Abstract

The atom transfer radical polymerization (ATRPs) of para-substituted styrenes bearing nitro, cyano, acetoxy, acetoxymethyl, and methoxy groups were performed to elucidate the effects of these substituents in terms of the Hammett equation. 4-Cyanostyrene (4CS) polymerized rapidly in acrylonitrile at 80 °C and afforded polymers with a narrow molecular weight distribution, while the ATRP of 4-acetoxystyrene (4AS) proceeded very slowly and gave the corresponding polymer in a low yield. The apparent polymerization rate constants (kpapp) of 4CS and 4-acetoxymethyl styrene were consistent with the Hammett equation with ρ = 1.52; however, the rate constant for the polymerization of 4AS did not follow the Hammett relation. The polymerization rate of 4AS was increased by the addition of 1,1,1,3,3,3-hexafluoro-2-propanol (HFIP); however, the NMR and MALDI-TOF-MS spectra of the resulting polymer revealed that a chain transfer radical polymerization took place to give a polymer with relatively low molecular weight. On the other hand, 4-methoxystyrene was immediately polymerized in 2,2,2-trifluoroethanol (TFE) and pentafluorophenol (PFP) by a cationic mechanism because of the electron-donating methoxy group, whereas 4AS did not polymerize in TFE and PFP. The deviant and irregular polymerization behavior of 4AS has been discussed in comparison with the reactivities of various para-substituted styrenes bearing electron-withdrawing and electron-donating groups.

Similar content being viewed by others

Introduction

Poly(4-hydroxystyrene) (poly(4HS)) is one of the most interesting substituted polystyrenes because of its various applications, including as a resin for deep-ultraviolet resistant materials [1] and in gate dielectric layers of organic thin-film transistors [2, 3], and when combined with poly(4-vinylpyridine), it offers unique repeatable adhesion [4]. Poly(4HS) cannot be obtained directly from 4HS because the phenolic OH group usually terminates radical and anionic polymerizations. Therefore, protected monomers, such as silyl-protected 4HS [5] and 4-acetoxystyrene (4AS), are polymerized first, and the resulting precursor polymers are converted to poly(4HS) by hydrolysis. The controlled radical polymerization of 4AS has been achieved by Barclay et al. [6]; the 2,2,6,6-tetramethyl-1-piperidinyloxy (TEMPO)-mediated free radical bulk polymerization of 4AS at 130 °C for 30 h produced the desired polymer with a unimodal molecular weight distribution (MWD) (Mw/Mn = 1.31), where Mn and Mw are the number-average and weight-average molecular weights, respectively. The reversible addition-fragmentation chain-transfer (RAFT) process using a benzyl dithiobenzoate derivative as a chain-transfer agent was also applied to the bulk and emulsion polymerizations of 4AS at 70–90 °C to give the polymer with a predictable Mn (Mn = 10,000) and narrow MWD (Mw/Mn = 1.12) [7]; however, the monomer conversion was less than 45%. Atom transfer radical polymerization (ATRP) reactions using a copper catalyst are well-known, controlled radical polymerizations; the undesired coupling termination and radical transfer reactions are regulated to give a well-defined polymer with a narrow MWD. Gao et al. conducted bulk ATRP reactions of 4AS using p-dibromoxylene as an initiator in the presence of CuBr and bipyridyl (bpy) at 90 °C to give a polymer with a relatively narrow MWD (Mw/Mn = 1.11–1.18) [8, 9]. The apparent rate constant of the polymerization (kpapp) of 4AS was estimated to be 10–6 mol–1 L s–1 by the first order plot, and this rate constant was lower than that of unsubstituted styrene (St). At higher monomer conversions (~70%), the first-order plot deviated from linearity because of the physical effects of the high viscosity of the bulk polymerization reaction mixture. Although solution polymerization might generate a reaction mixture with a lower viscosity, dilution of the monomer with a solvent usually further slows the radical polymerization and decreases the yield.

It has been reported that the ATRP reactions of para-substituted Sts with electron-withdrawing groups (EWGs), such as CF3 and halo groups, shows better control and faster polymerization rates than those of para-functionalized Sts with electron-donating groups (EDGs), such as methyl, tert-butyl, and methoxy groups, because the EWG substituents increase the reactivity of the monomer and decrease the stability of the dormant species [10]. EDGs increase the dissociation energy of the carbon-halogen bond at the propagating chain end of styrene, shifting the equilibrium of the ATRP toward the dormant species, decreasing the rate constant of propagation (kp), and slowing polymerization. Therefore, the ATRP of EDG-substituted Sts, such as 4-methoxystyrene (4MS), hardly proceeds as a result of extremely slow propagation. In the case of free radical polymerizations, EDG-substituted Sts also show slower polymerization rates than the analogous EWG-substituted Sts [11]. The proportional relationships between the Hammett substituent parameter (σp) and the radical polymerizability of the para-substituted St have been studied for a long time [12, 13]. In general, an acetoxy group is a weak EWG because of its positive Hammett parameter (σp = 0.31). However, the ATRP reaction of 4AS is unexpectedly slow, and it resembles the polymerization of a ST with a para EDG. On the other hand, the living cationic polymerization of 4AS proceeds in the presence of SnCl4 in dichloromethane (CH2Cl2) at 0 °C to give the polymer with a very narrow MWD [14, 15]. However, it takes 120 h to achieve 90% conversion, because of the slow propagation rate of the polymerization of 4AS, whereas the cationic polymerization of 4MS is complete within 20 s [16]. This result is reasonable because EWGs on vinyl monomers, such as 4AS and 4-chlorostyrene, are unfavorable for cationic polymerization.

