Abstract

Increasing sensitivity and decreasing assay time are two of the most crucial goals in the development of biosensing devices, such as immunoassays, protein electrophoresis, and bioimaging nanoprobes. We have developed three-dimensional (3D) nano/microstructured platforms for biosensing devices aimed at highly sensitive and rapid immunoassays. One such platform is a nanosphere structure with poly[2-methacryloyloxyethyl phosphorylcholine-co-n-butyl methacrylate-co-p-nitrophenyloxycarbonyl poly(ethylene glycol) methacrylate] (PMBN) prepared by the electrospray deposition (ESD) method. Compared with flat PMBN, the 3D nanosphere surface enables the immobilization of a large amount of antibody to enhance the specific signal of the immunoassay. Furthermore, PMBN is resistant to non-specific protein adsorption. Thus, this 3D nanosphere structure can be applied in microchip environments, leading to highly sensitive and rapid immunoassays. To obtain a more rapid assay that takes at most 5 min, we utilized another platform: a 3D polystyrene (PS) microfiber structure prepared by ESD paired with vacuum pump pressurization to induce bulk flow. This system takes advantage of the increased amount of antibody immobilized on the 3D microfiber and the accelerated propagation of antigens through the microfiber induced by the vacuum pump to enable an efficient and rapid immunoassay.

Similar content being viewed by others

Introduction

High-performance biosensing and device size reduction are strongly needed due to the endless challenges in the IOT (internet of things) society. The high sensitivity and rapidity of a biosensor-based assay biosensor are two of the main factors in its performance. Many researchers have focused on and improved the original design of biosensing devices. In general, the definition of sensitivity in biosensing is the signal-to-noise ratio. A specific signal results from the extent of specific binding of target molecules, and noise originates from the non-specific binding of non-target molecules. The preparation strategy for a highly sensitive biosensor is summarized in Fig. 1.

A nanometer scale structure having a large surface area is beneficial for the enhancement of a specific signal owing to the increase in the amount of an immobilized antibody [1]. Nano/microscale structures are fabricated by using a variety of nanofabrication techniques, such as photolithography [2, 3], imprinting [4], and nanomaterials including particles and nanotubes [5, 6]. Orientation control of the immobilized antibody is a superior way of enhancing the activity of the immobilized antibody using Protein A or G [7, 8]. Biotinylation can also be used for controlling the orientation of the immobilized antibody [9]. These technologies can further increase specific binding to increase the sensitivity [10].

To decrease the noise, non-specific signals (non-specific adsorption of analytes, labeled antibodies, and other proteins on the working surface) should be suppressed. Bovine serum albumin (BSA) and casein are commonly used as protein-based blocking reagents to decrease non-specific adsorption. Nevertheless, protein-based blocking reagents denature easily, and the variation between each production lot is large. As a result, several types of protein-free blocking reagents have been tested [11, 12]. Blocking reagents composed of water-soluble amphiphilic 2-methacryloyloxyethyl phosphorylcholine (MPC) polymers show effective resistance against non-specific protein adsorption for immunoassays [13]. As a more intricate material, poly[MPC-co-n-butyl methacrylate (BMA)-co-p-nitrophenyloxycarbonyl poly(ethylene glycol) methacrylate (MEONP)] (PMBN), which has units capable of reducing protein adsorption and protein binding, has been reported as an effective material for immunoassay applications [14, 15]. Plausible mechanisms underlying the reduction in protein adsorption have been discussed in terms of the structure of water on the polymeric materials, including the MPC polymer [16,17,18]. Furthermore, PMBN effectively suppresses the denaturation of the bound protein.

The combination of these approaches is effective in achieving highly sensitive biosensing; therefore, we have demonstrated the capability of using a nanosphere structure with PMBN that is prepared by the electrospray deposition (ESD) method [19]. The characteristics of MEONP units make them suitable for immobilizing biomolecules under mild conditions, and the biomolecules on the surface show high activity [14, 15, 19, 20]. Thus, the PMBN surface suppresses non-specific binding and maintains the residual activity of the immobilized antibody after long-term storage [14, 15].

