Abstract

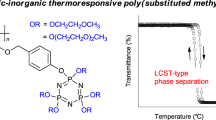

Star-shaped cyclopolymers were first synthesized on the basis of living cationic cyclopolymerization of divinyl ethers bearing a variety of bulky substituents, including cyclohexene, norbornene, norbornane, cyclic acetal, and adamantane groups. All the obtained cyclopolymers exhibited a high degree of cyclization, as high as ~97%, judging from the contents of residual pendant vinyl ether double bonds in the polymers. The glass transition temperatures (Tgs) of both the linear and star-shaped cyclopolymers were in the range of 145−229 °C depending on the pendant substituents. Methacrylate-terminated end-functionalized star-shaped cyclopolymers were synthesized by the functionalized initiator-based living cationic cyclopolymerization of divinyl ethers. The subsequent cross-linked core formation occurred via the reaction of the growing tail termini, whereas the methacrylate head terminals remained intact. The obtained end-functionalized star-shaped cyclopolymers were subjected to a thermal cross-linking reaction to yield star-shaped cyclopolymer networks with film-forming ability.

Similar content being viewed by others

Introduction

Vinyl ethers with various substituents are manufactured in industry [1], and their cationic polymerization has supplied a variety of polymers [2,3,4,5]. Polymers derived from vinyl ethers with linear alkyl substituents have low glass transition temperatures (Tgs) that are well below room temperature [6]. Therefore, the applications of poly(vinyl ether)s for rubber materials or elastomers have been intensively studied before [7,8,9,10].

In contrast, we have synthesized a new series of poly(vinyl ether)s with high Tgs well above room temperature by introducing aliphatic polycyclic substituents [11,12,13,14,15,16,17,18,19]. An example is the polymer of vinyl ether with a tricyclodecane unit (8-vinyloxytricyclodecane [5.2.1.02,6] ; TCDVE). Poly(TCDVE) showed a high Tg of ~100 °C as well as a high thermal decomposition temperature (Td) of ~350 °C, and was a candidate for a new transparent optical plastic with a relatively high-refractive index and high hydrophobicity [13, 17].

In the chain polymerization of vinyl monomers, cyclopolymerization of bifunctional vinyl monomers is capable of introducing cyclic structures into polymer-repeating units [20,21,22]. Bifunctional vinyl ethers (divinyl ether) generally polymerize to form cross-linked insoluble polymers [23,24,25]. Cyclopolymerization of divinyl ethers, on the other hand, yields a linear polymer, called a cyclopolymer, which consists of cyclized repeating units derived from intramolecular cyclization during the propagation reaction [26,27,28,29,30,31]. The rigid, consecutively cyclized main chains led to high-thermal stability and high glass transition temperatures of the resulting polymers [32,33,34,35,36,37]. However, to obtain a cyclized polymer with a high cyclization ratio in the cyclopolymerization, it is necessary to lower the initial concentration of the monomer to suppress the intermolecular propagation reaction [38], and accordingly, it is difficult to obtain high-molecular-weight cyclopolymers with a high degree of cyclization.

In contrast, the linking reaction of a living polymer with a divinyl compound is used to synthesize a high-molecular-weight, core-cross-linked, star-shaped polymer via microgel formation, which can conveniently synthesize a star-shaped polymer with a large number of arms [39, 40]. Furthermore, since a wide variety of arm chain polymers are available, and the size and type of the core can be changed, various properties and functions can be imparted [41,42,43,44,45,46]. In some cases, the star polymers have a higher glass transition temperature than the corresponding linear polymer [36, 37, 47] and excellent mechanical properties [43, 44, 48, 49]. It is also possible to obtain star-shaped polymers with a large number of end-functional groups [50, 51].

This study aims to synthesize a variety of high-molecular-weight cyclopoly(divinyl ether)s via living cyclopolymerization followed by star-polymer formation. Scheme 1 shows the divinyl ether monomers and the synthetic route employed. Divinyl ethers 1–3 and 5 possess pendant aliphatic cyclic substituents with different degrees of bulkiness, and divinyl ether 4 has a polar cyclic substituent. Living cyclopolymerization of divinyl ether monomers 1−5 and the subsequent reaction of the living polymers yielded core-cross-linked star-shaped cyclopolymers [Star-Poly(1−5)]. The obtained star-shaped polymers had high-molecular-weights and high Tgs. Because star-shaped polymers have many end groups per molecule, we studied the synthesis of star-shaped cyclopolymers with a polymerizable functional group introduced at the starting end and then the synthesis of novel network polymers consisting of rigid cyclized polymer chains to prepare cyclopolymer membranes (Scheme 2).

