Abstract

Telechelic poly(N-isopropylacrylamide) (PNIPAAm) was designed to prepare homogeneous and self-healable gels by end-crosslinking. The PNIPAAm with carboxyl groups at both polymer ends and trithiocarbonate (TTC) in the main chain was obtained by reversible addition-fragmentation chain transfer (RAFT) polymerization of NIPAAm with a symmetric TTC compound (CTA-1) as a RAFT agent. The obtained polymers of a series of molecular weights were well-defined within a narrow molecular weight distribution (Mw/Mn~1.1). Then, the end groups of the resultant PNIPAAms were quantitatively transformed into activated esters as reactive sites for gelation. These designed PNIPAAms were employed for an end-crosslinking reaction with trifunctional amine crosslinker, and it was found that gelation condition was closely related to the molecular weight and the concentration of the telechelic prepolymers. Furthermore, the obtained gel showed the characteristic ultraviolet-induced self-healing owing to the chain exchange reaction of TTC groups.

Similar content being viewed by others

Introduction

Polymer gels are one of the most versatile materials due to their characteristic structures consisting of a three-dimensional polymer network and fluid. Especially after the discovery of their volume-phase transition,1 polymer gels have been explosively developed as stimuli-responsive materials, and some of them are already being examined for practical applications in sensors, actuators, drug delivery and biomedical systems.2, 3, 4

To give various characteristic properties to polymer gels, vinyl polymers, which will potentially be able to have a wide variety of substituents, are attractive candidates as precursors of polymer gels. Vinyl polymer gels are generally prepared by free-radical copolymerization of vinyl monomers with small amounts of divinyl compound as a crosslinker. Although this synthetic method is simple and applicable to a wide variety of vinyl monomers, the molecular weight between crosslinking points cannot be essentially controlled and the three-dimensional polymer network generally has inhomogeneities.5 The resultant inhomogeneity in the gel network often leads to crucial mechanical damage in gel properties due to stress concentration. This weak mechanical property has been one of the main obstacles to practical application of polymer gels.

The weakness of polymer gels is due in part to network inhomogeneity. To produce a homogeneous network, it would be important to design the crosslinking structure and the polymer chains between crosslinking points, both of which are fundamental components of polymer gels. One of the most promising ways to produce a homogeneous network is by end-crosslinking the bifunctional mono-dispersed polymer, which is synthesized by living polymerization.6 For example, Sakai et al.7 successfully prepared homogeneous ‘tetra-PEG gel’ by cross-reaction between two kinds of end-functionalized four-armed poly(ethylene glycol) (PEG) star polymers synthesized by living anionic ring-opening polymerization. This gel was revealed to have a nearly ideal network and resultant high mechanical strength. However, it was difficult to introduce functional groups into this system because of the structural limitations of the monomer. On the other hand, vinyl monomers are rather attractive for the functionalization of polymer gels due to the structural variety of their side chains, and the synthesis of homogeneous vinyl polymer gels has been attracting much attention.8, 9, 10, 11, 12

In addition, self-healing is important in improving the mechanical properties of polymer gels, especially from the viewpoint of durability.13, 14, 15 Matyjaszewski et al.16, 17 reported that the polymer network containing trithiocarbonate (TTC) groups showed stimuli-responsive self-healing induced by radical initiator or ultraviolet (UV) light. Such TTC units can be incorporated into polymer chains via reversible addition-fragmentation chain transfer (RAFT) polymerization using a TTC compound as a chain transfer agent (CTA). RAFT polymerization can afford the living system that controls the molecular weight of the polymer with defined end groups.18, 19, 20 Such features would be suitable for the design of telechelic polymer, the precursor for the construction of network structure by the end-crosslinking method. Therefore, end-crosslinking of the telechelic polymers prepared by TTC-mediated RAFT polymerization is anticipated to give a homogeneous network, combining self-healing with excellent mechanical properties and durability.

