Abstract

This study is the first to present an integrated approach involving in silico and in vitro protocols that was pursued to analyse an antioxidative potency of Gouda cheese with modified content of β-casein. Firstly, the predictions of the presence of antioxidant peptides in the casein sequences were computed using the BIOPEP-UWM database. Then, the antioxidative bioactivity of six variants of Gouda cheese (with reduced, normative, and increased content of β-casein at the initial and final stage of ripening) was assessed. Finally, the RP-HPLC–MS/MS was applied to identify antioxidative peptides in Gouda-derived water-soluble extracts (WSEs). Analyses were supported with the heatmaps and the computation of parameters describing the efficiency of proteolysis of caseins in the modified Gouda cheeses, i.e., the frequency and the relative frequency of the release of antioxidative fragments during cheese ripening (AEexp and Wexp., respectively). All Gouda cheese variants exhibited the antioxidative potential which differed depending on the assay employed. The highest antioxidative activity (ABTS·+ radical scavenging effect, FRAP, and Fe-chelating) was observed for WSEs derived from Gouda cheese with increased content of β-casein after the 60th day of ripening. The results obtained suggest the potential of Gouda cheese as the antioxidant-promoting food.

Similar content being viewed by others

Introduction

Since 1950s, when the biological role of casein-derived peptides had been mentioned for the first time, loads of information were published concerning the discovery of new peptides, their function, identification, and production1. Today, it is well-known that peptides derived from foods exhibit various bioactivities, and thus are considered as biologically active regulators2.

Gouda is one of the most popular and known cheeses worldwide3 and, according to scientific reports, it was discovered as the source of enzyme inhibitors like: angiotensin-converting enzyme (ACE; EC 3.4.15.1) and/or dipeptidyl peptidase IV (DPP-IV; EC 3.4.14.5), responsible for blood pressure and glucose level regulation, respectively4,5. Although, some studies have confirmed the antioxidative potential of ripened cheeses6, there is paucity of literature data concerning specific types of cheeses as sources of peptidic antioxidants. To the best of our knowledge, no data can be found about the antioxidative peptides identified in Gouda cheese.

According to Sołowiej et al.7, casein—being a major cheese protein, is often incorporated to foods due to its certain functional properties, like e.g., consistency and fat-emulsifying ability. When looking at the issue entitled “peptides in ripened cheeses”, loads of data show that many peptides featuring various bioactivities were found in β-casein (β-CN) using in silico and in vitro protocols8,9,10.

In silico analyses became a supportive tool to study proteins and biopeptides of food origin because of the rapid development of methods for data collection and tools aiding the analysis of molecules. It especially concerns databases and software that support the analysis of the potential of bioactive peptides and their protein sources11. This methodology of peptide analysis is less costly and time-consuming when compared to the classical approach relying briefly on the following methodological steps in studying biopeptides from food sources: (i) finding a promising protein source of biopeptides and enzyme to hydrolyze it; (ii) isolating peptide(s) from a hydrolysate using, e.g. chromatography methods; and (iii) evaluating the bioactivity of isolated peptide(s)12. Therefore, scientists try to combine bioinformatic- and classical-assisted approaches to get a deeper insight into the nature of biologically active peptides. This methodology is called an integrated approach (a hybrid approach)13. This term was introduced by Udenigwe14 as the alternative solution for dealing with problems related to, e.g., identification of peptides in the protein by supporting the research with the information found in databases.

Taking into account the following aspects: (1) the abundance of β-casein in the fragments with biological activity; (2) the lack of sufficient data on the potential of Gouda cheese as the source of peptidic antioxidants, and (3) the growing popularity of methods involving bioinformatics to study proteins and peptides originating from foods, this study aimed to apply an integrated approach to analyze water-soluble extracts (WSEs) derived from Gouda cheese with a modified content of β-casein as the source of antioxidant peptides.

Results and discussion

Prediction of the presence of antioxidant peptides in casein sequences (in silico analysis)

The presence of antioxidant peptides in caseins was predicted using the parameter called the profile of potential biological (i.e. antioxidative) activity of protein. Briefly, it shows what antioxidative peptides match the protein sequence (see “Methods”). Such profiles were acquired from BIOPEP-UWM database15. The BIOPEP-UWM database described by Minkiewicz et al.15 is a collection of peptides with dozens of bioactivities that were identified experimentally by researchers. Moreover, this database is a universal tool serving for the evaluation of proteins as the potential sources of peptides15.

Citing the words of Halliwell16 “The terms ‘antioxidant’, ‘oxidative stress’ and ‘oxidative damage’ are widely used but rarely defined”. Thus, Tirzitis and Bartosz17 tried to systemize some terms concerning the so-called antioxidant activity of molecules. They have emphasized that there is a difference between antiradical and antioxidant activity of a compound and these terms do not coincide. Generally, antiradical bioactivity refers to a molecule’s ability to react with free radicals, whereas antioxidant activity entails the inhibition of the oxidation processes. Therefore, the tests involving a free radical, like e.g., DPPH and/or ABTS, provide the data concerning the radical scavenging activity or antiradical activity of a compound17. Thus, regardless of the test applied (e.g., FRAP, DPPH., ABTS.+, hydroxyl radical etc.), peptides with these bioactivities are specified in the BIOPEP-UWM database as “antioxidative”. Additional reason for such “definition” of the activity of these peptides is the measure of bioactivity. The BIOPEP-UWM database “accepts” the bioactivity of any peptide expressed as IC50 or EC50 (concentration of a peptide needed to inhibit or exhibit the effect corresponding to its half-maximal activity, respectively). The precise information on the measure as well as the individual sequence bioactivity was provided in the link called “Additional information”15. The results of bioinformatic predictions of the occurrence of antioxidative motifs in the casein sequences are shown in Table 1S (Supplementary Materials). These results include the predictions made for β-CN as well as other casein fractions like αs and κ. It results from the applied approach involving further identification of antioxidative peptides in Gouda cheese-derived samples.

Although the most common genetic variants of β-CN occurring in taurine breeds are A1, A2, and B18, antioxidative peptides were reported in all genetic variants β-CN. Some antioxidative peptides: KVLPVPQK, VLPVPQK, YQEP, and YQEPVLGP, occurred only in B variant of β-casein. There is no information about antioxidative activity of corresponding fragments of other genetic variants of the above protein, not only in the BIOPEP-UWM15, but also in the EROP-Moscow19 and MBPD databases20.

Among β-caseins, the best source of antioxidative peptides was genetic variant B (18 sequences encrypted), whereas the other variants of this protein fraction contained 14 sequences each. The number of peptide fragments found in a protein sequence (i.e. the higher, the better) suggests the high probability for their enzymatic release from a protein21. Looking at the length of the chain of antioxidative peptides encrypted in β-caseins, they were composed of two to maximum 11 amino acid residues. The most abundant were dipeptides < tripeptides < tetrapeptides. Longer motifs were less dominant in caseins. The length of a peptide chain affects the match of a protein sequence (the shorter the peptide is, the greater is its chance to match the protein)8.

Moreover, we analyzed the potential regularities between antioxidative motifs encrypted in β-caseins that may determine antioxidative activity. They were rich in Phe (F), His (H), Leu (L), and Tyr (Y). According to Zambrowicz et al.22, Y is found as an amino acid eliciting the antioxidative effect. Udenigwe and Aluko23 applied Partial Least Square (PLS) modelling to study quantitative structure–activity relationships (QSAR) of antioxidative peptides derived from food protein hydrolysates. They found that the presence of some amino acids, like Trp (W), Y, Met (M), C (Cys), H, F, and Pro (P), may contribute to the antioxidative activity of both purified food-derived and synthetic natural peptides. The presence of H negatively affected the antioxidative function of peptides23. However, the cited authors concluded that the presence of this residue in synthetic peptides promoted the antioxidative activity in a linoleic acid oxidation model. No such effect was observed in DPPH and superoxide radical-scavenging models23. Another QSAR studies confirmed that the presence of C-terminal W, Y and/or C enhanced the antioxidative activity of tripeptides. This was the case with the dataset of 19 peptide sequences representing i.a. DPPH-scavenging and FRAP activities24. N-terminal amino acids, like W or F, and Ile (I), M and Val (V) at the middle position were advantageous to the antioxidant bioactivity of tripeptides. In contrast, this activity was suppressed by the following residues: Ala (A), Gly (G), Ser (S) at position 1 and Asn (N), Asp (D), and C at position 2, but only in the case of the DPPH-scavenging effect24. To summarize, the presence of antioxidative peptides in the casein sequences, their variety in length of the chains, and their amino acid composition showing the antioxidative potential of β-caseins were the prerequisites to continue the studies on “casein-rich foods”, like different variants of Gouda cheese.

