FBSO-MPOSS21) prepared by the melt mixing method (−1 to 0 °C), indicating that the solution cast film has a higher crosslinking density than the melt mixing films. We could not measure the DMA of the FBSO and FBSO/MPOSS01 composites because of their brittleness. As a comparison, all the P(FBSO-MPOSS) films had higher tan δ peak temperatures than Bionolle #1020 (18.9 °C).

Table 1 summarizes the thermal properties of P(FBSO-BMI) and P(FBSO-MPOSS). Glass transition temperatures (Tg's) for P(FBSO-BMI) and P(FBSO-MPOSS) samples were not identified by means of differential scanning calorimetry. FBSO and FBSO/MPOSS01 composite showed clear Tg's at around −37 °C, a value that is comparable to the Tg of Bionolle #1020 (−32 °C). All the samples showed melting temperatures (Tm's) related to the crystalline butylene succinate oligomer segment. The heat of melting (ΔHm) of P(FBSO-MPOSS21) prepared by the solution precipitation method was lower than that of P(FBSO-MPOSS21) prepared by the melt mixing method, indicating that the crystallization of the butylene succinate segment is more significantly hindered by a higher degree of crosslinking of the former film. The 5 wt% weight loss temperature (Td) of P(FBSO-MPOSS) samples prepared by the melt mixing method was lower than that of the control FBSO, reflecting the low Td of MPOSS11 and MPOSS21 due to the presence of an urethane bond. The FBSO/MPOSS01 composite showed the highest Td, because MPOSS01 (Ocp-POSS) itself has a very high Td. Among P(FBSO-MPOSS) samples, P(FBSO-MPOSS21) formed by the solution precipitation method had the highest Td (317.2 °C), which was a little higher than that of FBSO (309.9 °C), reflecting a relatively high crosslinking density of the sample prepared by the solution precipitation method.

Conclusion

The DA polymerization of FBSO with Mn 1800 and BMI in chloroform at 60 °C for 48 h gave an exo-rich P(FBSO-BMI) with Mn 9000. The GPC analysis of the reaction mixture of P(FBSO-BMI) heated in DMF at 120 °C for 1 h revealed that FBSO and BMI are quantitatively recovered by the retro DA reaction. The DA reaction of FBSO and MPOSS21 in DMF at 60 °C for 48 h gave partially crosslinked P(FBSO-MPOSS21) insoluble to general organic solvents. The 1H NMR analysis revealed that the conversion of the DA reaction is low (ca 10%). The flexural strength and modulus (6.4 MPa and 1.3 GPa) of the P(FBSO-BMI) prepared by the melt mixing method were much higher than those of FBSO (1.8 MPa and 0.52 GPa), whereas those of the P(FBSO-MPOSS21) prepared by the melt mixing method were not as high. The P(FBSO-MPOSS21) prepared by the solution casting method showed the highest tensile strength (15.5 MPa) among the DA polymers studied in this study, although the tensile modulus was comparable to that of FBSO. The Tg measured by DMA for the P(FBSO-MPOSS21) was 8.2 °C, which was much higher than that of PBS (−32 °C).

References

Shah, A. A., Hasan, F., Hameed, A. & Ahmed, S. Biological degradation of plastics: a comprehensive review. Biotechnol. Adv. 26, 246–265 (2008).

Gunatillake, P., Mayadunne, R. & Adhikari, R. Recent developments in biodegradable synthetic polymers. Biotechnol. Annu. Rev. 12, 301–347 (2006).

Kaplan, D. L. in Biopolymers from Renewable Resources (ed. Kaplan, D. L.) Ch 1, 1–26 (Springer, Berlin, 1998).

Mohanty, A. K., Misra, M. & Hinrichsen, G. Biofibres, biodegradable polymers, biocomposites: an overview. Macromol. Mater. Engn. 276, 1–24 (2000).

Mohanty, A. K., Misra, M. & Drzal, L. T. Sustainable bio-composites from renewable resources: oppotinities and challenges in the green materials world. J. Polym. Environ. 10, 19–26 (2002).

Nampoothiri, K. M., Nair, N. R. & John, R. P. An overview of the recent developments in polylactide (PLA) research. Bioresour. Technol. 101, 8493–8501 (2010).

Lim, L. T., Auras, R. & Rubino, M. Processing technologies for poly(lactic acid). Prog. Polym. Sci. 33, 820–852 (2008).

Fujimaki, T. Processability and properties of aliphatic polyesters, ‘BIONOLLE’, synthesized by polycondensation reaction. Polym. Degrad. Stab. 59, 209–214 (1998).

Tukahara, T. GS Pla. JETI 52, 119–121 (2004).

Shibata, M., Inoue, Y. & Miyoshi, M. Mechanical properties, morphology, and crystallization behavior of blends of poly(L-lactide) with poly(butylene succinate-co-L-lactate) and poly(butylene succinate). Polymer 47, 3557–3564 (2006).

