Abstract

In this work, fluorescent and azo dyes were incorporated into CaCO3 and cyclodextrin (CD)-based network polymer thin-film hybrids through host–guest interactions. The hybrid films were prepared on poly(CD)s by a one-pot CaCl2 and Na2CO3 solution process in the presence of poly(acrylic acid). The hybrid-thin films containing fluorescent dyes demonstrate homogeneous fluorescence. The photoisomerization of azo dyes is observed in the solid thin-film hybrids.

Similar content being viewed by others

Introduction

Biomineralization is the process by which living organisms produce hard tissues.1, 2 During this process, living organisms deposit inorganic materials with elaborate structures under mild conditions.3, 4, 5, 6 It is therefore promising to mimic the mechanisms of biomineralization in the development of new environmental friendly approaches for synthesis of inorganic materials.7, 8, 9, 10, 11 Among biominerals, CaCO3 has attracted particular attention 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18 because it is the most abundant biomineral in nature.1 Biomimetic control of CaCO3 material crystallization under mild conditions has been extensively reported.8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23 These approaches achieved crystallization that mimics the biomineralization process by adding organic molecules to the CaCO3 crystallization solution.24, 25, 26

Our previous studies focused on preparing CaCO3 thin films9, 22, 27, 28, 29, 30, 31, 32, 33, 34, 35, 36, 37, 38, 39, 40, 41 and other organic/inorganic hybrids.42, 43, 44 To induce CaCO3 thin-film crystals in the presence of soluble electrolytes, we utilized insoluble polymers as matrices. Through this approach, CaCO3 thin-film hybrids were obtained on a variety of hydrophilic matrices including chitin,27, 28, 29, 30 chitosan,31, 32 poly(vinyl alcohol) (PVA),33, 34, 35, 36, 37, 38 pullulan39, 40 and polymer brushes.41 However, further functionalization of these organic/inorganic hybrids with hydrophobic molecules is difficult45, 46, 47, 48 because of the hydrophilicity of both the inorganic crystals and the matrices. Thus, the current study aims to use cyclodextrin (CD) as a functional molecule host in the CaCO3 thin films to introduce functional hydrophobic molecules.

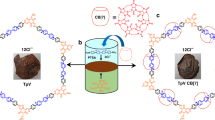

CDs are characterized by a hydrophilic exterior and a hydrophobic central cavity (Figure 1).49, 50 They can accommodate hydrophobic molecules while maintaining outer surface hydrophilicity.49, 50, 51, 52, 53, 54 Accordingly, we expect that matrices containing CDs will induce thin-film growth of CaCO3 while allowing for incorporation of hydrophobic molecules if the CD cavities are not hindered after crystallization. In the present study, hybrid films with host–guest interaction-incorporated fluorescent and azo dyes (Figure 2) were prepared on poly(CD)s (Figure 1b) through a one-pot CaCl2 and Na2CO3 solution process in the presence of poly(acrylic acid).

Experimental procedure

Materials

α-CD, β-CD, ethylene glycol diglycidyl ether (EDGE), bromoethane, sodium 6-(p-toluidino)naphthalene-2-sulfonate (D1), rhodamine B (D2), ammonium 8-anilinonaphthalene-1-sulfonate (D3), eosin Y (D4), dansyl-L-phenylalanine (D5), fluorescein (D6), anthracene-9-carboxylic acid (D7) and 1-aminopyrene (D8) were obtained from Tokyo Kasei (Tokyo, Japan). D2O was utilized as the solvent for nuclear magnetic resonance (NMR) and was obtained from Acros Organics (Bridgewater, NJ, USA). Calcium chloride, ammonium carbonate and all other solvents were purchased from Wako (Tokyo, Japan). All reagents were utilized without further purification.

Characterization

1H NMR spectra were recorded on a JNM-LA400 spectrometer (JEOL, Tokyo, Japan) with D2O as the solvent. Chemical shifts were referenced to the solvent residual peak (δ 4.79 p.p.m.). Crystal samples were coated with platinum for scanning electron microscopy observation using a Hitachi E-1030 ion sputter (Hitachi, Tokyo, Japan). Scanning electron microscopy images were obtained on a Hitachi S-4700 field-emission scanning electron microscopy (Hitachi). Ultraviolet–visible (UV) spectra were obtained on a V-670 UV spectrophotometer (Jasco, Tokyo, Japan) equipped with an integrating sphere. Circular dichroism spectra were obtained on a J-820 spectropolarimeter (Jasco). Irradiation of thin-film hybrids was carried out using a SP-9 light source (Ushio, Tokyo, Japan). U360 and Y44 filters (Hoya, Tokyo, Japan) were employed to obtain UV and Vis irradiation.

