Abstract

We measured the single-molecule interaction force between various hydroxybenzoic acids and a Si3N4 cantilever by atomic force microscopy in force curve mode. The hydroxybenzoic acids have different numbers/positions of hydroxyl groups covalently attached to the aromatic ring. The adhesion properties of these hydroxybenzoic acids were compared to determine the effect of the hydroxyl groups on single-molecule interactions. As the number of hydroxyl group increased, the number of single-molecule interactions increased and the interaction force also increased. The catechol system with two hydroxyl groups on the aromatic ring, similar to that found in mussel adhesive, has been well studied. Here, we demonstrate that gallic acid (GA) with three hydroxyl groups on the aromatic ring showed good adhesion and a large number of single-molecule interactions. We synthesized GA adhesives that exhibited sufficiently strong adhesion (10 MPa) to be of practical use.

Similar content being viewed by others

Introduction

The importance of adhesives is often overlooked; however, adhesives are critical in many areas such as engineering, architecture, the automotive industry and medicine. There are many different types of adhesives tailored to different purposes. Most of these adhesives are based on petroleum products that are not environmentally friendly, often constitute a health hazard and are also likely to become scarcer in the near future. Bio-based adhesives have attracted intense interest because of stricter environmental and health regulations.1, 2, 3, 4, 5, 6, 7, 8, 9, 10

Many researchers interested in adhesives have recently become interested in how mussels achieve strong adhesion to both organic and inorganic surfaces, even in sea water. Waite et al.1, 2 discovered that mussels produce an adhesive protein containing the amino acid 3,4-dihydroxyphenyl-L-alanine (DOPA) that contains a catechol group. Messersmith et al.3, 4, 5, 6, 7 applied the adhesive characteristics of DOPA to protein adhesives and soft adhesive sheets. Ruiz-Molina et al.8, 9 expanded the availability of catechol-based systems in which the adhesion mechanism depends on the two adjacent hydroxyl groups on the catechol aromatic ring. Single-molecule force spectroscopy measurements of the interaction between DOPA and a titanium surface in water revealed that the catechol group is strongly adhesive, and the adhesive strength easily exceeds the strength of a double hydrogen bond and the interaction strength of a tyrosine residue11. Recently, Li et al.12 revealed that DOPA adopts different binding modes depending on the surface. They measured the single-molecule interaction force between DOPA and nine surfaces, including Si, Au and polytetrafluoroethylene, in 100 mM Tris-HCl and 50 mM NaCl (pH 7.2) using a ‘multiple fishhook’ force spectroscopy technique.12

To explain catechol adhesion, we focused on the number of hydroxyl groups and their position on the aromatic ring. The catechol group has two hydroxyl groups that are adjacent to each other that may explain its strong adhesion. The adhesive force increases as the number of hydroxyl groups on the aromatic ring increases. Gallic acid (GA) is a natural compound that has three adjacent hydroxyl groups on the aromatic ring. GA has been used in studies on wood adhesives,13, 14 surface coatings15, 16 and self-adhering lipids.17, 18, 19 To determine the adhesive strength of GA, in this work we performed single-molecule force spectroscopy measurements of hydroxybenzoic acids (Figure 1) and investigated the relationship between the number and position of hydroxyl groups on the aromatic ring and single-molecule interaction strength. The adhesive strength of GA was the same as that of the catechol group; therefore, we synthesized a GA adhesive polymer.

We have previously reported the adhesive properties of plant-derived cinnamic acid monomers containing catechol groups and the synthesis of mussel-mimetic polyester adhesives from plant-derived monomers20, 21, 22 used as petroleum substitutes. In contrast to these previous studies of the catechol group, the main chain of our adhesive polymer in this work was designed to be a continuous structure of aromatic rings, thus providing chemical and physical stability. These bio-based adhesives have appealing properties such as biocompatibility,23 high heat resistance and suitability for fiber-reinforced resins because of their strong adhesive characteristics.24, 25 We recently developed bio-based super adhesives with adhesive strength exceeding that of epoxy resin26 using the semi-flexible bio-monomers 3,4-dihydroxyhydrocinnamic acid (DHHCA) and 3-(3-hydroxyphenyl)propionic acid (3HPPA).