The problem is that the propagation rates of 4AS and EDG-substituted Sts are too slow to achieve quantitative polymerization. Accelerating the propagation rate by using an appropriate solvent for ATRP would be an important advance in this field. The value of KATRP (ratio of the rate constants of activation (kact) and reverse reaction (kdeact) = kact/kdeact) depends on the hydrogen bond donating ability of the solvent, the acceptor ability, the polarizability parameter, and the Hildebrand solubility parameter, which is the linear solvation energy relationship described by the Kamlet–Taft expression [17]. A polar solvent can effectively increase the KATRP and polymerization rate; however, water and methanol are poor solvents for poly(St) derivatives. Direct activation of the monomer to increase it reactivity would be necessary to improve the ATRP of EDG-substituted styrenes.

Fluoroalcohols have been used for the stereospecific radical polymerization of polar monomers, such as acrylamide derivatives and methacrylates. Okamoto et al. performed the free-radical polymerization of methyl methacrylate (MMA) in the presence of 2,2,2-trifluoroethenol (TFE) and 1,1,1,3,3,3-hexafluoro-2-propanol (HFIP) at –40 °C to produce a syndiotactic-rich polymer as a result of hydrogen-bonding interactions between MMA and the fluoroalcohols [18]. A bimodal molecular weight and controlled tacticity were achieved by the ATRP of MMA in the presence of a fluoroalcohol [19]. Interestingly, the effect of HFIP as an additive was also observed in the radical polymerization of unconjugated monomers, such as N-vinylpyrrolidone [20] and vinyl acetate (VAc) [21], because of the coordination of the fluoroalcohol to the monomers. Iodine-transfer radical polymerizations of VAc in fluoroalcohols allowed simultaneous control of the molecular weight and stereospecificity [22]. Lewis acids, such as Y(OTf)3 and Sc(OTf)3, have been shown to have a significant effect on the reactivity of N-isopropylacrylamide (NIPAM) in radical polymerizations by the coordination of the Lewis acid to the monomer [23, 24]. NIPAM monomers also form complexes with Lewis bases, such as hexamethylphosphoramide and triisopropyl phosphate, through hydrogen bonding, leading to stereospecific free radical polymerizations [25, 26].

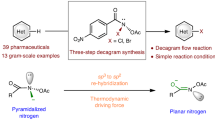

Considering these effects of fluoroalcohols and Lewis acids on radical polymerizations of polar monomers, a similar coordination to acetoxy- or alkoxy-substituted styrene monomers could also be expected. In this work, the ATRP reactions of 4AS, 4-methoxystyrene (4MS), and 4-acetoxymethylstyrene (4AMS) were performed in the presence of fluoroalcohols, such as HFIP, TFE, and pentafluorophenol (PHP), and Sc(OTf)3 as additives to assess whether intermolecular interactions between the para-substituent of the St and the additive could reduce the electron-donating ability of the monomer and accelerate the polymerization. In addition, the ATRP of EWG-substituted Sts such as 4-cyanostyrene (4CS) and 4-nitrostyrene (4NS) (Fig. 1) were also carried out in acetonitrile (AcCN) as control experiments to elucidate the effect of para-substituents on the polymerization rate in terms of the Hammett relationship.

Experimental procedures

Materials

Copper (I) bromide (CuBr, Wako Pure Chemicals, 99.9%) was purified through successive washes with acetic acid and ethanol and then dried under vacuum. Ethyl 2-bromoisobutyrate (EB, Tokyo Chemical Industry (TCI), 98%) was dried and distilled over calcium hydride (CaH2) before use. Commercially available CaH2 (Nacalai Tesque, Tokyo), azobisisobutyronitrile (AIBN, TCI), and sodium hydroxide (NaOH, Kishida Chemical Co.) were used as received without additional purification. AcCN (Kanto Chemical Co.) was purified by distillation over CaH2 under a nitrogen atmosphere. N,N,N′,N″,N″-Pentamethyl- diethylenetriamine (PMDETA) was purchased from Aldrich and used without further purification. Methanol, tetrahydrofuran (THF), phenol, pentafluorophenol (PFP), and sodium hydrogen carbonate (NaHCO3) were purchased from Wako Pure Chemicals and used as received. 2,2′-Bipyridyl (bpy, Wako Pure Chemicals, 99.5%) and N,N-dimethylformamide (DMF, Kanto Chemical Co., 99.7%) were used as received. 4AS (Aldrich, 96%) was purified by distillation from CaH2 under reduced pressure. 4AMS was synthesized by the reaction of 4-chloromethylstyrene and sodium acetate in DMSO at 45 °C. 4NS, 4MS, and 4-cyanostyrene (4CS) [27] were synthesized by the Wittig reaction of 4-benzaldehyde derivatives followed by the appropriate transformations (Supporting Information, S1).