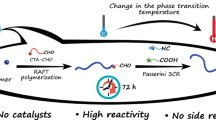

In this paper, we designed the end-crosslinking of controlled telechelic poly(N-isopropylacrylamide) (PNIPAAm) synthesized by TTC-mediated RAFT polymerization for the construction of a homogeneous network with self-healing, as shown in Scheme 1. Importantly, TTC units should be in the middle of the network chains for effective self-healing. Therefore, we utilized a symmetric TTC compound with two functional groups because it can give controlled telechelic polymers with the TTC unit in the middle of the polymer chain. After gelation by end-crosslinking, TTC groups would be positioned in the middle of network polymer chains between crosslinking points, and these TTC groups are supposed to confer a self-healing property to the designed polymer gels.

The detailed strategy is shown in Scheme 2. First, the controlled telechelic PNIPAAm was synthesized by RAFT polymerization with symmetric CTA, bis(2-propionic acid) trithiocarbonate (CTA-1; Scheme 2). NIPAAm was selected as a monomer because PNIPAAm gel shows thermoresponsive volume change at ~33 °C,21, 22 and PNIPAAm gel is promising in various applications, such as thermoresponsive sensors and actuators, in which improving mechanical strength and durability is necessary. Then, the obtained telechelic PNIPAAm was crosslinked by utilizing activated ester chemistry that is capable of effective reaction with primary amines under mild conditions.23, 24, 25 We evaluated the effect of the molecular weight and feed concentration of the telechelic polymers on gelation behavior to establish the optimal condition for the synthesis of end-crosslinked PNIPAAm gels with TTC groups in the middle of network chains. In addition, we verified the UV-stimulated self-healing ability of the obtained gel by the function of TTC groups.

Experimental Procedure

Materials

NIPAAm (Wako, Osaka, Japan; 98.0%) was recrystallized from toluene/n-hexane. CTA-1 was prepared according to the literature.26 2,2′-Azobis(isobutyronitrile) (AIBN; Wako; 98%), tetralin (1,2,3,4-tetrahydronaphthalene; 1H nuclear magnetic resonance (NMR) internal standard for NIPAAm; Aldrich, St Louis, MO, USA; 99%), N-hydroxysuccinimide (NHS; Wako; >98%), N,N′-dicyclohexylcarbodiimide (DCC; Tokyo Kasei, Tokyo, Japan; >98.0%), 4-dimethylaminopyridine (DMAP; Wako; >99.0%) and tris(2-aminoethyl)amine (TAEA; Wako; 97.0%) were used as received.

RAFT polymerization of NIPAAm

RAFT polymerization of NIPAAm was carried out in a glass flask with a three-way stopcock under dry nitrogen. A typical example of RAFT polymerization procedures employed here is as follows. CTA-1 (185 mg; 7.27 × 10–4 mol), NIPAAm (4.08 g; 3.60 × 10–2 mol), 1,4-dioxane (16.2 ml) and tetralin (0.97 ml) were introduced into a 50 ml round-bottomed flask to make the NIPAAm solution. AIBN solution (11.8 mg (7.18 × 10–5 mol) in 1.80 ml of 1,4-dioxane) was added to this NIPAAm solution at room temperature and nitrogen was bubbled through the solution for 10 min. The flask was then placed in an oil bath regulated at 60 °C, and the polymerization was conducted for 9 h. The polymerization was terminated by cooling the flask containing the reaction mixture from 60 °C down to –78 °C. Monomer conversion was determined from the residual monomer concentration measured by 1H NMR in reference to an internal standard, tetralin. The crude PNIPAAm was purified by reprecipitation into diethyl ether. The obtained PNIPAAm was 3.29 g (yield: 77%).

End-functionalization of PNIPAAm with activated ester

PNIPAAm (Mn=6100 (by 1H NMR), Mw/Mn=1.11 (by size-exclusion chromatography (SEC)); 2.01 g; 6.59 × 10–4 mol of end-carboxylic acid group), NHS (183 mg; 1.59 × 10–3 mol), DCC (341 mg; 1.65 × 10–3 mol) and DMAP (8.3 mg; 6.8 × 10–5 mol) were dissolved in CH2Cl2 (15.9 ml), and the solution was stirred at room temperature under dry nitrogen for 24 h. The white precipitate was filtrated off, and the filtrate was washed with water. Then, the filtrate was concentrated by evaporation of the solvent and poured into diethyl ether to precipitate the NHS ester-functionalized telechelic PNIPAAm. The resultant PNIPAAm (1.58 g, yield: 79%) was filtered off and dried in vacuo.