In this paper, we synthesized a copolymer of GA and glycolic acid (GLA) using the same method used to synthesize the bio-based super adhesives and obtained a white polymer with a melting point of ∼90 °C and with an adhesive strength equivalent to commercially available instant adhesive. GA has antibacterial and anti-inflammatory effects27, 28 in addition to its adhesive qualities, and therefore we thought about applying this adhesive polymer for medical applications.

Materials and methods

Preparation of the Si surface

A silicon (100) wafer was cut into ∼1 cm squares using a diamond pen to provide the substrates. The substrates were washed with acetone and dried in a desiccator, cleaned in a UV-ozone cleaner (UV253E, Filgen, Aichi, Japan) for 15 min and then immersed in piranha solution (H2O2/H2SO4=1:4) for 60 min to remove impurities and generate surface hydroxyl groups. Next, the substrates were immersed in 20% (v/v) 3-aminopropyltrimethoxysilane in toluene for 30 min to introduce surface amine groups. The amidated substrates were functionalized with polyethylene glycol (PEG) by immersion for 18 h in 5 mM Boc-PEG-N-hydroxysuccinimide (Mw: 3400 Da; BO-034TS, NOF, Tokyo, Japan) dissolved in dimethyl sulfoxide/H2O=1:4. The Boc protecting groups on PEG were deprotected with trifluoroacetic acid for 5 min and then the PEG amine groups were coupled with a hydroxybenzoic acid analog (Figure 1) and methoxyacetic acid (molar ratio=1:3) using a condensing agent solution (0.25 M 1,1,3,3-tetramethyluronium hexafluorophosphate, 0.28 M 1-hydroxy-1H-benzotriazole monohydrate, 0.47 M diisopropylethylamine, 4.3 M N-methylpyrrolidone and 0.12 M carboxylic acid (p-hydroxybenzoic acid/methoxyacetic acid=1:3) in N,N-dimethylformamide) for 14 h. The substrates were then washed with N,N-dimethylformamide and acetone.

Cleaning the atomic force microscope tip surface

Si3N4 atomic force microscopy (AFM) cantilevers (0.06 N m−1, NP-S10, Veeco, Plainview, NY, USA) were cleaned with a UV-ozone cleaner (UV253E, Filgen) for 15 min and then with piranha solution (H2O2/H2SO4=1:4) for 60 min to remove impurities and generate surface hydroxyl groups, and finally washed with ultrapure water and acetone.

Single-molecule force spectroscopy measurements

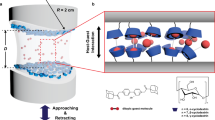

Force spectroscopy measurements were carried out in phosphate buffer saline (pH 7.97)29 at 25 °C using a multimode AFM (Nanoscope IIIa, DI, Santa Barbara, CA, USA) equipped with an AFM cantilever (Si3N4; NP-S10, Veeco) with a spring constant of 60 pN nm−1 and using Nanoscope Version 5.30r2 software. Discrepancies in measurements due to differences in the spring constants of cantilevers were avoided by conducting all measurements with the same tip. The measurement method is illustrated in Figure 2. First, the modified Si substrate was placed on the sample stage, and then the cantilever was brought close to the sample using a speed setting with a ramp size of 500 nm and a scan rate of 0.4895 Hz. The cantilever was pressed onto the surface with a force of 11–12 nN. The AFM tip was then detached from the surface with the same speed setting and the deflection of the tip was measured.

(a) Image of single-molecule interaction force measurement using atomic force microscopy (AFM; red circles: hydroxybenzoic acid, black circles: methoxyacetic acid, blue line: polyethylene glycol (PEG)). (b) Example of a force curve (p-hydroxybenzoic acid). Black line is the fit to the worm-like chain (WLC) model. A full color version of this figure is available at Polymer Journal online.

Data analysis of the force curves

The force curves were analyzed with an in-house protocol written in Igor Pro 6.1.2.1 (Wavemetrics, Portland, OR, USA). The cantilever deflection signal (V) of the force curves was multiplied with the sensitivity (nm V−1) to convert it to force (nN). The sensitivity was calculated from the contact slope of the force curves and the spring constant (60 pN nm−1). The height signal for the bending of the cantilever was converted to tip-sample separation as previously described30 and the force curves were fitted by using the worm-like chain (WLC) formula (Equation (1)) in the Igor Pro software. The persistence length (lp) and contour length (Lc) from the WLC fitting were used to prepare an lp histogram by collecting peaks from the hydroxybenzoic acid force curve that appeared to arise from single molecules, allowing the lp of a single molecule to be determined. Lp peaks in the center range of values on the histogram ±0.05 nm were treated as single-molecule peaks.

where x is the distance between tip and sample surface, T is the temperature and kb is the Boltzmann constant.