Polymerization of styrene derivatives

A well-dried glass tube fitted with a stopcock was charged with the monomeric styrene derivative (3–6 mmol) and 0.20 mL of EB in AcCN (0.10 M), and the solution was degassed by three freeze-pump-thaw cycles. CuBr (0.080 mmol), PMDETA (0.080 mmol), and AcCN (2.4 mL) were introduced into another glass tube that was fitted with a stopcock, and the mixture was degassed by the freeze-pump-thaw method to give a green solution. After a portion of the copper catalyst solution was added to the monomer solution, the reaction mixture was degassed again by three freeze-pump-thaw cycles and then stirred in an oil bath at 80 °C under argon. The reaction was terminated by exposing the mixture to air at 0 °C. The reaction mixture was poured into methanol to precipitate the polymer and unreacted monomer.

Polymerization of 4AS and 4MS in the presence of fluoroalcohol

A well-dried glass tube fitted with a stopcock was charged with CuBr (0.080 mmol), bpy (0.080 mmol), HFIP, EB in HFIP (0.20 M), and 4AS (6.54 mmol), and the mixture was degassed by three freeze-pump-thaw cycles. Subsequently, the reaction mixture was stirred in an oil bath under argon. The reaction was terminated by opening the glass vessel and exposing the contents to air at 0 °C. The reaction mixture was poured into methanol to precipitate the polymer and unreacted monomer.

Polymerization of 4AS and 4MS in the presence of phenol

A well-dried glass tube fitted with a stopcock was charged with CuBr (0.040 mmol), bpy (0.040 mmol), EB in AcCN (0.10 M), 4AS (3.27 mmol), and PFP in AcCN (6.6 M), and the mixture was degassed by three freeze-pump-thaw cycles. The reaction mixture was stirred in an oil bath under argon. Eventually, the reaction was stopped by exposing the contents of the glass vessel to air at 0 °C. The reaction mixture was poured into methanol to precipitate the polymer and unreacted monomer.

Characterization

1H NMR spectra were obtained using a Jeol ECX 400 spectrometer at 298 K with tetramethylsilane as the reference and either deuterated chloroform or methanol-d4 as the solvent. The number-average molecular weight (Mn) and MWD were determined by size-exclusion chromatography (SEC) of poly(4AS) and polystyrene (PS) using an HLC-8120 system (Tosoh Co., Ltd.) equipped with three directly connected PS gel columns (TSKgel G5000HXL and two G3000HXL columns) and a refractive index (RI) detector with THF as the eluent at a flow rate of 1.0 mL min−1 at 313 K. Calibration curves were prepared using a series of PS standards. The SEC of poly(4CS) was determined using a PU-980 system (Jasco Co., Tokyo) equipped with three directly connected polystyrene gel columns (two TSKgel ALPHA-3000 columns) and an RI detector with DMF containing 0.05 M LiBr as the eluent at a flow rate of 0.5 mL min−1 at 313 K. Calibration curves for this set of experiments were prepared using a series of PS standards. Matrix-assisted laser desorption/ionization time-of-flight mass spectrometry (MALDI-TOF-MS) experiments were performed on an Autoflex II (Bruker) spectrometer in positive linear mode operating at an ion acceleration voltage of 20 kV with a 355-nm nitrogen laser. Dithranol was used as the matrix. The polymer, dithranol, and sodium trifluoroacetate (NaTFA) were dissolved in THF at a concentration of 10 mg/mL. The MALDI sample was prepared by mixing 2 μL of the NaTFA solution, 10 μL of the dithranol solution, and 1 μL of the polymer solution in that order. A 2-μL aliquot of the mixed solution was then deposited on the target and air-dried.

Results and discussion

A series of para-substituted styrenes were polymerized by ATRP to assess the effects of functional groups on the polymerization rate. In this work, the ATRPs of Sts bearing nitro (NO2), cyano (CN), acetoxy (OAc), methoxy (OMe), and acetoxymethyl groups at the para position were carried out in acetonitrile at 80 °C and initiated with an alkyl bromide initiator (EB) in the presence of CuBr/PMDETA as the catalyst, as shown in Table 1. The ATRP of 4AS was homogeneous and proceeded very slowly at 80 °C, taking 72 h to generate the polymer in 17% yield (run 2). The Mn of the obtained poly(4AS) was 11,500 (g mol–1), which was much larger than the theoretical value calculated based on the yield and feed ratio of the monomer and EB; this result is probably due to low initiator efficiency. Gao et al. reported that the bulk ATRP of neat 4AS at 90 °C afforded the desired polymer with a predictable Mn in quantitative yield [8, 9], while in the present case, the ATRP of 4AS in acrylonitrile proceeded in an uncontrolled manner and gave a low yield of a polymer with a rather broad MWD (Mw/Mn = 1.66), as shown in Fig. 2. No polymer was obtained in the ATRP of methoxy-substituted St even after 72 h (run 3), indicating that the EDG-substituted St was hardly polymerized by conventional ATRP. The ATRP of 4AMS proceeded at 80 °C to provide the polymer in a 47% yield within 24 h (run 4).

