Abstract

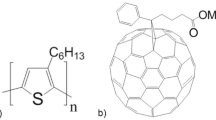

C60 fullerene derivatives, which are formed by grafting polymer chains on a C60 fullerene, can improve the solubility of C60 in solvents. These derivatives are able to composite with various functional polymers to form interpenetrating network gel structures. In this study, a composite gel composed of the C60 fullerene derivatives and poly(3,4-ethylenedioxythiophene)(PEDOT) was prepared using a low-temperature organic-solvent process, and its photoelectric properties were evaluated. Furthermore, the poly(ethylene glycol) (PEG) radicals were successfully trapped in the fullerene (C60), which worked as a cross-linking point to yield the C60-PEG gel. Then, PEDOT was composited with the gel using chemical oxidative polymerization to form the C60-PEG/PEDOT gel. The structure of the film prepared using this composite material was identified. The C60-PEG/PEDOT film had an amorphous network structure and the UV response was much higher than that of the C60-PEG gel. In addition, it was estimated that PEDOT was synthesized inside the C60-PEG gel and formed nanoscale junctions between C60 and PEDOT, which was beneficial for the movement of electrons and holes. The photocurrent was observed by irradiating the C60-PEG/PEDOT gel electrode with UV or simulated sunlight. The power conversion efficiency (PCE) was calculated as 1.2 × 10−3%. Therefore, it is expected that the C60-PEG/PEDOT material is applicable for the photoelectric field, such as solar cells.

Similar content being viewed by others

Introduction

For the past 20 years, C60 fullerene1, 2, 3 has been of significant interest to researchers because of its attractive physical and chemical properties, including its ability to accept and release electrons,4, 5 its ability to trap free radicals,6 its physiological activity7 and its photoactivity.8 The interaction of C60 with light had attracted significantly considerable interest for the applications (for example, solar cells9, 10, 11) that are related to the photochemical and photoinduced charge transfer properties of the C60 derivatives.12 Its remarkable electrochemical properties, with six reversible single-electron reduction waves,13 have arouse the hope of its successful use in many fields, such as biological14, 15, 16 and polymeric materials.17, 18, 19, 20

However, the solubility of C60 fullerene in most solvents21 was very poor, which hindered the widespread use of C60 fullerenes for applications. To solve the problem of bringing C60 fullerenes from basic research to developing applications, various methods have been reported.22, 23 One of the methods is to graft polymer chains onto C60 fullerene24 to improve its solubility and form a homogeneously dispersed solution. Doing so also enhances properties of the new network structured materials.25, 26, 27, 28

We have previously reported that the poly(ethylene glycol) (PEG) radicals, which are formed by the thermal decomposition of macro azo-initiator (Azo-PEG2),29, 30, 31 were successfully trapped on the C60 fullerene surface and C60 worked as a cross-linking point and produced the C60-PEG gel, which formed a network structure.

In this study, we focused on the photoactivity of a C60 device that has an important role as a solar cell with poly(3,4-ethylenedioxythiophene) (PEDOT). Preparation of the C60-PEG gel with PEDOT at low temperature using an organic-solvent process was demonstrated. The C60-PEG gel was composited with PEDOT, which was synthesized using chemical oxidative polymerization. The structure of the C60-PEG/PEDOT gel was identified using scanning electron microscopy (SEM), Fourier transform infrared (FT-IR) spectroscopy and X-ray diffraction (XRD). In addition, the photoelectric property of the composite gel was evaluated.

Experimental Procedure

Materials

C60 fullerene used for the experiments (nanom purple N60-ST) was obtained from the Frontier Carbon Corporation and was used without further purification. The purity was greater than 96% and the average particle size was 30–70 μm. C60 fullerene was dried in vacuum at 50 °C before use.

Macro azo-initiator, (Azo-PEG)n, was obtained from Wako Pure Chemical Industries, Osaka, Japan (the commercial name of (Azo-PEG)n was VPE-0201). The molecular weight of the PEG unit was 2.0 × 103 g mol−1 and it contained several azo groups, which could form polymer radicals.

