Abstract

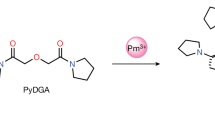

The thermal polymerization of 1:1 mixtures of zinc diacrylate (ZDA) and zinc dialkanoate (ZDCx) was investigated. The mixtures started to melt at lower temperatures than the melting points of the original components, and the polymerizations of the acrylate portions progressed in the molten state at lower temperatures than the thermal polymerization temperature of ZDA alone. The accelerated polymerization rate was found to be triggered by ion exchange in which one of the carboxylate anions of ZDA was exchanged with the alkanoate of ZDCx, just above the melting point.

Similar content being viewed by others

Introduction

The additives in polymer materials have an important role in varying their physical properties. The use of a single-component additive in a polymer material is quite rare; multiple components are usually added to polymers. Thus, it is worthwhile to investigate interactions among additives to understand how those interactions affect polymer composite materials. Zinc diacrylate (ZDA) is one additive used in polymers to improve their thermal and mechanical properties.1, 2 In our previous study, the thermal solid-state polymerization of ZDA was investigated using additives such as diphenyl disulfide (DPDS) derivatives, thiophenol (TP) derivatives and dicumyl peroxide (DCP).3 The spontaneous thermal polymerization of ZDA starts at temperatures above 170 °C; the addition of DPDS and TP derivatives accelerated the polymerization of ZDA. The addition of DCP lowered the polymerization temperature to 110 °C. Mixing small amounts of these additives to the solid monomer was a facile and efficient method for activating solid-state polymerization. The mechanism of action for these effects involves the thermal cleavage of the additives to generate radicals; these radicals then attacked the ZDA crystal surfaces to initiate solid-state polymerization. A similar mechanism of action for solid-state polymerization was also observed for butadiyne crystals in aqueous media.4, 5, 6

In the current study, the polymerization of ZDA was investigated in the presence of zinc dialkanoate (ZDCx). ZDCx derivatives have been also used as polymer additives to modify the properties.7, 8, 9, 10, 11, 12, 13 Zinc dioctanoate (ZDC8) and zinc dioctadecanoate (ZDC18) were mixed with ZDA; the resulting thermal polymerization behaviors of these mixtures were examined.

Experimental procedure

The ZDA and ZDCx solids were mixed in a 1:1 molar ratio, ground well and sealed in Pyrex tubes under reduced pressure. The mixtures were heated in a temperature-controlled oil bath. After the reaction, the mixtures were cooled to ambient temperature, and the products were removed from the tubes and weighed (w0). The products were washed with methanol to dissolve unreacted ZDA. The insoluble portions were washed with an appropriate solvent for solubilizing ZDCx, that is, chloroform for ZDC8 and toluene for ZDC18. The residues including polymer portions were dried and weighed (w). We defined conversion as w/w0 in this study. The averaged conversions were obtained by analyzing three samples treated under the same experimental conditions.

The thermal properties were evaluated by differential scanning calorimetry (DSC) using a Seiko Instruments (Chiba, Japan) DSC 6220 calorimeter with a heating rate of 10 °C min−1 under a nitrogen atmosphere. The Fourier transform infrared (FTIR) spectra were obtained using KBr-pelletized samples in a Horiba (Kyoto, Japan) FT-720 spectrometer. Powder X-ray diffraction patterns were obtained using a Rigaku (Akishima, Japan) RAD-rA diffractometer with a Cu Kα radiation source.

