Abstract

Dilithium diamides derived from silyl-protected diamines (that is, N,N′-bis(trimethylsilyl)-1,3-bis(aminomethyl)benzene and N,N′-bis(triisopropylsilyl)-1,3-bis(aminomethyl)benzene, 1a and 1b, respectively) were examined as difunctional initiators for the anionic polymerization of methyl methacrylate (MMA) in toluene with the aid of organoaluminum mediators. While the dilithium diamides in combination with tributylaluminum afforded the polymers in quantitative yields, the less sterically demanding silyl amide (1a) underwent 1,2-addition (carbonyl addition) during the initial stage of polymerization to form poly(MMA) (PMMA) containing the initiator fragment, with the methacryloyl group at the chain end as a minor component (26%). Dilithium diamide 1b, which contains triisopropylsilyl groups that prevent the 1,2-addition due to their steric bulkiness, afforded PMMA with a 1,3-xylylenediamine unit (initiation fragment) in the middle of the chain. H2/Pd-C-mediated cleavage of the diamine unit yielded PMMA with a half molar mass in a narrow molar-mass distribution, which provided proof of the equivalent reactivity of the two amide anions in 1b.

Similar content being viewed by others

Introduction

Difunctional initiators have been important for the preparation of triblock copolymers, telechelic polymers and macrocyclic polymers.1 Although triblock copolymers can be synthesized with monofunctional initiators using a three-step sequential monomer addition process, difunctional initiators allow for a more efficient two-step process.

Szwarc and Levy2 first reported the anionic polymerization of styrene in tetrahydrofuran initiated by sodium naphthalenide, which forms the styrene dimer anion as a difunctional anionic initiator2 that has been employed to prepare A-B-A-type triblock copolymers. However, the dimer anion formation reaction is performed in polar solvents, such as tetrahydrofuran, which limits its application to polymerization in non-polar hydrocarbon solvents where the difunctional anionic initiators have inherently poor solubility because of polymeric aggregate formation. To overcome this difficulty, polar additives, such as amines and ethers, have been used to solubilize the initiator to perform anionic polymerization in hydrocarbon media. For example, a diadduct formed from the addition of tert-butyllithium to 1,3-diisopropenylbenzene was prepared in cyclohexane in the presence of triethylamine and was used for the facile synthesis of A–B–A block copolymers of buta-1,3-diene and styrene.3 We have reported that the dilithium adduct prepared via a modified procedure can be employed for the anionic copolymerization of MMA and butyl acrylate in the presence of a bulky aluminum bisphenoxide in toluene in a monomer-selective manner to afford poly(methyl methacrylate) (PMMA)-block-poly(butyl acrylate)-block-PMMA.4

For such difunctional initiators to be truly effective, the initiator efficiency should be unity and devoid of any side reactions. Otherwise, the reaction may produce at least two types of polymer anions, where one propagates in both directions and the other in one direction. Therefore, each anionic site in the difunctional initiator should have a quantitative initiating ability.

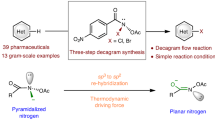

We have previously demonstrated that trialkylsilyl-substituted lithium amides, lithium N-benzyltrimethylsilylamide (BnTMSNLi) and lithium N-benzyltriisopropylsilylamide (BnTIPSNLi) exhibit a high enough initiating ability in the anionic polymerization of MMA in the presence of aluminum compounds in toluene to form PMMA with benzylamino end-functionality (Scheme 1).5 The degree of polymerization of the obtained polymer was close to the initial monomer/initiator ratio, which indicates a high initiator efficiency with the lithium amide initiators.

BnTMSNLi is readily soluble in a non-polar solvent and exists in solution as an equilibrium mixture of the dimer and unimer, while adopting a trimeric aggregate in the solid state.6 If these advantages of the silyl-protected lithium amides are extended to diamide initiators, difunctional initiators may be effective in non-polar solvents. In this report, the toluene-soluble difunctional initiators with a similar structural feature to BnTMSNLi and BnTIPSNLi, 1a and 1b (Scheme 2), were synthesized and employed as initiators for MMA polymerization in toluene. We found that the trialkylsilyl-protecting groups strongly affected the initiator efficiency. In addition, the bulkier one, 1b, afforded type A PMMA as expected, and the less bulky one, 1a, was involved in a side reaction (carbonyl attack) affording a mixture of two types of PMMA with different molar masses.

Experimental procedure

Materials

MMA (Nacalai Tesque, Kyoto, Japan) was purified by fractional distillation under reduced nitrogen pressure, dried over calcium dihydride (CaH2) (Nacalai Tesque) and vacuum-distilled immediately before use. Toluene was purified in the usual manner, mixed with a small amount of butyllithium (n-BuLi) (Nacalai Tesque) and distilled under high vacuum.

