Abstract

Developing tools to understand and control the effect of semiconducting polymer morphology on the optoelectronic performance remains an important objective. Introducing conjugation break spacers (i.e., flexible linkers) between π-conjugated segments in a semiconducting polymer is an emerging strategy toward this goal. Herein, we place this strategy in context with other extrinsic and intrinsic engineering approaches and highlight some of the recent results employing this “flexible linker” approach. We see that the inclusion of electrically insulating aliphatic spacers represents a versatile tool to gain insight into the nature of inter-molecular and intra-molecular charge carrier transport and can be broadly used to control morphology of solution-processed semiconducting polymer thin films. Moreover, this approach has afforded unique control over material processing and mechanical properties (e.g., viscosity and elasticity) without detrimental effect on the semiconducting ability. While the development of this technique remains at an early stage, its potential gives promise to reaching the goal of engineering the self-assembly of semiconducting polymers.

Similar content being viewed by others

Introduction

Over the past four decades, π-conjugated semiconducting polymers have attracted significant attention from both academic and industrial laboratories due to a wealth of potential applications in optoelectronic devices. Recently, the advancement of semiconducting polymers in solution-processed thin-film organic light-emitting diodes [1], field-effect transistors [2], photovoltaics [3], and bioelectronics [4] has given genuine promise to the possibility of inexpensive roll-to-roll fabrication or inkjet printing of high-performance devices using these materials. The key to progress in the field has come from innovation in synthetic methodology and material design, which has been extensively applied to manipulate the molecular structure of the π-conjugated polymer backbone and solubilizing side chains. This work has led to a vast library of oligomeric and polymeric semiconductors with tuneable functionality [5, 6]. However, while the control over the optoelectronic properties and processability of π-conjugated semiconducting polymers has been extensively investigated, the behavior of polymer semiconductor thin film devices is very complex. Indeed the chains of typical solution-processable semiconducting polymer consist of a semi-rigid backbone and flexible (solubilizing) sidechains. In the solid state these polymer chains do not form amorphous coils nor do they self-assembly into a perfect crystalline structure. Rather the solid-state morphology is somewhere in between, and a major challenge remains in the understanding of how the molecular structure translates into a solid-state morphology and further how this morphology dictates performance [7, 8].

For example, a fundamental performance metric of polymer semiconductors is the solid-state charge carrier mobility (e.g., hole mobility, µh). It is well known that charge transport in semiconductor polymers in the solid state occurs through relatively fast intramolecular charge carrier migration along the π-conjugated backbone together with the intermolecular hopping of charges between conjugated segments in the π-stacking direction. While much effort has been directed toward accurately predicting µh based on density functional theory (DFT), consideration of the complex thin-film morphological structure to precisely model the relationship between intermolecular and intramolecular transport limits the precision of these predictions [9,10,11]. This is apparent in the disaccord between the µh predicted using DFT and the experimentally measured values in a thin film transistor (TFT) device. Indeed, for the prototypical thiophene-based semiconducting polymers such as poly(3-hexylthiophene), P3HT, and poly-2,5-bis[3-alkylthiophen-2-ylthiono(3,2-b)thiophene], PBTTT, the predicted µh values are as high as 31 and 15 cm2 V−1 s−1, respectively, but TFT measurements give only up to 0.1 and 1.0 cm2 V−1 s−1 [12]. While this discrepancy indicates that optoelectronic performance is largely dictated by the thin film morphology of the polymer semiconductor, it also suggests that substantial improvement in performance remains attainable if the solid-state self-assembly of these materials can be controlled and understood over various length scales [13]. However, defects [14, 15], quasi-crystallinity [16], polymorphism [17,18,19] domain orientation/grain boundaries [20, 21], and phase separation (in blends or mixtures) [22] have all been identified as influential to the experimentally measured performance of solid-state semiconducting polymers and attempts in predicting these aspects and their effect on charge transport has remained a challenge [23,24,25]. Therefore, developing a set of tools to experimentally control morphology and crystallinity in polymer semiconductors is now under development to fully rationalize links between molecular structure, self-assembly, and function in π-conjugated semiconductors. This is in effort to further advance the field towards improving device performance [26] and realizing unique functionalities that open the field to novel applications [27,28,29]. In this focus review, we will briefly overview the tools used to control self-assembly and morphology in π-conjugated polymer semiconductors and highlight results using a promising and emerging approach, that is, employing conjugation break spacers (or flexible non-conjugated linkers) to control self-assembly.

Tools for controlling self-assembly in π-conjugated polymer semiconductors

Many tools have been developed to control the solid-state morphology of semiconducting polymers by modulating their self-assembly during the casting of the materials from solution. Extrinsic morphology control techniques such as the variation of solvent/processing conditions, meniscus-guided coating, and printing [30] have been established as powerful tools in controlling the thin film morphology in semiconducting polymers. Moreover, the use of processing additives such as nucleation promoters [31], electronically insulating polymers [32], and post-deposition treatments [33] have also been exploited. These approaches are greatly influenced by external factors, that is, the nature of substrate and solvent, evaporation rate, and processing technique used. Thus, extensive empirical optimization is required and the results are often not universal towards arbitrary molecular structure [13]. On the other hand, molecular engineering approaches can directly impact the intrinsic self-assembly of the π-conjugated semiconductor [34]. For instance, modulating the π-conjugated backbone by introducing highly planar π-extended conjugated monomer units [35, 36], alternating donor–acceptor moieties [37], restricting rotation between monomeric units via covalent bonds (i.e., ladder-type polymers) [38] or using non-covalent conformational locks [39], have all shown the ability to control the observed solid-state conjugation length and π–π stacking interactions, which directly affect the intra-molecular and inter-molecular charge transport, respectively (although we note that in some cases, addition of planar co-monomer units results in a curved backbone structure that hinders intermolecular electronic communication) [40]. Alternatively, side-chain engineering, which is typically used to induce solubility, can also be employed to modulate π–π stacking of neighboring conjugated segments [41]. Linear alkyl chains minimize intermolecular steric hindrances leading to 1D co-stacking of the conjugated backbone, while branching distorts efficient stacking [42, 43]. Interestingly, shifting the position of the branching point away from the conjugate core induces extremely short π–π stacking distances without comprising solubility [44]. In addition, inducing ordering by hydrogen bonding of urea containing groups [45], or functionalizing side chains via fluorinated alkyl chains with strong self-organization [46], have shown to drive a high degree of order between π-conjugated segments. Despite the potential of side-chain engineering in affecting self-assembly, it should be noted that π–π stacking interactions still dominate the overall supramolecular assembly [47].