Experimental procedures

Materials

4,4-Bis(vinyloxymethyl)cyclohexene (1), 2-methyl-5,5-bis(vinyloxymethyl)-1,3-dioxane (4), and 1,4-cyclohexane dimethanol divinyl ether (6) (Nippon Carbide Industries) were distilled under reduced pressure over calcium hydride before use. 5,5-Bis(vinyloxymethyl)-2-bicyclo[2,2,1]heptane (2), 2,2-bis(vinyloxymethyl)bicyclo[2,2,1]heptane (3), and 2,2-bis(vinyloxymethyl)tricycle[3,3,1,13,7]decane (5) (Nippon Carbide Industries) were used without further purification. Toluene was purified by drying over calcium chloride overnight followed by double distillation in the presence of calcium hydride. 1-(Isobutoxy)ethyl acetate (IBEA) was synthesized by the reaction of isobutyl vinyl ether with acetic acid at 60 °C and purified by distillation under reduced pressure [52]. Tetralin was purified by sequentially washing with sulfuric acid, water, a 10 wt% aqueous sodium hydroxide solution and water; drying over calcium chloride; and doubly distilling under reduced pressure in the presence of calcium hydride. Et1.5AlCl1.5 (Tosoh Finechem; 2.0 M solution in toluene) was used without further purification. Ethyl acetate (CH3COOEt) was dried over calcium chloride overnight and then distilled twice over calcium hydride. 2-[1-Acethoxyethoxy]ethyl methacrylate (AEEM) was synthesized by the addition reaction between 2-(vinyloxy)ethyl methacrylate, which was prepared by the reaction of 2-chloroethyl vinyl ether (Maruzen Petrochemical) with sodium methacrylate (Aldrich) [53], and acetic acid and then purified by distillation under reduced pressure [54].

Synthesis of cyclopolymers and star-shaped cyclopolymers

The polymerizations were performed under a nitrogen atmosphere in a glass tube equipped with a three-way stopcock, which was dried by a heat gun (400 °C). To initiate the reaction, prechilled solutions of IBEA (0.5 mL in toluene) and Et1.5AlCl1.5 (0.5 mL in toluene) were successively added to a monomer solution (4.0 mL in toluene) containing tetralin as an internal standard for gas chromatography. To synthesize star-shaped polymers [40], a solution of 6 as a cross-linker (1.0 mL in toluene) was added to the almost polymerized reaction mixture to cause chain linking among the preformed polymer chains. To terminate the reaction, methanol containing a small amount of aqueous ammonia (2.0 mL) was added to the reaction solution. Monomer conversion was determined from its residual concentration measured by gas chromatography using tetralin as an internal standard. To recover the products, the reaction mixture was diluted with methylene chloride, washed sequentially with 0.1 mol/L hydrochloric acid and 10 wt% aqueous sodium chloride to remove initiator residues, evaporated to dryness under reduced pressure and vacuum dried. The polymers were further purified by preparative gel permeation chromatography (GPC) to remove the unreacted monomer and tetralin completely for NMR analysis. Alternatively, the polymers were purified by reprecipitation in methanol for Poly(1)−Poly(5), in N,N-dimethylacetamide for Star-Poly(1), in ethyl acetate for Star-Poly(2), in triethylamine for Star-Poly(3), in acetonitrile for Star-Poly(4), and in a mixture of ethyl acetate and toluene (2/1 v/v) for Star-Poly(5) from tetrahydrofuran for thermal analysis.

Characterization

GPC measurements of the molecular weight distributions (MWDs) of the polymers were conducted in chloroform (at a 1.0 mL/min flow rate) at 40 °C on a Shimadzu LC-10AD liquid chromatograph equipped with three polystyrene gel columns (Shodex K-807, K-805 and K-804) and a Shimadzu RID-6A refractive index detector. The number-average molecular weight (Mn) and polydispersity ratio [weight-average molecular weight/number-average molecular weight (Mw/Mn)] were obtained by chromatograms with polystyrene calibration of the standard samples whose molecular weights were 775000, 355000, 168000, 50000, 17700, and 2800. The operation of preparative GPC was performed with chloroform as an eluent (flow rate: 3.0 mL/min) at room temperature on a Jasco Tri Totar-II liquid chromatograph with a polystyrene gel column (Jasco Megapak 201) and a Shodex RI SE-31 refractive index detector. To obtain the absolute molecular weight of the polymers, gel permeation chromatography with low-angle light scattering detection in conjunction with refractive index detection (LALS-GPC) was conducted in THF (at a 1.0 mL/min flow rate) at 40 °C on a Shimadzu LC-10AD chromatograph equipped with a Shodex KF-806M polystyrene gel column, an Asahi Techneion Viscotek Model 270 light scattering detector and a GL Sciences RI Model 504 refractive index detector with OmniSEC software (Asahi Techneion, Osaka, Japan). The 1H (500 MHz) NMR measurement was conducted by using a Jeol ECX-500 instrument at room temperature with tetramethylsilane as an internal standard. Differential scanning calorimetry (DSC) was performed with Rigaku Thermo Plus DSC 8230 L with 5 °C/min heating and cooling rates, during which the sample was purged by nitrogen gas. The Tg was defined as the temperature at the midpoint of the change in heat capacity on the second heating scan. FT-IR spectra were recorded on a Nicolet iS5 instrument (Thermo Fisher Scientific Inc.).

Results and discussion

Living cationic cyclopolymerization of 1−3

Living cationic cyclopolymerization of 1−3 was performed in toluene at 0 °C with the IBEA/Et1.5AlCl1.5/CH3COOEt initiating system [55, 56]. A relatively low initial monomer concentration ([Monomer]0 = 0.15 M) was applied to accelerate the intramolecular propagation leading to cyclized repeating units. Figure 1 shows the time-conversion plots (A), the Mn (B) and Mw/Mn (C) of the product polymers versus monomer conversion plots for the polymerization of 1−3. Polymerizations of all three monomers proceeded quantitatively and almost completely in ~60−90 min during the first stage of the polymerization. The Mns of the obtained polymers increased with increasing monomer conversion. The addition of fresh monomer to the almost completely polymerized reaction mixture led to a further increase in the Mns of the obtained polymers. These results indicate that the polymerizations of 1−3 proceeded in a living manner using the IBEA/Et1.5AlCl1.5/CH3COOEt initiating system. The Mw/Mn values of the obtained polymers were somewhat broad, especially in the later stages of the polymerizations. The broadening of the MWDs of polymers in the later stage of polymerization of monomer 1−3 is due to the post reaction of the pendant unreacted vinyl groups of the formed polymers [26,27,28].