Although the rapidity of the assay is another major prerequisite for a high-performance biosensing device, the conventional immunoassay based on antibody–antigen binding takes over 1 h to obtain results when a 96-well microtiter plate is used. Thus, many technologies using a microfluidic chip and a microarray have been developed to decrease the testing time to obtain results. Because the reaction area of a microchannel and microwell is controlled by the dimensional scale and because the antibody–antigen reaction is limited by diffusion, downscaling is highly effective in increasing the reaction rate between the antibody and antigen reagents [21, 22]. Consequently, the key technology of interest is the control of bulk flow by means of a three-dimensional (3D) polymeric microfiber with high porosity, an approach that is considered a new concept in dynamic flow control.

Here, our research [15, 19, 23,24,25,26] regarding highly sensitive and rapid biosensing on 3D polymer platforms prepared by ESD methods is reviewed.

3D nanosphere structure for enhanced sensitivity of ELISA

In this research [19, 23, 24], we synthesized PMBN (Fig. 2a) by free-radical polymerization, and a nanosphere structure was fabricated by the ESD method using PMBN (Fig. 2b). The nanosphere PMBN structure was applied to a substrate for enhanced sensitivity of enzyme-linked immunosorbent assay (ELISA). To establish a rapid immunoassay, we prepared a microchip with the 3D nanosphere structure.

Preparation of 3D nanosphere structure for ELISA

PMBN [19] comprises a single polymer chain containing units that prevent non-specific adsorption and those that can be conjugated with antibodies. The composition ratio of PMBN was MPC:BMA:MEONP = 22:65:13, as determined by 1H nuclear magnetic resonance (NMR) spectroscopy, and was optimized for use as a 3D-platform material for immunoassay applications. To prepare the nanosphere surface for increased immobilized antibody density, we used the ESD method. To determine the immobilization density of the antibody on the 3D nanosphere surface, we estimated it by means of the fluorescence intensity of a fluorescein isothiocyanate (FITC)-IgG conjugate. The 3D nanosphere surface could capture an antibody at a high density of ~860 ng/cm2. The highest packing density of immobilized antibody molecules on a flat surface was calculated as ~650 ng/cm2; thus, a noticeable increase in the amount of the antibody immobilized on the nanosphere surface was achieved.

To investigate the capability of our fabricated nanostructure to increase immunoassay sensitivity, ELISA was carried out on nanospherical PMBN surfaces by the following protocol. Separate microwells sized at 300 µL were attached to a Au-sputtered glass slide whose surface was already coated with PMBN by ESD. For comparison with this ESD-sprayed surface (PMBN ESD coating), a polystyrene plate was dipped in a 0.2 wt% ethanol solution of PMBN. Additionally, for comparison with the conventional method, BSA was employed as a blocking reagent by pipetting 1 wt% BSA on the bare polystyrene plate after antibody immobilization. Anti-[human thyroid stimulating hormone (TSH)] mouse antibody (IgG) was used as the primary antibody and allowed to react with the activated ester group of PMBN for 10 h at 25 °C. To conduct the antigen–antibody reaction, human TSH in PBS was pipetted into the wells. After incubation for 2 h at 25 °C and washing, horseradish peroxidase (HRP)-labeled human TSH IgG in PBS containing 1 wt% BSA was added into the wells. After incubation for 1 h at 25 °C, the wells were washed with PBS. Then, 100 µL of a tetramethylbenzidine solution was pipetted into the wells as a substrate for HRP and incubated for 20 min at 25 °C. Finally, 100 µL of H2SO4 was added into the wells, and the absorbance at 450 and 620 nm was measured using a multilabel counter.

The results of the ELISA with the PMBN ESD- and dip-coated surfaces are shown in Fig. 2c. The surface that was not cross-linked or heated yielded a modest specific signal relative to the background noise. In contrast, the PMBN surface that was both cross-linked and heated showed a large specific signal.