Monitoring of the proteolysis of Gouda cheese variants using SDS-PAGE electrophoresis

The designed Gouda cheese-making process consisted of a series of the filtration steps, i.e., MF and UF, carried out at different temperatures, which resulted in different contents of β-CN in cheese milk used to produce cheeses with the modified β-CN content (Table 1). The β-CN content was determined at 0.85% for control milk (Table 1). St-Gelais and Hache25 reported similar results, who determined the β-CN content at 0.83% in control milk as well as at 0.95, 1.08 and 1.22% in three milks supplemented with different amounts of β-CN. It should be noted that in the present study, the increase in β-CN content was not as high as expected. However, any changes in αs-CN to β-CN ratio affected not only the coagulation process of milk but also the course of proteolysis of the produced cheese. In the cheese-making process, more than 90% of casein is retained in the curd26. In a study carried out by Hallen et al.26 with model cheeses, the retention of particular casein fractions in cheese curd was determined at 93.3 ± 10.3, 97.7 ± 8.6, 92.7 ± 9.8 and 93.6 ± 7.7 for αs1-CN, αs2-CN, β-CN and κ-CN, respectively.

The ratios of αs-CN to β-CN in cheeses were determined on day 1 to monitor changes in the proteolysis process during cheese ripening (Table 2). However, no significant (P ≥ 0.05) differences were detected in the proportion of αs-CN to β-CN between cheeses with normative (G-CN0) and increased (G-CN+) content of β-CN. It is worth noting that β-CN content of milk used to manufacture these cheeses varied27 (Table 1). Further studies are needed to understand the coagulation process and properties of rennet gel produced from milk with the altered ratio of αs-CN/β-CN. The use of para-κ-CN as an internal standard allowed determining the percentage degradation of αs-CN and β-CN. No difference (P ≥ 0.05) was detected in αs-CN % degradation between cheeses with normative (G-CN0) and decreased (G-CN−) content of β-CN. The extent of αs-CN degradation in the cheese with the increased β-CN content was lower (P < 0.05) than in the other cheeses. St-Gelais and Hache25 produced cheeses with an increased β-CN content and found out that α-casein was hydrolyzed during cheese ripening and that the rate of its degradation decreased as protein and β-casein concentrations increased in the cheese. de Roos et al.28 and Dunnewind et al.29 have shown that the addition of a small amount of β-CN to the κ-CN/chymosin solution resulted in a strong suppression of chymosin association. β-CN competes with chymosin for one or more binding sites located on para-κ-CN, or a potential binding site for chymosin on the para-κ-CN molecule is shielded by β-CN. St-Gelais and Hache25 assumed that β-CN could also shield a potential binding site for chymosin on the α-CN in enriched cheeses. Generally, any changes in the ratio α-CN to β-CN would modify the properties of milk and resulted cheese. Van Hekken and Holsinger30 concluded that milk gels produced from milk enriched with β-casein formed softer gels more prompt to syneresis and lower water holding capacities than skim milk gels.

Water-soluble extracts (WSEs) of Gouda cheeses and their antioxidative activity

Four assays were used to assess the antioxidative effect of WSEs. According to the literature, there are several methods for quantifying the antioxidant bioactivity of a molecule31,32. Such a variety of methods results from the lack of a “quantification pattern” to determine this bioactivity due to the different oxidation mechanisms. Thus, to make any statement, it is recommended to employ at least two different methods to determine the antioxidative effect of a system33. To date, the antioxidant potential of cheeses of different types and origins has been measured using tests involving DPPH radical, ABTS cation radical, Fe ion-chelators, and ferric ion-reductants6,34,35. Thus, we used the same assays to measure the antioxidant capacities of WSEs derived from Gouda cheese variants (see Table 3). Moreover, being guided by words of Dontha36, according to which “an antioxidant is a molecule capable of inhibiting the oxidation of another molecule”, we converted the obtained results into IC50 values.

There were no statistically significant differences between antioxidative bioactivity of WSEs derived from different variants of Gouda cheese. According to Meira et al.34, who studied antioxidant activity of WSEs derived from ovine cheeses, it is difficult to establish the inter-relationships between the results of antioxidative activities. This may stem from various methods deployed that indicate the presence of various peptides in the WSEs but the activity is related to their different mode of action. Moreover, the following factors affect the antioxidant power of peptides: amino acid composition, size, amount and configuration (i.e. exposure of the terminal amino groups), and concentration of free amino acids34. Regardless of the test applied to measure the antioxidative effect of WSE, all samples exhibited this bioactivity. The highest effect was observed in the Fe-chelating ability of WSEs (the lowest values of IC50 parameter). Among them, WSE derived from freshly produced Gouda cheese (1st day; with normative content of β-casein) and from cheese after 60 days of ripening (Gouda with increased content of β-casein) displayed the highest Fe-chelating ability (IC50 for both cheese variants was 0.513 mg/mL). Öztürk and Akin37 analyzed the Fe-chelating potential of Turkish Tulum cheese during different ripening periods. They observed that Tulum WSEs had a higher Fe-chelating capacity than Roquefort, Cerrillano, and Pecorine-type cheeses produced from sheep milk. The highest bioactivity of Tulum cheese was observed on the 60th day of the ripening37. These findings are consistent with our study results concerning the samples derived from all variants of Gouda cheese. It can be explained by parallelism between ripening period and the formation of oligopeptides. Depending on the duration of the ripening process, plasmin, endogenous and microbial proteases are involved in the production of large and intermediate sized peptides from caseins. Then, secondary microflora leads to the transformation of these peptides to shorter fragments and amino acids37. The impact of hydrolysis time on Fe-chelating power was also confirmed for ovine milk caseinates hydrolyzed by microbial proteases38. During cheese proteolysis, the structure of proteins is disrupted, which increases solvent accessibility of amino acids which can chelate ions39. According to Meira et al.33, the metal-chelating function involves, i.a., amino acids possessing a ring (F, Y, H). Corrêa et al.38 suggested that residues, like C and H, were not hidden and exhibited redox and metal chelating abilities. Among 18 peptides identified in this experiment (see Table 2S in Supplementary Materials), 14 contained F, Y or H residues. Apart from peptides listed in Table 2S, also these containing phosphoserine residues may be involved in sequestering metal cations34. In turn, Huma et al.40 found that the presence of Q (Gln), K (Lys), M, Y, H, C, and P in peptide sequences determined the antioxidative effect of WSE of Roquefort cheese. 17 out for the 18 peptides identified using MS/MS in our WSE samples derived from Gouda cheese contained at least one of the above amino acid residues. Matemu et al.41 reported that some individual amino acids (Y, M, H, K, P, W) also possessed the antioxidative properties and/or influenced the antioxidant activity of peptides (see above). Moreover, when analyzing the other measures of the antioxidant power of the WSEs of all cheese samples, those derived from Gouda cheese with an increased content of β-casein on the 60th day of ripening had the highest FRAP (IC50 = 1.647 mg/mL) and elicited the strongest ABTS·+ radical scavenging effect (IC50 = 5.948 mg/mL). The comparison of the samples of the cheeses with the same content of β-casein and different ripening periods led to observe that regardless of the test applied, the antioxidative effect of “normative cheeses” increased over the ripening time (their IC50 values decreased). This regularity was observed in the samples of Gouda with a higher β-casein content, excluding the results of DPPH-radical scavenging activity (IC50 slightly changed from 7.203 to 8.962 mg/mL). In the case of Gouda cheese with a reduced β-casein content, the enhancement of antioxidant bioactivity between ripening periods was reported only for the Fe-chelating effect (IC50 changed from 0.655 to 0.533 mg/mL).