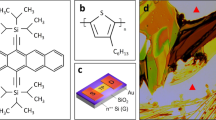

Recently, a method to control the supramolecular assembly without altering the side chains or changing the energetics of the π-conjugated core has emerged for semiconducting polymers in organic field effect transistor (OFET) and organic photovoltaic cell (OPV) applications. This strategy consists of covalently joining π-conjugated segments with a flexible non-semiconducting spacer—typically an aliphatic chain (see Fig. 1a) [48,49,50,51]. Since the non-conjugated spacer interrupts the continuous conjugation typical of most semiconducting polymers, the spacers are often referred to as “conjugation-break spacers.” Alternatively, since the spacers also add a degree of conformational freedom to the otherwise rigid conjugated backbone, they have also been referred to as “flexible linkers.” Intuitively, the inclusion of non-conjugated linkers along the polymer backbone could be expected to disrupt intramolecular charge carrier transport and create a high degree disorder in the material in the solid state. While at first glance this may be thought to only negatively impact the optoelectronic properties, recent demonstrations have highlighted the usefulness of this approach in easing backbone rigidity to enhance processability, and offering unique self-assembly motifs for efficient device performance [52,53,54,55,56,57,58,59,60,61]. In the next sections, we describe the historical development and specific applications of this flexible linker approach.

a (top) Chemical structure of a flexibly linked polymer FL-PBTTT and (bottom) a schematic of the structure indicating the relative rigidity of the conjugated segments and their approximate length/number. Tapping mode atomic force microscopy (AFM) topography of: b FL-PBTTT as cast from o-dichlorobenzene 20 mg ml–1, c FL-PBTTT after annealing at 130 °C, and d after annealing at 180 °C. The topographical profile along the indicated diagonal line in each case is shown below. The right side of each panel shows the 2D grazing-incidence X-ray diffraction plots of the same films with the vertical direction corresponding to the out-of-plane scatting vector, qz, and the horizontal direction corresponding to qxy. Red areas represent the highest scattering intensity, while blue represent the lowest. Adapted from Ref. [54] © The Royal Society of Chemistry 2014

Initial demonstrations of conjugation-break spacers with poly-phenylenevinylene

The concept of linking rigid conjugated segments with flexible spacers is not new and was initially developed in the 1970s and 1980s in the field of liquid crystalline polymers [62]. Specifically, thermotropic “main-chain” liquid crystalline polymers were extensively studied, and found to exhibit a wide variety of unusual mechanical and rheological phenomena [63]. However, the optoelectronic properties of this class of materials was not widely considered until semiconducting poly-phenylenevinylene (PPV) polymers became of broad interest. The concept of incorporating non-conjugated linkages in the backbone of PPV by copolymerization [64] or by partially saturating the vinyl linkages via selective elimination [65,66,67] was investigated in the 1990s and early 2000s for application in OLED devices to tune the bandgap, ease rigidity of the polymer backbone, and enhance solution processability. However, the effect on the charge carrier transport was generally negative. In 2011 Barbara and co-workers [68] used the Horner method to synthesize random copolymers of poly(2-methoxy-5-(2′-ethylhexyloxy)-p-phenylene vinylene) (MEH-PPV) that incorporated different backbone-directing monomers. Rigid and bent defects were found to lower the anisotropy of the single chain, while saturated defects provided rotational freedom for the chain backbone allow for a wide variety of possible configurations. Plunkett and co-workers [69] followed up on this work with PPV oligomers linked via flexible alkyl and glycol chains termed “flexible morphons” to direct the extent of the interchain interactions in the solid state. While the solution photophysical properties between the non-linked PPV oligomers and polymer-incorporated PPVs were very similar, their approach provided finer control over the effective conjugation length and the resulting thin-film properties of the conjugated PPV polymer [70]. Overall these studies, while not demonstrating practical optoelectronic device applications, laid the groundwork for being able to design semiconducting polymer morphologies whereby the addition of different directing groups to the main chain backbone could influence the molecular self-assembly of the polymer chains in the manner desired.

Decoupling inter-molecular and intra-molecular charge transport using a flexible linker approach

In a seminal demonstration of the application of the flexible linker approach to optoelectronic device applications, Gasperini et al. [54] gained important insight into the relationship between self-assembly and charge transport in PBTTT. In that work, short PBTTT segments [71] were connected into a flexibly linked structure coded as FL-PBTTT and shown in Fig. 1a (with n = 10–12, m = 4–5). It should be noted that the presence of free short PBTTT segments in the final sample was excluded by purification with preparatory size-exclusion chromatography. In solid-state thin films, FL-PBTTT was found to exhibit distinct morphologies from rod-like fibrils to terraces (see height topography images in Fig. 1b–d) by simply altering the temperature of a post-deposition thermal treatment. The crystallinity of the thin films was accordingly altered as well with the 130 °C annealing condition (Fig. 1c) producing the most crystalline film (with a more random alignment of crystalline domains) compared to the as-cast or 180 °C films (Fig. 1b, d), which were found to have an alignment of the lamellar stacking of the crystal domains aligned with the substrate (as seen by the 2D grazing-incidence X-ray diffraction plots in the insets of Fig. 1b–d). Importantly, this showed that without changing the length of the conjugated segments, the self-assembly could be drastically altered. In TFTs, changing the film morphology gave an improvement of the charge carrier mobility from fibril-type (0.01 cm2 V–1 s–1) to terrace morphologies (0.04 cm2 V–1 s–1), while actually decreasing the overall crystallinity of the film. These results suggest that the high µh observed in medium molecular weight PBTTT (e.g., n = 50) without a flexible linker is not solely due to improved intramolecular transport as suggested in one report [72], but rather reinforces the notion described by Salleo and co-workers [16], that is, that the 2D charge-transport network afforded by the self-assembly significantly contributes to the observed high charge carrier mobility.