The compound 3,4-ethylendioxythiophene (EDOT) was obtained from Sigma Aldrich, LLC (St Louis, MO, USA) and was used without further purification.

Reaction of C60 fullerene and (Azo-PEG)n

In total, 5.0 × 10−2 g (6.9 × 10−5 mol) of C60 fullerene, 0.70 g (PEG unit 3.5 × 10−4 mol) of (Azo-PEG)n and 20.0 ml of toluene were combined in a glass tube, degassed using several freeze–pump–thaw cycles and were sealed under high vacuum using the sealed tubes. Then, the sealed tubes were heated at 70 °C with stirring. After 12 h of heating and stirring, excess toluene was removed using a centrifugal evaporator. Then, the C60-PEG sol was prepared and coated onto the indium tin oxide (ITO) glass. After drying at 60 °C for 3 days, the C60-PEG gel was prepared.

Preparation of the C60-PEG/PEDOT gel using chemical oxidative polymerization

Before the C60-PEG sol was prepared, FeCl3 was used as an oxidative agent and EDOT/FeCl3 solution was prepared by mixing EDOT and FeCl3 in toluene. Then, EDOT/FeCl3 solution was added to the C60-PEG sol, and the sol was coated on the ITO glass. After drying at 60 °C for 3 days, the C60-PEG/PEDOT gel was prepared.

PEDOT was synthesized using chemical oxidative polymerization. FeCl3 was dissociated to Fe3+ and 3Cl− in the EDOT/FeCl3 toluene solution. Once EDOT and Fe3+ came in contact, polymerization of EDOT was initiated by transferring an electron from EDOT to Fe3+. EDOT works as an active center and is added to another EDOT molecule. This process was repeated many times and PEDOT was obtained (Scheme 1).

Measurements

To measure the characteristics of the composited gel, the C60-PEG/PEDOT gel was dried to produce a C60-PEG/PEDOT film. SEM was recorded using JSM-6510 (JEOL, Tokyo, Japan). Infrared spectra were recorded using FTIR-8400S FT-IR spectrophotometer (Shimazu Manufacturing, Kyoto, Japan). XRD was recorded with RINT2100 (Rigaku, Tokyo, Japan) using 0.2-mm-thick sample plates. The measurement wavelength was at 1.54 nm.

Photoelectric properties

The C60-PEG and C60-PEG/PEDOT gels were connected with a copper wire using Ag paste. The copper wire was connected to a digital multimeter (R6871EDC, Advantest, Tokyo, Japan). The gels were irradiated with a ultraviolet (UV) lamp (365 nm wavelength) for 5 min each at 20 °C and 65% humidity. Resistance was measured during this process. Electroconductivity was calculated using the resistance, thickness, width and length of the gel.

Power conversion efficiency

Power conversion efficiency (PCE) of the C60-PEG and C60-PEG/PEDOT gels was investigated. The devices were fabricated using the C60-PEG/PEDOT gel, which was connected with a copper wire using Ag paste. Photocurrent was measured with an applied voltage from −1.0 to 1.0 V under a solar simulator irradiation (HAL-C100, 100 W compact xenon light source, Asahi Spectra, Tokyo, Japan) with AM1.5G spectra at 100 mW cm−2 at room temperature. Dark current was measured under the same conditions without a simulated sunlight irradiation.

Results and discussion

Preparation of the C60-PEG/PEDOT composite gel

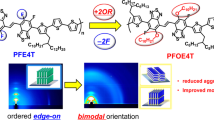

The C60-PEG gel electrode was prepared by casting the C60-PEG sol on the ITO electrode. PEDOT was synthesized inside the C60-PEG gel by dropping the FeCl3/EDOT solution. The C60-PEG gel and PEDOT formed the C60-PEG/PEDOT gel, a composite material that has a network structure (Scheme 1). By comparing the C60-PEG and C60-PEG/PEDOT gels that were prepared using chemical oxidative polymerization with a low-temperature organic-solvent process, we found that the C60-PEG gel had a flat brown-colored surface. The surface of the C60-PEG/PEDOT gel was rough, and its color slightly changed from brown to dark brown due to PEDOT. The C60-PEG/PEDOT film was flexible and elastic and could be processed easily.