End-crosslinking of PNIPAAm

Gel synthesis via end-crosslinking of telechelic PNIPAAm was conducted using three PNIPAAm prepolymers with different molecular weights under various concentration conditions. In all gelation reactions here, the concentration of the end-NHS ester group of PNIPAAm and that of amino groups of TAEA were equimolar. A typical example of end-crosslinking is as follows. The telechelic PNIPAAm having NHS ester end groups (Mn=6300 (by 1H NMR), Mw/Mn=1.11 (by SEC); 0.36 g; 1.2 × 10–4 mol of end-NHS ester group) was dissolved in dimethylformamide (DMF, 1.0 ml) and then to this solution TAEA (5.6 mg; 1.2 × 10–4 mol of amino groups) solution in DMF (0.10 ml) was added. The solution was held at room temperature for 24 h. The gelation was confirmed by checking the lack of fluidity (reaction vessel tilting method).

Self-healing experiment

Two pieces of the crosslinked PNIPAAm gel were kept in contact with each other in a vial sealed with nitrogen. The contacted gel sample in the vial was exposed to UV light (365 nm by UVP B-100AP with 100 W mercury lamp) at room temperature for 30 min.

Measurement

Mn and Mw/Mn of the polymers were determined by SEC at 40 °C using DMF containing 10 mM LiBr as eluent and two polystyrene gel columns (PLgel 3 μm MIXED-E and PLgel 20 μm MIXED-C) that were connected to a Shimadzu (Kyoto, Japan) LC-10AD precision pump, a Shimadzu RID-10 A refractive index detector, and a Shimadzu SPD-10A UV–visible detector set at 250 nm. The columns were calibrated against six standard polystyrene samples (Tosoh, Tokyo, Japan; Mw=2000–900,000; Mw/Mn<1.10). 1H NMR spectra were recorded on a JEOL (Tokyo, Japan) JNM-LA400 spectrometer, operating at 399.65 MHz.

Results and Discussion

Synthesis of controlled telechelic PNIPAAm

RAFT polymerization of NIPAAm with a bifunctional RAFT agent (CTA-1) was conducted at 60 °C in 1,4-dioxane. The polymerization results are shown in Table 1. The polymerization proceeded smoothly, and the monomer conversion reached 84% at 10 h (Entry 1a). Figure 1 shows the 1H NMR spectrum of the obtained polymer (1a). The small peak at 4.5 p.p.m. (a′) could be attributed to the methyne proton of the NIPAAm unit adjacent to a TTC group. From the intensity ratio between this peak and the peak attributed to the methyne proton (d) of the isopropyl group in the monomer unit at 4.0 p.p.m., the degree of polymerization (DPn) and the Mn of 1a were estimated (DPn=51, Mn, NMR=6100). This molecular weight was fairly close to the value (Mn, calcd.=5000) calculated from the feed ratio between the monomer and the RAFT agent in taking account of conversion. In addition, the SEC curve of the obtained polymer showed a narrow molecular weight distribution (Mw/Mn=1.11; Figure 2a). Although the Mn, SEC of the obtained PNIPAAm was much higher than the calculated value (Mn, SEC=18,700, Mn, calcd.=5000), this may be due to the difference in the coil volume between PNIPAAm and polystyrene (standard sample for SEC).27 These NMR and SEC results indicated that precision synthesis of PNIPAAm was successfully achieved with CTA-1. Similarly, well-controlled PNIPAAms with different molecular weights were prepared by varying the feed ratio between NIPAAm and CTA-1 (Entry 1b and 1c).