In the case of EWG-substituted styrenes, the polymerizations proceeded very quickly. The ATRP of 4CS occurred smoothly at 80 °C and gave 34% yield within 1 h (run 5). The obtained poly(4CS) had a narrow MWD (Mw/Mn = 1.19) and a reasonable Mn (10,500 g mol–1), which agreed well with the theoretical Mn. The first-order plot for the ATRP of 4CS showed a linear increase with reaction time (Fig. 3), which suggested that the polymerization of 4CS proceeded in a controlled manner. Nitro-substituted styrene was also polymerized by the ATRP catalyst, although the MWD of the obtained polymer was rather broad (run 6) because of its low solubility. Poly(4NS) is soluble in DMF and N,N-dimethylacetoamide but is insoluble in water, methanol, 2-propanol, AcCN, THF, chloroform, toluene, and hexane. Therefore, the reaction mixture became turbid as a result of the precipitation of poly(4NS) as the conversion increased. It is likely that the heterogeneous mixture led to the broad MWD.

Figure 3 shows the first-order plots for the ATRPs of St, 4CS, and 4AS in AcCN at 80 °C. The kpapp of 4CS was estimated to be 6.7 × 10–3 mol–1 L s–1 by the slope of the first-order plot, whereas the kpapp values of 4AS and St were 6.1 × 10–5 and 6.1 × 10–4 mol–1 L s–1, respectively. Obviously, the polymerization of 4CS proceeded much faster than that of 4AS. The cyano group at the para position favored the dissociation of the C–Br bond at the propagating end owing to its electron-withdrawing effect, leading to the formation of the active species in the ATRP system, which resulted in rapid polymerization. The temperature dependence of the rate of the polymerization was also studied to estimate the activation energy. These details and the kinetics plots are provided in Table S1 and Figure S1. The values of kpapp for the ATRP of St at 100, 80, and 60 °C were 1.3 × 10–3, 6.1 × 10–4, and 1.8 × 10–4 mol–1 L s–1, respectively. Furthermore, the kpapp values of the ATRP of 4CS at 80, 60, and 40 °C were 6.7 × 10–3, 3.2 × 10–3, and 4.9 × 10–4 mol–1 L s–1, respectively. From the Arrhenius plots shown in Figure S2, the apparent activation energy for the ATRP of St was estimated to be 51.2 kJ mol–1, which is close to the literature value (49.8 kJ mol–1) [28]. A slightly lower activation energy, 43.6 kJ mol–1, was observed for the ATRP of 4CS, probably because of the low activation enthalpy for the propagation of the St monomer bearing an EWG at the para position.

The apparent rate constants for the monomers are summarized in Table 2. The monomers with EWG substituents polymerized faster than St in the order 4CS > 4NS > 4AMS > St. This trend is in good agreement with previous reports. For example, Qiu et al. conducted the ATRP of various para-substituted Sts using 1-phenylethyl bromide as the initiator and CuBr/bpy as the catalyst in diphenyl ether at 110 °C and found that the EWG-substituted Sts polymerized faster than the EDG-substituted Sts in the order trifluoromethyl (CF3)>Br, Cl>F, H>methoxy (OMe)>methyl (Me)>tert-butyl (tBu) [10]. The kpapp values for the ATRP reactions of meta-substituted Sts were also investigated. As early as 1965, Imoto et al. reported that conventional, bulk free-radical polymerizations of para-EWG-substituted Sts at 30 °C showed polymerization rates in the order cyano (CN)>Br>Cl>F>H>Me>OMe [11]. A similar trend was confirmed by pulse laser polymerization measurements at 20–40 °C [13]. In the case of nitroxy-mediated polymerizations using TEMPO and benzoyl peroxide at 130 °C, St derivatives with chloromethyl (CH2Cl) and Cl substituents at the para position polymerized much faster than St derivatives with F, H, and OMe substituents. These substituent effects on the polymerizations of St derivatives have been described in many studies [29] by the Hammett relationship with respect to log(kpX/kpH), in which kpX and kpH are the propagation rate constants of substituted St and unsubstituted St, respectively. In this study, the apparent polymerization rate (kpapp) of the ATRP of para-substituted St and St were associated with kpX and kpH, respectively, to prepare a correlation chart for the Hammett parameter (σp), as shown in Fig. 4. This is the first report of the kinetic data of the ATRP reactions of 4CS, 4NS, and 4AMS.

Hammett relation plots for ln(kpX/kpH) of the ATRP of para-substituted styrenes (including St) initiated with EB using CuBr/PMDETA in acetonitrile at 80 °C. The kpX and kpH are the apparent rate constants of the polymerization of X-substituted St and unsubstituted St, respectively. The kpapp value for the ATRP of St in Table 2 was used as the kpH