Figure 2 shows the 1H NMR spectrum of poly(1) obtained in the early stage of the polymerization (conversion = 15%). In addition to the signals of the poly(vinyl ether) backbone and the cyclohexene pendants, a small signal of the unreacted vinyl ether methine proton (b’ at 6.5 ppm) was observed. By comparing the intensity of the vinyl ether methine protons (b’) with all the absorptions (δ 2.9−4.1) arising from the main chain methine groups (b, d) and the pendant methylene groups (e, f), the content of residual vinyl groups (the vinyl content) in the polymer was obtained to be 1.4 mol%. Therefore, the degree of cyclization for poly(1) was over 98% [34,35,36,37]. Figures S1 S2 show the 1H NMR spectra of poly(2) and poly(3), respectively. Similar to the results for poly(1), the contents of unreacted vinyl groups in the polymers were measured to be 1.1 mol% for poly(2) and 1.8 mol% for poly(3). Therefore, the degrees of cyclization for poly(2) and poly(3) were over 98%, a high value that was virtually the same as that of poly(1).

Living cationic cyclopolymerization of 4

Living cationic cyclopolymerization of 4 with a highly polar cyclic acetal moiety was performed in toluene at 0 °C using the IBEA/Et1.5AlCl1.5/CH3COOEt initiating system, similar to that of divinyl ether 1−3. Figure 3 shows the time-conversion plots (A), the Mn (B), and Mw/Mn (C) of the product polymers versus monomer conversion plots and the MWD curves of the polymers (D) for the polymerization of 4. The polymerization of 4 reached ~100% conversion in 10 h, and it was found that the polymerization rate was considerably lower than those of 1−3. This is probably because the highly polar acetal rings act as an added base, and weaken the activity of the growing end [56, 57]. The Mn of the polymer increased in direct proportion to monomer conversion and further increased upon addition of fresh monomer to the almost completely polymerized reaction mixture, indicating that the cyclopolymerization of 4 using IBEA/Et1.5AlCl1.5/CH3COOEt initiating system involved the long-lived propagating species. However, the Mw/Mn values of the obtained polymer of 4 increased at the high monomer conversion and showed a higher value than those for 1−3. In addition, large shoulders were observed in the MWD curves of the polymers at high monomer conversions.

Figure 4 shows the 1H NMR spectrum of poly(4) in the early stage of the polymerization (conversion = 16%). The absorptions of the poly(vinyl ether) backbone and the cyclic acetal pendants and a small signal attributed to the unreacted vinyl ether methine proton (b’ at 6.5 ppm) were observed. By comparing the intensity of the vinyl ether methine protons (b’) with all the absorptions (δ 2.5–5.0) arising from the main chain methine groups (b, d) and the pendant methylene groups (e, f, g, j) and the acetal methine (h), the vinyl content of the polymer was determined to be 2.9 mol%. Therefore, the degree of cyclization for the poly(4) was estimated to be 97%. The content of unreacted vinyl groups was greater, and hence, more branching and cross-linking occurred; the MWDs of the cyclized polymers of divinyl ether 4 were broader than those of the cyclized polymers of divinyl ethers 1−3.

Living cationic cyclopolymerization of 5

Living cationic cyclopolymerization of 5, which has a bulky, symmetrical and strain-free tricyclic (adamantane) moiety [58], was investigated in toluene at 0 °C using the IBEA/Et1.5AlCl1.5/CH3COOEt initiating system, similar to the polymerization of divinyl ethers 1−4. Figure 5 shows the time-conversion plots (A), the Mn (B), and Mw/Mn (C) of the product polymers versus monomer conversion plots and the MWD curves of the polymers (D) for the polymerization of 5. The reaction proceeded to 100% conversion within 30 min, the rate of which was much higher than those of the polymerizations of 1−4. This is probably because the added bases make it somewhat difficult to stabilize active cation species due to steric hindrance of the highly bulky adamantane group [12]. Nevertheless, the Mn of the polymer increased in direct proportion to monomer conversion and further increased upon addition of a fresh monomer feed to the almost completely polymerized reaction mixture, indicating that living cyclopolymerization of 5 using the IBEA/Et1.5AlCl1.5/CH3COOEt initiating system occurred. The MWDs of the polymers of 5 were narrower than those of the other cyclopolymers, even at high monomer conversions.

Figure 6 shows the 1H NMR spectrum of the poly(5) obtained in the early stage of polymerization (conversion = 35%). With the resonance of the poly(vinyl ether) backbone and the adamantane pendants, a very small signal of the unreacted vinyl ether methine proton (b’ at 6.5 ppm) was detected. By comparing the intensity of the vinyl ether methine protons (b’) with all the peaks (δ 2.9−4.7) arising from the main chain methine groups (b, d) and the pendant methylene groups (e, f), the vinyl content of the polymer was found to be 0.5 mol%. This means that the degree of cyclization of poly(5) was over 99%, which is the highest value among the cyclopolymers of divinyl ethers 1−5.