Then, the carboxy-end groups of the obtained PNIPAAm were functionalized by esterification with NHS, one of the typical activated esters. The results are summarized in Table 2. The reaction was performed with a 2.5-fold excess amount of NHS to the carboxy-end groups, and DCC/DMAP was used as the condensation agent at room temperature in CH2Cl2. Figure 3 shows the NMR spectrum of the product, 2a, obtained by the esterification of 1a. The signal attributed to methylene protons of end-NHS moieties (f) was observed at 2.8–2.9 p.p.m. The intensity ratio between the methylene peak and methyne peak adjacent to TTC (a′) was 7.9:2.0, which was close to the calculated ratio at the quantitative reaction of NHS and PNIPAAm (8.0:2.0). Furthermore, Mn, NMR was almost unchanged by end-functionalization (before: Mn, NMR=6100, after: Mn, NMR=6300). The SEC curve of 2a also kept unimodal and sharp with almost the same molecular weight (Figure 2b). These facts suggested that side-reactions no longer occurred throughout the esterification, and NHS was considered to be quantitatively introduced into the carboxyl-ends of PNIPAAm. Such end-functionalization was applied to polymers with different molecular weights (entry 2b and 2c). Thus, the telechelic PNIPAAms with activated ester end groups were successfully synthesized, and the activated ester end groups of the telechelic PNIPAAms are available for crosslinking to produce the three-dimensional network.

PNIPAAm gel synthesis by end-crosslinking

Gel synthesis was attempted by end-crosslinking of the telechelic PNIPAAms having NHS ester end groups. Activated esters such as NHS ester are known as useful functional groups to form covalent amide bonds with primary amines.23, 24, 25 When the multiple primary amines were applied to the telechelic PNIPAAm system, gelation was expected to occur (Scheme 2). In this work, a trifunctional primary amine compound, TAEA, was employed as a crosslinking agent. When TAEA was reacted with the end-functionalized PNIPAAm 2a (DPn=52; Mn, NMR=6300) at room temperature in DMF under the equimolar condition of end-NHS ester groups of 2a to primary amines of TAEA (NHS ester group of 2a)=(amine group of TAEA)=100 mM), the reaction solution gradually increased its viscosity within a few hours, and finally reached the gel state after 24 h (Figure 4).

Effects of polymer concentration and molecular weight on gelation behavior

Effects of the concentration and the molecular weight of PNIPAAm end-functionalized with NHS ester groups on gelation behavior by the end-crosslinking reactions were further studied. We employed telechelic PNIPAAms with a variety of molecular weights for the reaction with TAEA under a series of feed concentration conditions. The employed PNIPAAms are listed in Table 2. All reactions were performed at room temperature in DMF solvent under the condition of an equimolar ratio between the NHS ester groups of the telechelic PNIPAAm and the primary amine groups of TAEA, and the fluidity of the reaction solution was observed. Figure 5 shows the gelation behavior in relation to the molecular weight and feed concentration of the telechelic PNIPAAms. For the highest molecular weight polymer (2a; Mn=6300) among the PNIPAAms, fluidity was lost only at the highest concentration ([PNIPAAm]=50 mM). With the intermediate molecular weight of the PNIPAAm (2b; Mn=3100), the minimum polymer concentration for gelation was found to be 50 mM, which was the same as for the PNIPAAm with the highest molecular weight (2a). With the lowest molecular weight of the PNIPAAm (2c; Mn=2300), the minimum polymer concentration for gelation increased to 100 mM. These gelation behaviors were strongly related to a reaction mechanism affected by the concentration and the molecular weight of the polymers.

At the gelation point, the polymers should be connected by the end-crosslinking reaction, resulting in prevalent system-wide crosslinks. Therefore, it was reasonable that the minimum concentration for gelation increased when the shorter prepolymer was examined. The minimum concentration for gelation was the same when using the polymer with the highest (2a) or intermediate (2b) molecular weight. This suggested that a minimum concentration was required even for the high-molecular weight polymer in this system. We speculated that it was due to steric hindrance around the reactive sites for crosslinking. In the case of the reaction system consisting of telechelic polymers and three-branched crosslinker, high conversion of the reactive sites was required. In particular, all three reactive sites of some crosslinker molecules in the system should be consumed by branching and network formation. After two of the three amino groups of the crosslinker were consumed, the longer polymer chains caused greater steric hindrance than the shorter chains to the intact amino group, thereby prohibiting the branching reaction. In addition, amino groups could decompose TTC groups at each network chain during a crosslinking reaction.28 This aminolysis reaction might interrupt gelation by cleaving the network chains, but this reaction was secondary to the crosslinking reaction, as confirmed by the fact that gelation occurred and the obtained gels kept showing yellow color derived from the presence of TTC groups. Hence, a minimum concentration was supposedly required to reach the gelation point even with high-molecular weight prepolymers such as 2a.