Perna et al.33 observed an increase in the FRAP of ovine ripening cheeses throughout the progression of the ripening, which was in agreement with our results concerning the WSEs from Gouda cheeses with normative and increased contents of β-casein except WSEs derived from the cheese with a lower β-casein content (IC50 changed from 1.684 to 2.379 mg/mL). In turn, Bottesini et al.42 reported a stable trend in the antioxidative capacity in Parmigiano Reggiano cheeses over the ripening period. These authors claimed that molecules responsible for antioxidant bioactivity (i.e. peptides and proteins) were not affected by biochemical processes taking place during cheese maturation. The side chains of amino acids have been suggested to maintain the same (or almost the same) antioxidant capacity as both components of peptides and free compounds42.

Although it can be said that all Gouda cheese samples exhibited antioxidant bioactivity; generally, it cannot be concluded that the modification of β-casein content caused a definitive increase of this bioactivity as the ripening process proceeded. It was dependent on the assay applied to measure the antioxidant power. Some of our results were in agreement with those obtained by other authors. For example, in the case of two cheese variants (four WSE samples; see Table 3), ABTS·+ test results showed an increase in the antioxidant bioactivity during cheese ripening. Revilla et al.6 analyzed 224 samples of cheeses with varying proportions of cow, ewe, and goat milks used for their production. They observed that the antioxidant effect of cheeses tested with the ABTS·+ method increased along with ripening time6. According to Revilla et al.6, the enhanced antioxidant effect of cheese samples during ripening was due to the progress in proteolysis, leading to the production of peptides and sulfur-containing amino acids, being well known antioxidants. Other studies into the antioxidant power of cheeses discussed by Revilla et al.6 revealed that the content of water-soluble peptides increased during ripening and reached the maximum in the first month of this process. Meira et al.34 studied the antioxidant potential of ovine ripening cheeses involving all tests that were also applied in this research. The results that were expressed as percentages of inhibition differed. This difference can be explained by, e.g., different scavenging patterns (mechanisms) for DPPH and ABTS radicals. The ABTS water-soluble pre-formed cation is built by oxidation of ABTS.+ with potassium persulfate. It is reduced in the presence of hydrogen-donating and chain-breaking antioxidant molecules. In turn, DPPH. accepts an electron or hydrogen to become a stable diamagnetic molecule. Because DPPH. is pre-dissolved in alcohol, thus it may not diffuse to target peptides present in an aqueous solution34. Moreover, higher concentrations of the samples in DPPH. assay than in ABTS·+ test were applied, which could also indicate that the latter was a more sensitive method to assess the antioxidative activity of cheese-derived water-soluble extracts34.

To summarize, the highest antioxidative activity (ABTS·+ radical scavenging effect, FRAP, Fe-chelating) was observed for WSEs derived from Gouda cheese with increased content of β-casein after the 60th day of ripening. However, our results concerning the antioxidative potential of different WSEs varied depending on the assay applied. According to Shahidi and Zhong32, many assays were developed to measure the antioxidant capacity of food at the molecular and cellular levels. Each test has its pros and cons32. According to Chen et al.43, different antioxidant power assessment tests applied to the same WSE sample cause its diversified behavior dependent on the structure of the radical that reacts differently with the antioxidative molecule present in the WSE. Thus, taking into account the data concerning the antioxidant activity of WSEs derived from six variants of Gouda cheese, we decided to continue our studies with the identification of antioxidant peptides in the cheese samples.

Identification of antioxidant peptides of WSEs from Gouda cheese with a modified content of β-casein

The results of RP-HPLC–MS/MS identification of antioxidant peptides in all WSE variants, including the peptide sequence, its protein source, retention time, and mass-to-charge ratio, are shown in Table 2S. Eighteen sequences of antioxidant peptides were identified in WSEs. Nine peptides (LHS, YYV, GTQY, YQLD, FYQL, YQKFP, AVPYPQR, IPIQYVL, KVLPVPQK) were present in all cheese samples, regardless of their variant and ripening period. One peptide, RLKKY matching αS1-casein, was not identified in the WSEs derived from Gouda after 1 day of ripening—but instead it was found in WSEs after 60 days of ripening. Peptides HPH, VPYPQ, and ARHPHP were present in WSE samples derived from Gouda cheeses analyzed on the first day of ripening. None of them was found in the samples analyzed after 60 days. One peptide, PHQ, was identified only in the WSE samples derived from Gouda with “normative” and “increased” content of β-casein.

An example of the RP-HPLC–MS/MS chromatogram of a peptide identified in WSE sample is shown in Fig. 1. It presents the antioxidative PHQ peptide (BIOPEP-UWM ID: 8032) found in WSE derived from Gouda with increased content of β-casein (60th day of ripening, see also Fig. 2a). Antioxidative activity of PHQ was introduced by Saito et al.44 on the basis of radical- and peroxynitrite-scavenging abilities. Moreover, this sequence has been first described as the component of combinatorial library of tripeptides44. PHQ peptide matched the sequence of β-casein (all genetic variants). The m/z (M + H)+ of the precursor ion was 381.1 Da. One major peak was observed at ca. 14.5 min. The peptide with the sequence PHQ was identified in the WSE cheese samples derived from: increased content of β-casein and one day of ripening (see Fig. 2b) as well as normative content of β-casein and both stages of ripening (see Fig. 2c,d, respectively). There was no such a sequence in the samples corresponding to Gouda with reduced content of β-casein and both ripening periods (Fig. 2e,f, respectively).

An example of RP-HPLC–MS/MS chromatogram showing the identification of an antioxidative peptide PHQ in WSEs derived from different variants of Gouda cheese. Letters a and b denote samples derived from Gouda cheeses with increased content of β-casein (60th and 1st day of ripening, respectively); letters c and d denote samples derived from Gouda cheeses with normative content of β-casein (60th and 1st day of ripening, respectively); letters e and f denote samples derived from Gouda cheeses with reduced content of β-casein (60th and 1st day of ripening, respectively), tR retention time (min).

The spectrum of the PHQ sequence found in the cheese samples with increased content of β-casein (day 60) is shown in Fig. 3 with the corresponding b/y ion pairs. They were consistent with those predicted theoretically considering the precision of the mass spectrometer used. This method enables identifying peptides composed of 2–5 amino acids when the data on the specificity of enzyme is lacking23. Citing the words by Iwaniak et al.27 “proteomic software is often unable to detect such peptides using a low resolution ion trap mass spectrometer”.

To recapitulate, regardless of Gouda cheese variant and ripening stage, different peptides matching different fractions of caseins were found in their WSEs. Some antioxidative peptides were generated at both stages of ripening and in all Gouda cheese variants. The general results of the antioxidant assessments (see above) suggest that the antioxidant power of all Gouda cheese variants resulted from the presence of peptides, which was also reported by other scientists45. However, some peptidic antioxidants were identified at the end, whereas others at the beginning of ripening, which could explain successive degradation of peptides with extending storage period45.

Finally, additional in silico predictions were carried out to support the results of peptide identification in WSEs. The first step involved creating the heatmaps to visualize the presence of antioxidative peptides in all analyzed Gouda cheeses and casein sequences. The heatmap is presented in Fig. 4.

Heatmap of antioxidative peptides identified in Gouda-derived WSEs. Map A: Sample derived from: G-CN−1, G-CN−60–G-CN01, G-CN060, G-CN+1, G-CN+60, meaning Gouda cheese with reduced, normative, and increased content of β-casein after the 1st and 60th day of ripening (subscripts: 0 and 60, respectively); Map B: casein fraction the peptide matches to; colors: blue—“yes”, gray—“no”. Figure prepared using the Heatmapper program (see Methods).