Pandey, J. K., Reddy, K. R., Kumar, A. P. & Singh, R. P. An overview on the degradability of polymer nanocomposites. Polym. Degrad. Stabl. 88, 234–250 (2005).

Ray, S. S. & Bousmina, M. Biodegradable polymers and their layered silicate nanocomposites: in green the 21st century materials word. Prog. Mater. Sci. 50, 962–1079 (2005).

Pavlidou, S. & Papaspyrides, C. D. A review on polymer-layered silicate nanocomposites. Prog. Polym. Sci. 33, 1119–1198 (2008).

Bordes, P., Pollet, E. & Avérous, L. Nano-biocomposites: biodegradable polyester/nanoclay systems. Prog. Polym. Sci. 34, 125–155 (2009).

Vilaplana, F., Strömberg, E. & Karlsson, S. Environmental and resource aspects of sustainable biocomposites. Polym. Degrad. Stabl. 95, 2147–2161 (2010).

Hirayama, K., Irie, T., Teramoto, N. & Shibata, M. High performance bio-based thermosetting resins composed of dehydrated castor oil and bismaleimide. J. Appl. Polym. Sci. 114, 1033–1039 (2009).

Shibata, M., Teramoto, N. & Nakamura, Y. High performance bio-based thermosetting resins composed of tung oil and bismaleimide. J. Appl. Polym. Sci. 119, 896–901 (2011).

Sakuma, T., kumagai, A., Teramoto, N. & Shibata, M. Thermal and dynamic mechanical properties of organic-inorganic hybrid composites of itaconate-substituted poly(butylene succinate) and methacrylate-substituted polysilsesquioxane. J. Appl. Polym. Sci. 107, 2159–2164 (2008).

Goiti, E., Heatley, F., Huglin, M. B. & Rego, J. M. Kinetic aspects of the Diels-Alder reaction between oly(styrene-co-furfuryl methacrylate) and bismaleimide. Eur. Polym. J. 40, 1451–1460 (2004).

Adachi, K., Achimuthu, A. K. & Chujo, Y. Synthesis of organic-inorganic hybrids controlled by Diels-Alder reaction. Macromolecules 37, 9793–9797 (2004).

Teramoto, N., Arai, Y. & Shibata, M. Thermo-reversible Diels–Alder polymerization of difurfurylidene trehalose and bismaleimides. Carbohydrate Polym. 64, 78–84 (2006).

Watanabe, M. & Yoshie, N. Synthesis and properties of readily recyclable polymers from bisfuranic terminated poly(ethylene adipate) and multi-maleimide linkers. Polymer 47, 4946–4952 (2006).

Gandini, A., Coelho, D. & Silvestre, A. J. D. Reversible click chemistry at the service of macromolecular materials. Part 1: kinetics of the Diels-Alder reaction applied to furan-maleimide model compounds and linear polymerization. Eur. Polym. J. 44, 4029–4036 (2008).

Ishida, K. & Yoshie, N. Synthesis of readily recyclable biobased plastics by Diels-Alder reaction. Macromol. Biosci. 8, 916–922 (2008).

Canadell, J., Fischer, H., With, G. D. & Benthem, R.A.T.M.V. Stereoisomeric effects in thermo-remendable polymer networks based on Diels-Alder crosslink reactions. J. Polym. Sci. Part A 48, 3456–3467 (2010).

Tawney, P. O., Snyder, R. H., Conger, R. P., Leibbrand, K. A., Stiteler, C. H. & Williams, A. R. The chemistry of maleimide and its derivatives. II. Maleimide and N-methyolmaleimide. J. Org. Chem. 26, 15–21 (1961).

Ni, Y. & Zheng, S. A novel photocrosslinkable polyhedral oligomeric silsesquioxane and its nanocomposites with poly(vinyl cinnamate). Chem. Mater. 16, 5141–5148 (2004).

Liu, L., HU, Y., Song, L., Gu, X., Chen, Y. & Ni, Z. Mesoporous hybrid from anionic polyhedral oligomeric silsesquioxanes (POSS) and cationic surfactant by hydrothermal approach. Micropor. Mesopor. Mater. 132, 567–571 (2010).

Brown, J. F. Jr. & Vogt, L. H. Jr. The polycondensation of phenylsilanetriol. J. Am. Chem. Soc. 87, 4317–4324 (1965).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shibata, M., Teramoto, N., Akiba, T. et al. High-performance hybrid materials prepared by the thermo-reversible Diels–Alder polymerization of furfuryl ester-terminated butylene succinate oligomers and maleimide compounds. Polym J 43, 455–463 (2011). https://doi.org/10.1038/pj.2011.14

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2011.14

Keywords

This article is cited by

-

Gelation behavior and thermal and mechanical properties of polymer network formed by the Diels-Alder reaction of furan- and maleimide-terminated four-arm star-shaped ethylene glycol oligomers

Colloid and Polymer Science (2015)

-

High-performance bio-based bismaleimide resins using succinic acid and eugenol

Polymer Journal (2011)