Synthesis of poly(CD)s and preparation of poly(CD) matrices

Solutions of poly(α-CD) and poly(β-CD) were synthesized following the previously reported method but with minor modifications.55 α-CD (6.85 g, 7.05 × 10−3 mol) or β-CD (8 g, 7.05 × 10−3 mol) was dissolved in an aqueous solution of NaOH (20 ml, 1 M). EDGE (5 ml, 2.43 × 10−2 mol) was subsequently added into the solution. The mixture was stirred at 70 °C for 1 h, precipitated, washed with methanol and dried under vacuum to provide poly(α-CD) (4.73 g, 45%) or poly(β-CD) (4.85 g, 37%). 1H NMR of poly(α-CD) (D2O, 400 MHz): δ 5.35–4.85 (1-H of α-CD, 1H), 4.30–3.20 (2,3,4,5,6-H of α-CD and H of EDGE, 12.92H). 1H NMR of poly(β-CD) (D2O, 400 MHz): δ 5.35–4.85 (1-H of α-CD, 1H), 4.30–3.20 (2,3,4,5,6-H of α-CD and H of EDGE, 14.4H).

To prepare poly(CD) matrices, poly(CD)s were dissolved in dimethylsulfoxide at 16 wt%, and the resulting solutions were spin coated (2000 r.p.m., 30 s) onto glass substrates. The matrices were then air dried and annealed at 180 °C for 30 min to insolubilize them and thoroughly washed with deionized water. PVA matrices were prepared as previously described.35

Crystallization of CaCO3

Crystallization was performed using a previously reported method with minor modification.37 Briefly, the supersaturated solution of CaCO3 was prepared by mixing a solution of Na2CO3 (40 mM) and a solution of CaCl2 (40 mM) and poly(acrylic acid) (0.24 wt%; 1:1 v/v). Vessels containing polymer matrices and freshly prepared supersaturated CaCO3 solutions (4 ml) were placed in an FMU-131I incubator (Fukushima, Tokyo, Japan) with the temperature set to 25 °C. Samples were removed from the solution after 1 day and dried for characterization.

Synthesis of sodium 4-ethoxy-4′-azobenzene sulfonate (D9)

D9 was synthesized using the method reported by Bazuin and co-workers.56 Sodium 4-hydroxyazobenzene-4′-sulfonate (1.04 g, 3.46 × 10−3 mol), anhydrous potassium carbonate (1.43 g, 3 eq.) and bromoethane (3.76 g, 10 eq.) were added to anhydrous DMF (20 ml). The mixture was stirred at 80 °C for 2 days. Next, the mixture was centrifuged to remove insoluble substances. The supernatant was precipitated with acetone three times. The final precipitate was rinsed with small amounts of water and dried under vacuum, resulting in an orange powder (0.32 g, yield 27%). 1H NMR (D2O, 400 MHz): δ 1.36 (t, J=7.25 Hz, 3H), 4.16 (q, J=7.25 Hz, 2H), 7.06–7.13 (m, 2H), 7.76–7.97 (m, 6H).

Incorporation of dyes into thin-film hybrids of CaCO3/poly(CD)

Aqueous solutions (0.5 mM) were prepared for D1, D2, D3, D4 and D5. Solutions (0.5 mM) of D6, D7 and D8 were prepared in mixtures of methanol and water (1:1 v/v). D9 was dissolved in pure water (5 mM).

Thin-film hybrids of CaCO3/poly(CD) were immersed in the dye solutions for 1 h and then washed extensively with water to remove excess or weakly bound dye molecules.

