Abstract

Crosslinked liquid-crystalline polymers (CLCPs) show macroscopic deformation along with a change in molecular order, which is triggered by various stimuli such as heat, electricity, and light. CLCPs containing photochromic moieties are realizable as photoresponsive soft actuators. This review focuses on recent developments in novel network structures of CLCPs: rearrangeable networks and interpenetrating polymer networks (IPNs). CLCPs with dynamic covalent bonds could be reshaped into 3D architectures through the rearrangement of the network topology, in contrast with conventional crosslinked polymers memorizing permanent shapes. The reshaped samples showed various photoinduced motions depending on their initial shapes. Furthermore, amorphous polymers were incorporated into conventional CLCP networks to control mechanical and photoresponsive properties. The sequential formation of CLCP and amorphous polymer networks resulted in IPN films with a homogeneous alignment of mesogens. The elastic moduli of IPN films were controlled through the selection of amorphous components. The incorporation of soft components such as poly(dodecyl methacrylate) and poly(dimethylsiloxane) (PDMS) significantly enhanced the rate of photoinduced bending. These strategies of controlling the network structures of CLCPs could enable the versatile design of photomobile polymer materials as soft actuators with desired architectures and functions.

Similar content being viewed by others

Introduction

Crosslinked liquid-crystalline polymers (CLCPs) are a fascinating class of stimuli-responsive materials, which show macroscopic deformation along with a change in molecular order [1,2,3]. CLCPs containing photochromic moieties exhibit various photoinduced motions, such as bending, twisting, and rotation [3,4,5,6,7]. With the aid of spatial selectivity and the remote controllability of light, the use of photomobile polymer materials as untethered soft robots is feasible [8].

The deformation of photomobile polymer materials is based on the strong coupling between the alignment of mesogens and conformation of polymer chains in LCPs and was theoretically predicted by de Gennes in 1975 [9]. Finkelmann et al. developed CLCPs with polysiloxane backbones and investigated their mechanical properties [10, 11]. The authors observed that mesogens in polydomain films were homogeneously aligned under uniaxial stretching [11]. Furthermore, monodomain films were prepared through a two-step crosslinking method: a lightly crosslinked network is stretched to induce the uniaxial alignment of mesogens, and then further crosslinked to fix the alignment [12]. These films showed contraction upon heating to the nematic–isotropic transition temperature and reverted to the initial stretched state upon cooling. In the pioneering work, the thermally induced strain in these systems was 20%, which has since been enhanced to as high as 400% [2, 13]. Monodomain films have also been fabricated for CLCPs with polyacrylate and polymethacrylate backbones [14,15,16]. A typical procedure for obtaining these systems involved an in situ polymerization method: an LC mixture containing mono- and difunctional monomers is injected into a cell coated with alignment layers (e.g., rubbed polyimide) to obtain the homogeneous alignment of the LC phase, followed by polymerization to form the crosslinked network with aligned mesogens [15,16,17].

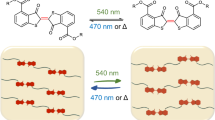

The photoactuation of CLCPs has been realized by the incorporation of azobenzene moieties. Azobenzene exhibits photoisomerization upon irradiation with UV and visible light (Fig. 1a). Rod-like trans-isomers stabilize LC phases, whereas bent cis-isomers disturb them. Therefore, the order–disorder transition can be isothermally induced upon photoirradiation [18, 19]. Finkelmann et al. introduced azobenzene moieties into monodomain films of CLCPs with polysiloxane backbones [20]. Upon irradiation with UV light, the film showed contraction along with a trans–cis isomerization of the azobenzene moieties and a change in the molecular order. The film recovered its initial length via a thermal cis–trans isomerization. Ikeda et al. developed CLCP films with a high concentration of azobenzene moieties through the copolymerization of azobenzene LC monomers and crosslinkers [21, 22]. A monodomain film showed bending toward a light source upon irradiation with UV light (Fig. 1b, c) [22]. This bending behavior was attributed to the predominant absorption of UV light by chromophores near the surface of the film, which led to a trans–cis isomerization, change in the molecular order, and contraction of the polymer chains at the surface region. Upon irradiation with visible light, the initial flat shape was recovered following a cis–trans isomerization. Moreover, the researchers succeeded in inducing a deformation of the polydomain films upon irradiation with linearly polarized UV light [21]. In this case, the bending axis of a film could be selected through the polarization direction of the incident light.