Synthesis of poly(GA-co-GLA)

Synthesis scheme is shown in Figure 6a and described as follows. The boiling temperature of GLA was increased by heating GLA (2.85 g, 37.5 mmol) in an oil bath at 175 °C in a vacuum (below 2.4 kPa) for 30 min, and then the product was mixed with GA (2.13 g 12.5 mmol), Na2HPO4 (0.43 g, 3 mmol) and acetic anhydride (8 ml, 85 mmol). The mixture was stirred in an oil bath at 120 °C for 2 h, and then excess acetic anhydride was removed by heating at 150 °C for 20 min in vacuum (below 2.4 kPa). The flask was placed in a mantle heater and heated at 120 °C for 8 h in a vacuum (50–300 Pa). Differential scanning calorimetry (DSC) measurement was carried out with a DSC7020 (Hitachi High-Technologies, Tokyo, Japan) in the temperature range 25 to 200 °C at a heating rate of 10 °C min−1.

Sample preparation for adhesive strength test

Carbon substrates (50 × 10 mm, 10 mm thick) were obtained from Masuda (Osaka, Japan) and used as received. The carbon substrates were put on a hot press machine heated at 200 °C for 5 min and then poly(GLA-co-GA) was melted on the heated carbon substrates for 5 min. Next, a carbon substrate was placed in contact with another substrate to provide a contact area of 1 cm2 and the two substrates were held together with a binder clip for 15 min while cooling to room temperature. Commercially available cyanoacrylate adhesive (Aron Alpha, Toagosei, Tokyo, Japan) was used to provide a comparison for the adhesive strength. Cyanoacrylate adhesive was placed on a carbon substrate and placed in contact with another substrate to provide a contact area of 1 cm2 and held together with a binder clip for 20 h at room temperature to allow complete curing.

Shear strength measurement of adhesive bonds by compression loading

Shear adhesion tests by compression loading were conducted by using a tensile testing machine (3366, Instron, Canton, MA, USA) at a crosshead speed of 1 mm min−1. The force and displacement of the fixture were simultaneously monitored, and stress was defined as force divided by the bonding area.

Results and discussion

Persistence length of single-molecule interactions

The persistence length (lp) of single-molecule interactions was determined by collecting force curve peaks corresponding to single hydroxybenzoic acid peaks. These peaks were fitted with the WLC model to obtain the lp and contour length (Lc) of the peaks. Figure 3a shows the scatter plot for lp and Lc. Most Lc values were 20–30 nm. PEG (Mw: 3400 Da) used to modify the substrates comprises an average of 70 ethylene glycol units. A previous study31 indicated that the molecular length of each ethylene glycol unit in the planar state and helical state of PEG is ∼3.59 and 2.80  , respectively, allowing the full-length planar and helical state of PEG to be estimated as 25 and 20 nm, respectively. This estimate is roughly consistent with the scatter plot. Figure 3b shows a histogram of lp values. Gaussian fitting of Figure 3b provided an lp value of 0.13 nm for a single-molecule interaction that is inconsistent with the lp value (0.38 nm±0.002 nm) reported previously.32 This difference may be caused by the effect on the polymerization of the silane coupling agents.33, 34

, respectively, allowing the full-length planar and helical state of PEG to be estimated as 25 and 20 nm, respectively. This estimate is roughly consistent with the scatter plot. Figure 3b shows a histogram of lp values. Gaussian fitting of Figure 3b provided an lp value of 0.13 nm for a single-molecule interaction that is inconsistent with the lp value (0.38 nm±0.002 nm) reported previously.32 This difference may be caused by the effect on the polymerization of the silane coupling agents.33, 34

(a) Scatter plot of persistence length (lp) and contour length (Lc) for p-hydroxybenzoic acid and Si3N4 at a loading rate of 489.5 nm s−1 in phosphate buffer saline (PBS) (pH 7.97). (b) Histogram of lp (n=93 in 1000 force curves, bin width of 0.02 nm). Only peaks that appeared to be single-molecule peaks were chosen for the scatter plot and histogram, and the peaks were fitted with the worm-like chain (WLC) model. A full color version of this figure is available at Polymer Journal online.