Results and Discussion

Solutions of poly(CD) in dimethylsulfoxide were utilized to prepare thin-film matrices of poly(CD) by crosslinking CDs55 with EDGE (Figure 1). The amounts of CDs in the poly(CD) solutions were roughly estimated by comparing integrations over the ranges of 5.35–4.85 (1-H of CDs) and 4.30–3.20 (2,3,4,5,6-H of CDs and H of EDGE) in the 1H NMR spectra. The poly(α-CD) matrix was estimated to contain 65 wt% of α-CD, corresponding to 3.0 residual EDGEs per α-CD unit. The β-CD content in the polymer was calculated to be 61 wt% based on the EDGE ratio (4.2 residues per β-CD).

CaCO3 was crystallized by immersing the poly(CD) matrices in a supersaturated solution of CaCO3, which was prepared by mixing a solution of Na2CO3 with a solution of CaCl2 and poly(acrylic acid). Thin-film hybrids with two types of spherulitic textures were obtained (Figure 3a). Type I films were larger with a weaker birefringence than type II films. The thin films were characterized by infrared and Raman spectra. The IR bands of CO32− at 878 cm−1 (v2, out-of-plane bending mode), 715 cm−1 (v4, in-plane bending mode) and 749 cm−1 (v4,) suggest that both calcite and vaterite exist in the hybrids (Figure 3b). The micro-Raman spectra (Figure 3c) show that two polymorphs are associated with the different thin-film types. Type I shows a split v1 band between 1090 and 1076 cm−1, which is indicative of vaterite formation. Type II show Raman bands at 1086 (v1) and 282 cm−1 (librational lattice mode), which suggests a calcite polymorph. We also measured the powder X-ray diffraction pattern of the whole thin-film sample. As shown in Supplementary Figure S1, peaks corresponding to both calcite and vaterite were observed in the X-ray diffraction pattern.

(a) Polarizing optical micrograph, (b) infrared spectra and (c) micro-Raman spectra of the CaCO3 thin films formed on poly(β-CD) matrices in the presence of poly(acrylic acid). Numbers I and II indicate the two different types of thin films. A full color version of this figure is available at Polymer Journal online.

The resultant thin-film hybrids of CaCO3/poly(β-CD) were characterized by scanning electron microscopy. Both types of CaCO3 thin films grew radially with spherulitic patterns (Figure 4a). The films consist of nanocrystals of ~10–20 nm in diameter (Figure 4b) with vacancies between these nanocrystals. Thus, dye molecules may access the entire hybrid film from these vacancies even after crystallization of CaCO3.

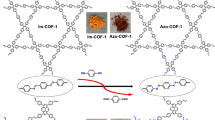

The β-CD cavities accommodate a variety of fluorescent dyes.57 The thin-film hybrids of CaCO3/poly(β-CD) were immersed in fluorescent dye solutions to allow for their incorporation into the matrices. Figures 5a and b show the hybrid matrix with a hydrophobic fluorescent dye D1. The hybrid of D1 and CaCO3/poly(β-CD) is fluorescent (Figure 5a). By contrast, the CaCO3/PVA hybrid exhibits almost no fluorescence (Figure 5b). D1 is a fluorescent probe with fluorescent intensity that increases with the hydrophobicity of its microenvironment.58 The fluorescence of D1 is negligible in water. Thus, the high intensity fluorescence of the hybrid of D1 and CaCO3/poly(β-CD) is direct evidence of the successful incorporation of D1 into the β-CD cavities.59

(a) Fluorescent micrograph of thin-film hybrids of CaCO3/poly(β-CD) after incorporation of sodium 6-(p-toluidino)naphthalene-2-sulfonate (D1). (b) Macroscopic images comparing the fluorescence intensity of thin-film hybrids of CaCO3/poly(β-CD) (I) and CaCO3/poly(vinyl alcohol) (PVA) (II) after incorporation of D1. (c) Fluorescent micrograph of thin-film hybrids of CaCO3/poly(β-CD) after incorporation of rhodamine B (D2). (d) Macroscopic images comparing the fluorescence intensity of thin-film hybrids of (I) and (II) after incorporation of D1.