In principle, electron-withdrawing substituents have larger Hammett parameters than electron-donating substituents in the order NO2 (σp = 0.78)>CN (σp = 0.66)>acetoxy (σp = 0.31)>acetoxymethyl (σp = 0.05) >OMe (σp = −0.27) [30, 31]. A proportional relationship was observed for 4CS, 4AMS, and St (Fig. 4). The reaction constant, ρ, as defined by the Hammett equation log(kpX/kpH) = ρ σp, was 1.52, which was consistent with previously obtained values [10]. The Hammett plot of 4NS was located below the linear relationship of the ATRP, whereas 4NS polymerized much faster than St and 4AMS, as expected based on its large Hammett parameter from the strong electron-withdrawing effect of NO2. According to a previous study [11], the ρ value for the free radical polymerization of substituted Sts is ~0.6, which is much lower than that for ATRP reactions. The polymerization of 4NS in AcCN was heterogeneous due to the poor solubility of poly(4NS), which precipitated out of solution. Therefore, the polymerization of 4NS might proceed in an uncontrolled manner even though an ATRP catalyst was used, resulting in a kpX/kpH value that falls below the line fit to 4CS, 4AMS and St based on the Hammett equation. The most irregular and intriguing plot in Fig. 4 is that of 4AS, which is located far from the expected Hammett relationship for both systems for controlled and free-radical polymerizations. The acetoxy substituent is a weak EWG, corresponding to a positive Hammett parameter; however, 4AS revealed an extremely low kpapp compared to that of St, and its polymerization behavior resembled that of an EDG-substituted St. This result indicated that 4AS likely has an intriguing reactivity in radical polymerizations.

To enhance the polymerization rate of the EDG-substituted monomer, the ATRP was carried out in fluoroalcohols and phenols, which are expected to form hydrogen bonds with the acetoxy or methoxy groups of the monomers. As shown in Table 3, all ATRPs were performed with bpy as the ligand instead of PMDETA because PMDETA reacts with fluoroalcohols to form an ammonium salt during the polymerization. 4AS did not polymerize in AcCN at 50 °C (run 7). In contrast, 4AS polymerized in the presence of HFIP, although the yield was only 4% (run 8). As the amount of HFIP in the ATRP was increased from 0.69 mL to 1.72 mL, the yield of poly(4AS) increased significantly from 4 to 71% (runs 8–14). However, the Mn of the obtained polymer was much lower than the theoretical Mn calculated from the yield and feed molar ratio of the monomer and EB. The observed Mn did not increase with the polymer yield, suggesting a chain transfer reaction or the generation of additional initiator species.

Figure 5 shows the 1H NMR spectrum of poly(4AS) obtained by the polymerization in HFIP. The intensity of the signal at 4.2–4.3 ppm corresponding to the methylene group of EB was very low. The Mn of poly(4AS) (run 11) estimated by the ratio of the integrals of the methylene signal of EB and that of the phenyl group of the polymer at 6.9–7.5 ppm was 25,500 g mol–1, which was much larger than the Mn (6940 g mol–1) determined by SEC. We supposed that proton elimination would occur to initiate new polymers after EB-initiated polymerization of 4AS in HFIP. The HFIP itself does not serve as an initiator because no polymer was obtained by the polymerization in HFIP without EB (run 15) or the copper catalyst (run 16).

Three types of sequential peaks were observed in the MALDI-TOF-MS spectrum of the poly(4AS) obtained by the polymerization in HFIP, as shown in Fig. 6. Each interval corresponded to the mass of the 4AS monomer (m/z = 162.19). However, there were no peaks corresponding to the mass of the polymer produced via EB initiation and terminated by bromide. The sequential mass peak with the highest intensity (marked with a circle) was consistent with the mass of the sodiated poly(4AS) initiated by a proton. The second sequential peak (marked with a triangle) was consistent with the mass of sodiated poly(4AS) having an ethyl isobutyrate fragment. The third peak (marked with a square) corresponded to the mass of poly(4AS) with a hydrogen and an OH group. Considering the ratio of the integrals of the MALDI-TOF-MS peaks, the amount of poly(4AS) generated by EB was very small. A significant number of protons, produced mainly by chain-transfer reactions, initiated the polymerization of 4AS to provide the polymer with a lower Mn than the theoretical value (runs 13 and 14). The 1H NMR spectrum in Fig. 5 also supported this mechanism. Signals corresponding to the CH=CH bond formed by proton elimination were observed at 6.0 ppm. The peaks at 3.4 and 3.6 ppm were assigned to the penultimate methine of the olefin end. The peaks at 1.0 and 3.0 ppm were attributed to the methyl and penultimate methine, respectively, of the chain head.

MALDI-TOF-MS spectrum of poly(4AS) synthesized by polymerization in the presence of CuBr/bby catalyst in HFIP at 50 °C for 24 h. Sodium trifluoroacetate was used as the ion source. The triangle, circle, and square indicate the sequential peaks corresponding to the chemical structure shown above, respectively

Based on these spectroscopic data, the following polymerization mechanism was proposed. In the early stages of the polymerization, EB initiated radical polymerization by the homolytic dissociation of the C–Br bond in the presence of catalytic CuBr. Next, β-proton elimination or HBr elimination at the propagating chain end occurred in the presence of HFIP to produce an unsaturated C=C bond and HBr. Subsequent addition of HBr to the 4AS monomer formed an HBr adduct of 4AS, which initiated ATRP to produce additional polymers. Indeed, Matyjaszewski et al. observed the elimination of HBr from the PS chain end in the ATRP [32]. According to their model reactions using 1-phenylethylbromide (1-PEBr), the elimination of HBr from 1-PEBr to form St occurred spontaneously in a polar solvent in the presence of a Cu(I) catalyst via the oxidation of the radical species. Because the rate of this elimination reaction is very low, the effect of this reaction is usually negligible in ATRP reactions when the polymerization rate is sufficiently high. In the case of 4AS, however, the elimination reaction catalyzed by Cu(I) likely occurred during the extremely slow polymerization of 4AS even in polar solvents, such as AcCN and HFIP. We supposed that the elimination of HBr from the propagating poly(4AS) chain end induced chain-transfer polymerization to give polymers with low Mn values.