Scanning electron microscope

The morphology of the C60-PEG/PEDOT films was observed using SEM. Figure 1 depicts three types of SEM images with different resolutions of the C60-PEG/PEDOT film surface. Porous structures of the C60-PEG/PEDOT composite material were confirmed using Figures 1b and c. It was determined that the porous structure of this material was formed due to the solvent evaporation. After toluene evaporated, many porous cells were formed in the spaces between C60-PEG and PEDOT. This was observed again in the cross-section of the polymer solar cell device using the C60-PEG/PEDOT gel as an active layer.

SEM micrographs of the C60-PEG/PEDOT films: (a) surface of the film, scale bar is 100 μm, (b) porous surface of the film, scale bar is 20 μm, (c) porous surface of the film, scale bar is 10 μm. C60-PEG, C60-poly(ethylene glycol); PEDOT, poly(3,4-ethylenedioxythiophene); SEM, scanning electron microscopy.

FT-IR spectrum

Figure 2 shows FT-IR spectra of (a) the C60-PEG gel, (b) PEDOT and (c) the C60-PEG/PEDOT gel. The C60-PEG gel spectrum showed characteristic PEG absorptions at 2925 and 1105 cm−1, which were characteristic of –CH2– and –O–, respectively. The PEDOT spectrum showed characteristic absorptions at 720 and 1520 cm−1, which were characteristic of thiophene. The spectrum of (c) the C60-PEG/PEDOT gel showed characteristic PEG and thiophene absorptions at 2925, 1520, 1105 and 720 cm−1. It was considered that the PEG biradicals were successfully trapped by C60 fullerene. C60 fullerene, as a cross-linking point, and PEDOT were synthesized into a C60-PEG film to form a composite material with an interpenetrating network structure.

X-ray diffraction

Figure 3 shows XRD patterns of the (a) C60-PEG and (b) C60-PEG/PEDOT gels. The C60-PEG gel has a broad peak from 15 to 25 degrees and two sharp peaks on the broad peak. The C60-PEG/PEDOT gel had a broad peak from 15 to 25 degrees, which was identical to the C60-PEG gel. However, sharp peaks were not observed in the C60-PEG/PEDOT gel. It was considered that C60-PEG gel had a crystalline structure because of the sharp XRD peaks. However, the C60-PEG/PEDOT gel dispersed the sharp peaks. It was suggested that the prepared C60-PEG/PEDOT gel had an amorphous structure and it was composited on a molecule scale.

Device structure

The device structure was shown in Figure 4a (starting from the bottom: glass/ITO, the C60-PEG/PEDOT photoactive layer with a final Ag electrode). Top-view SEM of the C60-PEG/PEDOT film on ITO glass is shown in Figure 1. Figure 4b shows the cross-sectional view using SEM. The results reveal that the C60-PEG/PEDOT film on ITO glass was uniform, and the surface was smooth. The cross-sectional SEM image of devices without the Ag electrode is shown in Figure 4b. The figure shows a well-defined, layer-by-layer structure with sharp interfaces. There are many holes in the active layer, as previously discussed. It is estimated that the active layer microstructure forms an interpenetrate network structure. When the material was drying, toluene (which was used as solvent in spaces of the structure) was evaporating, and holes remained on the surface and inside the active layer. The active layer thickness was ~33.3 μm. Here, the thickness of the C60-PEG/PEDOT layer was sufficient to act as a light-absorbing layer. Moreover, charge extraction from the photoactive layer to electrodes remained efficient due to the long carrier lifetime and good carrier transport properties. The C60-PEG/PEDOT film ensured a sufficient light absorption, which was the decisive factor for the photoelectric conversion performance.

Device structure of a low-temperature-processed polymer solar cell. (a) From the bottom: glass/ITO/C60-PEG/PEDOT/Ag. (b) The cross-section of the device except for the Ag electrode. The thicknesses of the active layer was 33.3 μm. C60-PEG, C60-poly(ethylene glycol); ITO, indium tin oxide; PEDOT, poly(3,4-ethylenedioxythiophene). A full color version of this figure is available at Polymer Journal online.