N,N′-bis(trimethylsilyl)-1,3-bis(aminomethyl)benzene was prepared from 1,3-bis(aminomethyl)benzene (m-xylylenediamine) (TCI) and trimethylsilyl chloride (Nacalai Tesque) in Et2O in the presence of CaH2.4 N,N′-bis(triisopropylsilyl)-1,3-bis(aminomethyl)benzene was prepared in a similar manner using triisopropylsilyl chloride (TCI) in CH3CN with diisopropylethylamine. These trialkylsilyl-protected diamines were reacted with n-BuLi in an equivalent molar amount to the NH of the amines in hexane at ambient temperature. The obtained lithium amides 1a and 1b were recrystallized from hexane and dissolved in toluene in the absence of polar additives for use as the toluene solution.

Tributylaluminum (n-Bu3Al; Kishida, Osaka, Japan) was used as received with dilution in dried toluene. 2,6-Di-tert-butylphenol was fractionally distilled and used for the heptane solution. The preparation of ethylaluminum bis(2,6-di-tert-butylphenoxide) (EtAl(ODBP)2) from 2,6-di-tert-butylphenol and triethylaluminum (Kishida) was performed according to a previously reported protocol.5

Measurements

The nuclear magnetic resonance (NMR) spectra were measured in CDCl3 at 55 °C, in CD3CN at 75 °C or in deuterated dimethyl sulfoxide (DMSO-d6) at 110 °C on a JEOL JNM 400 spectrometer (JEOL, Tokyo, Japan) operated at 400 MHz or a Varian Unity Inova 500 spectrometer (Varian, Palo Alto, CA, USA) operated at 500 MHz. Tacticities of the PMMAs were determined from the α-methyl hydrogen signals. The number-average molar mass (Mn) and molar-mass dispersity ĐM (Mw/Mn) were determined by size-exclusion chromatography (SEC) using a Jasco Tri Rotar-V chromatograph (Jasco, Tokyo, Japan) equipped with Polymer Laboratories SEC columns (Polymer Laboratories, Shropshire, UK) (PLgel 5 μm MIXED-C × 2 (300 mm × 7.5 mm)) using tetrahydrofuran as the eluent at 40 °C. The SEC chromatograms were calibrated against standard PMMA samples (Shodex, Tokyo, Japan).

SEC fractionation was performed at ambient temperature using chloroform as the eluent on a system composed of a Jasco model PU-986 pump, a Jasco model RI-1530 refractive index detector Jasco and a Polymer Laboratories SEC column (PLgel 10 μm MIXED-D (300 mm × 25 mm)).

Polymerization

The polymerizations were performed in glass ampoules filled with dried nitrogen, which were passed through 4A Molecular Sieves (Nacalai Tesque) cooled at −78 °C. Dried toluene (10 ml) and the aluminum compounds (1.2 mmol) were charged into the glass ampoules, which were then cooled to the polymerization temperature. After MMA (10 mmol) was added to the solution, the polymerization was initiated by adding the toluene solution containing the difunctional initiators (0.2 mmol). The reactions were quenched by adding methanol containing a small amount of aqueous HCl at the polymerization temperature. The reaction mixtures were poured into hexane (200 ml). The precipitates were collected by filtration and washed successively with hexane and HCl (1 M) several times. The recovered polymers were dried under vacuum at 60 °C.

Reductive cleavage of xylylenediamino group in PMMA

The hydrogenation of PMMA obtained using 1b, which contains a xylylenediamino group in the middle of the chain, was performed in tetrahydrofuran in the presence of Pd/C (Sigma Aldrich, St Louis, MO, USA) by the continuous bubbling of H2 from a rubber balloon through a syringe needle for 48 h at ambient temperature. The experimental details were similar to those reported for α-benzylamino PMMA.5

Results and discussion

Polymerization with 1a

The polymerizations of MMA with 1a/aluminum compounds were conducted in toluene at −78 °C, and the results are summarized in Table 1. When 1a was used alone, the obtained polymer had a rather large ĐM (Mw/Mn) value. In combination with EtAl(ODBP)2, which is an effective additive for living polymerization of MMA with the monofunctional BnTMSNLi,5 the polymerization medium became inhomogeneous as the polymerization was initiated because of the addition of 1a, and a polymer with a large ĐM value formed in relatively low yield.

In contrast, the polymerization, in the presence of n-Bu3Al, proceeded smoothly to produce a polymer with a relatively small ĐM value in quantitative yield. However, the SEC chromatogram of the obtained polymer showed a bimodal elution curve. The molar mass of the lower molar-mass fraction estimated by peak deconvolution was approximately one-half of that of the higher molar-mass fraction (Figure 1). This result suggested that one of the two lithium amide functional groups in 1a was partly deactivated by a side reaction and that the remaining amide initiated the polymerization to produce the low molar-mass fraction.