Typical example of photomobile polymer materials. a Photoisomerization of azobenzene. b Schematic illustration of the photoinduced deformation of a CLCP film. c Photoinduced bending behavior of a monodomain CLCP film, which was prepared by the copolymerization of the azobenzene monomer (1) and crosslinker (2)

Since the development of photomobile polymer materials, CLCP films composed of polysiloxanes and polyacrylates with covalent crosslinks have been extensively studied. Although various 3D motions have been demonstrated with these materials, the mechanical and photoresponsive properties should be enhanced for practical uses. Furthermore, the macroscopic architectures of CLCP samples should be controlled for versatile their application as soft actuators. CLCPs have been conventionally fabricated through two-step crosslinking and in situ polymerization methods, which typically yielded flat films. The remolding and reshaping of the flat shape have been difficult due to the presence of crosslinks formed by covalent bonds. The mechanical and photoresponsive properties, as well as the processability, could be improved by developing novel network structures with the aid of flexible designs of polymer materials.

This review describes the recent progress in photomobile polymer materials, focusing on newly developed network structures in CLCPs. Two novel approaches are detailed in the following sections: the enhancement in processability through the rearrangement of network structures and the control of mechanical and photoresponsive properties by the formation of interpenetrating polymer networks (IPNs).

Reshaping and photoactuation of CLCPs with rearrangeable networks

In the application of photomobile polymer materials as soft robots, CLCPs should be processable into adequate 3D shapes depending on their uses. However, the reshaping of CLCPs has been restricted by permanent crosslinks, which memorize the initial shapes during the formation of network structures. Dynamic covalent bonds have attracted substantial attention for their ability to allow the rearrangement of network structures in crosslinked polymers [23]. Leibler et al. developed epoxy networks called vitrimers, which are remoldable with heating through transesterification reactions [24, 25]. This strategy has also been applied for thermoresponsive CLCPs based on epoxy networks [26].

The reshaping of photomobile polymer materials has been enabled by the incorporation of dynamic covalent bonds into photoresponsive CLCPs [27]. Photochromic mesogens with ester groups and hydroxy groups were introduced to polysiloxanes through the hydrosilylation reaction between poly(hydrogenmethylsiloxane) and vinyl compounds (Fig. 2a). The hydroxy groups attack the ester bonds of crosslinks to induce transesterification, which leads to a rearrangement of the network topology (Fig. 2b). The phase transition behavior of the CLCPs was evaluated by differential scanning calorimetry and polarized optical microscopy. The CLCPs showed a glass transition at 4 °C and a nematic–isotropic transition at 150 °C.

Photomobile polymer materials with rearrangeable networks [27]. a Chemical structure. b Rearrangement of the network topology through transesterification. c Fusion test. Scale bars: 5 mm. d Preparation and photoactuation of a spiral. Intensities of UV and visible light: 97 mW cm−2 (365 nm) and 60 mW cm−2 (>540 nm). Scale bars: 10 mm. e Preparation and photoactuation of a helicoid. Intensities of UV and visible light: 120 mW cm−2 (365 nm) and 80 mW cm−2 (>540 nm). Scale bars: 5 mm

The rearrangement of the network structure was demonstrated through fusion tests, where two separate films were fused into one film by heating at 120 °C in a mechanical press (Fig. 2c). No fracture of the fused film was observed upon immersion in a good solvent, such as toluene. On the other hand, CLCP films without hydroxy groups could not be fused under the same conditions. These results imply that covalent bonds were formed at the interface between the films through the transesterification of ester and hydroxy groups.

Mesogens in CLCP films were realigned through the rearrangement of network topologies. The uniaxial alignment of mesogens was induced by stretching a CLCP film in an LC phase, which was further heated under constant strain to allow transesterification. The film showed a large decrease in stress during the heating process, which contrasted the behavior of polymer networks with permanent crosslinks. Through this procedure, monodomain films could be obtained, even after the formation of the network structure. The monodomain films showed bending toward a light source upon irradiation with UV light and reverted to the initial flat shape upon irradiation with visible light. This bending behavior was similar to that of a conventional CLCP film with a high concentration of azobenzene moieties, as described above.