To determine the cause of the difference in the PMBN ESD-sprayed surfaces, the surface morphology of each surface after immersion in water for 10 h was observed by scanning electron microscopy (SEM).

For the nanostructure of the PMBN ESD surface without heating and diamine cross-linking, the nanosphere-shaped structure became flat during the 12 h antibody–antigen assay. The nanostructure that was both heated and cross-linked did not change its shape at all after immersion in water. Since this nanostructure had high water stability, retaining its high porosity after immersion in water, the antigens could access the immobilized antibody without any obstacles arising from polymer swelling. Therefore, the immobilized antibody could react with the antigen and showed a strong specific signal. When we used the PMBN EDS coating that was both cross-linked and heated, the sensitivity was enhanced compared to that of the coating with the PMBN dip-coated and BSA-blocked surface. According to these results, the PMBN nanostructure with high porosity and high water stability yielded a highly sensitive immunoassay.

A microchip immunoassay with a 3D nanosphere structure

Miniaturized biosensors for microdiagnostic devices have become promising [23, 24] interdisciplinary tools for next-generation clinical diagnostics [27,28,29]. A microchip-based immunoassay system has been designed to enable bedside monitoring of chemicals and biomolecules in biological samples. Compared with conventional ELISA carried out in a polystyrene microtiter plate, microchip-based ELISA has greater reaction efficiency. It also has other advantages, such as short assay duration, low sample consumption, and assay automation [30]. Nevertheless, the significant decrease in sample volume results in weak specific signals. Furthermore, in the microscale environment, the high surface area/volume ratio magnifies the influence of non-specific binding of an analyte or a labeled antibody on the solid surface. These factors result in the weakness of specific signals and the high noise level. To develop a highly sensitive microchip-based ELISA system, both enhancement of specific signals and a reduction in non-specific signals should be achieved. Therefore, we have applied the 3D nanospherical PMBN structure to microchip-based ELISA [23, 24].

A schematic illustration of the processes of microchip fabrication (panel a) and a microchip ELISA system and a photograph of a completed microchip (panel b) are shown in Fig. 3. To prepare a conductive substrate for ESD, Au was sputter-coated on a slide glass. Nanospherical PMBN and flat PMBN surfaces on the Au glass slide were prepared by ESD and dip-coating, respectively. The patterned master was fabricated on a glass slide from SU-8 resist by photolithography. The PDMS with microchannels was applied to the PMBN ESD-coated glass slide after oxygen plasma treatment.

ELISA was carried out on the microchip with PMBN-coated surfaces as described in the following protocol. Anti-TSH mouse IgG (20 µg/mL) in phosphate buffer solution (pH 8) containing 0–1 wt% of Tween 20 was pipetted into the microchannel and allowed to react with the activated ester of PMBN for 5 min. To reduce the non-specific binding of proteins to the upper PDMS side of the microchannel, poly(MPC-co-BMA) (PMB30W) [31] was used as a blocking reagent. To perform the antigen–antibody reaction, 0–10 μIU/mL human TSH in PBS solution was pipetted into the microchannel. After incubation for 5 min, the microchannel was washed with 100 μL of PBS solution containing 0.1 wt% Tween 20, and then 1 μg/mL HRP-labeled hTSH IgG in PBS solution containing 1 wt% BSA was pipetted into the microchannel and incubated for 5 min. The microchannel was washed with 100 μL of PBS solution containing 0.1 wt% Tween 20 and placed in a spectrometer. Then, 20 μL of a chemiluminescent substrate for HRP was injected from a sample injector at 5 μL/min, and the chemiluminescence intensity was detected.