Heatmap A shows the presence of antioxidative peptides in individual Gouda cheese-derived WSE samples. The majority of antioxidant peptides were identified in all WSEs (blue area). Three peptides were absent (RLKKY, PHQ, and TSTA; grey area) in the samples derived from G-CN−1. Moreover, the RLKKY sequence was also absent in the G-CN01 and G-CN+1 samples. On the other hand, 4, 5, and 6 peptides were lost in WSEs derived from G-CN060, G-CN+60 and G-CN−60, respectively. During cheese ripening, plasmin and LAB-derived (i.e., lactic acid bacteria) enzymes contribute to the production of peptides, which can be accumulated or further degraded during storage46. This observation may explain the presence of peptides in Gouda cheese at the beginning of its ripening and their lack in the cheese at the final stage of this process. Heatmap B shows which casein sequences were the best sources of antioxidative peptides identified in WSEs. It was found that the best sources of such peptides were all genetic variants of β- as well as of αs1-caseins. These results were consistent with our initial in silico predictions. This consistency of the results concerned the casein sequences being the best sources of antioxidative peptides, but not the number of peptides that were identified using in silico and in vitro protocols. Finally, the results provided by heatmaps enabled calculating the values of the parameters describing proteolysis efficiency27,47 namely, the frequency of released fragments with antioxidative activity during Gouda cheese ripening (AEexp.), and the relative frequency of release of antioxidative fragments during Gouda cheese ripening (Wexp.). The results are presented in Fig. 5.

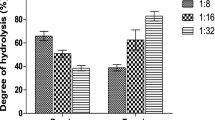

Graphical visualization of AEexp and Wexp values describing the efficiency of the release of antioxidant peptides from Gouda cheese variants. G-CN−1, G-CN−60–G-CN01, G-CN060, G-CN+1, G-CN+60, meaning Gouda cheese with reduced, normative, and increased content of β-casein after the 1st and 60th day of ripening (subscripts: 0 and 60, respectively); color bars—casein sequence including its genetic variant (see the superscripts).

The highest frequency of the release of antioxidative peptides (AEexp.) was determined for the WSEs obtained from G-CN−60 and G-CN060 samples (AEexp. = 0.038 each). It was related to the efficient release of antioxidative peptides from αS1-casein (genetic variant A). The AEexp. referring to the release of antioxidative peptides from the sequence above, but calculated for the G-CN+60 was 0.032. Identical values of this parameter were obtained for other cheese variants and the same casein sequence. All AEexp values were related to the number of the antioxidative peptides that were matching the casein sequences (the higher the number, the better the match). Taking into account the relative frequency of release of antioxidative fragments during Gouda cheese ripening (Wexp.), the highest value was determined for the samples derived from G-CN01 and G-CN+1 cheeses (Wexp. = 0.286 each). This value referred to the relative frequency of the release of antioxidative peptides from β-casein (genetic variants A1, A2, A3, C, E, and F). The Wexp. values obtained for the same variants of cheese but after 60 days of ripening were 0.214 each. Based on the values of AEexp. and Wexp., the progress in cheese ripening was found to contribute to the release of antioxidative peptides; however, these peptides were probably the substrates for further hydrolysis. Finally, based on results presented in Figs. 4 and 5, it can be concluded that αS1-casein was the major contributor to the antioxidant activity, whereas αS2-casein was the least one, regardless of the β-casein content or ripening day.

To summarize, the integrated approach was found useful to analyze different variants of modified Gouda cheese as the sources of antioxidative peptides. This research strategy is consistent with the point of view expressed by Barbano and Lynch48, according to whom, the combination and rapid development of different analytical methods for peptide identification in dairy foods would enable better understanding of the processes contributing to the more complex characteristics of nutritional and sensory values of cheeses. These methods can also include bioinformatic-aided characteristics of Gouda cheese derived-peptides27. However, it needs to be elucidated that in silico methods that were applied in our study “simplified” some phenomena naturally taking place in a food system, like e.g., ripening cheese. The production of peptides in ripening cheeses is a more complex issue than computer simulations. Apart from the action of coagulant, being the crucial step in cheese production, cheese proteolysis is also the result of the action of plasmin and microbial enzymes. The latter are crucial in the process of cheese ripening. Peptides’ release during cheese ripening depends on the enzyme involved, stage of proteolysis, and rate of hydrolysis of a particular casein fraction49. These factors are “not considered” by computer programs, including the BIOPEP-UWM database15. For example, a lack of data on the specificity of endogenous proteases was one of the limiting factors of an in silico identification of peptides in caseins. Thus, the detection (or not) of antioxidative peptides in the above protein fractions had to be made using the profile of potential antioxidative activity of casein. Despite such limitations, the usefulness of in silico tools in the analysis of “proteins as the sources of bioactive peptides” was confirmed in several studies50,51,52,53,54. To the best of our knowledge, there is no ideal bioinformatic tool for the analysis of food-derived components, including peptides.

To recapitulate, this study is the first which shows the application of integrated approach to study an antioxidative potency of modified dairy product i.e. Gouda cheese. The integrated approach combining in silico and in vitro analyses of Gouda cheese variants with different β-casein content allowed us to identify some regularities concerning the potential of caseins as sources of antioxidative peptides. However, some discrepancies could also be found when comparing the results obtained in silico and in vitro. The possible factors affecting the differences were discussed in our previous works and included, e.g., differences between the numbers of peptides identified in the casein sequences. In silico analyses include, e.g., the repetitions of the motif in a protein sequence, whereas identification of a peptide by RP-HPLC–MS/MS confirms its presence in a sample (if any), but does not show its quantity. All Gouda cheeses exhibited the antioxidative potential which differed depending on the assay used, which shows their potential as antioxidative-promoting food. Additionally, some authors55 recommend undertaking further studies involving, e.g., cell culture and/or animal models to get more insights on, e.g., mechanisms of action of food-derived antioxidative agents, their uptake, and metabolism.

Methods

Reagents

The following reagents were purchased from Sigma-Aldrich, Sp. z o. o., Poznan, Poland: acetic acid (C2H4O2, catalog No. A6283-1L), tris(hydroxymethyl)aminomethane hydrochloride (TRIS–HCl, cat. No. 93313), 2,2-diphenyl-β-picrylhydrazyl (DPPH, catalog No. D9132), 2, 2′-azino-bis(3-ethylbenzotialozline-6-sulfonic acid (ABTS, catalog No. A3219), phosphate buffer saline pH 7.4 (catalog No. P3813), trifluoroacetic acid (TFA, catalog No. T6508), urea (catalog No. U5378), 2,2-bis(hydroxymethyl)-2,2′,2″-nitrilotriethanol (BIS–TRIS, catalog No. B9754), sodium phosphate monobasic (NaH2PO4, catalog No. P5379), sodium hydroxide (NaOH, catalog No. S8045-500G), sodium phosphate dibasic (Na2HPO4, catalog No. P8281), potassium ferricyanide (K3Fe(CN)6, catalog No. 702587), trichloroacetic acid (TCA, catalog No. T6399), ferric chloride hexahydrate (FeCl3 × 6H2O, catalog No. 236489), iron (II) chloride tetrahydrate (FeCl2 × 4H2O, catalog No. 380024), ferrozine (TPTZ, 2,4,6-Tris(2-pyridyl)-s-triazine, catalog No. T1253), EDTA (ethylenediaminetetraacetic acid, catalog No. E9884), sodium acetate (CH3COONa, catalog No.S8750), sodium dodecyl sulfate Bioreagent (CH3(CH2)11OSO3Na, catalog No. L3771), glycerol (HOCH2CH(OH)CH2OH, catalog No. G5516), glycine (NH2CH2COOH, catalog No. G8898), Trizma base (NH2C(CH2OH)3, catalog No. T1503), bromphenol blue sodium salt (C19H9Br4NaO5S, catalog No. B5525), brilliant blue R (C45H44N3NaO7S2, catalog No. B7920), dithiothreitol (HSCH2CH(OH)CH(OH)CH2SH, catalog No. 43819), and acetic acid (glacial) (CH3CO2H, catalog No. 1018302500). Acetonitrile (ACN, supplier: Romil, Waterbeach, UK, catalog No. ROMILH048L), hydrochloric acid (HCl; supplier: Chempur, Piekary Slaskie, Poland): catalog No. 805313160 (0.1 mol/dm3) and 805313164 (1.0 mol/dm3), ethanol (C2H5OH, supplier: Chempur, Piekary Slaskie, Poland, catalogue No. 363-113964200-1L), methanol (CH3OH, supplier: Romil, Waterbeach, UK, catalog No. ROMILH409L and supplier: Eurochem BGD Sp. z o.o.), sulfuric acid (H2SO4, supplier POCH, Poland, catalogue No. 575000115), boric acid (H3BO3, supplier POCH, Poland, catalogue No. 531360738), sucrose (C12H22O11, supplier POCH, Poland, catalogue No. 772090110), Kjeltabs (K2SO4 + CuSO4·5H2O, supplier POL-AURA, Poland, catalogue No. 525085860#100) and sodium hydroxide (NaOH, supplier: Chempur, Piekary Slaskie, Poland): catalogue No. 810953168 (0.01 mol/dm3), 810953160 (0.1 mol/dm3) and 810953165 (1.0 mol/dm3) were acquired from ABChem Olsztyn, Poland. The Mini-Protean TGX Precast Gels (12% 10-well comb, 30 µL/well) were purchased from Bio-Rad Laboratories (Warsaw, Poland). Chemicals used in cheese production included: CaCl2 (0.02%, P.P.H. “STANLAB” Sp. J., Lublin, Poland), starter culture (CHN19, Chr. Hansen, Hoersholm, Denmark), and rennet (Chymax M 1000, Chr. Hansen). All reagents were of analytical grade.