Results and discussion

When the ZDA–ZDCx mixtures were heated at 140 °C, they became transparent liquids. Next, the mixtures were cooled to ambient temperature and became transparent solids. Figure 1 shows the conversion of ZDA–ZDCx (1:1) mixtures in relation to the heating time. For the ZDA–ZDC8 (1:1) mixture heated at 140 °C, the conversion gradually increased and reached slightly less than 80% conversion after 16 h. The reaction rate was much faster in the ZDA–ZDC18 (1:1) mixture, and the conversion for the reaction at 140 °C was ~80% within 4 h. At 170 °C, both mixtures reached ~90% conversion within 4 h. If only ZDA took part in the polymerization, the maximum conversions were 37% for the ZDA–ZDC8 (1:1) mixture and 25% for the ZDA–ZDC18 (1:1) mixture, as shown by the dashed lines in Figure 1. This observation is due to the extraction treatment of unreacted ZDC8 and ZDC18. However, it should be noted that the conversions were much higher than the expected maximum values in both cases, indicating that portions originating from ZDCx are incorporated with the ZDA-based polymer.

Conversion of (a) ZDA–ZDC8 (1:1) and (b) ZDA–ZDC18 (1:1) mixtures, according to heating time. The black up-pointing and gray down-pointing triangles correspond to the reactions at 140 °C and 170 °C, respectively. The error bars show s.d.’s for the three samples. The dashed lines indicate the maximum conversion when only the polymerization of ZDA takes place and ZDCx remains as is.

Figure 2 shows the FTIR spectra of ZDA, ZDCx and ZDA–ZDCx (1:1) mixtures as well as the spectra obtained after heating and subsequent extraction. ZDCx shows characteristic peaks assignable to the C–H stretching vibration of the alkyl group at 2850 and 2929 cm−1. In contrast, no prominent peaks around 2900 cm−1 were observed for ZDA. As shown in spectra (4) and (7) in Figure 2, peaks corresponding to alkyl groups were clearly detected for the materials obtained after heating ZDA–ZDCx (1:1) mixtures followed by solvent extraction. These observations indicate that alkanoate portions without any C=C bonds are included in the polymer, which also explains the higher than expected conversion.

Figure 3 shows DSC thermograms of ZDA, ZDCx and their 1:1 mixtures. ZDA showed a broad exothermic peak, whose onset occurred at ~170 °C. The spontaneous solid-state polymerization began near this temperature.3 Endothermic peaks of ZDC8 were observed at 121, 136 and 140 °C. The peak at 121 °C has been assigned as a solid–solid phase transition.14 The melting point of ZDC8 was reported between 135 and 141 °C.14, 15, 16, 17, 18 Thus, at a temperature greater than 140 °C, ZDC8 becomes an isotropic liquid. The origin of the peak at 136 °C was not clear, but there may be another phase transition just below the transition to an isotropic liquid. On the other hand, ZDC18 showed a unique endothermic peak at 125 °C in the measured temperature range; this peak corresponds to the melting point, which has been reported to be between 124 and 136 °C.14, 15, 16, 17 For both ZDA–ZDCx (1:1) mixtures, endothermic phenomena started at ~100 °C, which is slightly lower than the phase transition temperature of ZDC8 and the melting point of ZDC18. Because we observed the melting of the mixtures at the temperature, the endothermic peaks can be assigned as the melting points of the mixtures. When the temperature was elevated, the endothermic states turned to exothermic states in both cases. Notably, no exothermic peaks were observed for both mixtures above 170 °C, indicating that polymerization of the ZDA portion started just above the melting points and was completed before elevating the temperature to 170 °C.

The powder X-ray diffraction patterns of the mixtures before and after heating, as well as the related original components, are shown in Figure 4. The diffraction patterns of ZDA, ZDC8 and ZDC18 have already been reported,3, 19, 20 and they coincided with those obtained in this study. The diffraction patterns of the mixtures were understood as the summation of the ZDA and corresponding ZDCx patterns. However, after heating, the mixtures did not show prominent crystalline peaks (patterns (4) and (7) in Figure 4). ZDA is known to become amorphous after thermal polymerization.3 ZDCx should crystallize after melt cooling. Importantly, ZDA and ZDCx were not separated after heating the mixture.