The rather high cyclopolymerization tendency of divinyl ethers 1−5 is primarily due to the Thorpe−Ingold effect [34, 35, 59]. In addition, the highest cyclopolymerization tendency of divinyl ether 5 is probably a result of the steric hindrance of very bulky adamantane substituent of the monomer to suppress the intermolecular propagation. Therefore, the broadening of polymer MWDs was not observed at high conversions because the degree of cyclization was very high and the content of unreacted vinyl groups was quite small; thus, branching and cross-linking structures did not substantively occur.

Synthesis of star-shaped cyclopolymers

High-molecular-weight star-shaped cyclopolymers were synthesized by the reaction of the formed living cyclopolymers with a small amount of divinyl ether 6 as a cross-linking agent. Figure 7 shows the MWDs of the product polymers, in which a molar ratio of 6 to living polymer or r = [6]0/[P*]0 = 10 was employed. Divinyl ethers 1−5 were polymerized with the IBEA/Et1.5AlCl1.5/CH3COOEt system in toluene at 0 °C, and then the resulting living cyclopolymers were reacted and linked with divinyl ether cross-linker 6. Soluble products were obtained, and the Mns of product polymers reached 75,000−90,000, indicating the generation of core-cross-linked star-shaped cyclopolymers [36, 37]. The yield of star-shaped polymers was calculated by comparing the area of the MWD curve of the produced star-shaped polymer with that of the unreacted starting linear polymer. The yields of the star-shaped polymers of divinyl ethers 1−4 were 74−85%. In particular, the yield of the star-shaped polymer of divinyl ether 5 was 93%, which is higher than that of the other star-shaped polymers. Furthermore, purification of each synthesized star-shaped cyclopolymer was carried out by reprecipitation (Fig. S3). After reprecipitation, the peak derived from the unreacted polymer in the MWD curves disappeared, and therefore, it was found that only the star-shaped polymers could be recovered. The Mns of the star polymers should be estimated to be lower than absolute values because of the low hydrodynamic volume of the star-shaped polymers. Therefore, the number of arms of the star-shaped polymers was determined from the absolute molecular weight of the star-shaped cyclopolymers and their arm chain polymers measured by LALS-GPC (Table S1). Based on these values, the number of arm chains of a star-shaped cyclopolymer [number of arm chains = Mn of star-shaped polymer (LALS-GPC)/{Mn of arm chain polymer (LALS-GPC) + 196.29 (the molecular weight of divinyl ether 6) × r ( = 10)}] was found to be 26−45.

Thermal properties of cyclopolymers and star-shaped cyclopolymers

Table 1 shows the thermal properties of the obtained polymers. Poly(1) with monocyclic cyclohexene had a Tg of 115−122 °C. Poly(2) with polycyclic norbornene and Poly(3) with polycyclic norbornane exhibited a Tg of 150−170 °C. The reason why Poly(2) and Poly(3) show higher Tgs than Poly(1) is that the molecular motion of the polymer chains was further suppressed for Poly(2) and Poly(3) by bulkier substituents [16, 60]. Poly(4) with a highly polar cyclic acetal moiety exhibited a Tg of 161−168 °C. Although both Poly(1) and Poly(4) have the same six-membered ring in the side chain, Poly(4) had a higher Tg than Poly(1). The higher Tg of Poly(4) is likely due to the interaction between polymer chains through the polar acetal ring [61]. Poly(5) with bulky, symmetrica,l and strain-free tricyclic adamantine exhibited a Tg of 204−220 °C, much higher than those of the other cyclopolymers. The reason why Poly(5) shows a higher Tg than Poly(2) and Poly(3), which have similar polycyclic substituents, is that the adamantane unit is more rigid and bulkier than the norbornene and norbornane units, and hence, the molecular motion of the chains was further suppressed [14, 35, 62, 63]. Furthermore, the Tgs of star-shaped cyclopolymers were even higher than those of the corresponding linear cyclopolymers. The difference in Tgs could simply be because of the difference in their molecular weights. In addition, the presence of the stiff microgel core and crowded rigid arm chains connected to the core would elevate the Tgs of the star-shaped cyclopolymers [36, 37, 47].

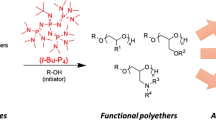

Synthesis of end-functionalized cyclopolymers

Living cationic cyclopolymerizations of 2 and 5 were investigated in toluene at 0 °C with the 2-(1-acetoxyethoxy)ethyl methacrylate (AEEM)/Et1.5AlCl1.5/CH3COOEt initiating system. Figure 8 shows the time-conversion plots (A), the Mn (B), and Mw/Mn (C) of the product polymers versus monomer-conversion plots and the MWD curves of the polymers (D) for the polymerization of 2 and 5. The Mn increased in direct proportion to monomer conversion and further increased in the second stage, indicating that polymerization of 2 and 5 proceeded in living manner with the AEEM/Et1.5AlCl1.5/CH3COOEt initiating system.

Figure 9 and Fig. S4 show the 1H NMR spectra of end-functionalized cyclopolymers 2 and 5 [End-Poly(2), End-Poly(5)] obtained in the early stage of polymerization (conversion = 14 and 41%, respectively). For End-Poly(2), a small signal of the unreacted vinyl ether methine proton (b’ at 6.5 ppm) was observed. By comparing the intensity of the resonance of the vinyl ether methine protons (b’) with all the peaks (δ 2.4–4.3) due to the main chain methine groups (b, d), the pendant methylene groups (e, f), and the pendant methine groups (h, k), the vinyl content of the polymers was found to be 1.4 mol%. As is the case with Poly(5), the vinyl content of the End-Poly(5) was 0.4 mol%. In other words, the degree of cyclization for the End-Poly(2) was over 98%, and for the End-Poly(5) was over 99%. Furthermore, a small signal of the methacrylate unit at the starting end was also observed in the 1H NMR spectrum of each polymer. The Mns of each polymer determined by NMR based on this peak were almost consistent with the calculated values. This indicates that one methacrylate moiety at the starting end of each polymer is present per polymer chain.