Water used to formulate solutions and buffers was prepared using a Milli-Q PLUS system (Millipore Corp., New York, NY, USA). Nylon membrane filters (Whatman®, 0.2 μm pore size, catalog No. WHA7402004) were purchased from Sigma-Aldrich Sp. z o.o. (Poznań, Poland) and Munktell-Filtrak 390 grade filters (catalog No. 8.012.120.900) from EQUIMED (Olsztyn, Poland). All chemicals and reagents were of analytical and/or MS grade.

Bioinformatic predictions

To predict the presence of antioxidant fragments in caseins, the following sequences were acquired from the BIOPEP-UWM database available at: https://biochemia.uwm.edu.pl/biopep-uwm/15,56: β—genetic variants: A1, A2, A3, B, C, E, and F (209/ID 1097; 209/ID 1098; 209/ID 1099; 209/ID 1103; 209/ID 1100; 209/ID 1101; 209/ID 1102; 209/ID 1103, respectively) as well as αS1—genetic variants: A, B, C, and D (186/ID 1086; 199/ID 1087; 214/ID 1089; 199/ID 1088; 199/ID 1088, respectively); αS2—genetic variant A (222/ID 1090); κ—genetic variant A (190/ID 1117). The numbers in brackets mean the length of the protein chain (i.e. number of residues) and the BIOPEP-UWM accession number of casein, respectively. The above-mentioned prediction is called a profile of potential activity of the protein, which is described as the type and the location of a peptide with specific activity in a protein chain15. In our studies, the peptide profile of a protein should be understood as the type and the location of antioxidative fragments in the casein sequences. Our predictions excluded the presence of fragments encrypted in signal peptides which are unlikely to be found in milk and hence in dairy products.

The antioxidative peptide profiles of caseins were obtained using a tool called “Analysis” available in the BIOPEP-UWM database56. Thus, after entering the BIOPEP-UWM database and clicking the bar called “Proteins” or “Bioactive peptides”, the procedure was as follows (in exact words as provided in this database): Analysis → Profiles of potential biological activity → Select activity (open the bar and select: antioxidative) → Protein database (open the bar and select the protein sequence using its accession ID).

Production of Gouda cheese with modified β-casein content

The Gouda cheese was produced in a semi-industrial scale at the pilot plant of the University’s Dairy Research and Development Center (Department of Dairy Science and Quality Management, University of Warmia and Mazury in Olsztyn) as described by Iwaniak et al.27. The series of membrane filtration processes were applied to modify β-casein content in cheese milk (Fig. 6). The production protocol for Gouda cheese manufacture is shown in Fig. 7. Finally, three variants of Gouda cheese with different contents of β-casein were produced. They were defined as: G-CN0, G-CN+, G-CN− meaning Gouda cheese with normative, increased, and reduced content of β-casein, respectively. To summarize, there were three productions of each Gouda cheese variant. Thus, the sample should be understood as a mixture of sub-samples collected from the independent batch representing individual variant of Gouda cheese.

Scheme for production of cheese milk with altered ratio of αs-casein to β-casein using a series of filtration processes. CF concentration factor, SM skim milk, RMF50 microfiltration retentate produced at 50 °C, PMF50 microfiltration permeate produced at 50 °C, RUF50 ultrafiltration retentate produced at 50 °C, PUF50 ultrafiltration permeate produced at 50 °C, RMF7 microfiltration retentate produced at 7 °C, PMF7 microfiltration permeate produced at 7 °C, RDF7 diafiltration retentate produced at 7 °C, PDF7 diafiltration permeate produced at 7 °C, PRUF ultrafiltration retentate from MF/DF permeates, PPUF ultrafiltration permeate from MF/DF permeates, SW polyethersulfone spiral-wound membrane.

The samples of cheese milk were analyzed for total nitrogen (TN) and non-casein nitrogen (NCN) contents using the Kjeldahl method57 (method 991.20; 33.2.11), and Kjeldahl method57 (method 998.05; 33.2.64) with modifications according to Wojciechowski and Barbano58, respectively. Casein was calculated by subtracting NCN from TN and multiplying the result by 6.38.

Protein composition of cheese milk and monitoring of the proteolysis of Gouda cheese variants using SDS-PAGE electrophoresis

SDS-PAGE was deployed to determine the relative protein proportions (band %) according to the protocol proposed by Zulewska et al.59. The change in the content of β-casein in milks used to produce Gouda cheeses was expressed as the ratio of αs-casein to β-casein and the percentage of β-casein of milk proteins in cheese milks used for Gouda production59.

The proteolysis of αs- and β-CN during Gouda aging was also monitored by SDS-PAGE. The procedure was described by Verdi et al.60, except that a constant 12% acrylamide gel (Biorad Laboratories, Warsaw, Poland) concentration was used. 10 μL of day-1 and day-60 cheese sample buffer mixtures were loaded per slot. As a reference sample, a pasteurized milk was also loaded on each gel at a volume of 7 μL. The destained gels were scanned using a Lumi Bis Bioimaging Systems DNR scanner (Jerusalem, Israel) and analyzed using TotalLab 1D v 11.3 (New Castle, England). The gels were scanned to obtain relative protein proportions within each sample. Each sample was replicated 3 times on a gel. Para-κ-CN was used as an internal standard, since it is not hydrolyzed during Cheddar cheese aging61, and similar patterns apply to Gouda cheese. The ratio of αs-CN (i.e., αs1- + αs2-CN) peak height and β-CN peak height to para-κ-CN peak height at each time of aging was calculated62. The percentage degradation of αs-CN was calculated by subtracting each of the ratios (αs-CN/para-κ-CN) on day 60 from the ratio (αs-CN/para-κ-CN) on day 1, dividing by the ratio (αs-CN/para-κ-CN) on day 1, and multiplying by 10063. The same procedure was followed for β-CN degradation. The original electropherograms of cheese samples are presented in Supplementary Figs. 1S and 2S. Gels were obtained within the same experiment and concerned the same samples (cheese) in different time related to their process of ripening.

Determination of antioxidant activity of water-soluble extracts derived from Gouda cheese

General information

Regardless of the assay applied, absorbance of samples derived from each Gouda variant was measured using a UV/Vis spectrophotometer (Genesys™ 150). All measurements were performed in triplicate. The final results of each measurement were converted to the concentrations corresponding to the half-maximal antioxidant inhibition (IC50) of WSEs. This conversion was done using GraphPad Prism 5.02 software for Windows®64,65. The computations were carried out using the following options: “Nonlinear regression” → “Dose–response curves—Inhibition” → “inhibition (log) vs. normalized response—variable slope”. They included standard error (at 95% confidence interval). According to the instructions concerning the estimation of IC5066, we applied at least five separate WSE concentrations (i.e., sample).