On the other hand, it should be noted that the recently developed polymer semiconductors based on napthalenediimides [73], diketopyrrolopyrrole (DPP) [74], and carbazoles [75] do not exhibit long-range crystalline order like P3HT and PBTTT, but exhibit superior µh over 1 cm2 V−1 s−1. Interestingly, despite a seemingly disordered morphology, these polymers exhibit aggregation consistent with improved intermolecular associations (indicative from resolvable vibronic progression near the absorption edge, and red shifting in their optical absorption spectra) [76]. This indicates that the short-range ordering of the aggregates is sufficient for efficient intermolecular charge transport, so long as the aggregates are sufficiently interconnected [77]. Overall, these observations have led to a design principle for efficient charge mobility in a conjugated polymer film, whereby rather than inducing high crystallinity, improving the interconnectedness between aggregated domains, and reducing the amount of disorder within conjugated segments (making rigid backbones) seems to be the key to facilitate the optimum intramolecular and intermolecular charge transport at the device length scale.

Controlling morphology and film formation of highly crystalline semiconductors using a flexible linker

Based on the notion that interconnectedness of domains is key to optimizing charge transport in organic semiconductors, the flexible linker strategy can also contribute to useful control of this aspect. Indeed, this strategy has been employed to improve the connectivity of domains in highly crystalline solution-processed thin films of small-molecule semiconductors. Despite the purported advantages of small molecule (or molecular) semiconductors over polymer semiconductors (including synthetic simplicity and the ability to remove batch-to-batch variations) [78] this class of π-conjugated semiconductors typically self-assemble into highly crystalline domains that result in film dewetting, unpredictable crystallite dimensions, and grain boundaries which confound the morphological control and charge transport in devices fabricated from these materials. To address this, a flexible linker concept was applied to a common molecular semiconductor, coded as DPP(TBFu)2 or 3,6-bis(5-(benzofuran-2-yl)thiophen-2-yl)-2,5-bis(2-ethylhexyl)-2,5-dihydropyrrolo[3,4-c]pyrrole-1,4-dione, resulting in a polymer with flexibly linked conjugated segments identical to DPP(TBFu)2, and coded as FL-DPP(TBFu)2 (see Fig. 2a) [49]. It should be noted that the synthesis of FL-DPP(TBFu)2 was simply performed via the Stille cross-coupling condensation polymerization using a functionalized bis(benzofuranyl)alkane. TFTs based on pure FL-DPP(TBFu)2 showed no measureable µh (which is likely due lack of intramolecular charge transport since the π-conjugated backbone of small molecules are independent of each other). However, we note that a comparable system based on poly(rod-coil) polymers consisting of short benzothiophene-centered acceptor–donor–acceptor (A–D–A)-type [51] and DPP-centered [79] D–A–D-conjugated segments linked with non-conjugated aliphatic spacers did exhibit hole transporting properties in a bulk heterojunction OPV device with a modest maximum device performance of ca. 1.0%. Despite the poor charge transport of this class of materials, the FL-DPP(TBFu)2 proved to be useful as an additive to films of DPP(TBFu)2. Indeed, blending FL-DPP(TBFu)2 with DPP(TBFu)2 exhibited interesting results when subjected to thermal stress (at 100 °C) for 3 h (see Fig. 2b). TFTs containing pure DPP(TBFu)2 (0 wt%) gave µh that decreased by an order of a magnitude (due to film dewetting) whereby a considerably lower decrease was observed when 1 wt% of the FL-DPP(TBFu)2 was added, and notably at 5 wt%, the µh remained constant. This indicates the ability of the FL-DPP(TBFu)2 to control and stabilize the crystalline domain formation in the thin film. A further demonstration of this was accomplished with bulk heterojunction blends of DPP(TBFu)2 with phenyl-C61-butyric acid methyl ester (PC61BM) in OPV devices. Morphological topography and young modulus mapping via atomic force microscopy of the BHJ blend films under prolonged annealing (at 100 °C) exhibited similar intermixed BHJ morphology between as-cast films and after 22 h at 100 °C with 1.5 wt% of FL-DPP(TBFu)2 (see Fig. 2c, e) indicating a preservation of the BHJ morphology. On the other hand, with 0 wt% the BHJ was found to be devoid of the PC61BM as it was excluded due to the crystallization of the DPP(TBFu)2 (see Fig. 2d). This morphological evolution correlated well with the preservation of device performance (See Fig. 2f). While the control (0 wt%) device decreased in power conversion efficiency with respect to time under thermal stress due to phase segregation, including only 0.5 wt% of the FL-DPP(TBFu)2 stopped this process from occurring. Considering the polymeric structure of the FL-DPP(TBFu)2, a plausible explanation for the observed behavior suggests that the FL-DPP(TBFu)2 acted as a tie-in molecule to bridge adjacent crystal domains of DPP(TBFu)2, effectively locking-in the active layer morphology.

A flexibly linked small-molecule semiconductor. a The synthetic scheme for FL-DPP(TBFu)2, the polymer used to control the morphology of its parent (non-flexibly linked) small-molecule semiconductor, DPP(TBFu)2. (b) The thin film transistor performance of blended FL-DPP(TBFu)2: DPP(TBFu)2 at different wt% of the FL polymer mobility as a function of device annealing time at 100 °C. The morphology of bulk heterojunctions of DPP(TBFu)2:PC61BM with or without FL-DPP(TBFu)2 is shown in c–e with topography (left side) and Young’s modulus mapping (right side) of the corresponding area (the scale bars are 500 nm). f The OPV PCE as a function of the active layer annealing time at 100 °C of devices with 0 and 0.5 wt% of FL-DPP(TBFu)2. Figures are adapted from Ref. [49] © 2015 WILEY-VCH Verlag GmbH & Co. KGaA

An important general question regarding the use of the aliphatic linking technique is the effect of the linking position. To gain insight into this aspect with the model DPP(TBFu)2 system, Jeanbourquin et al. [80] compared two distinct dimer analogs (see structures in Fig. 3). The “vertically-linked,” V-(DPP)2, and the “horizontally-linked,” H-(DPP)2, dimers were both found to have the same optical bandgap of the parent DPP(TBFu)2 molecule, but exhibit very different self-assembly properties. Interestingly, while V-(DPP)2 exhibited poor crystallinity in pure films, it enhanced µh in FETs by 10-fold, when used as an additive with the primary DPP(TBFu)2 molecule. This increase was ascribed to a nucleation promotion effect of the dimer, where fewer large charge-trapping grain boundaries were observed but the crystallinity of the DPP(TBFu)2 in the thin film remained present. On the other hand, H-(DPP)2 had no significant effect in charge carrier transport, but was found to increase thermodynamic miscibility between the donor and acceptor phases which induced an enhanced BHJ thermal stability in DPP(TBFu)2:PCBM blends. OPV devices accordingly retained 90% of their initial conversion efficiency after 5 h of thermal treatment (at 100 °C), compared to a 45% retention for the devices without the dimer additive.