Synthesis of end-functionalized star-shaped cyclopolymers and thermal properties

End-functionalized star-shaped cyclopolymers were synthesized by the reaction of the formed living cyclopolymer with divinyl ether 6 as a cross-linking agent. Figure 10 shows the MWDs of the product polymers, where a molar feed ratio of 6 to living polymer, r = [6]0/[P*]0 = 10, was employed. Soluble end-functionalized star-shaped cyclopolymers with high-molecular-weights compared with those of the starting cyclopolymer were obtained. The yields of the star polymers were 77 and 85%, calculated by comparison of the area of the MWD curve of the produced star polymers with those of the unreacted starting linear polymers.

GPC traces of the products in the synthesis of star-shaped polymers using monomer divinyl ether 2 or 5 and divinyl ether 6 as a cross-linker with AEEM/Et1.5AlCl1.5/CH3COOEt in toluene at 0 °C: [Monomer]0 = 0.15 M; [AEEM]0 = 5.0 mM; [Et1.5AlCl1.5]0 = 60 mM; [CH3COOEt]0 = 1.0 M; r = [6]0/[P*]0 = 10: Purification of End-Star-Poly(2) by reprecipitation in ethyl acetate from THF and purification of End-Star-Poly(5) by reprecipitation in a mixture of ethyl acetate and toluene from THF

The end-functionalized star-shaped cyclopolymers were purified by reprecipitation in ethyl acetate from THF for End-Star-Poly(2) in a mixture of ethyl acetate and toluene (2/1:v/v) from THF for End-Star-Poly(5). After reprecipitation, the peak derived from homopolymers almost disappeared, and therefore, the star-shaped polymers could be purified. Figure S5 shows DSC thermograms of star-shaped polymers after purification. At the 1st heating, an exothermic peak was observed ~140−160 °C. This exothermic peak may be derived from the reaction of methacrylate at the end of the star-shaped polymers [64, 65]. During the 2nd heating process, no exothermic peaks were observed because the methacrylate double bonds that can undergo thermal reaction were consumed in the 1st heating scan.

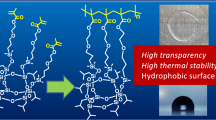

Synthesis of networked-star-shaped cyclopolymers: preparation of membrane of end-functionalized star-shaped cyclopolymers

The preparation of membranes of synthesized end-functionalized star-shaped cyclopolymers was investigated. The synthesized polymers were dissolved in toluene, poured into a Teflon dish, air dried at room temperature for 6 days, and then heated in a vacuum oven at 140 °C for 30 minutes to give membranes. Figure 11 shows the IR spectra of End-Star-Poly(2) and End-Star-Poly(5) before and after cross-linking. The absorptions at 1640 cm−1 assigned to the stretching of C = C double bonds and at 1100 cm−1 assigned to the stretching of C−O−C were detected in the spectrum before cross-linking. With the thermal cross-linking reaction, the peak intensity of the double bonds was apparently decreased. The extent of the reaction of C = C double bonds was calculated from their peak strength at 1640 cm−1 compared with the peak strength at 1100 cm−1 due to the C−O−C absorption. The extents of the reactions of C = C double bonds for End-Star-Poly(2) and End-Star-Poly(5) were 23 and 15%, respectively. Figure 12 shows photographs of membranes after thermal cross-linking. The membranes before thermal cross-linking were brittle, and could not be grasped with tweezers, but after cross-linking, their strength increased, and they could be grasped with tweezers. These results indicate that networked polymers composed of rigid cyclized star-shaped polymer chains were obtained.

We synthesized and molded many vinyl ether polymers in our previous studies so far [17, 18]. However, due to the fragility of the rigid polymer structure, most of them should contain soft or flexible comonomer units, and therefore, the Tgs of the polymers were lower than those of the corresponding homopolymers [17, 18]. However, our novel network polymers synthesized in this study can be molded without containing flexible comonomer units, and they are expected to be applied as heat-resistant plastics. In addition, it is known that in the polymer membrane, if the polymer main chains are rigid and the side chains are bulky substituents, spaces are present between the polymeric molecules, and their polymer membranes show high gas permeability [66, 67]. A study on this topic is now underway in our laboratory.

Conclusions

Controlled cationic cyclopolymerizations of divinyl ethers with a cyclohexene, norbornene, norbornane, cyclic acetal, or adamantane moiety were carried out. The degree of cyclization of the polymers was determined to be over ~97%. High-molecular-weight star-shaped cyclopolymers were obtained by chain-linking reactions among the formed living cyclopolymers with divinyl ether cross-linker 6. Cyclopolymers and star-shaped cyclopolymers exhibited very high glass transition temperatures (Tgs). End-functionalized star-shaped cyclopolymers were synthesized with divinyl ether monomers 2 or 5 and divinyl ether cross-linker 6 using a methacrylate-pendant initiator in a similar manner. Novel networked polymer membranes were obtained by thermal cross-linking of the methacrylate termini of the end-functionalized star-shaped polymers.

References

Weissermel K, Arpe H-J. Industrial organic chemistry, Chapter 9. Weinheim: Wiley-VCH, 2003; p. 237−8.