In our previous report,5 it was revealed that a small amount of N-benzylmethacrylamide was found in the polymerization mixture when MMA was polymerized with trialkylsilyl-protected monofunctional lithium amides including BnTMSNLi. It is known that methacrylamide derivatives do not polymerize anionically, with few exceptions (that is, N-methacryloylaziridine7 and its substituted analogs).8 Therefore, the N-benzyl-N-trimethylsilylmethacrylamide produced by the in situ 1,2-addition is expected to remain intact and is converted to N-benzylmethacrylamide by acid treatment upon termination. Then, the N-benzylmethacrylamide can be removed by a conventional precipitation–purification process. A lithium amide with a bulkier silyl substituent, lithium N-benzyltriisopropylsilylamide (BnTIPSNLi), completely suppresses the methacrylamide formation.5

To determine if this type of side reaction (1,2-addition) occurs in the difunctional initiator system, the structure of the polymer obtained with 1a was analyzed by proton NMR (1H NMR) spectroscopy with a particular focus on the initiator fragment (Figure 2). The expanded 1H NMR spectrum of the polymer treated with aqueous HCl shows a broad signal at 4.25 p.p.m. corresponding to the benzyl methylene protons adjacent to the ammonium nitrogen (Figure 2c). The respective signal shifted to a higher magnetic field in the spectrum of the neutralized PMMA, which is similar to that reported for the monofunctional amide initiators,5 and cannot be observed in the spectral range in Figure 2b. In addition, the spectra clearly show olefinic proton signals (5.4 and 5.7 p.p.m.) that do not correspond to the MMA monomer and a signal (4.45 p.p.m.) corresponding to benzylic methylene protons.

These chemical shift values are similar to those of N-benzylmethacrylamide, which is a byproduct formed when a monofunctional initiator is employed.5 These results suggest that a portion of the lithium amide group was involved in the carbonyl addition, resulting in the formation of a methacrylamide moiety, as shown in Scheme 3. In addition, SEC fractionation was performed, followed by 1H NMR analysis of the lower and higher molar-mass fractions (Figure 3). The signals of the olefinic protons were only observed in the spectrum of the lower molar-mass fraction but not in that of the higher molar-mass fraction. These facts suggest that the low molar-mass fraction contains a methacrylamide structure produced through 1,2-addition of one of the two lithium amide sites on 1a to MMA during the initiation process (Scheme 3).

If such a reaction occurs, only one lithium amide function can initiate polymerization (1,4-addition) to form a polymer, type 3 in Scheme 3, which is expected to have a half molar mass. This assumption coincides with the fact that the Mn of the lower molar-mass fraction was approximately one-half of that of the high molar-mass fraction (cf. Figure 1). Therefore, the polymer obtained with 1a/n-Bu3Al in toluene was actually a mixture of type 2 and type 3, where type 3 was produced by 1,2-addition (Scheme 4). The molar composition of type 2 and type 3 was 74:26, as estimated from the intensities of the benzyl proton signals from type 2 and type 3 in their 1H NMR spectrum. Therefore, the selectivity in the 1,4-addition (initiation) and 1,2-addition (carbonyl attack) of each lithium amide function in 1a is estimated to be 87/13. This value is comparable to that of the monofunctional BnTMSNLi, which is 85/15.5

Polymerization with 1b

In a previous report,5 we described how the monofunctional lithium amide with bulky triisopropylsilyl substituent, BnTIPSNLi, completely suppresses 1,2-addition. Because of the importance of the steric effect of the silyl-protecting group, we examined a difunctional lithium amide with a triisopropylsilyl substituent, 1b, as a truly difunctional initiator. The polymerization results are summarized in Table 1. When 1b/n-Bu3Al was used as the initiator, PMMA with a small ĐM value and a molar mass close to the calculated value was quantitatively obtained. The SEC chromatogram of the obtained polymer using 1b/n-Bu3Al is unimodal without any shouldered peaks, which was also observed for the PMMA prepared using 1a/n-Bu3Al (Figure 4). The expanded 1H NMR spectrum of the obtained polymer is shown in Figure 5. The signals due to the methacrylamide end-group observed in the spectra of the polymer formed with 1a (Figure 5) are completely absent in the spectrum of PMMA obtained with 1b (Figure 5). This result indicates that the 1,2-addition of the lithium amide to MMA was completely suppressed by the introduction of the bulky triisopropylsilyl substituent in the initiator. Therefore, all of the PMMA chains formed should contain a 1,3-xylylenediamine unit in the middle of the chains.