UV response

Figure 5 shows response of the C60-PEG/PDOT film to UV light. Once the film was UV irradiated, the electroconductivity rapidly increased and reached a constant value. Without UV irradiation, the electroconductivity rapidly decreased.

Conductivity of the C60-PEG film increased from 2.96 × 10−11 to 1.79 × 10−9 S cm−1, and conductivity of the C60-PEG/PEDOT film increased from 2.11 × 10−6 to 6.05 × 10−6 S cm−1, respectively. The conductivity increased because electrons in the π-conjugated system of C60 moved faster when the C60-PEG/PEDOT gel was UV irradiated. The C60-PEG/PEDOT gel has a much higher response compared with the C60-PEG gel, because PEDOT was synthesized inside the C60-PEG gel. It was estimated that the nanoscale junctions were formed between C60 and PEDOT. During UV exposure, C60 worked as a n-type semiconductor and PEDOT worked as a p-type semiconductor, and electroconductivity of the C60-PEG/PEDOT gel increased by transferring an electron from C60 to PEDOT.

Power conversion efficiency

We achieved operational devices based on the low-temperature (less than 70 °C) organic-solvent-processed polymer solar cells. This result suggests that it was possible to obtain functional flexible polymer solar cell devices based on the utilized processing techniques. A photograph of the flexible active layer is shown in Figure 6a, and the current density–voltage curve of the C60-PEG/PEDOT device is shown in Figure 6b. Photocurrent was measured with an applied voltage from −1.0 to 1.0 V under a solar simulator irradiation (HAL-C100, 100 W compact xenon light source, Asahi Spectra) with AM1.5G spectra at 100 mW cm−2 at room temperature. On the basis of the photocurrent results under the simulated sunlight irradiation, the C60-PEG/PEDOT heterojunction solar cell device shows a classical polymer solar cell photovoltaic behavior with a short-circuit current Jsc of 0.02 mA cm−2, an open-circuit voltage Voc of 0.16 V, a fill factor FF of 42.26 and a PCE η (%) of 1.2 × 10−3. The PCE losses are due to the decrease of the Jsc and Voc values. This is attributed to a smooth surface and a large thickness of the active layer. These challenges will be resolved in the near future by surface modification to mimic the unique functionalities of biological systems, such as the antireflection and antiglaring properties of the moth eye microstructure.

(a) Photo image of the flexible C60-PEG/PEDOT film and (b) the current density–voltage curves of the C60-PEG/PEDOT heterojunction solar cell under illumination. C60-PEG, C60-poly(ethylene glycol); PEDOT, poly(3,4-ethylenedioxythiophene). A full color version of this figure is available at Polymer Journal online.

From these results, photocurrent was observed in the C60-PEG/PEDOT device. However, photocurrent was not observed either in the C60-PEG device or in a simple layer stack of the C60-PEG gel and PEDOT device. Thus, it was determined that PEDOT and C60-PEG were contacting on the nanoscale to form bulk heterojunction polymer solar cells with interpenetrating network structures that were able to transfer electrons and holes efficiently. Photocurrent of a simple layer stack of the C60-PEG gel and PEDOT was not observed, because C60 and PEDOT were contacting only at the interface. Thus, the electron and hole transfer process was hindered.

Conclusions

We prepared the C60-PEG/PEDOT gel using chemical oxidative polymerization using a low-temperature organic-solvent process. The film prepared from this material was characterized using the SEM, FT-IR, XRD and UV response measurements. These results showed that PEDOT was synthesized inside of the C60-PEG gel and that the C60-PEG/PEDOT gel had an amorphous structure, contrary to the C60-PEG crystalline structures. Then, we fabricated polymer solar cell devices using this composite material. It was confirmed that the composite film showed UV response and PCE by irradiating it with a UV or simulated sunlight. The results showed that UV response of the C60-PEG/PEDOT device was much higher than that of the C60-PEG device. UV response was improved by synthesizing PEDOT in the C60-PEG gel to form new interpenetrating network structures. PCE of the C60-PEG/PEDOT device was ~1.2 × 10−3%. It is expected that all organic-solvent polymer solar cells with a new interpenetrating network structure will use the C60 derivate and conductive polymer composite materials to improve PCE in the future.

