Abstract

The macro petrographic compositions and its pore characteristics of coal reservoir play critical role in the accumulation and development of coalbed methane (CBM). In this paper, the pore characteristics of vitrain and durain were analyzed through the experiment and fractal theory. The results indicated that the micropores and microfractures develop in vitrain, and that transitional pores develop in durain. The pore volume and specific surface area (SSA) of vitrain are larger than those of durain, with the micropore SSA of vitrain being 35% higher than that of durain. The threshold pressure and tortuosity of vitrain are greater than that of durain, but the mean pore size of vitrain is smaller than that of durain. The fractal dimension D1 of vitrain is greater than that of durain, while the fractal dimension D2 is opposite, indicating that the pore surface of vitrain is coarser, and the pore structure of durain is more complex. The fractal dimension Dk of vitrain is larger than that of durain, the mean fractal dimension Ds of vitrain is smaller than that of durain, which shows that the diffusivity of vitrain is weak but the seepage capacity is strong due to the developed fractures. The difference in material composition and pore characteristics between vitrain and durain provides a new understanding for the development of CBM in low rank coal.

Similar content being viewed by others

Introduction

Coalbed methane (CBM) is a by-product of coal formation that is widely used due to its clean and low-carbon energy properties1,2,3. CBM is stored in the pore and fracture system of the coal reservoir in multiple occurrence states4,5,6. Hence, the pore development characteristics of coal are the crucial factors for the adsorption/desorption capacity of CBM7,8,9,10. To date, a large number of studies have been conducted on the pore characteristics of coal using multi-scale testing and analysis methods11,12,13,14, and numerous research results have been achieved15,16,17,18. Through literature review, it was found that the main influencing factors controlling the pore development and structural characteristics of coal reservoir are the degree of metamorphism, chemical structure, maceral components, tectonic action etc17,19,20,21. As the coal metamorphism degree increases, the macropores decrease and the micropores develop22. Due to the low proportion of aromatic nuclei in low-rank coal, the high proportion of functional groups and long side chains, the spatial structure of coal reservoir is loose. With increasing the aromatic nuclei, the side chains gradually decompose and the length decreases, so that the structure becomes more compact23. Vitrinite showed a strong positive correlation with micropores and pore specific surface area, while inertinite showed a negative correlation24. In different coal ranks, macerals have different effects on adsorption capacity25. The pore structure of tectonic coal is more complex than that of primary coal, suggesting that tectonic action changed the adsorption/desorption capacity of methane through its influence on the pore distribution26. In order to intuitively describe the occurrence states and migration characteristics of methane in different pore sizes, Hu et al.27 proposed new pore classification method, i.e. inaccessible pores (< 0.38 nm), filling pores (0.38–1.5 nm), diffusion pores (1.5–100 nm), and seepage pores (> 100 nm). Nano-scale micropores provide adsorption sites for methane, while nano-scale mesopores and all micro-scale pores have no adsorption energy for CH428, the most important factors affecting methane adsorption capacity were the volume and specific surface area of ultra-micropores8.

The pore structure of coal is very complex and its pore distribution and surface topography are heterogeneous. It is difficult to quantitatively describe their complex pore characteristics using traditional euclidean geometric theory29. However, the pore structure of coal shows self-similarity within a certain scale, and its spatial distribution pattern is between two and three dimensions. Like most natural rocks, they have fractal characteristics30 and are more suitable for fractal geometric description31. As a tool to describe complex phenomena, fractal theory provides a new scientific method for studying the complex pore structure of coal32. The fractal characteristics of the coal pore structure correlate with the heterogeneity and complexity of the pore structure with its adsorption and seepage capacity of methane, micropores are the primary causes of heterogeneity33. That is, by analyzing the relationship fractal dimension and coal rank, coal composition and pore structure, and revealed the influence of pore structure on CH4 adsorption and seepage capacity34. Fractal dimension D2 displayed a positive correlation with SSA, and the negative correlation with mean pore size35. Coal reservoir with more complex pore surfaces and simpler pore structures has stronger methane adsorption capacity36, and the coalification makes coal surfaces and pore networks comparatively smoother and more regular for lower rank coals, but rougher and more complex for higher rank coals37. The width that corresponds to the inflection points of the fractal curves are considered to be the critical value for determining the pores and fractures in coal38.Therefore, it is very important to quantitatively analyze the fractal characteristics of pore structure by using fractal dimension.