Comparison of single-molecule interaction strength of hydroxybenzoic acids

The Si surface of the substrates was modified with hydroxybenzoic acid-terminated PEG and the interaction force between the hydroxybenzoic acid and the AFM tip surface (Si3N4) in phosphate buffer saline (pH 7.97) was measured at 25 °C by AFM. The WLC model was used to fit 300 force curves of each compound shown in Figure 1. The number of peaks fitted was 56 for methoxyacetic acid, 41 for p-hydroxybenzoic acid, 334 for 3,4-dihydroxybenzoic acid, 117 for 3,5-dihydroxybenzoic acid, 229 for 2,5-dihydroxybenzoic acid and 640 for 3,4,5-trihydroxybenzoic acid (Figure 4a). The results show that as the number of hydroxyl groups in the aromatic ring increases, the number of interaction events increases, with 3,4-dihydroxybenzoic acid providing the most interaction events. Unexpectedly, a hydroxyl group at the para position provides more interaction events than a hydroxyl group at the meta position. The adhesion surface was Si3N4 treated with piranha solution. Silanol groups (3–4.9 sites per nm2) and silylamine groups (0.05–2 sites per nm2) are present on Si3N4 surfaces treated with an oxidizing agent such as a mixture of potassium dichromate and sulfuric acid.35 Therefore, it is expected that there were silanol and silylamine groups on the AFM tip surface treated with piranha solution. The increase in the number of interaction events with the number of hydroxyl groups on the aromatic ring was probably caused by the silanol and silylamine groups on the AFM tip surface hydrogen bonding with the hydroxyl groups of hydroxylbenzoic acids. The increased number of interaction events with a para position hydroxyl group compared with a meta position hydroxyl group may have arisen from the quinone C=O group interacting with the NH2 groups on the AFM tip surface to generate a Schiff base. Mussel-inspired adhesive research has shown that quinone DOPA reacts with the amine group of the lysine side chain. Quinones can be either ortho or para, but not meta. Therefore, the number of interaction events of m-dihydroxybenzoic acid was lower than that of other dihydroxybenzoic acids (Figure 5a). It has been reported that quinone-type GA also reacts with amine groups at pH 8.36 We collected lp peaks in the range of 0.13±0.05 nm for 300 force curves for each molecule and constructed single-molecule interaction force histograms from the data (Figures 4b and c). After Gaussian fitting, the center values of the interaction forces were 124 pN (methoxyacetic acid, n=22), 153 pN (p-hydoroxybenzoic acid, n=16), 269 pN (3,4-dihydroxybenzoic acid, n=142), 229 pN (3,5-dihydroxybenzoic acid, n=57), 240 pN (2,5-dihydroxybenzoic acid, n=102) and 274 pN (3,4,5-trihydroxybenzoic acid, n=157). These results show that the single-molecule rupture force increased when the number of hydroxyl groups on the aromatic ring increased from 1 to 2, although when the number of hydroxyl groups increased from 2 to 3, the rupture force increased only slightly. It is possible that two hydroxyl groups touched the AFM tip surface when the PEG molecule was lifted. It was reported that GA adsorbs onto a TiO2 substrate through two hydroxyl groups, and the third hydroxyl group does not contribute to the chemical adsorbtion.37 Our results suggest to be consistent with the previous reports (Figure 5b). If the positions of the two hydroxyl groups are different, despite the compatibility of the center values provided by Gaussian fitting with the results of the interaction events, an increase in the distance between the hydroxyl groups seems to increase the frequency of weak interaction forces. It has been reported that single-molecule interaction forces between the phenylalanine side chain and a Si surface in water are 219±18 pN.38 The present work shows that two hydroxyl groups interact more easily as they become closer and the substrate surface interacts with the aromatic rings.

(a) Number of peaks fitted by the worm-like chain (WLC) model from 300 force curves for each molecule tested. Methoxy: methoxyacetic acid, OH1: p-hydroxybenzoic acid, OH2-o: 3,4-dihydroxybenzoic acid, OH2-m: 3,5-dihydroxybenzoic acid, OH2-p: 2,5-dihydroxybenzoic acid, OH3: 3,4,5-trihydroxybenzoic acid. (b) Histogram (bin width of 20 pN) of single-molecule interaction force of hydroxybenzoic acids with different numbers of hydroxyl groups. (c) Histogram (bin width of 20 pN) of single-molecule interaction force of hydroxybenzoic acids with two hydroxyl groups in various positions. A full color version of this figure is available at Polymer Journal online.