Higashimura T. Cationic polymerization, Chapter 6. Kagaku Dojin: Kyoto, 1971, pp 213−46.

Sawamoto M. Modern cationic vinyl polymerization. Prog Polym Sci. 1991;16:111–72.

Sawamoto M. Controlled polymer synthesis by cationic polymerization. In: Matyjaszewski, K, editor. Cationic polymerizations: mechanisms, synthesis, and applications. Marcel Dekker: New York, 1996; p. 381.

Aoshima S, Kanaoka S. A renaissance in living cationic polymerization. Chem Rev. 2009;109:5245–87.

Lal J, Trick SG. Glass transformation temperature of poly(vinyl alkyl ethers) and poly(vinyl alkyl sulfides). J Polym Sci, Part A: Polym Chem. 1964;2:4559–72.

Lal J, McGrath JE. Effect of sulfur during radiation curing of poly(vinyl ethyl ehter) and ethylene-propylene rubber. Rubber Chem Technol. 1963;36:248–58.

Lal J, McGrath JE. Vulcanization of poly(vinyl alkyl ethers) with dicumyl peroxide and sulfur. Rubber Chem Technol. 1963;36:1159–72.

Lal J, McGrath JE. Dynamic mechanical properties of poly(vinyl alkyl ethers). J Appl Polym Sci. 1965;9:3471–87.

Lal J, McGrath JE. Identification of volatile products produced during the peroxide vulcanization of poly(vinyl alkyl ethers). J Polym Sci, Part A: Polym Chem. 1967;5:785–93.

Namikoshi T, Hashimoto T, Kodaira T. Living cationic polymerization of vinyl ethers with a tricyclodecane or tricyclodecene unit: synthesis of new poly(vinyl ether)s with high glass-transition temperature. J Polym Sci, Part A: Polym Chem. 2004;42:3649–53.

Shiono S, Kanaoka S, Aoshima S. Thermo-responsive film prepared from block copolymers of vinyl ether with a polycyclic hydrocarbon substituent. Kobunshi Ronbunshu. 2005;62:92–5.

Namikoshi T, Hashimoto T, Urushisaki M. Synthesis of poly(vinyl ether) plastics for optical use by cationic copolymerization of tricyclodecyl vinyl ether with n-butyl vinyl ether. J Polym Sci, Part A: Polym Chem. 2007;45:4389–93.

Hashimoto T, Makino Y, Urushisaki M, Sakaguchi T. Living cationic polymerization of 2-adamantyl vinyl ether. J Polym Sci, Part A: Polym Chem. 2008;46:1629–37.

Hashimoto T, Namikoshi T, Irie S, Urushisaki M, Sakaguchi T, Nemoto T, et al. Synthesis and microphase-separeted structure of poly(tricyclodecyl vinyl ether)-block-poly(n-Butyl vinyl ether)-block-poly(tricyclodecyl vinyl ether): new triblock copolymer as thermoplastic elastomer composed solely of poly(vinyl ether) backbones. J Polym Sci, Part A: Polym Chem. 2008;46:1902–6.

Sakaguchi T, Koide Y, Hashimoto T. Synthesis of membranes of poly(vinyl ether)s and their gas permeability. J Appl Polym Sci. 2009;114:2339–43.

Namikoshi T, Hashimoto T, Suzuki Y, Urushisaki M, Sakaguchi T. Synthesis of poly(vinyl ether) optical plastics by cationic coplymerization of tricyclodecane vinyl ether with functionalized vinyl ethers. J Appl Polym Sci. 2012;126:E307–14.

Namikoshi T, Hashimoto T, Makino Y, Imaeda T, Urushisaki M, Sakaguchi T. Synthesis and properties of poly(2-adamantyl vinyl ether)-based optical plastics. Polym Bull. 2014;71:1389–402.

Sakaguchi T, Okunaga R, Irie S, Urushisaki M, Hashimoto T. Carbon dioxide-permselective polymer membranes composed of poly(vinyl ether)-based, ABA-type triblock copolymers with pendant oxyethylene chains. Polym Bull. 2017;74:2017–31.

Butler GB. Cyclopolymerization and cyclocopolymerization, Chapter 1. Marcel Decker: New York, 1992; p. 1−38.

Butler GB. Cyclopolymerization and cyclocopolymerization. Acc Chem Res. 1982;15:370–8.

Kodaira T. Structural control during the cyclopolymerization of unconjugated dienes. Prog Polym Sci. 2000;25:627–76.

Hashimoto T, Kanai T, Kodaira T. Gel formation in cationic polymerization of divinyl ethers. i. 1,4-bis(2-vinyloxyethoxy)benzene. J Polym Sci, Part A: Polym Chem. 1998;36:675–83.

Hashimoto T, Mishima M, Kodaira T. Gel formation in cationic polymerization of divinyl ethers. II. 2,2-Bis{4-[(2-vinyloxy)ethoxy]phenyl}propane. J Polym Sci, Part A: Polym Chem. 1999;37:1931–41.

Hashimoto T, Ohashi M, Kodaira T. Effect of central spacer chain structure on cationic cyclopolymerization tendency of divinyl ethers. J Polym Sci, Part A: Polym Chem. 2002;40:4002–12.

Rahman MS, Hashimoto T, Kodaira T. Cationic cyclopolymerization of new divinyl ethers: the effect of ether and ester neighboring functional groups on their cyclopolymerization tendency. J Polym Sci, Part A: Polym Chem. 2003;41:281–92.