Synthesis of PEDOT using chemical oxidative polymerization. PEDOT.

References

Martin, N., Sanchez, L., Illescas, B. & Perez, I. C60-based electroactive organofullerenes. Chem. Rev. 98, 2527–2547 (1998).

Taherpour, A. A. Quantitative structural relationship and theoretical study of electrochemical properties of C60@[SWCN(5, 5)-Armchair-CnH20] complexes. Chem. Phys. Lett. 469, 135–139 (2009).

Wu, J. W., Alemany, L. B., Li, W. L., Petrie, L., Welker, C. & Frotner, J. D. Reduction of hydroxylated fullerene (fullerol) in water by zinc: reaction and hemiketal product characterization. Environ. Sci. Technol. 48, 7384–7392 (2014).

Guldi, D. M. & Prato, M. Excited-state properties of C60 fullerene derivatives. Acc. Chem. Res. 33, 695–703 (2000).

Bendikov, M. & Wudi, F. Tetrathiafulvalenes, oligoacenenes, and their buckminsterfullerene derivatives: the brick and mortar of organic electronics. Chem. Rev. 104, 4891–4945 (2004).

Allen, N. S., Zeynalov, E. B., Taylor, K. & Birkett, P. Antioxidant capacity of novel amine derivatives of buckminsterfullerene: determination of inhibition rate constants in a model oxidation system. Polym. Degrad. Stabil. 94, 1932–1940 (2009).

Zakharian, T. Y., Seryshev, A., Sitharaman, B., Gilbert, B. E., Knight, V. & Wilson, L. J. A fullerene-paclitaxel chemotherapeutic: synthesis, characterization, and study of biological activity in tissue culture. J. Am. Soc. 127, 12508–12509 (2005).

Sudeep, P. K., Ipe, B. L., Thomas, K. G. & George, M. V. Fullerene-functionalized gold nanoparticles. a self-assembled photoactive antenna-metal nanocore assembly. Nano Lett. 2, 29–35 (2002).

Wrobel, D. & Graja, A. Photoinduced electron transfer processes in fullerene–organic chromophore systems. Coord. Chem. Rev. 255, 2555–2577 (2011).

Magnel, G.-I., Peuntinger, K., Kahnt, A., Krausmann, J., Vazquez, P., David, G.-R., Guldi, D. M. & Torros, T. Supramolecular assembly of multicomponent photoactive systems via cooperatively coupled equilibria. J. Am. Chem. Soc. 135, 19311–19318 (2013).

Hoppe, H., Niggemann, M., Winder, C., Krant, J., Hiesgen, R., Hinsch, A., Meissner, D. & Sariciftci, N. S. Nanoscale morphology of conjugated polymer/fullerene-based bulk-heterojunction solar cells. Adv. Funct. Mater. 14, 1005–1011 (2004).

Brabec, C. J., Saeiciftci, N. S. & Hummelen, J. C. Plastic solar cells. Adv. Funct. Mater. 11, 15–26 (2001).

Blach, A. L., Costa, D. A., Fawcett, W. R. & Winkler, K. Electronic communication in fullerene dimers. electrochemical and electron paramagnetic resonance study of the reduction of C120O. J. Phys. Chem. 100, 4823–4827 (1996).

Jensen, A. W., Wilson, S. R. & Schuster, D. I. Biological applications of fullerenes. Biologan. Med. Chem. 4, 767–779 (1996).

Fletcher, J. S., Lockyer, N. P. & Vickerman, J. C. C60, buckminsterfullerene: its impact on biological ToF-SIMS analysis. Surf. Interface. Anal. 38, 1393–1400 (2006).