Radical scavenging activity assay using 2,2-diphenyl-β-picrylhydrazyl (DPPH)

0.1 mL of an aqueous solution of WSE was mixed with 3.9 mL of a freshly prepared DPPH. ethanol solution (60 μM/dm3). Then, the samples were left at a room temperature for 45 min. Afterward, their absorbance was measured at λ = 517 nm. The percentage of DPPH. reduction by the sample was calculated using the formula below34:

where: A—absorbance of the control sample (H2O + DPPH.); B—absorbance of the test sample (WSE + DPPH.).

Radical scavenging activity assay using 2,2′-azino-bis(3-ethylbenzotialozline-6-sulfonic acid) diammonium salt (ABTS) cation radical

Firstly, the stock solution combined of 5 mL ABTS·+ (7 mM) and 88 μL of potassium persulfate (K2SO4; 140 mM/dm3) was prepared and left in the dark at a room temperature for 12–16 h. Then, the ABTS·+ solution was diluted with a phosphate buffer saline (PBS; 10 mM; pH 7.4) to get an absorbance 0.7 (± 0.02) at 734 nm. Finally, 1 mL of diluted ABTS·+ was mixed with 10 μL of the sample (WSE). The absorbance of all samples was measured after 10 min. The rate (%) of ABTS·+ reduction by the WSE was calculated using the following formula34:

where: A—absorbance of the control sample (H2O + ABTS·+); B—absorbance of the test sample (WSE + ABTS·+).

Fe ion-chelating activity

1 mL of WSE solution was mixed with 0.02 mL of FeCl2 × 4H2O (2.0 mM/dm3) and 3.7 mL of distilled water. The reaction was initiated by adding 0.04 mL of ferrozine 3-(2-pyridyl)-5,6-bis (4-phenyl-sulfonic acid)-1,2,4-triazine). Then, the samples were incubated at a room temperature for 20 min. Finally, the absorbance of the mixture was measured at 562 nm against a blank. EDTA (ethylenediaminetetraacetic acid) was used as a positive control. The Fe ion-chelating percentage was calculated using the following equation67:

where: A0—absorbance without the sample (water instead), A1—absorbance of the chelator (sample; WSE).

Ferric-reducing antioxidant power (FRAP)

The FRAP reagent (1150 µL per sample) composition was as follows: one part of 10 mM TPTZ, one part of 20 mM FeCl3 × 6H2O, and ten parts of 300 mM acetate buffer (pH 3.6), at 37 °C. Then, freshly prepared FRAP reagent was mixed with different concentrations of WSE methanolic solutions (50 µL) and incubated (20 min; room temperature). Finally, the absorbance of all samples was measured at λ = 593 nm against a blank (1150 µL FRAP reagent + 50 µL distilled water)68. The percentage of the ferric-reducing antioxidant power (FRAP) was calculated using the formula adapted from Venskutonis et al.69:

where: A—absorbance of the blank (see above); B—absorbance of the test sample (see above).

Identification of antioxidative peptides in water-soluble extracts of Gouda cheese variants using liquid chromatography and mass spectrometry (RP-HPLC–MS/MS) analysis

The identification of peptides in WSEs was carried out using the Reversed Phase High Performance Liquid Chromatography (RP-HPLC–MS/MS, i.e. RP-HPLC coupled with mass spectrometry). The data concerning the equipment and software applied for data acquisition and processing was described by Iwaniak et al.27. Details concerning LC–MS/MS analysis are presented in Table 4.

The presence of antioxidative peptides in all WSEs was visualized using the Heatmapper program (http://www.heatmapper.ca/)70,71. Additionally, we calculated the frequency of the release of antioxidative fragments during cheese ripening (AEexp.) and the relative frequency of the release of bioactive peptides during cheese ripening (Wexp.)27. The equations describing these two parameters were as follows:

where: dexp.—the number of antioxidative peptides identified in WSEs depending on the stage of Gouda ripening; N—the number of amino acid residues in a protein (acquired from the BIOPEP-UWM database).

where: A—the frequency of the occurrence of antioxidative peptides in a protein sequence (acquired from the BIOPEP-UWM database). These formulas were analogical to those introduced by Minkiewicz et al.47.

Statistical analysis

To determine whether there were significant differences in the proportion of αs-CN to β-CN between Gouda cheese variants, all data were analyzed by ANOVA using Statistica (version 13.1, 1984–2016, StatSoft Inc., Tulsa, OK). P value < 0.05 was considered significant in all tests.

Data availability

All data are available within this article as well as Supplementary Materials.

References

Abiola, D.S.-A. et al. A scoping review on bioactive peptides from meat and some daily food and their role in human health and nutrition. Int. J. Eng. Sci. 9(1), 40–51 (2019).

Sánchez, A. & Vázquez, A. Bioactive peptides: A review. Food Qual. Saf. 1, 29–46. https://doi.org/10.1093/fqsafe/fyx006 (2017).

Saravani, M., Ehsani, A., Aliakbarlu, J. & Ghasempour, Z. Gouda cheese spoilage prevention: Biodegradable coating induced by Bunium persicum essential oil and lactoperoxidase system. Food Sci. Nutr. 7, 959–968. https://doi.org/10.1002/fsn3.888 (2019).

Sieber, R. et al. ACE inhibitory activity and ACE-inhibiting peptides. Dairy Sci. Technol. 90, 47–73. https://doi.org/10.1051/dst/2009049 (2010).

Uenishi, H., Kabuki, T., Seto, Y., Serizawa, A. & Nakajima, H. Isolation and identification of casein-derived dipeptidyl-peptidase 4 (DPP-4)-inhibitory peptide LPQNIPPL from Gouda-type cheese and its effect on plasma glucose in rats. Int. Dairy J. 22, 24–30. https://doi.org/10.1016/j.idairyj.2011.08.002 (2012).

Revilla, I. et al. Antioxidant capacity of different cheeses: Affecting factors and prediction by near infrared spectroscopy. J. Dairy Sci. 99(7), 5074–5082. https://doi.org/10.3168/jds.2015-10564 (2016).

Sołowiej, B. et al. The effect of pH and modified maize starches on texture, rheological properties and meltability of acid casein processed cheese analogues. Eur. Food Res. Technol. 242, 1577–1585. https://doi.org/10.1007/s00217-016-2658-4 (2016).

Iwaniak, A. & Dziuba, J. BIOPEP-PBIL tool in the analysis of the structure of biologically active motifs derived from food proteins. Food Technol. Biotechnol. 49(1), 118–127 (2011).

Iwaniak, A., Minkiewicz, P., Hrynkiewicz, M., Bucholska, J. & Darewicz, M. Hybrid approach in the analysis of bovine milk protein hydrolysates as a source of peptides containing di- and tripeptide bitterness indicators. Pol. J. Food Nutr. Sci. 70(2), 139–150. https://doi.org/10.31883/pjfns/113532 (2020).

FitzGerald, R. J., Cermeño, M., Khalesi, M., Kleekayai, T. & Benavent-Amigo, M. Application of in silico approaches for the generation of milk protein-derived bioactive peptides. J. Funct. Foods 64, 103636. https://doi.org/10.1016/j.jff.2019.103636 (2020).

Panyayai, T. et al. FeptideDB: A web application for new bioactive peptides from food protein. Heliyon 5(7), e02076. https://doi.org/10.1016/j.heliyon.2019.e02076 (2019).

Tu, M., Cheng, S., Lu, W. & Du, M. Advancement and prospects of bioinformatics analysis for studying bioactive peptides from food-derived protein: Sequence, structure, and functions. Trends Anal. Chem. 105, 717. https://doi.org/10.1016/j.trac.2018.04.005 (2018).