Hashimoto T, Watanabe K, Kodaira T. Cationic cyclopolymerization of 1,2-bis(2-vinyloxyethoxy)benzenes: introduction of bulky substituents to increase cyclopolymerization tendency. J Polym Sci, Part A: Polym Chem. 2004;42:3373–9.

Hashimoto T, Nakamura T, Tanahashi S, Kodaira T. Gel formation in cationic polymerization of divinyl ethers. III. Effect of oligooxyethylene chain versus oligomethylene chain as central spacer units. J Polym Sci, Part A: Polym Chem. 2004;42:3729–38.

Kakuchi T, Kobayashi O, Nakaya D, Yokota K. Synthesis of some tailor-made poly(benzo-19-crown-6)s via cyclopolymerization of divinyl ether with hydrogen iodide/iodide initiator. Polym J. 1989;21:649–53.

Kakuchi T, Haba O, Yokota K. Cyclopolymerization of divinyl ethers. synthesis and the cation-binding property of poly(crown ether)s. Macromolecules. 1992;25:4854–8.

Kakuchi T, Aoki K, Haba O, Yokota K. Cationic copolymerization of divinyl ethers with vinyl ether. synthesis and cation-binding property of coplymer with benzo-19-crown-6 units. Polym J. 1993;25:839–45.

Lee H-J, Kodaira T, Urushisaki M, Hashimoto T. Cyclopolymerization. Part XXXII. Radical polymerization of α-(2-phenylallyloxy)methylstyrene: synthesis of highly cyclized polymers with high glass transition temperatures and thermal stability. Polymer. 2004;45:7505–12.

Lee H-J, Nakai H, Kodaira T, Urushisaki M, Hashimoto T. Cyclopolymerization XXXIII. Radical polymerizations and copolymerizations of 1,6-dienes with 2-phenylallyl group and thermal properties of polymers derived therefrom. Eur Polym J. 2005;41:1225–33.

Hashimoto T, Takagi H, Hasegawa Y, Matsui H, Urushisaki M, Sakaguchi T. Living/controlled cationic cyclopolymerization of divinyl ether with a cyclic acetal moiety: synthesis of poly(vinyl ether)s with high glass transition temperature based on incorporation of cyclized main chain and cyclic side chains. J Polym Sci, Part A: Polym Chem. 2010;48:952–8.

Morita K, Hashimoto T, Urushisaki M, Sakaguchi T. Cationic cyclopolymerization of divinyl ethers with norbornane-, norbornene-, or adamantane-containing substituents: synthesis of cyclopoly(divinyl ether)s with bulky rigid side chains leading to high glass transition temperature. J Polym Sci, Part A: Polym Chem. 2013;51:2445–54.

Hashimoto T, Matsui H, Urushisaki M, Sakaguchi T. Star-shaped cyclopolymers: a new category of star polymer with rigid cyclized arms prepared by controlled cationic cyclopolymerization and subsequent microgel formation of divinyl ethers. J Polym Sci, Part A: Polym Chem. 2015;53:1094–102.

Niwa T, Hashimoto T, Urushisaki M, Sakaguchi T. Living cationic cyclopolymerization of divinyl ether: synthesis of high-molecular-weight cyclopolymers by sequential monomer addition and formation of star-shaped polymer. Kobunshi Ronbunshu. 2017;74:215–24.

Smets G, Hous P, Deval N. Cyclopolymerization. IV. Structure of polymethacrylic anhydride and kinetics of polymerization of methacrylic anhydride. J Polym Sci, Part A: Polym Chem. 1964;2:4825–34.

Kanaoka S, Sawamoto M, Higashimura T. Star-shaped polymers by living cationic polymerization. 1. Synthesis of star-shaped polymers of alkyl vinyl ethers. Macromolecules. 1991;24:2309–13.

Shibata T, Kanaoka S, Aoshima S. Quantitative synthesis of star-shaped poly(vinyl ether)s with a narrow molecular weight distribution by living cationic polymerization. J Am Chem Soc. 2006;128:7497–504.

Kanaoka S, Yagi N, Fukuyama Y, Aoshima S, Tsunoyama H, Tsukada T, et al. Thermosensitive gold nanoclusters stabilized by well-defined vinyl ether star polymers: reusable and durable catalysts for aerobic alcohol oxidation. J Am Chem Soc. 2007;129:12060–1.

Oda Y, Shibata T, Tsujimoto H, Kanaoka S, Aoshima S. Highly efficient synthesis of heteroarm star-shaped polymers using polymer-linking reaction and their characteristic stimuli-responsive behaviors. Polym J. 2012;44:541–9.

Imaeda T, Hashimoto T, Urushisaki M, Sakaguchi T. Synthesis of ABA-triblock and star-diblock copolymers with poly(2-adamantyl vinyl ether) and poly(n-butyl vinyl ether) segments: new thermoplastic elastomers composed solely of poly(vinyl ether) backbones. J Polym Sci, Part A: Polym Chem. 2013;51:1796–807.

Okunaga R, Hashimoto T, Urushisaki M, Sakaguchi T. Gas permeability of star-shaped diblock copoly(vinyl ether)s with oxyethylene side chains. Kobunshi Ronbunshu. 2016;73:333–6.

Koda Y, Terashima T, Sawamoto M. Fluorous microgel star polymers: selective recognition and separation of polyfluorinated surfactants and compounds in water. J Am Chem Soc. 2014;136:15742–8.