In addition to hydrophobic dyes, hydrophilic dyes with hydrophobic moieties can be incorporated into the hybrid matrices. For example, it can be seen that the CaCO3/poly(β-CD) hybrid contains more D2 than the CaCO3/PVA hybrid (Figure 5d, right). Although both D1 and D2 were introduced into the hybrids after crystallization of CaCO3 thin films, the hybrid fluorescence is generally homogeneous. This observation suggests that the CD cavities remained accessible to the fluorescent dyes after CaCO3 crystallization. Figure 6 shows fluorescence of thin-film hybrids complexed with various fluorescent dyes (D3–D8). The fluorescence intensity of each dye in the CaCO3/poly(β-CD) hybrids is higher than that of the dyes in the CaCO3/PVA matrices. These results suggest that the dyes interact more strongly with the cavities of poly(β-CD) than with the PVA chains.

Microscopic images showing the fluorescence of thin-film hybrids of CaCO3/poly(β-CD) after incorporation of various fluorescent dyes: (a) 8-anilinonaphthalene-1-sulfonate (D3), (b) eosin Y (D4), (c) dansyl-L-phenylalanine (D5), (d) fluorescein (D6), (e) anthracene-9-carboxylic acid (D7) and (f) 1-aminopyrene (D8). Insets are photographs comparing the fluorescence of thin-film hybrids of CaCO3/poly(β-CD) (left) and CaCO3/poly(vinyl alcohol) (right).

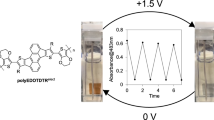

Azo-dyes show cis–trans isomerization. They have been previously incorporated into a variety of polymeric materials.60, 61, 62 For introduction of an azo dye, D9 (Figure 7), into the thin-film materials, a CaCO3/poly(α-CD) hybrid was utilized, as cis-azobenzene binds more strongly to the smaller cavities of α-CD than to the cavities of β-CD.63 The morphology of the obtained CaCO3/poly(α-CD) hybrid was similar to that of the CaCO3/poly(β-CD) hybrid. The hybrid was immersed into an aqueous solution of D9 (5 mM) to allow for dye incorporation. The incorporation of D9 into poly(α-CD) is evidenced by the induced circular dichroism of D9, as shown in Figure 8. D9 adsorbed onto the thin-film hybrid of CaCO3/PVA exhibits no circular dichroism, as D9 is achiral (Figure 8a). However, for D9 adsorbed onto the thin-film hybrid of CaCO3/poly(α-CD), two cotton bands at ~350 and 450 nm are observed (Figure 8a). These two bands correspond to the π→π* and n→π* transition of D9.64 The induced circular dichroism suggests the presence of interactions between D9 and poly(α-CD) in the hybrid. D9 in solution of poly(α-CD) also shows two cotton bands located at ~350 and 450 nm (Figure 8a). However, relative intensities of these two bands are different from those in the spectrum of the CaCO3/poly(α-CD) hybrid.

The hybrids were washed and characterized by UV–Vis spectroscopy. The attachment of D9 to the CaCO3/PVA hybrid is relatively weak, as it is observed that no D9 remains in the hybrid after washing (Figure 9). By contrast, because of the interaction between D9 and poly(α-CD), the absorption peak of D9 is still distinct in the spectrum of the washed CaCO3/poly(α-CD) hybrid. The photoisomerization behavior of D9 in the CaCO3/poly(α-CD) hybrid was examined (Figure 9). On irradiation with UV light, the absorption at ~350 nm (π→π*) decreases (Figure 9a), suggesting that the incorporated D9 changes conformation from trans to cis. Recovery of this conformational change is observed when the hybrid is subsequently irradiated with visible light, as shown in Figure 9b. Photoisomerization of azo dyes is generally disturbed in the solid state,65 because such isomerization requires free volume.66 The observed photoisomerization of D9 in the hybrid may be facilitated by the cavities of α-CDs.67, 68

Time-dependent Ultraviolet–visible (UV–Vis) spectra of thin-film hybrid of CaCO3/poly(α-CD) after incorporation of sodium 4-ethoxy-4′-azobenzene sulfonate (D9) with (a) irradiation of 350 nm UV light and (b) irradiation of visible light (>440 nm light) after 350 nm UV irradiation for 5 min. The UV–Vis spectrum of thin-film hybrids of CaCO3/poly(vinyl alcohol) after incorporation of D9 and subsequent washing is also displayed.