The monodomain films were reshaped into various 3D architectures. The heating of monodomain films at 120 °C while fixed in desired shapes resulted in the transformation of the natural shapes before irradiation (Fig. 2d, e). The homogeneous alignment of mesogens was preserved during the heating at the LC temperature. A spiral sample showed an unwinding behavior upon irradiation with UV light and reverted to its initial shape with visible light (Fig. 2d). As the mesogens in this sample aligned along the spiral, the outer surface of the spiral showed a contraction, leading to the unwinding motion. On the other hand, a sample with a helicoidal shape showed bending toward the UV light source, which was caused by the contraction of the surface facing the light source (Fig. 2e). The cylindrical symmetry of the helicoid enabled bending toward the UV light source at freely selected directions. Thus, photoinduced motions could be programmed through the initial shapes, which were modified by the rearrangement of network topologies.

Modification of the mechanical and photoresponsive properties of CLCPs through the incorporation of amorphous polymers

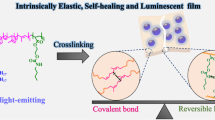

Enhancements in mechanical toughness are essential for the application of CLCPs as soft actuators. Conventional photomobile CLCPs with polyacrylate backbones typically show brittleness due to the high crosslinking density. The mechanical toughness of photomobile polymer materials has been enhanced though the fabrication of bilayers (e.g., a CLCP and polyethylene [28]) and composites (e.g., a CLCP and carbon nanotubes [29]). In addition, the elastic modulus should be adequately controlled for a variety of practical uses. The mechanical properties of polymer materials can be improved by blending multiple polymer components. In crosslinked systems, IPNs have been extensively applied as various systems including hydrogels [30, 31] and dielectric elastomers [32]. IPN films composed of a crosslinked azobenzene LC polymer (PAzo) and various amorphous polymers were developed to control the mechanical and photoresponsive properties of photomobile materials (Fig. 3a) [33, 34]. Improvements in the performance of photomobile materials was achieved by choosing adequate amorphous polymers.

Photomobile polymer materials with IPN structures [33, 34]. a Schematic illustration of IPNs. b Stress–strain curves of films upon stretching along the director axis of the azobenzene moieties. c Photoinduced bending behavior of films upon irradiation with UV light (366 nm, 10 mW cm−2). Size of the films: 3 mm × 1 mm × 16 μm. d Photoinduced bending behavior of pristine PAzo and PAzo/PDMS films upon irradiation with UV light (365 nm, 10 mW cm−2). Size of the films: 3 mm × 1 mm × 20 μm

IPN films were obtained by the sequential formation of CLCP and amorphous networks [33]. First, a PAzo network was formed by the photopolymerization of azobenzene LC monomers and crosslinkers in the presence of inert LCs. After the polymerization in a glass cell coated with alignment layers, the inert LCs were removed to obtain a PAzo network with numerous pores (PAzoTP), which was used as a template for the formation of IPN structures. After the injection of methacrylate monomers—methyl methacrylate (MMA), n-butyl methacrylate (BMA), or n-dodecyl methacrylate (DDMA)—and crosslinkers, amorphous networks were formed through a thermally initiated polymerization. The resultant films (PAzo/PMMA, PAzo/PBMA, and PAzo/PDDMA) showed the uniaxial alignment of mesogens implying that the alignment was programmed into the crosslinks of the PAzo network, which was preserved even after the incorporation of amorphous components.

The mechanical properties of IPN films were investigated through tensile tests (Fig. 3b). The Young’s moduli were evaluated from the initial slopes of the stress–strain curves. PAzoTP yielded a smaller elastic modulus than that of the pristine PAzo film, due to the presence of numerous pores in the film. The Young’s modulus was increased by the incorporation of PMMA and PBMA in the pores of PAzoTP. On the other hand, PAzo/PDDMA exhibited a smaller Young’s modulus than that of PAzoTP. This result implies that the mobility of the PAzo chains was increased by the formation of IPN structures with soft components. A wide range of elastic moduli was achieved by the incorporation of various amorphous components. Moreover, the mechanical toughness could be improved by the incorporation of amorphous polymers. In particular, PAzo/PMMA showed a significantly higher fracture stress than that of the pristine PAzo film.