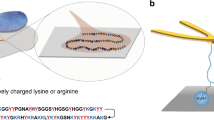

(a) Illustration of interaction between NH2 groups of tip surface and hydroxybenzoic acids. Meta-dihydroxybenzoic acid does not form covalent bond with NH2 groups because it does not become quinone type. (b) The third hydroxyl group of gallic acid does not interact with tip surface because of the distance.

Synthesis of adhesive polymer using GA

Our results indicate that GA, like the catechol group, can be used as an adhesion molecule. Therefore, we synthesized an adhesive polymer using GA. GA was polymerized to increase its melting point. GLA is a natural product extracted from sources such as sugarcane, and poly(GLA) is used in medical devices such as sutures. We previously reported a hyper-branched adhesive polyether (poly(DHHCA-co-3HPPA)) with a catechol group at the end of the molecular chain20, 21, 22, 23, 24, 25, 26 whose adhesive strength was greater than 25.6 MPa for glass, 29.6 MPa for carbon, 15.7 MPa for steel and 16.3 MPa for bovine dentin, exceeding that of epoxy resin adhesive.26 We here prepared a copolymer of GA and GLA (poly(GA-co-GLA)) by using the same method as for poly(DHHCA-co-3HPPA). A white polymer (Figure 6b) was obtained with a melting point at ∼90 °C, determined by DSC measurements. The adhesive strength of this polymer to a carbon substrate (Figure 7b) was similar to that of a commercially available cyanoacrylate adhesive cured for 20 h at room temperature (Figures 7a and c). The adhesive strength of poly(GA-co-GLA) was lower than that of epoxy resin and our poly(DHHCA-co-3HPPA) adhesive, probably for the following two reasons. (1) GA has three hydroxyl groups and thus the polymer is highly branched and its melting temperature easily increases. To obtain a low melting temperature, we used a relatively low molecular weight (Mw=13 000). As the molecular weight of a polymer decreases, the entanglement of the polymer decreases, decreasing the adhesive strength. (2) GA contains hydroxyl groups and a carboxylic group directly bonded to the aromatic ring. If the polymer consisted of only GA, it is expected that the bulk material would be fragile because of the rigidity of the molecular chain. Therefore, we intend to improve the adhesive strength of the polymer by introducing long, soft chains to the chemical structure of the polymer.

(a) Adhesive strength of commercially available cyanoacrylate cured for 20 h at room temperature on a carbon substrate. (b) Adhesive strength of poly(GA-co-GLA) hot-melted at 200 °C on a carbon substrate. (c) Comparison of adhesive strength for a carbon substrate (n=5). GA, gallic acid; GLA, glycolic acid. A full color version of this figure is available at Polymer Journal online.

In this paper, we investigated the relationship between single-molecule interaction force and the number and position of hydroxyl groups on the aromatic ring of hydroxybenzoic acids. The number of interaction events increased with the number of hydroxyl groups. The increase in the single interaction force was greater when the number of hydroxyl groups increased from 1 to 2 than when it increased from 2 to 3. As the distance between the hydroxyl groups increased, the interaction force decreased slightly. The results suggest that GA can be used as an adhesive molecule, as can the catechol group. An adhesive polymer was prepared from GA and GLA that exhibited an adhesive strength to a carbon substrate similar to that of a commercially available cyanoacrylate adhesive.

References

Waite, J. H. & Tanzer, M. L. Polyphenolic substance of mytilus edulis: novel adhesive containing L-Dopa and hydroxyproline. Science 212, 1038–1040 (1981).

Waite, J. H. Surface chemistry - Mussel power. Nat. Mater. 7, 8–9 (2008).

Lee, H., Lee, P. B. & Messersmith, B. P. A reversible wet/dry adhesive inspired by mussels and geckos. Nature 448, 338 (2007).

Gunawan, R. C., King, A. J., Lee, P. B., Messersmith, B. P. & Miller, M. W. Surface presentation of bioactive ligands in a nonadhesive background using DOPA-tethered biotinylated poly(ethylene glycol). Langmuir 23, 10635–10643 (2007).

Lee, H., Dellatore, M. S., Miller, M. W. & Messersmith, B. P. Mussel-inspired surface chemistry for multifunctional coatings. Science 318, 426–430 (2007).