Conclusions

In this study, we prepared thin-film CaCO3-based hybrid materials using poly(CD) matrices. The resulting hybrids were easily functionalized by immersion in solutions of functional molecules. The selected functional molecules were incorporated into the thin-film organic/inorganic hybrids and dispersed throughout the molecular level with efficient function. These studies provide an option for fusion materials inspired by biomineralization. CaCO3-based biominerals are attractive due to their environmental friendly processing and formation; however, the function of synthetic CaCO3 is relatively limited. Here, we provide a new approach to the addition of photofunction to CaCO3-based hybrid materials. These fusion materials take advantage of the harmonization of organic and inorganic, soft and hard and polymeric and ceramic materials with the aim of providing new functional materials.

References

Lowenstam, H. A . & Weiner, S . On Biomineralization (Oxford University Press, New York, 1989)

Mann, S . Biomineralization: principles and Concepts in Bioinorganic Materials Chemistry (Oxford University Press, New York, 2001).

Addadi, L . & Weiner, S . A pavement of pearl. Nature 389, 912–913 (1997).

Aizenberg, J ., Tkachenko, A ., Weiner, S ., Addadi, L . & Hendler, G . Calcitic microlenses as part of the photoreceptor system in brittlestars. Nature 412, 819–822 (2001).

Weaver, J ., Milliron, G ., Miserez, A ., Evans-Lutterodt, K ., Herrera, S ., Gallana, I ., Mershon, W ., Swanson, B ., Zavattieri, P ., DiMasi, E . & Kisailus, D . The stomatopod dactyl club: a formidable damage-tolerant biological hammer. Science 336, 1275–1280 (2012).

Gilbert, P. U. P. A ., Metzler, R. A ., Zhou, D ., Scholl, A ., Doran, A ., Young, A ., Kunz, M ., Tamura, N . & Coppersmith, S. N . Gradual ordering in red abalone nacre. J. Am. Chem. Soc. 130, 17519–17527 (2008).

Yao, H. B ., Fang, H. Y ., Wang, X. H . & Yu, S. H . Hierarchical assembly of micro-/nano-building blocks: bio-inspired rigid structural functional materials. Chem. Soc. Rev. 40, 3764–3785 (2011).

Nudelman, F . & Sommerdijk, N. A. J. M . Biomineralization as an inspiration for materials chemistry. Angew. Chem. Int. Ed. 51, 6582–6596 (2012).

Kato, T ., Sugawara, A . & Hosoda, N . Calcium carbonate-organic hybrid materials. Adv. Mater. 14, 869–877 (2002).

Sugawara-Narutaki, A . Bio-inspired synthesis of polymer-inorganic nanocomposite materials in mild aqueous systems. Polym. J. 45, 269–276 (2013).

Nishimura, T ., Ito, T ., Yamamoto, Y ., Yoshio, M . & Kato, T . Macroscopically ordered polymer/CaCO3 hybrids prepared by using a liquid-crystalline template. Angew. Chem. Int. Ed. 47, 2800–2803 (2008).

Guo, X.-H ., Yu, S.-H . & Cai, G.-B . Crystallization in a mixture of solvents by using a crystal modifier: morphology control in the synthesis of highly monodisperse CaCO3 microspheres. Angew. Chem. Int. Ed. 45, 3977–3981 (2006).

Oaki, Y ., Adachi, R . & Imai, H . Self-organization of hollow-cone carbonate crystals through molecular control with an acid organic polymer. Polym. J. 44, 612–619 (2012).

Pouget, E. M ., Bomans, P. H. H ., Goos, J. A. C. M ., Frederik, P. M ., de With, G . & Sommerdijk, N. A. J. M . The initial stages of template-controlled CaCO3 formation revealed by Cryo-TEM. Science 323, 1455–1458 (2009).

Politi, Y ., Arad, T ., Klein, E ., Weiner, S . & Addadi, L . Sea urchin spine calcite forms via a transient amorphous calcium carbonate phase. Science 306, 1161–1164 (2004).

Gebauer, D ., Völkel, A . & Cölfen, H . Stable prenucleation calcium carbonate clusters. Science 322, 1819–1822 (2008).

Tanaka, Y . & Naka, K . Synthesis of calcium carbonate particles with carboxylic-terminated hyperbranched poly(amidoamine) and their surface modification. Polym. J. 44, 586–593 (2012).