Since this dimer linking strategy is easily generalizable, it has been exploited for a number of other molecules. For example, McCulloch and co-workers [81] demonstrated a “dumbbell” fullerene dimer, (PCB)2C2 (see Fig. 3 for chemical structure) bridged by an alkyl spacer attached on the ester functional group of PCBM. The dumbbell dimer inhibited the formation of micron-scale crystallites of the parent PCBM molecule when used as an additive in a BHJ blend with a polymer donor, which improved OPV device lifetimes by 20% under thermal stress (at 80 °C) as compared to blends without the dumbbell dimer additive. A notable example by Yagai and co-workers [53] demonstrated a dimension-controlled self-organization of perylenediimide (PDI) dimers coded as PCnP (see Fig. 3 for chemical structure), where the relative orientation of tethered PDI units is regulated by the odd/even effect of the flexible linkers which influence its packing structures.

In addition to dimers, the flexible linker approach was also recently utilized in a donor–b–acceptor block-copolymer (BCP) system [82], where nanophase segregation of the respective donor and acceptor block remains a pertinent challenge [83, 84]. Introduction of a non-conjugated alkyl spacer between the donor and acceptor blocks of the BCP to give the polymer coded as PTQi-b-PNDISL (see Fig. 3 for structure) permitted an increase in the degrees of conformational freedom, as compared to the fully conjugated BCP. This allowed the two electronically distinct blocks to crystallize independently forming a prominent nanophase separation behavior where a significantly larger OPV power conversion efficiency of 1.54% was obtained as compared to 0.36% of the fully conjugated BCP. A similar approach was also employed in a small-molecule BHJ based on DPP(TBFu)2:PCBM, where the donor and acceptor semiconductor were connected with an aliphatic spacer to form a molecular compatibilizing additive [85]. The additive demonstrated significant control over the degree of phase segregation in the small-molecule BHJ that stabilized its OPV device performance under thermal stress.

Overall, these reports demonstrate that linking conjugated segments with a flexible aliphatic chain is a promising approach to control molecular self-assembly without changing the nature of the semiconducting molecular core. Further exploitation of this strategy will likely lead to an increased understanding of the important relationships between molecular self-assembly and the performance of organic electronic devices.

Tuning mechanical properties and processability with a flexible linker approach

Another notable aspect of the flexible linker strategy is the ability to tune the processabililty of π-conjugated semiconductors. Indeed, as the rigidity of the backbone increases the critical polymer length for entanglement also increases (as evidenced by comparing entanglement molecular weights for the classic polymers P3HT [86] and PBTTT [71]). The polymer chain entanglement will not only greatly affect processability but it will also, for conjugated polymers, influence the molecular self-assembly and the resulting carrier transport [87]. Bao and co-workers [56] recently showed that the incorporation of non-conjugated flexible linkers into an isoindigo based semiconducting polymer coded Pil2T-X (see chemical structure in Fig. 4a) affected the processability of this material through modulating its viscoelastic properties [56]. Rheometry and dynamic mechanical analysis revealed that solution viscosity was directly proportional to the content of non-conjugated linkers in the polymer backbone. Indeed, flow curves (Fig. 4b) indicate that the viscosity of the polymer solutions in dichlorobenzene (o-DCB) decrease from 0.1 Pa s (Pil2T control without flexible linker) to 0.01 Pa s when 20% of the flexible linker monomer was included in the polymer backbone (Pil2T-20). The effect of the side chains is also highlighted here as the Pil2T-Ref polymer, which has shorter 2-octyldodecyl side chains, was found to gel under the same conditions and have a remarkably higher viscosity of 1 Pa s. Interestingly, the resulting measured µh in TFTs were unexpectedly high compared to other flexibly linked polymers (e.g., FL-PBTTT) reaching a carrier mobility of 1.4 cm2 V−1 s−1 with Pil2T-5 and 0.23 cm2 V−1 s−1 with Pil2T-20 despite having a non-fully conjugated polymer backbone. Due to the good semiconductor properties and the enhanced processability due to the lower viscosity, a solution shearing method used to coat large-area substrates could be employed using Pil2T-X as a donor polymer in an all-polymer solar cell (with a PDI polymer acceptor). The device with Pil2T-5 or Pil2T-20 achieved reasonable power conversion efficiency values of 3.7% or 3.0%, respectively.

a The chemical structure of Pil2T-X and b the rheological flow curves of different Pil2T-X polymers (where X is the mole percent of flexible linker) in a solution of 1,2 dicholorobenzene at 20 mg ml−1 at room temperature. Pil2T-Ref has different side chains (see the main text). Panel b is adapted from Ref. [56] © 2016 WILEY-VCH Verlag GmbH & Co. KGaA. Chemical structure of DPP-Cx shown in Scheme (d), while the schematic in c illustrates the melt-processing approach; the images in f shows the melted DPP-Cx matrix film and the corresponding devices using a peel-off and transfer approach. Panels d and e is adapted from Ref. [59] © 2017 WILEY-VCH Verlag GmbH & Co. KGaA

Another interesting line of work leading to enhanced processability using a flexible linking strategy has been recently reported by Mei and co-workers [57,58,59]. This group demonstrated that the inclusion of flexible linkers into the conjugated backbone of DPP-based semiconducting polymer coded DPP-Cx (see chemical structure in Fig. 4c) had a profound influence on its melting transition, and that the blending of a polymer containing non-conjugated linkers, DPP-C5, in a matrix with its fully-conjugated counterpart, DPP-C0, the flexible linker functions as a tie-chain which improves charge transport [57, 58]. The blending of the two polymers was shown to impart strong intermolecular interactions between the components that stabilize its morphology, and even permitted the melt processing of the polymers. In general, melt processing (which involves a reversible liquefaction-solidification process and is widely used in industry to produce commodity plastic thin films [88]) is a promising approach to afford the solvent-free “green” manufacturing of organic electronic devices. Zhao et al. [59] demonstrated melt processing with the DPP-Cx system using an extrusion process (see schematic Fig. 4d) where a continuous film was obtained by hot-pressing the polymer blend sandwiched between two octadecyltrichlorosilane-modified SiO2/Si wafers on a hot plate. The polymer film was then peeled off and transferred onto a pre-patterned TFT substrate. Photographs of the resulting continuous polymer films and the transfer process are shown in Fig. 4e. Furthermore, the melt-processed TFTs obtained an excellent average µh of 0.4 cm2 V−1 S−1 [59].