In comparison with the behavior of the pristine PAzo film, a photoinduced bending was observed for the IPN and PAzoTP films (Fig. 3c). All of the films presented bending toward the light source when irradiated with UV light and then reverted to their initial shapes with visible light. The rate of bending was directly related to the elastic modulus: the films with smaller elastic moduli showed a faster bending behavior. It has been revealed that the rate of bending could be enhanced through the adequate selection of the amorphous polymer components.

The strategy of incorporating amorphous components into CLCPs was also applied for the fabrication of IPN films with PAzo and poly(dimethylsiloxane) (PDMS) [34]. In this case, hydrogen-terminated PDMS was crosslinked with multivinyl compounds through the hydrosilylation reaction in PAzoTP. Although the IPN film possessed a phase-separated structure, the uniaxial alignment of mesogens in the PAzo network was preserved. Upon irradiation with UV light, PAzo/PDMS exhibited a bending behavior ~10 times faster than that of a pristine PAzo film (Fig. 3d), thanks to the soft nature of PDMS.

Conclusion

Novel network structures were applied to photomobile CLCPs to enhance their performance and function. The reshaping and realignment of CLCPs were allowed with rearrangements of the network topology. The reshaped samples showed various 3D motions depending on their initial shapes. This result implies that photoinduced motions can be programmed through initial macroscopic shapes as well as the alignment of mesogens. Moreover, photomobile polymer materials with IPN structures were fabricated through the incorporation of amorphous polymers such as poly(alkyl methacrylate)s and PDMS into CLCP networks. The sequential formation of CLCP and amorphous polymer networks allowed the construction of IPN structures without disturbing the alignment of mesogens. The mechanical properties and photoinduced bending behavior were successfully controlled through the adequate selection of amorphous components. These approaches to controlling the network structures of photomobile polymer materials could broaden the possibility of designing soft actuators with demanded mechanical and photoresponsive properties, architectures, and functions.

References

Warner M, Terentjev EM. Liquid crystal elastomers. Oxford: Oxford University Press; 2003.

Ohm C, Brehmer M, Zentel R. Liquid crystalline elastomers as actuators and sensors. Adv Mater. 2010;22:3366–87.

White TJ, Broer DJ. Programmable and adaptive mechanics with liquid crystal polymer networks and elastomers. Nat Mater. 2015;14:1087–98.

Ikeda T, Mamiya J, Yu Y. Photomechanics of liquid-crystalline elastomers and other polymers. Angew Chem Int Ed. 2007;46:506–28.

Yamada M, Kondo M, Mamiya J, Yu Y, Kinoshita M, Barrett CJ, et al. Photomobile polymer materials: towards light-driven plastic motors. Angew Chem Int Ed. 2008;47:4986–8.

Ikeda T, Ube T. Photomobile polymer materials: from nano to macro. Mater Today. 2011;14:480–7.

Ube T, Ikeda T. Photomobile polymer materials with crosslinked liquid-crystalline structures: molecular design, fabrication, and functions. Angew Chem Int Ed. 2014;53:10290–9.

Rich SI, Wood RJ, Majidi C. Untethered soft robotics. Nat Electron. 2018;1:102–12.

de Gennes PG. Reflexions sur un type de polymeres nematiques. C R Acad Sci B. 1975;281:101–3.

Finkelmann H, Kock H, Rehage G. Investigations on liquid-crystalline polysiloxanes. 3. liquid-crystalline elastomers—a new type of liquid-crystalline material. Makromol Chem Rapid Commun. 1981;2:317–22.

Finkelmann H, Kock HJ, Gleim W, Rehage G. Investigations on liquid crystalline polysiloxanes, 5. Orientation of LC-elastomers by mechanical forces. Makromol Chem Rapid Commun. 1984;5:287–93.

Küpfer J, Finkelmann H. Nematic liquid single-crystal elastomers. Makromol Chem Rapid Commun. 1991;12:717–26.

Wermter H, Finkelmann H. Liquid crystalline elastomers as artificial muscles. e-Polym. 2001;1:111–23.

Roberts PMS, Mitchell GR, Davis FJ. A single director switching mode for monodomain liquid crystal elastomers. J Phys II. 1997;7:1337–51.

Thomsen DL, Keller P, Naciri J, Pink R, Jeon H, Shenoy D, et al. Liquid crystal elastomers with mechanical properties of a muscle. Macromolecules. 2001;34:5868–75.