Kim, Y. Y ., Ganesan, K ., Yang, P. C ., Kulak, A. N ., Borukhin, S ., Pechook, S ., Ribeiro, L ., Kroger, R ., Eichhorn, S. J ., Armes, S. P ., Pokroy, B . & Meldrum, F. C . An artificial biomineral formed by incorporation of copolymer micelles in calcite crystals. Nat. Mater. 10, 890–896 (2011).

Meldrum, F. C . & Cölfen, H . Controlling mineral morphologies and structure in biological and synthetic systems. Chem. Rev. 108, 4332–4432 (2008).

Gower, L. B . Biomimetic model systems for investigating the amorphous precursor pathway and its role in biomineralization. Chem. Rev. 108, 4551–4627 (2008).

Cai, G.-B ., Chen, S.-F ., Liu, L ., Jiang, J ., Yao, H.-B ., Xu, A.-W . & Yu, S.-H . 1,3-Diamino-2-hydroxypropane-N,N,N′,N′-tetraacetic acid stabilized amorphous calcium carbonate: nucleation, transformation and crystal growth. CrystEngComm 12, 234–241 (2010).

Kato, T ., Sakamoto, T . & Nishimura, T . Macromolecular templating for the formation of inorganic-organic hybrid structures. MRS Bull. 35, 127–132 (2010).

Imai, H . & Oaki, Y . Bioinspired hierarchical crystals. MRS Bull. 35, 138–144 (2010).

Suzuki, M ., Saruwatari, K ., Kogure, T ., Yamamoto, Y ., Nishimura, T ., Kato, T . & Nagasawa, H . An acidic matrix protein, Pif, is a key macromolecule for nacre formation. Science 325, 1388–1390 (2009).

Weiner, S . & Addadi, L . Design strategies in mineralized biological materials. J. Mater. Chem. 7, 689–702 (1997).

Gries, K ., Heinemann, F ., Gummich, M ., Ziegler, A ., Rosenauer, A . & Fritz, M . Influence of the insoluble and soluble matrix of abalone nacre on the growth of calcium carbonate crystals. Cryst. Growth Des. 11, 729–734 (2011).

Kato, T . Polymer/calcium carbonate layered thin-film composites. Adv. Mater. 12, 1543–1546 (2000).

Sugawara, A ., Nishimura, T ., Yamamoto, Y ., Inoue, H ., Nagasawa, H . & Kato, T . Self-organization of oriented calcium carbonate/polymer composites: effects of a matrix peptide isolated from the exoskeleton of a crayfish. Angew. Chem. Int. Ed. 45, 2876–2879 (2006).

Kumagai, H ., Matsunaga, R ., Nishimura, T ., Yamamoto, Y ., Kajiyama, S ., Oaki, Y ., Akaiwa, K ., Inoue, H ., Nagasawa, H ., Tsumoto, K . & Kato, T . CaCO3/Chitin hybrids: recombinant acidic peptides based on a peptide extracted from the exoskeleton of a crayfish controls the structures of the hybrids. Faraday Discuss. 159, 483–494 (2012).

Kato, T ., Suzuki, T . & Irie, T . Layered thin-film composite consisting of polymers and calcium carbonate: a novel organic/inorganic material with an organized structure. Chem. Lett. 29, 186–187 (2000).

Sugawara, A ., Oichi, A ., Suzuki, H ., Shigesato, Y ., Kogure, T . & Kato, T . Assembled structures of nanocrystals in polymer/calcium carbonate thin-film composites formed by the cooperation of chitosan and poly(aspartate). J. Polym. Sci. A Polym. Chem. 44, 5153–5160 (2006).

Sugawara, A . & Kato, T . Aragonite CaCO3 Thin-film formation by cooperation of Mg2+ and organic polymer matrices. Chem. Commun. 6, 487–488 (2000).

Hosoda, N ., Sugawara, A . & Kato, T . Template effect of crystalline poly(vinyl alcohol) for selective formation of aragonite and vaterite CaCO3 thin films. Macromolecules 36, 6449–6452 (2003).

Sakamoto, T ., Oichi, A ., Oaki, Y ., Nishimura, T ., Sugawara, A . & Kato, T . Three-dimensional relief structures of CaCO3 crystal assemblies formed by spontaneous two-step crystal growth on a polymer thin film. Cryst. Growth Des. 9, 622–625 (2009).