The molecular interactions between 4AS and HFIP were observed by NMR spectroscopy. As shown in Figure S3, the signal of the C=O carbon of 4AS in CDCl3 was clearly shifted from 169.60 to 170.25 ppm upon addition of HFIP. Furthermore, the β-carbon of 4AS at 114.18 ppm also shifted downfield to 114.32 ppm in the presence of HFIP. The center peak of the split signal of the methine CH(–OH) of HFIP also shifted slightly from 69.70 to 59.57 ppm upon mixing with 4AS. These shifts indicated that the significant attractive interactions between the C=O of 4AS and the OH of HFIP led to an electron-withdrawing effect and reduced the electron density on the vinyl group [33]. This effect favored the ATRP of 4AS and increased the rate of the radical polymerization. Therefore, poly(4AS) was obtained by polymerization in HFIP even at 30 °C (run 12). The Mn of the poly(4AS) produced at 30 °C in run 12 was larger than the theoretical values, probably because of the retardation of HBr elimination and low efficiency of the initiator at low temperatures.

No significant change in the tacticity was observed based on the 13C NMR signals of the aromatic quaternary carbon and methylene carbon of poly(4AS), as shown in Figure S4. The split signal pattern [34] suggested that a relatively syndiotactic rich polymer (mm/mr/rr = 0.06/0.36/0.58) was formed by the polymerizations in the presence and absence of HFIP. In addition, the tacticity of the poly(4AS) obtained by the ATRP process was the same as that of the polymer synthesized by free-radical polymerization with AIBN.

Due to its potential for much stronger molecular interactions, PFP was added to the monomer because PFP has greater acidity than HFIP based on their pKa values, which increase in the order of PFP (pKa = 5.50)<HFIP (9.3)<phenol (9.95)<TFE (12.5). However, no poly(4AS) was obtained in runs 17–21, probably because PFP and phenol functioned as radical inhibitors. The polymerization of 4AS in the presence of Sc(OTf)3 gave polymers with Mn values as large as 30,500 g mol−1 in 69% yield within 18 h (runs 22 and 23). In this case, however, the cationic polymerization of 4AS might be promoted rather than the radical polymerization, considering the strong Lewis acidity of Sc(OTf)3, much larger Mn and higher yield compared with those obtained by the ATRP in HFIP. Polymerization of 4AS might also occur via a cationic mechanism instead of ATRP because the living cationic polymerization of 4AS initiated by 1-phenylethyl chloride using SnCl4 has already been reported [14]. In addition, Kuznetsov et al. reported that HFIP activated benzaldehyde dimethyl acetal to initiate the cationic polymerization of St and indene [35, 36]. They also suggested that adventitious water could be the initiating species in HFIP. Another possibility was that the propagating radical species was oxidized to a carbocation by coexisting Cu(II) catalyst in a single-electron transfer process [37]. The one-electron oxidation of the propagating radical to the carbocation by a higher-valent transition metal complex has also been reported [38]. Therefore, the poly(4AS) with a hydrogen and an OH group at the chain ends, which is indicated by the mass spectrum in Fig. 6, might be produced via a cationic polymerization initiated by a proton formed from the β-proton elimination and terminated by the small amount of moisture remaining in the polymerization mixture. However, the cationic polymerization of 4AS was a minor process in this study, because the intensity of the mass peak of the OH-terminated poly(4AS) was very small compared with the other peaks in this sequence. The tacticity of the polymer (Figure S4) and negligible polymerization in the presence of a radical inhibitor (run 21) also suggested that 4AS was mainly polymerized via a radical mechanism in HFIP.

In the case of 4MS, cationic polymerization occurred in the presence of fluoroalcohols. No polymer was obtained by the normal ATRP of 4MS even at 100 °C (run 24), whereas the polymer was formed in 90% yield in the presence of HFIP at 50 °C after 8 h (run 25). In addition, the polymerization without EB in HFIP also gave poly(4MS) with a Mn value of 53,400 g mol–1 and a very broad MWD (run 26), indicating that HFIP acted as an initiator of the cationic polymerization of 4MS. Similar results were observed in the polymerization of 4MS using TFE (runs 27, 28), PFP (run 29), and phenol (run 30). The Mn values of the polymers obtained using EB were in the range of 2100–8530 g mol–1, which were much smaller than the theoretical value based on the feed ratio of [4MS]/[EB] and the yield. Therefore, chain transfer polymerization must occur very frequently during cationic polymerization. The MALDI-TOF-MS spectrum of the poly(4MS) prepared in the presence of PFP showed sequential mass peaks that mainly corresponded to the polymerization initiated by a proton and terminated by β-proton elimination, as shown in Figure S4. The MALDI-TOF-MS data could not be used to determine whether a Friedel–Crafts reaction had occurred because the m/z values of the poly(4MS) terminated by β-proton elimination and the Friedel–Crafts reaction were the same. A mass peak attributable to PHP-terminated poly(4MS) was also observed.