Lee, H., Lee, Y., Statz, R. A., Rho, J., Park, G. T. & Messersmith, B. P. Substrate-independent layer-by-layer assembly by using mussel-adhesive-inspired polymers. Adv. Mater. 20, 1619 (2008).

Lee, H., Rho, J. & Messersmith, B. P. Facile conjugation of biomolecules onto surfaces via mussel adhesive protein inspired coatings. Adv. Mater. 21, 431 (2009).

Saiz-Poseu, J., Sedo, J., Garcia, B., Benaiges, C., Parella, T., Alibes, R., Hernando, J., Busque, F. & Ruiz-Molina, D. Versatile nanostructured materials via direct reaction of functionalized catechols. Adv. Mater. 25, 2066–2070 (2013).

Darshan, D. G., Michael, L., Yu, Z., Amit, P. S., Saroj, N., Ulrike, T., Moshe, E. & Ganpati, R. Annealing-induced interfacial toughening using a molecular nanolayer. Nature 447, 299–302 (2007).

Matos-Perez, C. R., White, J. D. & Wilker, J. J. Polymer composition and substrate influences on the adhesive bonding of a biomimetic, cross-linking polymer. J. Am. Chem. Soc. 134, 9498–9505 (2012).

Lee, H., Scherer, N. F. & Messersmith, P. B. Single-molecule mechanics of mussel adhesion. Proc. Natl Acad. Sci. USA 103, 12999–13003 (2006).

Li, Y., Qin, M., Li, Y., Cao, Y. & Wang, W. Single molecule evidence for the adaptive binding of DOPA to different wet surfaces. Langmuir 30, 4358–4366 (2014).

Trosa, A. & Pizzi, A. Industrial hardboard and other panels binder from waste lignocellulosic liquors phenol-formaldehyde resins. Holz Roh. Werkstoff 56, 220–233 (1998).

GarroGalvez, J. M. & Riedl, B. Pyrogallol-formaldehyde thermosetting adhesives. J. Appl. Polym. Sci. 65, 399–408 (1997).

Sileika, T. S., Barrett, D. G., Zhang, R., Lau, K. H. & Messersmith, P. B. Colorless multifunctional coatings inspired by polyphenols found in tea, chocolate, and wine. Angew. Chem. Int. Ed. 52, 10766–10770 (2013).

Szekeres, M., Illés, E., Janko, C., Farkas, K., Tóth, I. Y., Nesztor, D., Zupkó, I., Földesi, I., Alexiou, C. & Tombácz, E. Hemocompatibility and biomedical potential of poly(gallic acid) coated iron oxide nanoparticles for theranostic use. J. Nanomed. Nanotechnol. 6, 1000252 (2015).

Pollastri, M. P., Porter, N. A., McIntosh, T. J. & Simon, S. A. Synthesis, structure, and thermal properties of 1, 2-dipalmitoylgalloylglycerol (DPGG), a novel self-adhering lipid. Chem. Phys. Lipids 104, 67–74 (2000).

Do Kang, H., Jung, H.-S., Ahn, N., Yang, S. M., Seo, S., Suh, K.-Y., Chang, P.-S., Jeon, N. L., Kim, J. & Kim., K. Janus-compartmental alginate microbeads having polydiacetylene liposomes and magnetic nanoparticles for visual lead(II) detection. ACS Appl. Mater. Interfaces 6, 10631–10637 (2014).

Schmidt, R. & DeWolf, C. E. Monolayer behavior of 1,2-dipalmitoylgalloylglycerol, a synthetic lipid with strong cohesive properties. Langmuir 20, 3284–3288 (2004).

Kaneko, D., Kinugawa, S., Matsumoto, K. & Kaneko, T. Terminally-catecholized hyper-branched polymers with high performance adhesive characteristics. Plant Biotechnol. 27, 293–296 (2010).

Kaneko, D., Wang, S., Matsumoto, K., Kinugawa, S., Yasaki, K., Chi, D. H. & Kaneko, T. Mussel-mimetic strong adhesive resin from bio-base polycoumarates. Polymer J. 43, 855–858 (2011).

Wang, S., Kaneko, D., Kan, K., Jin, X. & Kaneko, T. Syntheses of hyperbranched liquid-crystalline biopolymers with strong adhesion from phenolic phytomonomers. Pure Appl. Chem. 84, 2559–2568 (2012).