Iwaniak, A., Darewicz, M., Mogut, D. & Minkiewicz, P. Elucidation of the role of in silico methodologies in approaches to studying bioactive peptides derived from foods. J. Funct. Foods 61, 103486. https://doi.org/10.1016/j.jff.2019.103486 (2019).

Udenigwe, C. C. Bioinformatic approaches, prospects and challenges of food bioactive peptide research. Trends Food Sci. Technol. 36(2), 137–143. https://doi.org/10.1016/j.tifs.2014.02.004 (2014).

Minkiewicz, P., Iwaniak, A. & Darewicz, M. BIOPEP-UWM database of bioactive peptides: Current opportunities. Int. J. Mol. Sci. 20, 5978. https://doi.org/10.3390/ijms20235978 (2019).

Halliwell, B. Biochemistry of oxidative stress. Biochem. Soc. Trans. 35(5), 1147–1150. https://doi.org/10.1042/BST0351147 (2007).

Tirzitis, G. & Bartosz, G. Determination of antiradical and antioxidant activity: Basic principles and new insights. Acta Biochim. Pol. 57(1), 139–142 (2010).

Caroli, A. M., Savino, S., Bulgari, O. & Monti, E. Detecting β-casein variation in bovine milk. Molecules 21(2), 141. https://doi.org/10.3390/molecules21020141 (2016).

Zamyatnin, A. A., Borchikov, A. S., Vladimirov, M. G. & Voronina, O. L. The EROP-Moscow oligopeptide database. Nucleic Acids Res. 34, D261–D266. https://doi.org/10.1093/nar/gkj008 (2006).

Nielsen, S. D., Beverly, R. L., Qu, Y. & Dallas, D. C. Milk bioactive peptide database: A comprehensive database of milk protein-derived bioactive peptides and novel visualization. Food Chem. 232, 673–682. https://doi.org/10.1016/j.foodchem.2017.04.056 (2017).

Iwaniak, A., Minkiewicz, P., Pliszka, M., Mogut, D. & Darewicz, M. Characteristics of biopeptides released in silico from collagens using quantitative parameters. Foods 9(7), 965. https://doi.org/10.3390/foods9070965 (2020).

Zambrowicz, A. et al. Multifunctional peptides derived from an egg yolk protein hydrolysate: Isolation and characterization. Amino Acids 47(2), 369–380. https://doi.org/10.1007/s00726-014-1869-x (2015).

Udenigwe, C. C. & Aluko, R. E. Chemometric analysis of the amino acid requirements of antioxidant food protein hydrolysates. Int. J. Mol. Sci. 12(5), 3148–3161. https://doi.org/10.3390/ijms12053148 (2011).

Chen, N., Chen, J., Yao, B. & Li, Z. QSAR study on antioxidant tripeptides and the antioxidant activity of the designed tripeptides in free radical systems. Molecules 23(6), 1407. https://doi.org/10.3390/molecules23061407 (2018).

St-Gelais, D. & Hache, S. Effect of β-casein concentration in cheese milk on rennet coagulation properties, cheese composition and cheese ripening. Food Res. Int. 38, 523–531. https://doi.org/10.1016/j.foodres.2004.11.006 (2005).

Hallen, E., Lunden, A., Allmere, T. & Andren, A. Casein retention in curd and loss of casein into whey at chymosin-induced coagulation of milk. J. Dairy Res. 77, 71–76. https://doi.org/10.1017/S0022029909990434 (2010).

Iwaniak, A., Mogut, D., Minkiewicz, P., Żulewska, J. & Darewicz, M. Gouda cheese with modified content of β-casein as a source of peptides with ACE- and DPP-IV-inhibiting bioactivity: A study based on in silico and in vitro protocol. Int. J. Mol. Sci. 22(6), 2949. https://doi.org/10.3390/ijms22062949 (2021).

de Roos, A. L., Geurts, T. J. & Walstra, P. The association of chymosin with artificial casein micelles. Int. Dairy J. 10(4), 225–232. https://doi.org/10.1016/S0958-6946(00)00050-9 (2000).

Dunnewind, B., de Roos, A. L. & Geurts, T. J. Association of chymosin with caseins in solution. Neth. Milk Dairy J. 50(2), 121–133 (1996).

Van Hekken, D. L. & Holsinger, V. H. Use of cold microfiltration to produce unique β-casein enriched milk gels. Láit 80, 69–76. https://doi.org/10.1051/lait:2000108 (2000).

Benzie, I. F. F. & Choi, S.-W. Chapter one—Antioxidants in food: Content, measurement, significance, action, cautions, caveats, and research needs. Adv. Food Nutr. Res. 71, 1–53. https://doi.org/10.1016/B978-0-12-800270-4.00001-8 (2014).

Shahidi, F. & Zhong, Y. Measurement of antioxidant activity. J. Funct. Foods 18, 757–781. https://doi.org/10.1016/j.jff.2015.01.047 (2015).

Perna, A., Intaglietta, I., Simonetti, A. & Gambacorta, E. Short communication: Effect of genetic type on antioxidant activity of Caciocavallo cheese during ripening. J. Dairy Sci. 98(6), 3690–3694. https://doi.org/10.3168/jds.2014-9097 (2015).

Meira, S. M. M. et al. Bioactive peptides in water-soluble extracts of ovine cheeses from Southern Brazil and Uruguay. Food Res. Int. 48(1), 322–329. https://doi.org/10.1016/j.foodres.2012.05.009 (2012).

Unal, G. Antioxidant activity of commercial dairy products. AgroFOOD Ind. Hi-tech 23(1), 39–41 (2012).

Dontha, S. A review on antioxidant methods. Asian J. Pharm. Clin. Res. 9, 14–32. https://doi.org/10.22159/ajpcr.2016.v9s2.13092 (2016).

Öztürk, H. İ & Akin, N. Comparison of some functionalities of water soluble peptides derived from Turkish cow and goat milk Tulum cheeses during ripening. Food Sci. Technol. 38(4), 674–682. https://doi.org/10.1590/1678-457x.11917 (2018).

Corrêa, A. P. et al. Antioxidant, antihypertensive and antimicrobial properties of ovine milk caseinate hydrolyzed with a microbial protease. J. Sci. Food Agric. 91(12), 2247–2254. https://doi.org/10.1002/jsfa.4446 (2011).

Álvarez Ramos, L., Baez, A. D., Ortiz, D. G., Ruiz Ruiz, C. J. & Toledo López, M. V. Antioxidant and antihypertensive activity of Gouda cheese at different stages of ripening. Food Chem. X 14, 100284. https://doi.org/10.1016/j.fochx.2022.100284 (2022).

Huma, N., Rafiq, S., Sameen, A., Pasha, I. & Khan, M. I. Antioxidant potential of buffalo and cow milk Cheddar cheeses to tackle human colon adenocarcinoma (Caco-2) cells. Asian-Aust. J. Anim. Sci. 31(2), 287–292. https://doi.org/10.5713/ajas.17.0031 (2018).

Matemu, A., Nakamura, S. & Katayama, S. Health benefits of antioxidative peptides derived from legume proteins with a high amino acid score. Antioxidants 10(2), 316. https://doi.org/10.3390/antiox10020316 (2021).

Bottesini, C. et al. Antioxidant capacity of water-soluble extracts from Parmigiano–Reggiano cheese. Int. J. Food Sci. Nutr. 64, 953–958. https://doi.org/10.3109/09637486.2013.821696 (2013).

Chen, P. et al. Antioxidant activity of Cheddar cheese during its ripening time and after simulated gastrointestinal digestion as affected by probiotic bacteria. Int. J. Food Prop. 22(1), 218–229. https://doi.org/10.1080/10942912.2019.1579836 (2019).

Saito, K. et al. Antioxidative properties of tripeptide libraries prepared by the combinatorial chemistry. J. Agric. Food Chem. 51, 3668–3674. https://doi.org/10.1021/jf021191n (2003).

Lee, N.-K., Jeewanthi, R. K. C., Park, E.-H. & Paik, H.-D. Short communication: Physicochemical and antioxidant properties of Cheddar-type cheese fortified with Inula britannica extract. J. Dairy Sci. 99(1), 83–88. https://doi.org/10.3168/jds.2015-9935 (2016).