Conclusions

In this study, the irregular and intriguing polymerization behavior of 4AS in ATRP reactions has been described with regard to the Hammett relationship among 4NS, 4CS, 4AMS, St, and 4MS. The 4NS and 4CS monomers with typical EWGs at the para position showed much higher polymerization rates than that of unsubstituted St. In contrast, an extremely low polymerization rate was observed for 4AS in the ATRP using CuBr/PMDETA in AcCN at 80 °C, even though the acetoxy group is categorized as a weak EWG in terms of its Hammett value. To promote the radical polymerization of 4AS, HFIP was added to the polymerization system to improve the polymer yield. However, chain transfer radical polymerization involving the elimination of HBr from the propagating chain end occurred. In the initiation step, the molecular interactions of HFIP with 4AS enhanced the reactivity of the monomer toward the radical polymerization, but the elimination of HBr from the chain end generated the unsaturated bond. The HBr reacted with another monomer to form an HBr adduct, potentially initiating another ATRP of 4AS, increasing the polymer yield. On the other hand, 4MS was not polymerized by ATRP, but instead it was immediately polymerized via a cationic mechanism with HFIP and TFE because the electron-donating methoxy group likely stabilized the propagating cation. The effects of a para EDG on styrene on the polymerization rate and mechanism have been described.

References

MaKean DR, Hinsberg WD, Sauer TP, Willson G, Vicali R, Gordon DJ. Methylated poly(4-hydroxystyrene): a new resin for deep-ultraviolet resist application. J Vac Sci Tech B. 1990;8:1466–9.

Lim SC, Kim SH, Koo JB, Lee JH, Ku CH, Yang YS, et al. Hysteresis of pentacene thin-film transistors and inverters with cross-linked poly(4-vinyl phenol) gate dielectrics. Appl Phys Lett. 2007;90:173512.

Park J, Bae JH, Kim WH, Kim MH, Keum CM, Lee SD, et al. Effects of interfacial charge depletion in organic thin-film transistors with polymeric dielectrics on electrical stability. Materials . 2010;3:3614–24.

Yoshioka H, Izumi C, Shida M, Yamaguchi K, Kobayashi M. Repeatable adhesion by proton donor-acceptor interaction of polymer brushes. Polymer . 2017;119:167–75.

Hirao A, Yamaguchi K, Takenaka K, Suzuki K, Nakahama S, Yamazaki N. Polymerization of monomers containing functional groups protected by trialkylsilyl groups, 1. Synthesis of poly(4-vinylphenol) by means of anionic living polymerization. Makromol Chem Rapid Commun. 1982;3:941–6.

Barclay GG, Hawker CJ, Ito H, Orellana A, Malenfant PRL, Sinta RF. The “living” free radical synthesis of poly(4-hydroxystyrene): physical properties and dissolution behavior. Macromolecules . 1998;31:1024–31.

Kanagasabapathy S, Sudalai A, Benicewicz BC. Reversible addition-fragmentation chain-transfer polymerization for the synthesis of poly(4-acetoxystyrene) and poly(4-acetoxystyrene)-block-polystyrene by bulk, solution and emulsion techniques. Macromol Rapid Commun. 2001;22:1076–80.

Gao B, Chen X, Iván B, Kops J, Batsverg W. Living atom transfer radical polymerization of 4-acetoxystyrene. Macromol Rapid Commun. 1997;18:1095–100.

Gao B, Chen X, Iván B, Kops J, Batsverg W. Synthesis of triblock and random copolymers of 4-acetoxystyrene and styrene by living atom transfer radical polymerization. Polym Bull. 1997;39:559–65.

Qiu J, Matyjaszewski K. Polymerization of substituted styrenes by atom transfer radical polymerization. Macromolecules . 1997;30:5643–8.

Imoto M, Kinoshita M, Nishigaki M. Vinyl polymerization 93. polar effects in radical polymerization of p-substituted styrenes. Die Makromol Chem. 1965;86:217–30.

Kagita T, Sumida Y. Evaluation of Activation energy for additon reactions of radicals to vinyl compounds. Polym J. 1970;1:137–46.

Coote ML, Davis TP. Propagation kinetics of para-substituted styrenes: a test of the applicability of the hammett relationship to free-radical polymerization. Macromolecules . 1999;32:4290–8.

Ashida J, Yamamoto H, Yonezumi M, Kanaoka S, Aoshima S. Living cationic polymerization of various styrenes using SnCl4 in the presece of an added base. Polym Prepr Jpn. 2008;57:2380–1.

Shinke Y, Yamamoto H, Kanazawa A, Kanaoka S, Aoshima S. Precision synthesis of graft copolymers via living cationic polymerization of p-acetoxystyrene followed by Friedel-Crafts-type termination reaction. J Polym Sci Part A: Polym Chem. 2013;51:4675–83.

Aoshima S, Kanaoka S. A renaissance in living cationic polymerization. Chem Rev. 2009;109:5245–87.

Braunecker WA, Tsarevsky NV, Gennaro A, Matyjaszewski K. Thermodynamic components of the atom transfer radical polymerization equilibrium: quantifying solvent effects. Macromolecules . 2009;42:6348–60.

Isobe Y, Yamada K, Nakano T, Okamoto Y. Stereospecific free-radical polymerization of methacrylates using fluoroalcohols as solvents. Macromolecules . 1999;32:5979–81.