In addition to lowering viscosity and enabling melt processing, the flexible linker approach has recently been shown to enhance the elasticity of the resulting semiconducting polymer films. A unique functionalized FL-linker design concept presented by Bao and co-workers was found to induce an intrinsic stretchability and self-healing properties [61]. The DPP-based conjugated polymer coded PX (see chemical structure in Fig. 5a) includes a non-conjugated linker with a chemical moiety 2,3-pyridine dicarboxamide (PDCA), which was included to promote dynamic non-covalent hydrogen bond crosslinking in the polymer network (due to the presence of moderate hydrogen bonding between the amide groups as illustrated in the schematic in Fig. 5b). The authors proposed that the non-covalent crosslinking moieties dissipate energy during stretching, allowing the breaking/reforming of hydrogen bonds when strain is applied. TFTs fabricated from these materials exhibited µh up to 1.3 cm2 V−1 s−1. The charge carrier mobility remained as high as 1.12 cm2 V−1 s−1 even at 100% strain. The effect of incorporating the non-conjugated PDCA linker on the TFT performance is clear. When comparing the µh under strain of the control polymer P1 (with 0 mol% of the PDCA linker), the mobility is seen to decrease significantly with applied strain (see Fig. 5c, d). However, when P3 (with 10 mol% PDCA) was used, the µh (measured in the direction parallel or perpendicular to the applied strain) was less affected. Moreover, µh of damaged devices could be almost fully recovered using a solvent/thermal healing treatment.

Enhancing elasticity with a non-conjugated linker. a The chemical structure of PX. The proposed general mechanism for the enhancement of stretchability in the polymer via dynamic bonding illustrated in the schematic in b. Field-effect (hole) mobility μFE as a function of various strains is shown for P1 (0 mol% PDCA linker) and P3 (10 mol% PDCA linker) along the strain direction (c) and perpendicular to strain direction (d). The point “Re” corresponds to the measurement after relaxing the film. Panels b and c is adapted from Ref. [61] © 2016 Macmillan Publishers Limited, part of Springer Nature

In another example, Savagatrup et al. [89] used copolymers of the aforementioned DPP-Cx (x = 3) with a fully conjugated monomer and measured the crack‐onset strain. They found that with increasing fraction of flexible monomer the crack-onset strain increased, suggesting more elastic properties with the flexible linker incorporation. Interestingly, despite the authors initial hypothesis that the pure DPP‐C3 (with fully flexible backbone) would be the most ductile, they observed this material to have the greatest brittleness. It was suggested that the smallest lamellar spacing and also the greatest lamellar order present in that material lead to the surprizing deviation. This reinforces the idea that both the molecular structure and the packing arrangement in the solid state govern the mechanical (and of course optoelectronic) properties of the resulting material. Overall, these initial results demonstrating the tuning elasticity of semiconducting polymers represent a major step forward towards skin-inspired stretchable organic electronics that could be integrated into wearable devices.

Conclusion

The examples highlighted in this focus review have illustrated that introducing non-conjugated break spacers (i.e., flexible linkers) between π-conjugated segments in polymer semiconductors is a promising tool to engineer the self-assembly of these materials while preserving the core electronic nature of the π-conjugated backbone. It was shown that charge transport can be relatively preserved despite the presence of aliphatic spacers between π-conjugated segments, this has given new insight into the roles of inter-molecular and intra-molecular charge transport in these materials. The flexible linker approach has also been broadly applied to control the morphology of polymer semiconductors. In addition, this approach proved useful to improving the connectivity of small molecule organic semiconductor thin films when used as a tie-in polymer additive in order to stabilize the active layer morphology. Moreover, the ability of this approach to ease the rigidity of the conjugated polymer backbone has afforded progress toward developing alternative processing techniques (e.g. tuning of viscosity of the polymer for solution shearing depositions, and permitting the solvent-free melt-processing of polymer thin films). Furthermore, functionalizing the non-conjugated aliphatic spacer to promote hydrogen bonding has shown unique self-assembly motifs that permitted stretchability and self-healing properties. While there remains much to explore in this field, like the precise effect of the linker length and position on the self-assembly, the flexible linker approach shows much promise. Future efforts in this field will likely improve our ability at controlling morphology and also open up vast possibilities to employ alternative processing techniques such as “green” and scalable melt processing or introducing functional properties for flexible devices especially for bioelectronics and wearable, stretchable devices [90].

References

Thejo Kalyani N, Dhoble SJ. Organic light emitting diodes: energy saving lighting technology—a review. Renew Sust Energy Rev. 2012;16:2696–723.

Sirringhaus H. 25th Anniversary Article: organic field-effect transistors: the path beyond amorphous silicon. Adv Mater. 2014;26:1319–35.

Kang H, Kim G, Kim J, Kwon S, Kim H, Lee K. Bulk-heterojunction organic solar cells: five core technologies for their commercialization. Adv Mater. 2016;28:7821–61.

Someya T, Bao Z, Malliaras GG. The rise of plastic bioelectronics. Nature. 2016;540:379–85.

Morin P-O, Bura T, Leclerc M. Realizing the full potential of conjugated polymers: innovation in polymer synthesis. Mater Horiz. 2016;3:11–20.

Beaujuge PM, Fréchet JMJ. Molecular design and ordering effects in π-functional materials for transistor and solar cell applications. J Am Chem Soc. 2011;133:20009–29.

Anthony JE. Organic electronics: addressing challenges. Nat Mater. 2014;13:773–5.

Street RA. Unraveling charge transport in conjugated polymers. Science. 2013;341:1072–3.

Brédas JL, Calbert JP, da Silva Filho DA, Cornil J. Organic semiconductors: a theoretical characterization of the basic parameters governing charge transport. Proc Natl Acad Sci USA. 2002;99:5804–9.

Zhan C-G, Nichols JA, Dixon DA. Ionization potential, electron affinity, electronegativity, hardness, and electron excitation energy: molecular properties from density functional theory orbital energies. J Phys Chem A. 2003;107:4184–95.

Oberhofer H, Reuter K, Blumberger J. Charge transport in molecular materials: an assessment of computational methods. Chem Rev. 2017;117:10319–57.

Northrup JE. Atomic and electronic structure of polymer organic semiconductors: P3HT, PQT, and PBTTT. Phys Rev B. 2007;76:245202.

Hiszpanski AM, Khlyabich PP, Loo Y-L. Tuning kinetic competitions to traverse the rich structural space of organic semiconductor thin films. MRS Commun. 2015;5:407–21.