The results of microchip ELISA are presented in Fig. 4a. The surface dip-coated with PMBN showed a weak specific signal, whereas the surface ESD-coated with PMBN yielded a rather weak signal. When 1% Tween 20 was added to the primary antibody solution, the specific signal of the PMBN ESD-coated surface was enhanced. The sensitivity enhancement by Tween 20 was due to an increase the amount of antibody immobilized on the surface of the PMBN ESD coating. When 1% Tween 20 was added to the antibody solution, the amount of antibody immobilized on the ESD-sprayed surface was large: 3.4 μg/cm2, which was 4 times higher than that for samples without Tween 20. This was because the surface tension of the aqueous antibody solution was reduced by the addition of surfactant (the surface tension of an IgG solution in PBS is 65 dyn/cm, and the surface tension of an IgG solution in PBS with 1% Tween 20 is 36 dyn/cm). Most likely, a large amount of IgG was immobilized, and the surface reaction proceeded effectively when the solution infiltrated the inside of the nanostructured PMBN because of the decreased solvent surface tension. Figure 4b illustrates the results of utilizing microchip ELISA to evaluate both specific and non-specific signals. In the case of the non-coated Au surface using BSA as a blocking reagent, the specific signal (TSH = 10 μIU/ml) was relatively strong, but the non-specific signal (TSH = 0 μIU/ml) was also substantial. This finding indicated that the blocking effect of BSA was not sufficient and could not fully inhibit non-specific binding of HRP-labeled IgG to the surface. On the other hand, the PMBN ESD-coated surface yielded a much lower non-specific signal than the Au surface blocked with BSA. It is possible that the MPC unit in PMBN successfully prevented the non-specific adsorption of HRP-labeled IgG. With respect to specific signals, the PMBN ESD coating without Tween 20 produced a weak signal, but the PMBN ESD coating with 1% Tween 20 in the solution of the primary antibody yielded considerably stronger signals.

a Detection of TSH by chemiluminescence intensity in the microchip ELISA using fabricated PMBN surfaces. b Integrated chemiluminescence intensity obtained by the microchip ELISA. Tw20 indicates Tween 20 in the antibody solution. c The standard curve of TSH obtained by microchip ELISA using a PMBN surface created by ESD with 1% Tween 20 in the antibody solution

Both enhancement in the specific signal and reduction in the non-specific signal were achieved in the case of the PMBN ESD coating in the presence of Tween 20: the sensitivity was enhanced 2.6-fold relative to that for the Au surface blocked with BSA. When we used the PMBN ESD coating with Tween 20, a standard curve of TSH was obtained successfully and showed linearity in human blood at normal concentrations (Fig. 4c). Compared with those for conventional ELISA in a microtiter plate, the assay duration for the microchip was shortened from ~4 h to 20 min, and sample consumption was reduced from ~100 μL to 5 μL.

In summary, antibodies were immobilized at high density on the nanospherical PMBN surface, and the 3D structure enhanced the specific signal in the microchip-based immunoassay. The sensitivity of the nanospherical PMBN surface with Tween 20 (in the solution for antibody immobilization) was 2.6-fold higher than that of the surface without Tween 20. The assay time was reduced to 20 min (short assay time). Furthermore, the PMBN ESD coating produced low background signals compared to the Au surface blocked with BSA because the MPC units reduced non-specific protein adsorption.

3D microfiber structure for a rapid immunoassay

Recently [25, 26], to shorten the test time of conventional immunoassays, a large number of studies that involve microbeads, a microfluidic channel, or a nanostructured microchip have been conducted [32]. We have reported a microchip ELISA with a nanospherical PMBN structure prepared by the ESD method, which yields a rapid assay (within 20 min) with high sensitivity. The performance is good enough, but there is still a need to decrease the assay duration when a medical doctor uses this test for on-site diagnosis. To achieve an even faster immunoassay (5 min target diagnostic), we used a 3D microfiber structure instead of nanosphere structure. The strategy leverages a large surface area, which allows the immobilization of a high concentration of antibody on the surface. This strategy involves a similar mechanism to that used in the aforementioned nanosphere structure, which enhances the probability of collisions between the antigen and antibody. Furthermore, we apply forced convection to the bulk solution with a vacuum pump. In a conventional static assay, incubation takes several hours due to the diffusion of analyte molecules across long distances before encountering surface-immobilized antibodies. Microchip ELISA can decrease the test duration, but the flow volume and flow rate are quite slow due to the microchannel. In our method of forced convection by vacuum, the antigen is transferred to the antibodies on the surface quickly due to the vacuum conditions. This method is expected to ensure an ultrafast assay (~5 min) by combining a microfiber method and vacuum technique.