Wang, S., Tateyama, S., Kaneko, D., Ohki, S.-Y. & Kaneko, T. Synthesis of well-defined hyperbranched polymers bio-based on multifunctional phenolic acids and their structure-thermal property relationships. Polym. Degrad. Stabil. 96, 2048–2054 (2011).

Kaneko, D., Matsumoto, K., Kinugawa, S., Tateyama, S. & Kaneko, T. Effects of adhesive characteristics of the catechol group on fiber-reinforced plastics. Polymer J. 43, 944–947 (2011).

Chauzar, M., Tateyama, S., Ishikura, T., Matsumoto, K., Kaneko, D., Ebitani, K. & Kaneko, T. Hydrotalcites catalyze the acidolysis polymerization of phenolic acid to create highly heat-resistant bioplastics. Adv. Func. Mater 22, 3438–3444 (2012).

Hiraishi, N., Kaneko, D., Taira, S., Wang, S., Otsuki, M. & Tagami, J. Mussel-mimetic, bioadhesive polymers from plant-derived materials. J. Investig. Clin. Dent. 6, 59–62 (2013).

Kang, M.-S., Oh, J.-S., Kang, I.-C., Hong, S.-J. & Choi, C.-H. Inhibitory effect of methyl gallate and gallic acid on oral bacteria. J. Microbiol. 46, 744–750 (2008).

Kim, S.-H., Jun, C.-D., Suk, K., Choi, B.-J., Lim, H., Park, S. & Lee, S. H. Gallic acid inhibits histamine release and pro-inflammatory cytokine production in mast cells. Toxicol. Sci. 91, 123–131 (2006).

Tamura, T. Pocket Manual of Bioreagent Preparation 183–184 (Yodosha Co., Ltd, Tokyo, Japan, 2004).

Senden, T. J. Force microscopy and surface interactions. Curr. Opin. Colloid Interface Sci. 6, 85–101 (2001).

Oesterhelt, F., Rief, M. & Gaub, H. E. Single molecule force spectroscopy by AFM indicates helical structure of poly(ethylene-glycol) in water. New J. Phys. 1, 6.1–6.11 (1999).

Kienberger, F., Pastushenko, V. P., Kada, G., Gruber, H. J., Riener, C., Schindler, H. & Hinterdorfer, P. Static and dynamical propertiesof single poly(ethylene glycol) molecules investigated by force spectroscopy. Single Mol. 2, 123–128 (2000).

Smith, E. A. & Chen, W. How to prevent the loss of surface functionality derived from aminosilanes. Langmuir 24, 12405–12409 (2008).

Fadeev, A. Y. & McCarthy, T. J. Self-assembly is not the only reaction possible between alkyltrichlorosilanes and surfaces: monomolecular and oligomeric covalently attached layers of dichloro- and trichloroalkylsilanes on silicon. Langmuir 16, 7268–7274 (2000).

Barhoumi, H., Maaref, A. & Jaffrezic-Renault, N. Experimental study of thermodynamic surface characteristics and pH sensitivity of silicon dioxide and silicon nitride. Langmuir 26, 7165–7173 (2010).

Yang, Z., Yang, Y., Yan, W., Tu, Q., Wang, J. & Huang, N. Construction of polyfunctional coatings assisted by gallic acid to facilitate co-immobilization of diverse biomolecules. ACS Appl. Mater. Interfaces 5, 10495–10501 (2013).

Araujo, P. Z., Morando, P. J. & Blesa, M. A. Interaction of catechol and gallic acid with titanium dioxide in aqueous suspensions. 1. Equilibrium studies. Langmuir 21, 3470–3474 (2005).

Razvag, Y., Gutkin, V. & Reches, M. Probing the interaction of individual amino acids with inorganic surfaces using atomic force spectroscopy. Langmuir 29, 10102–10109 (2013).

Acknowledgements

This research was financially supported by the New Energy and Industrial Technology Development Organization and the Kaneko project (11D16002d).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Kinugawa, S., Wang, S., Taira, S. et al. Single-molecule interaction force measurements of catechol analog monomers and synthesis of adhesive polymer using the results. Polym J 48, 715–721 (2016). https://doi.org/10.1038/pj.2015.140

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2015.140

This article is cited by

-

Gallol-Containing Polymers: Synthesis and Applications

Chemistry Africa (2023)