Mikhnenko OV, Kuik M, Lin J, van der Kaap N, Nguyen T-Q, Blom PWM. Trap-limited exciton diffusion in organic semiconductors. Adv Mater. 2014;26:1912–7.

Liscio F, Albonetti C, Broch K, Shehu A, Quiroga SD, Ferlauto L, Frank C, Kowarik S, Nervo R, Gerlach A, Milita S, Schreiber F, Biscarini F. Molecular reorganization in organic field-effect transistors and its effect on two-dimensional charge transport pathways. ACS Nano. 2013;7:1257–64.

Noriega R, Rivnay J, Vandewal K, Koch FPV, Stingelin N, Smith P, Toney MF, Salleo A. A general relationship between disorder, aggregation and charge transport in conjugated polymers. Nat Mater. 2013;12:1038–44.

Galindo S, Tamayo A, Leonardi F, Mas-Torrent M. Control of polymorphism and morphology in solution sheared organic field-effect transistors. Adv Funct Mater. 2017;27:1700526.

Jones AOF, Chattopadhyay B, Geerts YH, Resel R. Substrate-induced and thin-film phases: polymorphism of organic materials on surfaces. Adv Funct Mater. 2016;26:2233–55.

Diao Y, Lenn KM, Lee W-Y, Blood-Forsythe MA, Xu J, Mao Y, Kim Y, Reinspach JA, Park S, Aspuru-Guzik A, Xue G, Clancy P, Bao Z, Mannsfeld SCB. Understanding polymorphism in organic semiconductor thin films through nanoconfinement. J Am Chem Soc. 2014;136:17046–57.

Rivnay J, Jimison LH, Northrup JE, Toney MF, Noriega R, Lu S, Marks TJ, Facchetti A, Salleo A. Large modulation of carrier transport by grain-boundary molecular packing and microstructure in organic thin films. Nat Mater. 2009;8:952–8.

Proctor CM, Kher AS, Love JA, Huang Y, Sharenko A, Bazan GC, Nguyen T-Q. Understanding charge transport in molecular blend films in terms of structural order and connectivity of conductive pathways. Adv Energy Mater. 2016;6:1502285.

Lee SS, Muralidharan S, Woll AR, Loth MA, Li Z, Anthony JE, Haataja M, Loo Y-L. Understanding heterogeneous nucleation in binary, solution-processed, organic semiconductor thin films. Chem Mater. 2012;24:2920–8.

Price SL. Predicting crystal structures of organic compounds. Chem Soc Rev. 2014;43:2098–111.

Huang C-F, Wu S-L, Huang Y-F, Chen Y-C, Chang S-T, Wu T-Y, Wu K-Y, Chuang W-T, Wang C-L. Packing principles for donor–acceptor oligomers from analysis of single crystals. Chem Mater. 2016;28:5175–90.

Do K, Ravva MK, Wang T, Brédas J-L. Computational methodologies for developing structure–morphology–performance relationships in organic solar cells: a protocol review. Chem Mater. 2016;29:346–54.

Henson ZB, Müllen K, Bazan GC. Design strategies for organic semiconductors beyond the molecular formula. Nat Chem. 2012;4:699.

Brandt JR, Salerno F, Fuchter MJ. The added value of small-molecule chirality in technological applications. Nat Rev Chem. 2017;1:0045.

Ke C. A light-powered clockwork. Nat Nanotechnol. 2017;12:504.

Dumur F, Gigmes D, Fouassier J-P, Lalevée J. Organic electronics: an El Dorado in the quest of new photocatalysts for polymerization reactions. Acc Chem Res. 2016;49:1980–9.

Diao Y, Shaw L, Bao Z, Mannsfeld SCB. Morphology control strategies for solution-processed organic semiconductor thin films. Energy Environ Sci. 2014;7:2145–59.

Treat ND, Nekuda Malik JA, Reid O, Yu L, Shuttle CG, Rumbles G, Hawker CJ, Chabinyc ML, Smith P, Stingelin N. Microstructure formation in molecular and polymer semiconductors assisted by nucleation agents. Nat Mater. 2013;12:628–33.

Scaccabarozzi AD, Stingelin N. Semiconducting:insulating polymer blends for optoelectronic applications-a review of recent advances. J Mater Chem A. 2014;2:10818–24.

Hiszpanski AM, Loo Y-L. Directing the film structure of organic semiconductors via post-deposition processing for transistor and solar cell applications. Energy Environ Sci. 2014;7:592–608.

Tsao HN, Mullen K. Improving polymer transistor performance via morphology control. Chem Soc Rev. 2010;39:2372–86.

Pisula W, Kastler M, Wasserfallen D, Mondeshki M, Piris J, Schnell I, Müllen K. Relation between supramolecular order and charge carrier mobility of branched alkyl hexa-peri-hexabenzocoronenes. Chem Mater. 2006;18:3634–40.

Zhang L, Rose BD, Liu Y, Nahid MM, Gann E, Ly J, Zhao W, Rosa SJ, Russell TP, Facchetti A, McNei CR, Bredas JL, Briseno AL. Efficient naphthalenediimide-based hole semiconducting polymer with vinylene linkers between donor and acceptor units. Chem Mater. 2016;28:8580–90.

Marszalek T, Li M, Pisula W. Design directed self-assembly of donor–acceptor polymers. Chem Commun. 2016;52:10938–47.

Lee J, Kalin AJ, Yuan T, Al-Hashimi M, Fang L. Fully conjugated ladder polymers. Chem Sci. 2017;8:2503–21.

Huang H, Yang L, Facchetti A, Marks TJ. Organic and polymeric semiconductors enhanced by noncovalent conformational locks. Chem Rev. 2017;117:10291–318.

Lee T-H, Wu K-Y, Lin T-Y, Wu J-S, Wang C-L, Hsu C-S. Role of the comonomeric units in reaching linear backbone, high solid-state order and charge mobilities in heptacyclic arene-based alternating copolymers. Macromolecules. 2013;46:7687–95.

Mei J, Bao Z. Side chain engineering in solution-processable conjugated polymers. Chem Mater. 2014;26:604–15.

Balakrishnan K, Datar A, Naddo T, Huang J, Oitker R, Yen M, Zhao J, Zang L. Effect of side-chain substituents on self-assembly of perylene diimide molecules:morphology control. J Am Chem Soc. 2006;128:7390–8.