Swelling experiment of end-crosslinked PNIPAAm gels

The obtained gels (prepared in ca. 1 ml DMF) were immersed in a large amount of water (50 ml) to check the network formation. Consequently, the gel prepared from PNIPAAm with the highest molecular weight (2a) swelled while keeping its original shape (Figure 6), and the gels synthesized from PNIPAAm with lower molecular weight (2b and 2c) were found to dissolve in water. These results could be explained by the crosslinking efficiency related to the network formation process, which proceeds through a step-growth reaction mechanism. This mechanism produced a small network, that is, a microgel, in the early stage of the reaction, and then the small networks were crosslinked one after another to give a higher molecular weight network, that is, a macrogel. Here, the linking reaction between small networks was supposed to be strongly affected by the freedom of the polymer chains at the surface of the small networks, which reacted with the amino groups of other networks. The prepolymer with high-molecular weight (2a) had higher mobility in the interfacial polymer chain, allowing the crosslinking reaction to proceed more efficiently, in contrast to the prepolymer with lower molecular weight. Therefore, the networks could expand to cover the whole system, and the obtained gel could swell in water without dissolving. In contrast, the linking between microgels was insufficient with the shorter chain (2b and 2c), probably because of relatively large steric hindrance of the polymer chain at the surface of the microgel. Thus, this end-crosslinking system involved inefficiency in the crosslinking reaction, which gave inhomogeneities in the network such as loop formation and network defects. However, end-crosslinking of controlled telechelic prepolymers afforded unimodal network chains between each incorporated crosslinker with determined molecular weight, and this approach would contribute to the design of the homogeneous vinyl polymer network.

Self-healing property

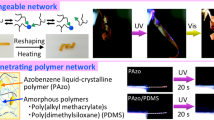

TTC units derived from RAFT agents could re-initiate the radical reactions by external stimuli such as UV light, even in gels.16, 17 Radical reaction mediated by TTC could be induced by UV light since TTC compounds are known as photoinitiators of RAFT polymerization.29, 30 Then, we demonstrated UV-induced self-healing of the obtained gel carrying TTC in the middle of the network chains between crosslinking points.

We employed the gels prepared from 2a and 2b (the preparation condition: [PNIPAAm]=50 mM for 2a and 100 mM for 2b in DMF at room temperature). Two pieces of the gels prepared by end-crosslinking of the telechelic PNIPAAm were set in contact with each other. The gels did not change at all without any stimuli, and the two pieces were apart when the gels were pulled. On the other hand, UV irradiation (λ=365 nm) to the gels over 30 min induced the fusion of two pieces into one (Figure 7a). When this fused gel was cut into two pieces and subjected to UV irradiation, the fusion was observed again. This UV-stimulated self-healing could be repeated at least three times.

This self-healing phenomenon is probably due to the radical-induced chain exchange reaction at the interface of the two pieces (Figure 7b). By UV irradiation, a polymer radical was produced from the TTC moiety at one piece of the gel, and this polymer radical attacked the TTC present at another piece of the gel to induce a chain exchange. After this chain exchange reaction was repeated, the contact surfaces of the two pieces were glued by covalent bonds. The employed gels might have unreacted activated ester groups and amine groups in the network, especially in the gel prepared from 2b, because of insufficient crosslinking. These unreacted groups could participate in fusing, but gel pieces did not show self-healing without UV irradiation. It is also suggested that TTC groups in the network contributed to the self-healing property. Thus, it was found that the gels prepared by end-crosslinking of telechelic PNIPAAms carrying TTC exhibited the UV-induced self-healing.