Koda Y, Terashima T, Sawamoto M. Fluorinated microgels in star polymers: from in-core dynamics to fluorous encapsulation. Macromolecules. 2015;48:2901–8.

Yoshizaki T, Kanazawa A, Kanaoka S, Aoshima S. Quantitative and ultrafast synthesis of well-defined star-shaped poly(p-methoxystyrene) via one-pot living cationic polymerization. Macromolecules. 2016;49:71–9.

Shim JS, Kennedy JP. Novel thermoplastic elastomers. II. Properties of star-block copolymers of PSt-b-PIB arms emanating from cyclosiloxane cores. J Polym Sci, Part A: Polym Chem. 1999;37:815–24.

Asthana S, Kennedy JP. Star-block polymers of multiple polystyrene-b-polyisobutylene arms radiating from polydivinylbenzene core. J Polym Sci, Part A: Polym Chem. 1999;37:2235–43.

Zhang X, Xia J, Matyjaszewski K. End-functionalized poly(tert-butyl acrylate) star polymers by controlled radical polymerization. Macromolecules. 2000;33:2340–5.

Baek K-Y, Kamigaito M, Sawamoto M. Star poly(methyl methacrylate) with end-functionalized arm chains by ruthenium-catalyzed living radical polymerization. J Polym Sci, Part A: Polym Chem. 2002;40:1972–82.

Aoshima S, Higashimura T. Living cationic polymerization of vinyl monomers by organoalminium halides. 3. Living polymerization of isobutyl vinyl ether by EtAlCl2 in the presence of ester additives. Macromolecules. 1989;22:1009–13.

Aoshima S, Higashimura T. Living cationic polymerization of vinyl monomers by organoalminium halides. 1. EtAlCl2/ester initiating systems for living polymerization of vinyl ethers. Polym Bull. 1986;15:417–23.

Zhang H, Ruckenstein E. Graft copolymers by combined anionic and cationic polymerizations based on the homopolymerization of a bifunctional monomer. Macromolecules. 1998;31:746–52.

Aoshima S, Oda H, Kobayashi E. Synthesis of thermally-induced phase separating polymer with well-defined polymer structure by living cationic polymerization. I. Synthesis of poly(vinyl ether)s with oxyethylene units in the pendant and its phase separation behavior in aqueous solution. J Polym Sci, Part A: Polym Chem. 1992;30:2407–13.

Aoshima S, Onishi H, Kamiya M, Shachi K, Kobayashi E. Role of added lewis base and alkylaluminium halide on living cationic polymerization of vinyl ether. J Polym Sci, Part A: Polym Chem. 1994;32:879–87.

Aoshima S, Kobayashi E. Living cationic polymerization of vinyl ethers in the presence of added bases: recent advances. Macromol Symp. 1995;95:91–102.

Fort RC Jr., Schleyer PVR. Adamantane: consequences of the diamondoid structure. Chem Rev 1964;64:277–300.

Beesley RM, Ingold CK, Thorpe JF. The formation and stability of spiro-compounds. Part I. Spiro-compounds from cyclo-hexane. J chem Soc Trans. 1915;107:1080–106.

Cramail H, Deffieux A. Living cationic polymerization of cyclohexyl vinyl ether. Macromol Chem Phys. 1994;195:217–27.

Namikoshi T, Hashimoto T, Urushisaki M. Living cationic polymerization of vinyl ether with a cyclic acetal group. J Polym Sci, Part A: Polym Chem. 2007;45:4855–66.

Kang B-G, Shoji H, Kataoka H, Kurashima R, Lee J-S, Ishizone T. Living anionic polymerization of N-(1-adamantyl)-N-4-vinylbenzylideneamine and N-(2-adamantyl)-N-4-vinylbenzylideneamine: effects of adamantyl groups on polymerization behaviors and thermal properties. Macromolecules. 2015;48:8489–96.

Acar HY, Jensen JJ, Thigpen K, Mcgowen JA, Mathias LJ. Evaluation of the spacer effect on adamantane-containing vinyl polymer T g’s. Macromolecules. 2000;33:3855–9.

Sakaguchi T, Yamazaki S, Hashimoto T. Crosslinked membranes of poly(vinyl ether)s having oxyethylene side chains: the effects of the side chain length and the crosslinkable group on CO2 permeability. Polymer. 2017;112:278–87.

Sakaguchi T, Yamazaki S, Hashimoto T. Enhancement of CO2 permeability of poly(vinyl ether)s having oxyethylene chains by the sequence control of crosslinking sites. RSC Adv. 2017;7:13879–85.

Nagai K, Masuda T, Nakagawa T, Freeman BD, Pinnau I. Poly[1-(trimethylsilyl)-1-propyne] and related polymers: synthesis, properties and functions. Prog Polym Sci. 2001;26:721–98.

Sakaguchi T, Yumoto K, Shida Y, Shiotsuki M, Sanda F, Masuda T. Synthesis, properties, and gas permeability of novel poly(diarylacetylene) derivatives. J Polym Sci, Part A: Polym Chem. 2006;44:5028–38.

Acknowledgements

We are grateful to Nippon Carbide Industries (Tokyo, Japan) for providing divinyl ethers 1−6.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Yamamoto, T., Hashimoto, T., Urushisaki, M. et al. Synthesis of high-molecular-weight star-shaped cyclopoymers of divinyl ethers and their network membranes via controlled cationic cyclopolymerization. Polym J 51, 1273–1285 (2019). https://doi.org/10.1038/s41428-019-0241-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-019-0241-0