Preparation of polystyrene microfibers as an immunoassay platform

In the second chapter [26], we used a polymeric material (PMBN) that swells in water. In this chapter, we fabricated non-swelling polymeric microfibers with strong mechanical properties. Recently, a microfiber platform for biodevices, such as protein-based diagnostics [33] and drug delivery systems [34], was reported, as well as its application to conventional tissue engineering [35, 36]. Polystyrene (PS) is one of the candidate materials for the construction of 3D microfiber membranes by the ESD method. PS solutions (Mw = 9.0 × 105, at 5, 10, 15, 20, or 25 wt%) were prepared in a 1:1 volume ratio mixture of tetrahydrofuran (THF) and N,N′-dimethylformamide (DMA) containing with 2 wt% Triton X and then sprayed to make nano- and microfiber substrates. The diameter and morphology of the microfibers were primarily controlled by the applied voltage, viscosity of the polymer solution and distance between the nozzle and conductive substrate. Figure 5a shows SEM images of the electrospun PS microfibers obtained by changing the concentration of the polymer solution. The diameter of the microfibers increased in proportion to the concentration of the PS solution. The surface area-to-volume ratio of the PS microfibers made from the 10 wt% PS solution was much higher than that of the others. The surface area was calculated from a 3D image built from a fluorescence confocal laser scanning microscopy image after microfiber staining. We selected the 10 wt% PS microfibers as a candidate for further studies because of its superior capability to obtain a high specific signal due to the large amount of antibodies immobilized. As an additional design element to increase the reaction area, four layers of the abovementioned 10 wt% PS microfibers were soaked in ethanol (EtOH), stacked and then lightly compressed under a weight of 2 kg. A single 10 wt% PS microfiber sheet layer was ~50 µm thick, whereas the thickness of four layers was increased to 160 μm. The antibody immobilization density on the PS microfibers fixed to a bottomless well plate showed a linear relationship with the surface area. The maximum value of antibody immobilization density was 300 ng/well for four layers of PS microfiber sheets having a surface area of 1400 mm2, while the value of antibody immobilization density was 60 ng/well for a flat PS surface with a surface area of 50 mm2.

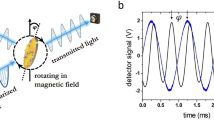

The immunoassay system with the microfiber sheets was prepared, and its illustration is shown in Fig. 5b. The PS microfiber sheet was set underneath a bottomless microtiter plate. During the assay, the reagent solutions and washing buffer were vacuumed from the bottom of the microfiber sheet well. By vacuuming, the antigen solution flowed through the microfiber sheet and reacted efficiently with the antibody. Furthermore, vacuuming improved the efficiency of washing and increased the signal-to-noise ratio.

Evaluation of the rapid immunoassay of 3D microfiber

Figure 6a showed the significance [26] of the combined 3D microfiber and vacuum system in comparison to a flat substrate within a 96-well plate environment. The difference in protocol was merely the antigen–antibody reaction time. In terms of the reagents, the primary antibody utilized was goat anti-human albumin in solution at 10 µg/mL, and it was immobilized by physical adsorption. For blocking, a conventional protein-based reagent, Blocking One, was utilized. The analyte (i.e., antigen) reagent used was human serum albumin at 1 µg/mL. The reaction time of antigen-antibody was varied at 1 s and 5 s for fiber well, and 30 min and 60 min for flat well. Finally, the secondary (i.e., detection) antibody utilized was FITC-conjugated goat anti-human albumin at 10 µg/mL and incubation time was 2 hours. The primary antibody solution was prepared with PBS, while both the antigen and detection antibody reagents were prepared in a PBS solution containing 0.05 vol% Tween 20. Between each step, the well was washed with PBS solution containing 0.05 vol% Tween 20.