Conclusions

We successfully synthesized PNIPAAm gels with self-healing by end-crosslinking of controlled telechelic prepolymers with a TTC group. The telechelic prepolymers functionalized with activated esters were prepared by RAFT polymerization of NIPAAm with a symmetric TTC compound (CTA-1), followed by esterification of carboxy-ends. Gelation behavior by end-crosslinking was strongly affected by the molecular weight and concentration of the telechelic polymer. The obtained gel exhibited UV-induced self-healing due to the presence of TTC in the middle of the network chains. The crosslinking efficiency still requires improvement, but our design produces a homogeneous network with self-healing. We believe that a homogeneous network with self-healing will contribute to the development of highly functional gel materials with high strength as well as good durability.

Design of network structure by end-crosslinking of controlled telechelic polymers synthesized by symmetric TTC-mediated RAFT polymerization.

Synthetic scheme of end-crosslinked PNIPAAm network.

References

Tanaka, T., Fillmore, D., Sun, S.-T., Nishio, I., Swislow, G. & Shah, A. Phase transitions in ionic gels. Phys. Rev. Lett. 45, 1636–1639 (1980).

Osada, Y. & Gong, J. Stimuli-responsive polymer gels and their application to chemomechanical systems. Prog. Polym. Sci. 18, 187–226 (1993).

Kikuchi, A. & Okano, T. Pulsatile drug release control using hydrogels. Adv. Drug Deliv. Rev. 54, 53–77 (2002).

Chaterji, S., Kwon, I. K. & Park, K. Smart polymeric gels: redefining the limits of biomedical devices. Prog. Polym. Sci. 32, 1083–1122 (2007).

Shibayama, M. Spatial inhomogeneity and dynamic fluctuations of polymer gels. Macromol. Chem. Phys. 199, 1–30 (1998).

Gérard, H. Model networks based on 'endlinking' processes: synthesis, structure and properties. Prog. Polym. Sci. 23, 1019–1149 (1998).

Sakai, T., Matsunaga, T., Yamamoto, Y., Ito, C., Yoshida, R., Suzuki, S., Sasaki, N., Shibayama, M. & Chung, U.-I. Design and fabrication of a high-strength hydrogel with ideally homogeneous network structure from tetrahedron-like macromonomers. Macromolecules 41, 5379–5384 (2008).

Johnson, J. A., Lewis, D. R., Díaz, D. D., Finn, M. G., Koberstein, J. T. & Turro, N. J. Synthesis of degradable model networks via ATRP and click chemistry. J. Am. Chem. Soc. 128, 6564–6565 (2006).

Zhou, H. & Johnson, J. A. Photo-controlled growth of telechelic polymers and end-linked polymer gels. Angew. Chem. Int. Ed. Engl. 52, 2235–2238 (2013).

Ooi, H. W., Jack, K. S., Peng, H. & Whittaker, A. K. 'Click' PNIPAAm hydrogels-a comprehensive study of structure and properties. Polym. Chem. 4, 4788–4800 (2013).

Ooi, H. W., Jack, K. S., Whittaker, A. K. & Peng, H. Photo-initiated thiol–ene 'click' hydrogels from RAFT-synthesized poly(N-isopropylacrylamide). J. Polym. Sci. A Polym. Chem. 51, 4626–4636 (2013).

Oshima, K., Fujimoto, T., Minami, E. & Mitsukami, Y. Model polyelectrolyte gels synthesized by end-linking of tetra-arm polymers with click chemistry: synthesis and mechanical properties. Macromolecules 47, 7573–7580 (2014).

Murphy, E. B. & Wudl, F. The world of smart healable materials. Prog. Polym. Sci. 35, 223–251 (2010).

Billiet, S., Hillewaere, X. K. D., Teixeira, R. F. A. & Du Prez, F. E. Chemistry of crosslinking processes for self-healing polymers. Macromol. Rapid Commun. 34, 290–309 (2013).

Harada, A., Takashima, Y. & Nakahata, M. Supramolecular polymeric materials via cyclodextrin–guest interactions. Acc. Chem. Res. 47, 2128–2140 (2014).

Nicolaÿ, R., Kamada, J., Van Wassen, A. & Matyjaszewski, K. Responsive gels based on a dynamic covalent trithiocarbonate cross-linker. Macromolecules 43, 4355–4361 (2010).