Miura Y, Satoh T, Narumi A, Nishizawa O, Okamoto Y, Kakuchi T. Atom transfer radical polymerization of methyl methacrylate in fluoroalcohol: simultaneous control of molecular weight and tacticity. Macromolecules . 2005;38:1041–3.

Wan D, Satoh K, Kamigaito M, Okamoto Y. Xanthate-mediated radical polymerization of N-vinylpyrrolidone in fluoroalcohols for simultaneous control of molecular weight and tacticity. Macromolecules . 2005;38:10397–405.

Nagara Y, Yamada K, Nakano T, Okamoto Y. Stereospecific polymerization of vinyl acetate in fluoroalcohols and synthesis of syndiotactic poly(vinyl alcohol). Polym J. 2001;33:534–9.

Koumura K, Satoh K, Kamigaito M, Okamoto Y. Iodine transfer radical polymerization of vinyl acetate in fluoroalcohols for simultaneous control of molecular weight, stereospecificity, and regiospecificity. Macromolecules . 2006;39:4054–61.

Isobe Y, Fujioka D, Habaue S, Okamoto Y. Efficient Lewis acid-catalyzed stereocontrolled radical polymerization of acrylamides. J Am Chem Soc. 2001;123:7180–1.

Ray B, Isobe Y, Morioka K, Habaue S, Okamoto Y, Kamigaito M, et al. Synthesis of isotactic poly(N-isopropylacrylamide) by RAFT polymerization in the presence of Lewis acid. Macromolecules . 2003;36:543–5.

Hirano T, Kitajima H, Ishii S, Seno M, T Sato T. Hydrogen-bond-assisted stereocontrol in the radical polymerization of N-isopropylacrylamide with secondary alkyl phosphate: The effect of the bulkiness of the ester group. J Polym Sci Part A Polym Chem. 2005;43:3899–908.

Hirano T, Kitajima H, Seno M, Sato T. Hydrogen-bond-assisted stereocontrol in the radical polymerization of N-isopropylacrylamide with bidentate Lewis base. Polymer . 2006;47:539–46.

Ishizone T, Hirao A, Nakamama S. Anionic polymerization of monomers containing functional groups. 2. Anionic living polymerization of 4-cyanostyrene. Macromolecules . 1991;24:625–6.

Matyjaszewski K, Patten TE, Xia J. Controlled/“Living” radical polymerization. Kinetics of the homogeneous atom transfer radical polymerization of styrene. J Am Chem Soc. 1997;119:674–80.

Ishizone T, Hirao A, Nakahama S. Anionic Polymerization of Monomers Containing Functional Groups. 6. Anionic Block Copolymerization of Styrene Derivatives Para-Substituted with Wlectron-Withdrawing Groups. Macromolecules. 1993;26:6964–75.

McDaniel DH, Brown HC. An extended table of hammett substituent constants based on the ionization of substituted benzoic acid. J Org Chem. 1958;23:420–7.

Hansch C, Leo A, Taft RW. A suvey of Hammett substituent constants and resonance and Field parameters. Chem Rev. 1991;91:165–95.

Matyjaszewski K, Davis K, Patten TE, Wei M. Observation and analysis of a slow termination process in the atom transfer radical polymerization of styrene. Tetrahedron . 1997;53:15321–9.

Craik DJ, Brownlee RTC. Substituent effects on chemical shifts in the sidechains of aromatic systems. Progress Phys Org Chem. 1983;14:1–73.

Randall JC. Polymer sequence determination carbon-13 NMR method. Academic Press; 1977. p. 87–92 and 116–9. New York

Kuznetsov DM, Tumanov VV, Smit WA. Acetal-induced cationic polymerization of styrene and indene in hexafluoropropanol. Mendeleev Commun. 2013;23:274–6.

Kuznetsov DM, Tumanov VV, Smit WA. Cationic polymerization of styrene and indene initiated by aryl acetals in hexafluoropropanol medium. J Polym Res. 2014;21:562.

Bengough WI, ONeill T. Effects of salts of metals on vinyl polymerization. Part 4. Polymerization of styrene in presence of cupric chloride. Trans Faraday Soc. 1968;64:1014–21.

Dass NN, George MH. Effects of iron(III) chloro-complexes in the polymerization of styrene—II. Retardation and Inhibition kinetics in dimethyl sulphoxide. Eur Polym J. 1971;7:1185–95.

Acknowledgements

MALDI-TOF-MS measurements were performed under the Cooperative Research Program (No. 20161265, 20171318, and 20181285) of the Network Joint Research Center for Materials and Devices, with Prof. Takahara at Kyushu University. This research was also supported by a Grant-in-Aid under the Japan Science Promotion Society (JSPS) KAKENHI Scientific Research C (No. 17K05887) from the Ministry of Education, Culture, Science, Sports and Technology of Japan (MEXT), and by the Biomolecules System Research Center (BMSC) program for Strategic Research at Private Universities (Kogakuin University) from MEXT.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Yoshioka, H., Yamaguchi, K. & Kobayashi, M. Deviant polymerization behavior of 4-acetoxystyrene found through a detailed study on the ATRP of para-substituted styrenes. Polym J 51, 627–636 (2019). https://doi.org/10.1038/s41428-019-0179-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-019-0179-2