Bosi, S., Ros, T. D., Spalluto, G. & Prato, M. Fullerene derivatives: an attractive tool for biological applications. Eur. J. Med. Chem. 38, 913–923 (2003).

Walker, B., Tamayo, A. B., Dang, X.-D., Zalar, P., Seo, J. H., Garcia, A., Tantiwiwat, M. & Nguyen, T.-Q. Nanoscale phase separation and high photovoltaic efficiency in solution-processed, small-molecule bulk heterojunction solar cells. Adv. Funct. Mater. 19, 3063–3069 (2009).

Spanggaard, H. & Krebs, F. C. A brief history of the development of organic and polymeric photovoltaics. Sol. Energ. Mat. Sol. C 83, 125–146 (2004).

Wang, C., Guo, Z.-X., Fu, S., Wu, W. & Zhu, D. Polymers containing fullerene or carbon nanotube structures. Prog. Polym. Sci. 29, 1079–1141 (2004).

Blouin, N., Michaud, A. & Leclerc, M. A low-bandgap poly(2,7-Carbazole) derivative for use in high-performance solar cells. Adv. Mater. 19, 2295–2300 (2007).

Marcus, Y., Simth, A. L., Korobov, M. V., Mirakyan, A. L., Avramenko, N. V. & Stukalin, E. B. Solibility of C60 fullerene. J. Phys. Chem. B 105, 2499–2506 (2001).

Okamura, H., Ide, N., Minoda, M., Komatsu, K. & Fukuda, T. Solubility and micellization behavior of C60 fullerenes with two well-defined polymer arms. Macromolecules 31, 1859–1865 (1998).

Giacalone, F. & Martin, N. Fullerene polymer: synthesis and properties. Chem. Rev. 106, 5136–5190 (2006).

Ederle, Y. & Mathis, C. Grafting of anionic polymers onto C60 in polar and nonpolar solvents. Macromolecules 30, 2546–2555 (1997).

Moule, A. & Meerholz, K. Controlling morphology in polymer–fullerene mixtures. Adv. Mater. 20, 240–245 (2008).

Yu, G., Gao, J., Hummelen, J. C., Wudl, F. & Heeger, A. J. Polymer photovoltaic cells: enhanced efficiencies via a network of internal donor-acceptor heterojunctions. Science 270, 1789–1791 (1995).

Theobald, J. A., Oxtoby, N. S., Phillips, M. A., Champness, N. R. & Beton, P. H. Controlling molecular deposition and layer structure with supramolecular surface assemblies. Nature 424, 1029–1031 (2003).

Ma, W., Gopinathan, A. & Heeger, A. J. Nanostructure of the interpenetrating networks in poly(3-hexylthiophene)/fullerene bulk heterojunction materials: implications for charge transport. Adv. Mater. 19, 3656–3659 (2007).

Wakai, H., Momoi, T., Shinno, T., Yamauchi, T. & Tsubokawa, N. A novel polymer-grafted C60 fullerene having both hydrophilic and hydrophobic chains. Mater. Chem. Phys. 118, 142–147 (2009).

Wakai, H., Shinno, T., Yamauchi, T. & Tsubokawa, N. Grafting of poly(ethylene oxide) onto C60 fullerene using macroazo initiators. Polymer 48, 1972–1980 (2007).

Wakai, H., Momoi, T., Yamauchi, T. & Tsubokawa, N. A simple preparation of C60-poly(ethylene glycol) gel and its properties. Polym. J. 41, 40–45 (2009).

Acknowledgements

We express their gratitude to Professor N Tsuboi and Dr R Ishikawa Niigata University for their kind help with the power conversion efficiency measurements of the C60-PEG/PEDOT device. This work was supported by JSPSKAKENHI (grant number 2412001).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Huiqiu, Z., Ichinose, M., Takahashi, H. et al. Photoelectric properties of C60-poly(ethylene glycol) and poly(3,4-ethylenedioxythiophene) composite gel prepared via a low-temperature organic-solvent process. Polym J 48, 163–168 (2016). https://doi.org/10.1038/pj.2015.65

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2015.65