Schroeder BC, Kurosawa T, Fu T, Chiu Y-C, Mun J, Wang G-JN, Gu X, Shaw L, Kneller JWE, Kreouzis T, Toney MF, Bao Z. Taming charge transport in semiconducting polymers with branched alkyl side chains. Adv Funct Mater. 2017;27:1701973.

Kang I, Yun H-J, Chung DS, Kwon S-K, Kim Y-H. Record high hole mobility in polymer semiconductors via side-chain engineering. J Am Chem Soc. 2013;135:14896–9.

Yao J, Yu C, Liu Z, Luo H, Yang Y, Zhang G, Zhang D. Significant improvement of semiconducting performance of the diketopyrrolopyrrole–quaterthiophene conjugated polymer through side-chain engineering via hydrogen-bonding. J Am Chem Soc. 2016;138:173–85.

Kang B, Kim R, Lee SB, Kwon S-K, Kim Y-H, Cho K. Side-chain-induced rigid backbone organization of polymer semiconductors through semifluoroalkyl side chains. J Am Chem Soc. 2016;138:3679–86.

Tsao HN, Cho DM, Park I, Hansen MR, Mavrinskiy A, Yoon DY, Graf R, Pisula W, Spiess HW, Müllen K. Ultrahigh mobility in polymer field-effect transistors by design. J Am Chem Soc. 2011;133:2605–12.

Schroeder BC, Li Z, Brady MA, Faria GC, Ashraf RS, Takacs CJ, Cowart JS, Duong DT, Chiu KH, Tan C-H, Cabral JT, Salleo A, Chabinyc ML, Durrant JR, McCulloch I. Enhancing fullerene-based solar cell lifetimes by addition of a fullerene dumbbell. Angew Chem Int Ed. 2014;53:12870–5.

Gasperini A, Jeanbourquin XA, Rahmanudin A, Yu X, Sivula K. Enhancing the thermal stability of solution-processed small-molecule semiconductor thin films using a flexible linker approach. Adv Mater. 2015;27:5541–6.

Liang Z, Cormier RA, Nardes AM, Gregg BA. Developing perylene diimide based acceptor polymers for organic photovoltaics. Synth Met. 2011;161:1014–21.

Xiang X, Shao W, Liang L, Chen X-Q, Zhao F-G, Lu Z, Wang W, Li J, Li W-S. Photovoltaic poly(rod-coil) polymers based on benzodithiophene-centred A–D–A type conjugated segments and dicarboxylate-linked alkyl non-conjugated segments. RSC Adv. 2016;6:23300–9.

Ding L, Li H-B, Lei T, Ying H-Z, Wang R-B, Zhou Y, Su Z-M, Pei J. Alkylene-chain effect on microwire growth and crystal packing of π-moieties. Chem Mater. 2012;24:1944–9.

Lin X, Hirono M, Seki T, Kurata H, Karatsu T, Kitamura A, Kuzuhara D, Yamada H, Ohba T, Saeki A, Seki S, Yagai S. Covalent modular approach for dimension-controlled self-organization of perylene bisimide dyes. Chem Eur J. 2013;19:6561–5.

Gasperini A, Bivaud S, Sivula K. Controlling conjugated polymer morphology and charge carrier transport with a flexible-linker approach. Chem Sci. 2014;5:4922–7.

Shao W, Liang L, Xiang X, Li H-J, Zhao F-G, Li W-S. Changing to poly(rod-coil) polymers: a promising way for an optoelectronic compound to improve its film formation. Chin J Chem. 2015;33:847–51.

Schroeder BC, Chiu Y-C, Gu X, Zhou Y, Xu J, Lopez J, Lu C, Toney MF, Bao Z. Non-conjugated flexible linkers in semiconductingpolymers: a pathway to improved processability without compromising device performance. Adv Electron Mater. 2016;2:1600104.

Zhao Y, Zhao X, Zang Y, Di C-A, Diao Y, Mei J. Conjugation-break spacers in semiconducting polymers: impact on polymer processability and charge transport properties. Macromolecules. 2015;48:2048–53.

Zhao X, Zhao Y, Ge Q, Butrouna K, Diao Y, Graham KR, Mei J. Complementary semiconducting polymer blends: the influence of conjugation-break spacer length in matrix polymers. Macromolecules. 2016;49:2601–8.

Zhao Y, Zhao X, Roders M, Gumyusenge A, Ayzner AL, Mei J. Melt-processing of complementary semiconducting polymer blends for high performance organic transistors. Adv Mater. 2017;29:1605056.

Erdmann T, Fabiano S, Milián-Medina B, Hanifi D, Chen Z, Berggren M, Gierschner J, Salleo A, Kiriy A, Voit B, Facchetti A. Naphthalenediimide polymers with finely tuned in-chain π-conjugation: electronic structure, film microstructure, and charge transport properties. Adv Mater. 2016;28:9169–74.

Oh JY, Rondeau-Gagné S, Chiu Y-C, Chortos A, Lissel F, Wang G-JN, Schroeder BC, Kurosawa T, Lopez J, Katsumata T, Xu J, Zhu C, Gu X, Bae W-G, Kim Y, Jin L, Chung JW, Tok JBH, Bao Z. Intrinsically stretchable and healable semiconducting polymer for organic transistors. Nature. 2016;539:411.

Noël C, Navard P. Liquid crystal polymers. Prog Polym Sci. 1991;16:55–110.

Chung TS. The recent developments of thermotropic liquid crystalline polymers. Polym Eng Sci. 1986;26:901–19.

Sokolik I, Yang Z, Karasz FE, Morton DC. Blue‐light electroluminescence from p‐phenylene vinylene‐based copolymers. J Appl Phys. 1993;74:3584–6.

Padmanaban G, Ramakrishnan S. Conjugation length control in soluble poly[2-methoxy-5-((2′-ethylhexyl)oxy)-1,4-phenylenevinylene] (MEHPPV): synthesis, optical properties, and energy transfer. J Am Chem Soc. 2000;122:2244–51.

Martens HCF, Blom PWM, Schoo HFM. Comparative study of hole transport in poly(p-phenylene vinylene) derivatives. Phys Rev B. 2000;61:7489–93.

Hu D, Yu J, Padmanaban G, Ramakrishnan S, Barbara PF. Spatial confinement of exciton transfer and the role of conformational order in organic nanoparticles. Nano Lett. 2002;2:1121–4.