For further structural confirmation of the polymer obtained with 1b, the polymer was subjected to a reaction with H2/Pd-C to cleave the benzylamino C–N bonds of the mid-chain initiator fragment (Scheme 5). The 1H NMR spectrum of the original PMMA shows aromatic and benzylammonium methylene proton signals (Figure 6a). In the spectrum of the hydrogenated product, these characteristic peaks disappeared (Figure 6b), confirming the complete removal of the 1,3-xylylene unit. The SEC chromatogram of the hydrogenated product exhibited a unimodal distribution curve with nearly half of the molar mass of the original polymer (Figure 7). These results clearly demonstrate the exclusive formation of type 2 PMMA in the polymerization with 1b/n-Bu3Al, which proves the effectiveness of 1b as a difunctional initiator. In addition, the narrow molar-mass distribution of the cleaved product suggests an equivalent reactivity of the two lithium amide anions in 1b.

In summary, the novel difunctional lithium amide 1b was determined to be a truly effective difunctional anionic initiator through studies of the side reaction in the initiation step. The obtained polymer had mid-chain functionality involving two benzylic amine groups, which may allow for further functionalization. Amide 1b is soluble in hydrocarbon solvents, such as toluene, in which several stereospecific living polymerizations have been performed with the appropriate additives.9, 10, 11 Therefore, 1b is expected to have substantial synthetic utility as a practical difunctional anionic initiator for the polymerization of (meth)acrylates.

Anionic polymerization of methyl methacrylate (MMA) with lithium N-benzyltrimethylsilylamide (BnTMSNLi) and lithium N-benzyltriisopropylsilylamide (BnTIPSNLi).

Anionic polymerization of methyl methacrylate (MMA) with the difunctional initiators, 1a and 1b.

Formation of the type 3 product.

Polymerization products obtained with 1a/n-Bu3Al.

Hydrogenation of the type 2 polymer obtained with 1b/n-Bu3Al.

References

Hsieh, H. L. & Quirk, R. P. Anionic Polymerization, Principles and Practical Applications, (Marcel Dekker, New York, NY, USA, 1996).

Szwarc, M. & Levy, M. Polymerization initiated by electron transfer to monomer. A new method of formation of block polymers. J. Am. Chem. Soc. 78, 2656 (1956).

Yu, Y. S., Dubois, Ph., Jérôme, R. & Teyssié, Ph. Difunctional initiators based on 1,3-diisopropenylbenzene. 3. Synthesis of a pure dilithium adduct and its use as difunctional anionic polymerization initiator. Macromolecules 29, 2738 (1996).

Kitayama, T., Ogawa, M. & Kawauchi, T. Monomer-selective living copolymerization of butyl acrylate and methyl methacrylate with a difunctional initiator—a facile synthesis of ABA-type triblock copolymer. Polymer (Guildf) 44, 5201 (2003).

Kitaura, T. & Kitayama, T. Anionic polymerization of (meth)acrylates with trialkylsilyl-protected lithium N-benzylamide. Polym. J. 40, 37 (2008).

Armstrong, D. R., Baker, D. R., Craig, F. J., Mulvey, R. E., Clegg, W. & Horsburgh, L. Benzyl(trimethylsilyl)amidolithium: structural studies by ab initio mo and X-ray crystallographic methods, and comparison with the known structures of dibenzyl and bis(trimethylsilyl) analogues. Polyhedron 20, 3533 (1996).

Okamoto, Y. & Yuki, H. Anionic polymerization of N-methacryloylaziridine. J. Polym. Sci. Polym. Chem. Ed. 19, 2647 (1981).

Suzuki, T., Kusakabe, J., Kitazawa, K., Nakagawa, T., Kawauchi, S. & Ishizone, T. Living anionic polymerization of N-methacryloylazetidine: anionic polymerizability of N,N-dialkylmethacrylamides. Macromolecules 43, 107 (2010).

Kitaura, T. & Kitayama, T. Anionic polymerization of methyl methacrylate with the aid of lithium trimethylsilanolate (Me3SiOLi)—superior control of isotacticity and molecular weight. Macromol. Rapid Commun. 28, 1889 (2007).

Kitayama, T., Shinozaki, T., Masuda, E., Yamamoto, M. & Hatada, K. Highly syndiotactic poly(methyl methacrylate) with narrow molecular weight distribution formed by tert-butyllithium-trialkylaluminum in toluene. Polym. Bull. 20, 505 (1988).

Kitayama, T., Zhang, Y. & Hatada, K. Preparetion of highly heterotactic polymethacrylate with narrow molecular weight distribution by t-butyllithium/bis(2,6-di-t-butylphenoxy)methylaluminum in toluene. Polym. J. 26, 868 (1994).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kitaura, T., Kitayama, T. Anionic polymerization of methyl methacrylate by difunctional lithium amide initiators with trialkylsilyl protection. Polym J 45, 1013–1018 (2013). https://doi.org/10.1038/pj.2013.29

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2013.29

Keywords

This article is cited by

-

Comb-shaped Poly(eicosyl methacrylate) Polymer via reverse ATRP using Fe(III) complex

Journal of Polymer Research (2023)