The PS microfiber system exhibited a decrease in the antigen–antibody reaction time through vacuum aspiration, leading to detectable antigen capture between 1 s and 5 s. The antigen capture ratio for the PS microfiber system in 5 s was slightly greater than that of the conventional flat 96-well plate in 60 min. From the standard curves, the flat PS and PS microfiber systems (Fig. 6b) displayed similar limits of detection; however, the PS microfiber system showed a much greater linear range of detection. This phenomenon is explained by the fact that the bulk flow in the PS microfiber system can overcome the diffusion rate limitation of the antigen–antibody reaction within the conventional flat plate system. The increase in the amount of antibody immobilized on the 3D microfibers and the resultant increase in antigen capture due to controlled vacuum pressure-driven bulk flow are expected to eventually be utilized in a rapid immunoassay device.

More recently, we expanded these technologies by introducing a new method that involves using 3D electrospun PS microfibers for the selective capture of specific cells from whole blood, e.g., circulating tumor cells (CTCs) [37, 38]. The schematic outline and typical experimental results of cell capture are shown in Fig. 7. Whole blood in its entirety can pass through the microfiber sheet system via vacuum aspiration without damaging the blood cells by controlling the degree of porosity of the fiber through which the blood cells pass. The combination of vacuum aspiration and anti-EpCAM-antibody-conjugated PS microfibers can specifically capture EpCAM-expressing cells within seconds. The electrospun PS microfiber device for the rapid capture of cells may be suitable for clinical on-site applications.

Conclusions and perspective

To obtain a highly sensitive and rapid immunoassay, a 3D polymer microstructure prepared by the ESD method has been developed. Nanosphere and microfiber structures have a strong potential for increasing the antibody immobilization density due to the control of the surface tension of the solution, which can in turn increase the specific signal. When a biocompatible polymer resistant to non-specific protein adsorption is employed as a nano- and/or microstructured platform for biosensing, it decreases the noise. As a result, the platform ensures highly sensitive biosensing. Furthermore, the nano- and/or microstructured platform can be applied to a microchip immunoassay to decrease the assay duration. The microfiber structure is unique not only because of the high-density immobilization of an antibody but also because of the increased flow rate induced by vacuum aspiration. An ultrafast immunoassay can be implemented using the combination of the microfiber platform and forced convection of an analyte solution. In conclusion, 3D polymeric nano- and/or microstructures show great promise as a platform for biodevice applications.

References

Jianrong C, Yuqing M, Nongyue H, Xiaohua W, Sijiao L. Nanotechnology and biosensors. Biotechnol Adv. 2004;22:505–18.

Honda N, Inaba M, Katagiri T, Shoji S, Sato H, Homma T, Osaka T, Saito M, Mizuno J, Wada Y. High efficiency electrochemical immuno sensors using 3D comb electrodes. Biosens Bioelectron. 2005;20:2306–9.

Valsesia A, Mannelli I, Colpo P, Bretagnol F, Rossi F. Protein nanopatterns for improved immunodetection sensitivity. Anal Chem. 2008;80:7336–40.

Lavignac N, Allender C, Brain K. Current status of molecularly imprinted polymers as alternatives to antibodies in sorbent assays. Anal Chim Acta. 2004;510:139–45.

Lu J, Liu S, Ge S, Yan M, Yu J, Hu X. Ultrasensitive electrochemical immunosensor based on Au nanoparticles dotted carbon nanotube–graphene composite and functionalized mesoporous materials. Biosens Bioelectron. 2012;33:29–35.