Li MH, Keller P, Li B, Wang X, Brunet M. Light-driven side-on nematic elastomer actuators. Adv Mater. 2003;15:569–72.

Broer DJ, Finkelmann H, Kondo K. In-situ photopolymerization of an oriented liquid-crystalline acrylate. Makromol Chem. 1988;189:185–94.

Tazuke S, Kurihara S, Ikeda T. Amplified image recording in liquid-crystal media by means of photochemically triggered phase-transition. Chem Lett. 1987;16:911–4.

Ikeda T. Photomodulation of liquid crystal orientations for photonic applications. J Mater Chem. 2003;13:2037–57.

Finkelmann H, Nishikawa E, Pereira GG, Warner M. A new opto-mechanical effect in solids. Phys Rev Lett. 2001;87:015501.

Yu Y, Nakano M, Ikeda T. Directed bending of a polymer film by light. Nature. 2003;425:145.

Ikeda T, Nakano M, Yu Y, Tsutsumi O, Kanazawa A. Anisotropic bending and unbending behavior of azobenzene liquid-crystalline gels by light exposure. Adv Mater. 2003;15:201–5.

Denissen W, Winne JM, Du Prez FE. Vitrimers: permanent organic networks with glass-like fluidity. Chem Sci. 2015;7:30–8.

Montarnal D, Capelot M, Tournilhac F, Leibler L. Silica-like malleable materials from permanent organic networks. Science. 2011;334:965–8.

Capelot M, Montarnal D, Tournilhac F, Leibler L. Metal-catalyzed transesterification for healing and assembling of thermosets. J Am Chem Soc. 2012;134:7664–7.

Pei Z, Yang Y, Chen Q, Terentjev EM, Wei Y, Ji Y. Mouldable liquid-crystalline elastomer actuators with exchangeable covalent bonds. Nat Mater. 2014;13:36–41.

Ube T, Kawasaki K, Ikeda T. Photomobile Liquid-crystalline elastomers with rearrangeable networks. Adv Mater. 2016;28:8212–7.

Yamada Y, Kondo M, Miyasato R, Naka Y, Mamiya J, Kinoshita M, et al. Photomobile polymer materials—various three-dimensional movements. J Mater Chem. 2009;19:60–2.

Wang W, Sun X, Wu W, Peng H, Yu Y. Photoinduced deformation of crosslinked liquid-crystalline polymer film oriented by a highly aligned carbon nanotube sheet. Angew Chem Int Ed. 2012;51:4644–7.

Gong JP, Katsuyama Y, Kurokawa T, Osada Y. Double-network hydrogels with extremely high mechanical strength. Adv Mater. 2003;15:1155–8.

Gong JP. Why are double network hydrogels so tough? Soft Matter. 2010;6:2583–90.

Ha SM, Yuan W, Pei QB, Pelrine R, Stanford S. Interpenetrating polymer networks for high-performance electroelastomer artificial muscles. Adv Mater. 2006;18:887–91.

Ube T, Takado K, Ikeda T. Photomobile materials with interpenetrating polymer networks composed of liquid-crystalline and amorphous polymers. J Mater Chem C. 2015;3:8006–9.

Ube T, Minagawa K, Ikeda T. Interpenetrating polymer networks of liquid-crystalline azobenzene polymers and poly(dimethylsiloxane) as photomobile materials. Soft Matter. 2017;13:5820–3.

Acknowledgements

The author thanks Prof. Tomiki Ikeda for collaboration and discussion. The author acknowledges the experimental support provided by the students at Chuo University, especially Kiyohide Takado, Kyohei Kawasaki, and Ken Minagawa. This work was supported by JSPS KAKENHI Grant Numbers JP26870592, JP15K13712, JP15H01095, JP16H04157, JP17H05271, JP17K19161, JP18H04524, and JP18K14286.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ube, T. Development of novel network structures in crosslinked liquid-crystalline polymers. Polym J 51, 983–988 (2019). https://doi.org/10.1038/s41428-019-0224-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-019-0224-1

This article is cited by

-

Light- and humidity-driven fluorescence changeable soft robot enabled by water-gated photoinduced electron transfer pathway

Science China Materials (2023)

-

Photomechanical materials driven by photoisomerization or photodimerization

Polymer Journal (2020)