Amamoto, Y., Kamada, J., Otsuka, H., Takahara, A. & Matyjaszewski, K. Repeatable photoinduced self-healing of covalently cross-linked polymers through reshuffling of trithiocarbonate units. Angew. Chem. Int. Ed. 50, 1660–1663 (2011).

Moad, G., Rizzardo, E. & Thang, S. H. Living radical polymerization by the RAFT process. Aust. J. Chem. 58, 379–410 (2005).

Moad, G., Rizzardo, E. & Thang, S. H. Radical addition–fragmentation chemistry in polymer synthesis. Polymer 49, 1079–1131 (2008).

Moad, G., Rizzardo, E. & Thang, S. H. Living radical polymerization by the RAFT process – a second update. Aust. J. Chem. 62, 1402–1472 (2009).

Hirokawa, Y. & Tanaka, T. Volume phase transition in a nonionic gel. J. Chem. Phys. 81, 6379–6380 (1984).

Schild, H. G. Poly (N-isopropylacrylamide): experiment, theory and application. Prog. Polym. Sci. 17, 163–249 (1992).

Batz, H.-G., Franzmann, G. & Ringsdorf, H. Model reactions for synthesis of pharmacologically active polymers by way of monomeric and polymeric reactive esters. Angew. Chem. Int. Ed. Engl. 11, 1103–1104 (1972).

Ferruti, P., Bettelli, A. & Feré, A. High polymers of acrylic and methacrylic esters of N-hydroxysuccinimide as polyacrylamide and polymethacrylamide precursors. Polymer 13, 462–464 (1972).

Theato, P. Synthesis of well-defined polymeric activated esters. J. Polym. Sci. A Polym. Sci. 46, 6677–6687 (2008).

Venkataraman, S. & Wooley, K. L. Synthesis and characterization of block copolymers containing poly(di(ethylene glycol) 2-ethylhexyl ether acrylate) by reversible addition–fragmentation chain transfer polymerization. J. Polym. Sci. A: Polym. Chem. 45, 5420–5430 (2007).

Narumi, A., Fuchise, K., Kakuchi, R., Toda, A., Satoh, T., Kawaguchi, S., Sugiyama, K., Hirao, A. & Kakuchi, T. A versatile method for adjusting thermoresponsivity: synthesis and ‘click’ reaction of an azido end-functionalized poly(N-isopropylacrylamide). Macromol. Rapid Commun. 29, 1126–1133 (2008).

Willcock, H. & O'Reilly, R. K. End group removal and modification of RAFT polymers. Polym. Chem. 1, 149–157 (2010).

You, Y.-Z., Hong, C.-Y., Bai, R.-K., Pan, C.-Y. & Wang, J. Photo-initiated living free radical polymerization in the presence of dibenzyl trithiocarbonate. Macromol. Chem. Phys. 203, 477–483 (2002).

Ran, R., Yu, Y. & Wan, T. Photoinitiated RAFT polymerization in the presence of trithiocarbonate. J. Appl. Polym. Sci. 105, 398–404 (2007).

Acknowledgements

This research was partially supported by the Japan Society for the Promotion of Science through a Grant-in-aid for Scientific Research (C) (No. 24552059) and for Young Scientists (B) (No. 16K17962), for which the authors are grateful.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Ida, S., Kimura, R., Tanimoto, S. et al. End-crosslinking of controlled telechelic poly(N-isopropylacrylamide) toward a homogeneous gel network with photo-induced self-healing. Polym J 49, 237–243 (2017). https://doi.org/10.1038/pj.2016.112

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2016.112

This article is cited by

-

Preparation of PDMS STEM gels through oxygen tolerance nitroxide mediated polymerization

Journal of Polymer Research (2023)

-

Preparation of hydrophobic macroinimer–based novel hybrid sorbents for efficient removal of organic liquids from wastewater

Environmental Science and Pollution Research (2021)

-

Structural design of vinyl polymer hydrogels utilizing precision radical polymerization

Polymer Journal (2019)

-

Spontaneous synthesis of a homogeneous thermoresponsive polymer network composed of polymers with a narrow molecular weight distribution

NPG Asia Materials (2018)

-

PJ ZEON Award for outstanding papers in Polymer Journal 2017

Polymer Journal (2018)