Sakamoto, T ., Oichi, A ., Nishimura, T ., Sugawara, A . & Kato, T . Calcium carbonate/polymer thin-film hybrids: induction of the formation of patterned aragonite crystals by thermal treatment of a polymer matrix. Polym. J. 41, 522–523 (2009).

Zhu, F. J ., Nishimura, T ., Sakamoto, T ., Tomono, H ., Nada, H ., Okumura, Y ., Kikuchi, H . & Kato, T . Tuning the stability of CaCO3 crystals with magnesium ions for the formation of aragonite thin films on organic polymer templates. Chem. Asian J. 8, 3002–3009 (2013).

Kajiyama, S ., Nishimura, T ., Sakamoto, T . & Kato, T . Aragonite nanorods in calcium carbonate/polymer hybrids formed through self-organization processes from amorphous calcium carbonate solution. Small 10, 1634–1641 (2014).

Zhu, F ., Nishimura, T ., Eimura, H . & Kato, T . Supramolecular effects on formation of CaCO3 thin films on a polymer matrix. CrystEngComm 16, 1496–1501 (2014).

Sakamoto, T ., Oichi, A ., Sugawara, A . & Kato, T . Self-organization of patterned CaCO3/polymer composite films: tuning of their morphologies by the change of molecular weights of acidic polymers. Chem. Lett. 35, 310–311 (2006).

Sugawara, A ., Ishii, T . & Kato, T . Self-organized calcium carbonate with regular surface-relief structures. Angew. Chem. Int. Ed. 42, 5299–5303 (2003).

Han, Y ., Nishimura, T . & Kato, T . Morphology tuning in the formation of vaterite crystal thin films with thermo-responsive poly(N-isopropylacrylamide) brush matrices. CrystEngComm 16, 3540–3547 (2014).

Han, Y ., Nishimura, T . & Kato, T . Biomineralization-inspired approach to the development of hybrid materials: Preparation of patterned polymer/strontium carbonate thin films using thermo-responsive polymer brush matrices. Polym. J. 46, 499–504 (2014).

Oaki, Y ., Kajiyama, S ., Nishimura, T . & Kato, T . Selective synthesis and thin-film formation of α-cobalt hydroxide through an approach inspired by biomineralization. J. Mater. Chem. 18, 4140–4142 (2008).

Nishimura, T ., Imai, H ., Oaki, Y ., Sakamoto, T . & Kato, T . Preparation of thin-film hydroxyapatite/polymer hybrids. Chem. Lett. 40, 458–460 (2011).

Tajima, T ., Tsutsui, A ., Fujii, T ., Takada, J . & Takaguchi, Y . Fabrication of novel core-shell microspheres consisting of single-walled carbon nanotubes and CaCO3 through biomimetic mineralization. Polym. J. 44, 620–624 (2012).

Oaki, Y ., Kajiyama, S ., Nishimura, T ., Imai, H . & Kato, T . Nanosegregated amorphous composites of calcium carbonate and an organic polymer. Adv. Mater. 20, 3633–3637 (2008).

Oaki, Y . & Imai, H . Hierarchically organized superstructure emerging from exquisite association of inorganic crystals, organic polymers, and dyes: a model approach toward suprabiomineral material. Adv. Funct. Mater. 15, 1407–1414 (2005).

Oaki, Y ., Ohno, H . & Kato, T . Nanosegregated composites of an imidazolium salt and a layered inorganic compound: organization of both anions and cations in interlayer space. Nanoscale 2, 2362–2365 (2010).

Bender, M. L . & Komiyama, M . Cyclodextrin Chemistry (eds Hafner, K., Lehn, J.-M., Rees, C. W., Shleyer, P., von Rague Schleyer, P., Trost, B. M., Zahradnik, R.) (Springer-Verlag, Berlin, 1978).

Szejtli, J . Cyclodextrin Technology, (Kluwer Academic Publishers, Boston, 1988).

Hapiot, F ., Tilloy, S . & Monflier, E . Cyclodextrins as supramolecular hosts for organometallic complexes. Chem. Rev. 106, 767–781 (2006).

Takashima, Y ., Fukui, Y ., Otsubo, M ., Hamada, N ., Yamaguchi, H ., Yamamoto, H . & Harada, A . Emission properties of cyclodextrin dimers linked with perylene diimide-effect of cyclodextrin tumbling. Polym. J. 44, 278–285 (2012).