Soukka T, Harma H, Paukkunen J, Lovgren T. Utilization of kinetically enhanced monovalent binding affinity by immunoassays based on multivalent nanoparticle-antibody bioconjugates. Anal Chem. 2001;73:2254–60.

Jung Y, Lee JM, Jung H, Chung BH. Self-directed and self-oriented immobilization of antibody by protein G−DNA conjugate. Anal Chem. 2007;79:6534–41.

Tajima N, Takai M, Ishihara K. Significance of antibody orientation unraveled: well-oriented antibodies recorded high binding affinity. Anal Chem. 2011;83:1969–76.

Trilling AK, Beekwilder J, Zuilhof H. Antibody orientation on biosensor surfaces: a minireview. Analyst. 2013;21:1619–27.

Cho I-H, Paek E, Lee H, Kang JY, Kim TS, Paek SH. Site-directed biotinylation of antibodies for controlled immobilization on solid surfaces. Anal Biochem. 2007;365:14–23.

Nagasaki Y, Kobayashi H, Katsuyama Y, Jomura T, Sakura T. Enhanced immunoresponse of antibody/mixed-PEG co-immobilized surface construction of high-performance immunomagnetic ELISA system. J Colloid Interface Sci. 2007;309:524–30.

Ishihara K, Takai M. Bioinspired interface for nanobiodevices based on phospholipid polymer chemistry. J R Soc Interface. 2009;3:S279.

Kurosawa S, Park J-W, Aizawa H, Wakida S-I, Tao H, Ishihara K. Quartz crystal microbalance immunosensors for environmental monitoring. Biosens Bioelectron. 2006;22:473–81.

Park J, Kurosawa S, Takai M, Ishihara K. Antibody immobilization to phospholipid polymer layer on gold substrate of quartz crystal microbalance immunosensor. Colloid Surf B Biointerfaces. 2007;55:164–72.

Nishizawa K, Konno T, Takai M, Ishihara K. Bioconjugated phospholipid polymer biointerface for enzyme-linked immunosorbent assay. Biomacromolecules. 2008;9:403–7.

Ishihara K, Nomura H, Mihara T, Kurita K, Iwasaki Y, Nakabayashi N. Why do phospholipid polymers reduce protein adsorption? J Biomed Mater Res. 1998;39:323.

Morisaku T, Watanabe J, Konno T, Takai M, Ishihara K. Hydration of phosphorylcholine groups attached to highly swollen polymer hydrogels studied by thermal analysis. Polymers. 2008;49:4652–7.

Nagasawa D, Azuma T, Noguchi H, Uosaki K, Takai M. Role of interfacial water in protein adsorption onto polymer brushes as studied by SFG spectroscopy and QCM. J Phys Chem C. 2015;119:17193–201.

Nishizawa K, Konno T, Takai M, Ishihara K. Stabilization of phospholipid polymer surface with three-dimensional nanometer-scaled structure for highly sensitive immunoassay. Colloid Surf B Biointerfaces. 2010;77:263–9.

Goto Y, Matsuno R, Konno T, Takai M, Ishihara K. Artificial cell membrane-covered nanoparticles embedding quantum dots as stable and highly sensitive fluorescence bioimaging probes. Biomacromolecules. 2008;9:828–33.

Kuwabara K, Ogino M, Ando T, Miyauchi A. Enhancement of fluorescence intensity from an immunoassay chip using high-aspect-ratio nanopillars fabricated by nanoimprinting. Appl Phys Lett. 2008;93:033904(1)–033904(3).

Ng AHC, Uddayasankar U, Wheeler AR. Immunoassays in microfluidic systems. Anal Bioanal Chem. 2010;397:991–1007.

Nishizawa K, Konno T, Takai M, Ishihara K. Microchip immunoassay using high density bioconjugation on the phospholipid polymer interface. Trans Mater Res Soc Jpn. 2008;33:787–90.

Nishizawa K, Takai M, Ishihara, K. Microchip immunoassay with 3D nanostructured phospholipids polymer biointerface. Proc. μTAS 1584–6 (2009).