Our observations of the thermal polymerization of a ZDA–ZDCx (1:1) mixture are summarized as follows: when the temperature increases, the melting of the mixture starts below the melting points of the mixture’s individual components, and the mixture becomes a homogeneous liquid. Simple hydrocarbon liquids, such as tetradecane and decahydronaphthalene, do not dissolve ZDA even at 140 °C. A plausible explanation for this observation is that ion exchange occurs between ZDA and ZDCx after melting to form zinc acrylate alkanoate (ZACx). This ion exchange occurs in nearly quantitative yield, which is likely due to an entropic reason. At 140 °C, the coexisting state of crystalline ZDA and liquid ZDCx is less entropically favorable than the liquid state of ZACx. The polymerization of ZACx progresses at a temperature above the melting point. The polymerization is almost complete within 16 and 4 h for the ZDA mixtures of ZDC8 and ZDC18, respectively, at 140 °C. Finally, the polymers comprise polyacrylates with alkanoate pendants linked by Zn2+. However, the coordination state may not be a simple 1:1 interaction between an acrylate and an alkanoate because the Zn2+ cation is often tetrahedrally coordinated by four carboxylate anions.21, 22

The polymerized product obtained from the mixture of ZDA and ZDC8 was esterified with methanol to confirm the identity of the components. The polymerized product was added to a methanol–chloroform mixture, and sulfuric acid was added to protonate the carboxylate groups and catalyze the esterification. After refluxing the mixture for 1 day, it was lightly evaporated, and the residual portion was extracted with chloroform and water. There were insoluble solids in both phases and the FTIR spectra of the solids are similar to that of thermally polymerized ZDA. Methyl octanoate was isolated from the chloroform phase, and its structure was confirmed by NMR. These results also supported the polymerization mechanism proposed above.

Conclusion

We found that the polymerization of ZDA–ZDCx (1:1) mixtures progressed with a different mechanism from that of ZDA alone. Namely, one of the carboxylate anions of ZDA was exchanged with the alkanoate of ZDCx just above the melting point, and the polymerization of the acrylate was promoted by forming ZACx. This type of ion-exchange-assisted polymerization is an interesting mechanism for efficient polymerization in polymer composite materials.

References

Costin, R., Ekwall, R. & Nagel, W. Metallic coagents for curing elastomers with scorch safety. Kaut. Gummi. Kunstst. 45, 648–650 (1992).

Ahn, N. Effects of diacrylate monomers on the bond strength of polymer concrete to wet substrates. J. Appl. Polym. Sci. 90, 991–1000 (2003).

Tsuchida, J., Saito, Y., Sato, S., Yuki, U., Inayama, S., Tatewaki, Y., Okada, S., Shindo, A., Mikura, C., Fushihara, K. & Yamada, M. Thermal solid-state polymerization of a divalent metal salt of an unsaturated carboxylic acid and the effects of additives. Polym. J. 45, 1007–1012 (2013).

Arai, M. & Okada, S. Polymerization of a butadiyne derivative in crystalline state stimulated by radical initiators. Chem. Lett. 35, 1012–1013 (2006).

Kato, S., Kinemuchi, T., Tatewaki, Y., Okada, S., Masuhara, A., Kasai, H. & Oikawa, H. Radical-initiator-induced solid-state polymerization of butadiyne nanocrystals in water and their dispersion stabilization. J. Nanosci. Nanotechnol. 11, 3340–3344 (2011).

Kinemuchi, T., Moritani, Y., Tatewaki, Y. & Okada, S. Fixation of surface-modified polydiacetylene nano/microcrystals on substrates. Jpn J. Appl. Phys. 50, 095202 (2011).

Mandel, U. K., Tripathy, D. K. & De, S. K. Effect of zinc stearate on the rheology of ionic elastomer based on carboxylated nitrile rubber. Polym. Eng. Sci. 36, 283–287 (1966).

Mori, K., Kikuchi, I. & Nakamura, Y. Effects of 6-anilino-1,3,5-triazine-2,4-dithiol, zinc stearate, and barium stearate on the thermal stabilization of PVC. J. Appl. Polym. Sci. 27, 1067–1079 (1982).