Santiago-López, L. et al. Bioactive compounds produced during cheese ripening and health effects associated with aged cheese consumption. J. Dairy Sci. 101(5), 3742–3757. https://doi.org/10.3168/jds.2017-13465 (2018).

Minkiewicz, P., Dziuba, J. & Michalska, J. Bovine meat proteins as potential precursors of biologically active peptides—A computational study based on the BIOPEP database. Food Sci. Technol. Int. 17, 39–45. https://doi.org/10.1177/1082013210368461 (2011).

Barbano, D. M. & Lynch, J. M. Major advances in testing of dairy products: Milk component and dairy product attribute testing. J. Dairy Sci. 89(4), 1189–1194. https://doi.org/10.3168/jds.S0022-0302(06)72188-9 (2006).

McSweeney, P. L. H. Biochemistry of cheese ripening. Int. J. Dairy Technol. 57(2/3), 127–144. https://doi.org/10.1111/j.1471-0307.2004.00147.x (2004).

Díaz-Gómez, J. L. et al. In silico analysis and in vitro characterization of the bioactive profile of three novel peptides identified from 19 kDa α-zein sequences of maize. Molecules 25, 5405. https://doi.org/10.3390/molecules25225405 (2020).

Gallego, M., Arnal, M., Talens, P., Toldrá, F. & Mora, L. Effect of gelatin coating enriched with antioxidant tomato by-products on the quality of pork meat. Polymers 12, 1032. https://doi.org/10.3390/polym12051032 (2020).

Mora, L., González-Rogel, D., Heres, A. & Toldrá, F. Iberian dry-cured ham as a potential source of α-glucosidase-inhibitory peptides. J. Funct. Foods 67, 103840. https://doi.org/10.1016/j.jff.2020.10384 (2020).

Panjaitan, F. C. A., Gomez, H. L. R. & Chang, Y.-W. In silico analysis of bioactive peptides released from giant grouper (Epinephelus lanceolatus) roe proteins identified by proteomics approach. Molecules 23, 2910. https://doi.org/10.3390/molecules23112910 (2018).

Udechukwu, M. C., Dang, C. & Udenigwe, C. C. Identification of zinc-binding peptides in ADAM17-inhibiting whey protein hydrolysates using IMAC-Zn2+ coupled with shotgun peptidomics. Food Prod. Process. Nutr. 3, 5. https://doi.org/10.1186/s43014-020-00048-4 (2021).

Liu, R., Xing, L., Fu, Q., Zhou, G.-H. & Zhang, W.-G. A review of antioxidant peptides derived from meat muscle and by-products. Antioxidants 5(3), 32. https://doi.org/10.3390/antiox5030032 (2016).

BIOPEP-UWM database. University of Warmia and Mazury. https://biochemia.uwm.edu.pl/biopep-uwm/. Accessed June 30, 2021 (2021).

AOAC International. Official Methods of Analysis, 18th edn. (AOAC International, 2007).

Wojciechowski, K. L. & Barbano, D. M. Modification of the Kjeldahl noncasein nitrogen method to include bovine milk concentrates and milks from other species. J. Dairy Sci. 98, 7510–7526. https://doi.org/10.3168/jds.2015-9580 (2015).

Zulewska, J., Kowalik, J. & Dec, B. Flux and transmission of β-casein during cold microfiltration of skim milk subjected to different heat treatments. J. Dairy Sci. 101, 10831–10843. https://doi.org/10.3168/jds.2018-14496 (2018).

Verdi, R. J., Barbano, D. M. & Dellavalle, M. E. Variability in true protein, CN, nonprotein nitrogen, and proteolysis in high and low somatic cell milks. J. Dairy Sci. 70, 230–242. https://doi.org/10.3168/jds.S0022-0302(87)80002-4 (1987).

Nath, K. R. & Ledford, R. A. Growth response of Lactobacillus casei variety casei to proteolysis in cheese during ripening. J. Dairy Sci. 56, 710–715. https://doi.org/10.3168/jds.S0022-0302(73)85238-5 (1973).

Lau, K. Y., Barbano, D. M. & Rasmussen, R. R. Influence of pasteurization of milk on protein breakdown in Cheddar cheese during aging. J. Dairy Sci. 74, 727–740 (1991).

Neocleous, M., Barbano, D. M. & Rudan, M. A. Impact of low concentration factor microfiltration on the composition and aging of Cheddar cheese. J. Dairy Sci. 85, 2425–2437. https://doi.org/10.3168/jds.S0022-0302(02)74325-7 (2002).

GraphPad Software. http://www.graphpad.com/. Accessed July, 2021 (2021).

Quirós, A., Hernández-Ledesma, B., Ramos, M., Amigo, L. & Recio, I. Angiotensin-converting enzyme inhibitory activity of peptides derived from caprine kefir. J. Dairy Sci. 88(10), 3480–3487. https://doi.org/10.3168/jds.S0022-0302(05)73032-0 (2005).

Sebaugh, J. L. Guidelines for accurate EC50/IC50 estimation. Pharm. Stat. 10(2), 128–134. https://doi.org/10.1002/pst.426 (2011).

Guo, T., Wei, L., Sun, J., Hou, C.-L. & Fan, L. Antioxidant activities of extract and fractions from Tuber indicum Cooke & Massee. Food Chem. 127(4), 1634–1640. https://doi.org/10.1016/j.foodchem.2011.02.030 (2011).

Benzie, I. F. F. & Strain, J. J. The ferric reducing ability of plasma (FRAP) as a measure of “antioxidant power”: The FRAP assay. Anal. Biochem. 239, 70–76. https://doi.org/10.1006/abio.1996.0292 (1996).

Venskutonis, P. R., Gruzdiene, D., Tirzite, D. & Tirzitis, G. Assessment of antioxidant activity of plant extracts by different methods. In: Proc. WOCMAP III, Vol. 3: Perspectives in Natural Product Chemistry. Eds: Başer, K. H. C., Franz, G., Cañigueral, S., Demirci, F., Cracker, L. E., & Gardner Z.E. Acta Hortic. 677, 99–107 (2005).

Heatmapper. http://www.heatmapper.ca/. Accessed September, 2021 (2021).

Babicki, S. et al. Heatmapper: Web-enabled heat mapping for all. Nuclecic Acids Research 44, W147–W153. https://doi.org/10.1093/nar/gkw419 (2016).

Acknowledgements

Authors wish to thank Dr. Monika Pliszka for her technical support during the assays of the antioxidative bioactivity of Gouda cheese water-soluble extracts as well as Dr. hab. Jaroslaw Kowalik, Prof. UWM, Waldemar Brandt MSc, Hanna Nowak MSc, Roman Łaszek MSc, and Mr. Sławomir Wiśniewski for technical assistance during cheese production. The authors would also like to thank Prof. Władysław Chojnowski and Dr. Maria Czerniewicz for scientific advices during cheese making. The funding sponsors had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

Funding

Project financially supported by the Minister of Education and Science under the program entitled “Regional Initiative of Excellence” for the years 2019–2022, Project No. 010/RID/2018/19, amount of funding 12.000.000 PLN as well as the funds of the University of Warmia and Mazury in Olsztyn (Project No. 17.610.014-110).

Author information

Authors and Affiliations

Contributions

Conceptualization, A.I.; Formal analysis, all authors; Funding acquisition, M.D.; Investigation, A.I. and D.M; Methodology, all authors; Project administration, M.D.; Figures, P. M., J. Ż., and D. M; Resources, M.D.; Supervision, A.I.; Visualization, A.I., P. M., and D.M.; Writing—original draft, A.I..; Writing—review and editing, A.I., P.M., J.Ż., and M.D.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Iwaniak, A., Mogut, D., Minkiewicz, P. et al. An integrated approach to the analysis of antioxidative peptides derived from Gouda cheese with a modified β-casein content. Sci Rep 12, 13314 (2022). https://doi.org/10.1038/s41598-022-17641-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-022-17641-x

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.