Fukushima T, Takai M. Ultra-fast immunoassay with 3D structured microfiber devices. Proc. μTAS 1209–11 (2011).

Hoy C, Kushiro K, Takai M. Fabrication and assessment of an electrospun polymeric microfiber-based platform under bulk flow conditions with rapid and efficient antigen capture. Analyst. 2018;148:865–73.

Sato K, Tokeshi M, Kimura H, Kitamori T. Determination of carcinoembryonic antigen in human sera by integrated bead-bed immunoasay in a microchip for cancer diagnosis. Anal Chem. 2001;73:1213–8.

Oki A, Takai M, Ogawa H, Takamura Y, Fukasawa T, Kikuchi J, Ito Y, Ichiki T, Horiike Y. Healthcare chip for checking health condition from analysis of trace blood collected by painless needle. Jpn J Appl Phys. 2003;42:3722–7.

Herr AE, Hatch AV, Throckmorton DJ, Tran HM, Brennan JS, Giannobile WV, Singh AK. Microfluidic immunoassays as rapid saliva-based clinical diagnostics. Proc Natl Acad Sci USA. 2007;104:5268–73.

Duffy DC, McDonald JC, Schueller OJA, Whitesides GM. Rapid prototyping of microfluidic systems in poly(dimethylsiloxane). Anal Chem. 1998;70:4974–84.

Ishihara K, Iwasaki Y, Nakabayashi N. Polymeric lipid nanosphere consisting of water-soluble poly(2-methacrylaoyloxyethyl phosphorylcholine-co-n-butyl metacrylate). Polym J. 1999;31:1231.

Sun J, Xianyu Y, Jiang X. Point-of-care biochemical assays using gold nanoparticle-implemented microfluidics. Chem Soc Rev. 2014;43:6239–53.

Serafim M, Leitolis A, Crestani S, Marcon BH, Foti L, Petzhold CL, Radtke C, Krieger MA, Saul CK. Electrospinning induced surface activation (EISA) of highly porous PMMA microfiber mats for HIV diagnosis. Mater Chem B. 2016;4:6004–11.

Xue J, Niu Y, Gong M, Shi R, Chen D, Zhang L, Lvov Y. Electrospun microfiber membranes embedded with drug-loaded clay nanotubes for sustained antimicrobial protection. ACS Nano. 2015;9:1600–12.

Yanga F, Muruganb R, Wangc S, Ramakrishna S. Electrospinning of nano/micro scale poly(l-lactic acid) aligned fibers and their potential in neural tissue engineering. Biomaterials. 2005;26:2603–10.

Burger C, Hsiao BS, Chu B. Nanofibrous materials and their applications. Annu Rev Mater Res. 2006;36:333–68.

Ueki T, Yoshihara A, Teramura Y, Takai M. Fast and selective cell isolation from blood sample by microfiber fabric system with vacuum aspiration. Sci Technol Adv Mater. 2016;17:807–15.

Yoshihara A, Sekine R, Ueki T, Kondo Y, Sunaga Y, Nakaji-Hirabayashi T, Teramura Y, Takai M. Rapid and highly efficient capture and release of cancer cells using polymeric microfibers immobilized with enzyme-cleavable peptides. Acta Biomater. 2018;67:32–41.

Acknowledgements

This work was partly supported by a Grant-in-Aid for Exploratory Research from the Ministry of Education, Culture, Sports, Science and Technology of Japan. We would like to thank Prof. Kazuhiko Ishihara and Dr. Kazuki Nishizawa, Department of Materials Engineering, School of Engineering, The University of Tokyo, who were collaborators on the research into 3D nanosphere structures for immunoassays. We thank my PhD student Carlton FO. Hoy for the helpful discussion about the research on 3D microfibers.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Takai, M. Highly sensitive and rapid biosensing on a three-dimensional polymer platform. Polym J 50, 847–855 (2018). https://doi.org/10.1038/s41428-018-0049-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-018-0049-3