Bounos G, Ghosh S, Lee AK, Plunkett KN, DuBay KH, Bolinger JC, Zhang R, Friesner RA, Nuckolls C, Reichman DR, Barbara PF. Controlling chain conformation in conjugated polymers using defect inclusion strategies. J Am Chem Soc. 2011;133:10155–60.

Zhu X, Traub MC, Vanden Bout DA, Plunkett KN. Well-defined alternating copolymers of oligo(phenylenevinylene)s and flexible chains. Macromolecules. 2012;45:5051–7.

Traub MC, DuBay KH, Ingle SE, Zhu X, Plunkett KN, Reichman DR, Vanden Bout DA. Chromophore-controlled self-assembly of highly ordered polymer nanostructures. J Phys Chem Lett. 2013;4:2520–4.

Gasperini A, Sivula K. Effects of molecular weight on microstructure and carrier transport in a semicrystalline poly(thieno)thiophene. Macromolecules. 2013;46:9349–58.

Zhang X, Bronstein H, Kronemeijer AJ, Smith J, Kim Y, Kline RJ, Richter LJ, Anthopoulos TD, Sirringhaus H, Song K, Heeney M, Zhang W, McCulloch I, DeLongchamp DM. Molecular origin of high field-effect mobility in an indacenodithiophene–benzothiadiazole copolymer. Nat Commun. 2013;4:2238.

Sciascia C, Martino N, Schuettfort T, Watts B, Grancini G, Antognazza MR, Zavelani-Rossi M, McNeill CR, Caironi M. Sub-Micrometer charge modulation microscopy of a high mobility polymeric n-channel field-effect transistor. Adv Mater. 2011;23:5086–90.

Kronemeijer AJ, Gili E, Shahid M, Rivnay J, Salleo A, Heeney M, Sirringhaus H. A selenophene-based low-bandgap donor–acceptor polymer leading to fast ambipolar logic. Adv Mater. 2012;24:1558–65.

Beiley ZM, Hoke ET, Noriega R, Dacuña J, Burkhard GF, Bartelt JA, Salleo A, Toney MF, McGehee MD. Morphology-dependent trap formation in high performance polymer bulk heterojunction solar cells. Adv Energy Mater. 2011;1:954–62.

Steyrleuthner R, Schubert M, Howard I, Klaumünzer B, Schilling K, Chen Z, Saalfrank P, Laquai F, Facchetti A, Neher D. Aggregation in a high-mobility n-type low-bandgap copolymer with implications on semicrystalline morphology. J Am Chem Soc. 2012;134:18303–17.

Pasveer WF, Cottaar J, Tanase C, Coehoorn R, Bobbert PA, Blom PWM, de Leeuw DM, Michels MAJ. Unified description of charge-carrier mobilities in disordered semiconducting polymers. Phys Rev Lett. 2005;94:206601.

Collins SD, Ran NA, Heiber MC, Nguyen TQ. Small is powerful: recent progress in solution-processed small molecule solar cells. Adv Energy Mater. 2017;7:1602242–n/a.

Li H-J, Wang J-T, Mei C-Y, Li W-S. A new class of organic photovoltaic materials: poly(rod-coil) polymers having alternative conjugated and non-conjugated segments. Chem Commun. 2014;50:7720–2.

Jeanbourquin XA, Rahmanudin A, Gasperini A, Ripaud E, Yu X, Johnson M, Guijarro N, Sivula K. Engineering the self-assembly of diketopyrrolopyrrole-based molecular semiconductors via an aliphatic linker strategy. J Mater Chem A. 2017;5:10526–36.

Schroeder BC, Li Z, Brady MA, Faria GC, Ashraf RS, Takacs CJ, Cowart JS, Duong DT, Chiu KH, Tan C-H, Cabral JT, Salleo A, Chabinyc ML, Durrant JR, McCulloch I. Enhancing fullerene-based solar cell lifetimes by addition of a fullerene dumbbell. Angew Chem Int Ed. 2014;53:12870–5.

Lee DH, Lee JH, Kim HJ, Choi S, Park GE, Cho MJ, Choi DH. (D)n-[sigma]-(A)m type partially conjugated block copolymer and its performance in single-component polymer solar cells. J Mater Chem A. 2017;5:9745–51.

Lombeck F, Sepe A, Thomann R, Friend RH, Sommer M. Compatibilization of all-conjugated polymer blends for organic photovoltaics. ACS Nano. 2016;10:8087–96.

Lombeck F, Komber H, Sepe A, Friend RH, Sommer M. Enhancing phase separation and photovoltaic performance of all-conjugated donor–acceptor block copolymers with semifluorinated alkyl side chains. Macromolecules. 2015;48:7851–60.

Rahmanudin A, Jeanbourquin XA, Hänni S, Sekar A, Ripaud E, Yao L, Sivula K. Morphology stabilization strategies for small-molecule bulk heterojunction photovoltaics. J Mater Chem A. 2017;5:17517–24.

Koch FPV, Rivnay J, Foster S, Müller C, Downing JM, Buchaca-Domingo E, Westacott P, Yu L, Yuan M, Baklar M, Fei Z, Luscombe C, McLachlan MA, Heeney M, Rumbles G, Silva C, Salleo A, Nelson J, Smith P, Stingelin N. The impact of molecular weight on microstructure and charge transport in semicrystalline polymer semiconductors–poly(3-hexylthiophene), a model study. Prog Polym Sci. 2013;38:1978–89.

Zhao K, Khan HU, Li R, Su Y, Amassian A. Entanglement of conjugated polymer chains influences molecular self-assembly and carrier transport. Adv Funct Mater. 2013;23:6024–35.

John M, Dealy JW. Melt rheology and its applications in the plastics industry. 2 ed. Netherlands: Springer; 2013.

Savagatrup S, Zhao X, Chan E, Mei J, Lipomi DJ. Effect of broken conjugation on the stretchability of semiconducting polymers. Macromol Rapid Commun. 2016;37:1623–8.

Wang GJN, Gasperini A, Bao Z. Stretchable polymer semiconductors for plastic electronics. Adv Electron Mater. 2018;4:1700429.

Acknowledgements

We thank the European Research Commission (ERC starting grant “CEMOS” Project 336506) and the Swiss National Science Foundation (200021_169215) for financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Rahmanudin, A., Yao, L. & Sivula, K. Conjugation break spacers and flexible linkers as tools to engineer the properties of semiconducting polymers. Polym J 50, 725–736 (2018). https://doi.org/10.1038/s41428-018-0069-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-018-0069-z