Lévai, G., Ocskay, G., Nyitrai, Z. & Meszlényi, G. Kinetics of the stabilizing effect of calcium and zinc stearates in the thermal degradation of PVC: Part I. Polym. Degrad. Stab. 25, 61–72 (1989).

Luyt, A. S. A differential scanning calorimetric study of the interaction of zinc benzothiazole-2-thiolate, sulfur, stearic acid, and zinc stearate in the absence and presence of polyisoprene. J. Appl. Polym. Sci. 47, 2177–2185 (1993).

Parrondo, A., Allen, N. S., Edge, M., Liauw, C. M., Fontán, E. & Corrales, T. Additive interactions in the stabilization of film grade high-density polyethylene. Part I: stabilization and influence of zinc stearate during melt processing. J. Vinyl Add. Tech. 8, 75–89 (2002).

Helaly, F. M., El Sabbagh, S. H., El Kinawy, O. S. & El Sawy, S. M. Effect of synthesized zinc stearate on the properties of natural rubber vulcanizates in the absence and presence of some fillers. Mater. Des. 32, 2835–2843 (2011).

Chen, G., Gu, L. & Yao, Y. A novel zinc-containing additive for the long-term thermal stabilization of poly(vinyl chloride). Polym. Degrad. Stab. 107, 113–119 (2014).

Taylor, R. A. & Ellis, H. A. Polymorphism, crystal-crystal and liquid crystalline thermotropic phase transition behavior of even chain length zinc(II) n-alkanoates. Liq. Cryst. 36, 257–268 (2009).

Ekwunife, M. E., Nwachukwu, M. U., Rinehart, F. P. & Sime, S. J. Properties of molten carboxylates part 1. –Electrical conductance and molar volumes of some molten lead and zinc carboxylate. J. Chem. Soc., Faraday Trans. 1 71, 1432–1446 (1975).

Konkoly-Thege, I., Ruff, I., Adeosun, S. O. & Sime, S. J. Properties of molten carboxylates part 6. A quantitative differential thermal analysis study of phase transitions in some zinc and cadmium carboxylates. Thermochim. Acta 24, 89–96 (1978).

Taylor, R. A. & Ellis, H. A. Room temperature molecular and lattice structures of a homologous series of anhydrous zinc(II) n-alkanoate. Spectrochim. Acta A 68, 99–107 (2007).

Tokmenko, I. I. T., Mirnaya, A. & Yaremchuk, G. G. Phase diagrams and optical properties of binary liquid-crystal systems of cobalt(II) caprylate with a divalent metal caprylate. Russ. J. Inorg. Chem. 57, 1141–1224 (2012).

Šegedin, P., Lah, N., Žefran, M., Leban, I. & Golič, L. Synthesis and characterization of bis(carboxylato)zinc(II) (C6-C8) –crystal structure of bis(hexanoato)zinc(II), Zn(O2CC5H11)2 –Form A. Acta Chim. Slov. 46, 173–184 (1999).

Corbeil, M. C. & Robinet, L. X-ray powder diffraction data for selected metal soaps. Powder Diffr. 17, 52–60 (2002).

Lacouture, F., Peultier, J., François, M. & Steinmetz, J. Anhydrous polymeric zinc(II) octanoate. Acta Crystallogr. C56, 556–557 (2000).

Taylor, R. A. & Ellis, H. A. Anhydrous polymeric zinc(II) pentanoate. Acta Crystallogr. E64, m895 (2008).

Acknowledgements

We thank Mr Kei Mizuguchi for his experimental support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Nakashima, S., Tatewaki, Y., Okada, S. et al. Polymerization of a divalent metal salt of an unsaturated carboxylic acid stimulated by ion exchange with a metal salt of fatty acids. Polym J 48, 855–858 (2016). https://doi.org/10.1038/pj.2016.41

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2016.41