Harada, A . Supramolecular polymer chemistry (Wiley-VCH, Weinheim, 2012).

Ito, K . Novel entropic elasticity of polymeric materials: why is slide-ring gel so soft? Polym. J. 44, 38–41 (2012).

Rodriguez-Tenreiro, C ., Alvarez-Lorenzo, C ., Rodriguez-Perez, A ., Concheiro, A . & Torres-Labandeira, J. J . New cyclodextrin hydrogels crosslinked with diglycidylethers with a high drug loading and controlled release ability. Pharm. Res. 23, 121–130 (2006).

Zhang, Q ., Wang, X ., Barrett, C. J . & Bazuin, C. G . Spacer-free ionic dye-polyelectrolyte complexes: influence of molecular structure on liquid crystal order and photoinduced motion. Chem. Mater. 21, 3216–3227 (2009).

Dsouza, R. N ., Pischel, U . & Nau, W. M . Fluorescent dyes and their supramolecular host/guest complexes with macrocycles in aqueous solution. Chem. Rev. 111, 7941–7980 (2011).

Stryer, L . Fluorescence spectroscopy of proteins. Science 162, 526–533 (1968).

Harada, A ., Furue, M . & Nozakura, S . Interaction of cyclodextrin-containing polymers with fluorescent compounds. Macromolecules 10, 676–681 (1977).

Shishido, A . Rewritable holograms based on azobenzene-containing liquid-crystalline polymers. Polym. J. 42, 525–533 (2010).

Ikeda, T ., Sasaki, T . & Ichimura, K . Photochemical switching of polarization in ferroelectric liquid-crystal films. Nature 361, 428–430 (1993).

Alimada, B ., Yamamoto, S . & Moriya, O . Synthesis of thermo- and photoresponsive polysilsesquioxane containing tetraethylene glycol chains and an azobenzene group. Polym. J. 46, 243–249 (2014).

Yamaguchi, H ., Kobayashi, Y ., Kobayashi, R ., Takashima, Y ., Hashidzume, A . & Harada, A . Photoswitchable gel assembly based on molecular recognition. Nat. Commun. 3, 603 (2012).

Bandara, H. M. D . & Burdette, S. C . Photoisomerization in different classes of azobenzene. Chem. Soc. Rev. 41, 1809–1825 (2012).

Evans, R. A ., Hanley, T. L ., Skidmore, M. A ., Davis, T. P ., Such, G. K ., Yee, L. H ., Ball, G. E . & Lewis, D. A . The generic enhancement of photochromic dye switching speeds in a rigid polymer matrix. Nat. Mater. 4, 249–253 (2005).

Knopf, G. K . & Otani, Y . Optical Nano and Micro Actuator Technology (CRC Press, Boca Raton, 2013)

Yabe, A ., Kawabata, Y ., Niino, H ., Tanaka, M ., Ouchi, A ., Takahashi, H ., Tamura, S ., Tagaki, W ., Nakahara, H . & Fukuda, K . cis–trans isomerization of the azobenzenes included as guests in Langmuir–Blodgett films of amphiphilic β-cyclodextrin. Chem. Lett. 17, 1–4 (1988).

Imai, H ., Tochimoto, N ., Nishino, Y ., Takezawa, Y . & Oaki, Y . Oriented nanocrystal mosaic in monodispersed CaCO3 microspheres with functional organic molecules. Cryst. Growth Des. 12, 876–882 (2012).

Acknowledgements

We acknowledge financial support by a Grant-in-Aid for Scientific Research (No. 22107003) on the Innovative Areas: ‘Fusion Materials: Creative Development of Materials and Exploration of Their Function through Molecular Control’ (Area no. 2206) from the Ministry of Education, Culture, Sports, Science and Technology in Japan (MEXT).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Supplementary Information accompanies the paper on Polymer Journal website

Supplementary information

Rights and permissions

About this article

Cite this article

Zhu, F., Nishimura, T. & Kato, T. Organic/inorganic fusion materials: cyclodextrin-based polymer/CaCO3 hybrids incorporating dye molecules through host–guest interactions. Polym J 47, 122–127 (2015). https://doi.org/10.1038/pj.2014.123

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2014.123