These studies form the basis for further investgation on the pore structure of coal and adsorption/desorption of CBM. It must be noted that the macro petrographic composition has different effects on adsorption/desorption and migration of methane39,40,41,42,43,44, but litter research has been done on the pore characteristics of macro petrographic composition. In this study, the pore characteristics of vitrain and durain (two typical macro petrographic composition) were investigated by mercury intrusion porosimetry (MIP), low-pressure nitrogen adsorption (LP-N2) and low-pressure carbon dioxide (LP-CO2). Based on the test data, the appropriate evaluation model of pore fractal characteristics were selected to analyze the difference of pore fractal characteristics between vitrain and durain, which fully reflects the surface roughness of micropores, pore complexity of mesoporous pores, and seepage and diffusion capacity of macropores in the same coal sample. It provides a new perspective for studying methane adsorption, storage and desorption-transport capacity of different macro petrographic composition in low-rank coal reservoirs, which is helpful to actively promote the efficient development of CBM in low-rank coal.

Experiments and methods

Sample preparation

In this study, coal samples come from 12102 working face of Yuanzigou mine (YZG) in Yonglong mine area and 20418 working face of Huangling No. 2 mine (HL) in Huangling mine area of Huanglong coal field. YZG-JM and HL-JM represent vitrain, and YZG-AM and HL-AM represent durain. According to GB/T 482-2008, large block coal samples were collected from the working face, and the size of 1.0 cm sample was used for MIP. The stripped vitrain and durain fragments were ground into powder with size of 0.18–0.25 mm, the proximate analysis, LP-N2 adsorption and LP-CO2 adsorption were conducted. The particle size < 1.0 mm were selected for maceral identification.

Experimental test method

AutoPore IV 9500 was used for mercury intrusion porosimetry (MIP). The pore size range is 0.005–1000 μm, and the reporting range is 0.10–61,000.00 psia. The volume accuracy of MIP is better than 0.1uL. The ASAP 2020 (V4.03) equipment was selected for low pressure nitrogen adsorption/low pressure carbon dioxide adsorption (LP-N2/ LP-CO2). Analysis parameters: specific surface area 0.0005 m2/g, pore size analysis 3.5–5000 Å, resolution 0.2 Å, minimum pore volume detection 0.0001 ml/g, and N2 temperature is 77 K. The principle of LP-CO2 adsorption is similar to that of LP-N2 adsorption. Compared with N2, CO2 gas molecules are smaller, diffusion rate is faster, and there is a higher saturation pressure at 273.15 K, which can be used for fine characterization of micropores.

Evaluation method of pore fractal characteristics

The pore structure of coal plays a crucial role in the adsorption/desorption of CBM, and the fractal model can well characterize the roughness and the complexity of pore structure45. At present, the main methods to calculate the fractal dimension of pores based on LP-N2 adsorption data include fractal BET model, fractal FHH model and thermodynamic model. Among them, FHH (Frenkel-Halsey-Hill) proposed by PFEIFER et al46 is widely used in the calculation of fractal dimension of pore structure characteristics of porous materials due to its convenient calculation. Its calculation formula (1) is as follows:

where \(P\) is adsorption capacity of gas at equilibrium pressure P, cm3/g; \(p_0\) is saturated vapor pressure of gas, MPa; \(C\) is constant; \(D\) is fractal dimension. Therefore, with \(\ln \left[ {\ln (p_{0} /P)} \right]\) as the horizontal coordinate, and \(\ln V\) as the vertical coordinate, the curve slope can be obtained through linear fitting, and the fractal dimension can be scored.

MIP can well characterize macropores in coal reservoirs, so the Washburn equation is the basis for calculating the fractal dimension by MIP. There are mainly Menger sponge model, Capillary model, Sierpinski model and Thermodynamic model for calculating pore fractal dimension of MIP47. Jia Tengfei et al.45 evaluated the pore fractal model of low-rank coal reservoirs and found that there are certain differences in the characterization of fractal dimension obtained by different models. The relationship between fractal dimension and pore structure parameters shows that Menger sponge synthesis model and capillary synthesis model have limited parameters and insufficient precision. The Sierpinski model can well characterize the pore morphology of coal reservoir. Based on the relationship between pressure and mercury intrusion amount, the model is obtained45, the calculation formula as (2):

where \(V\) is mercury intrusion amount (mL/g); \(\alpha\) is constant; \(P\) is mercury intrusion pressure (MPa); \(P_c\) is the threshold pressure (MPa).

Results and discussion

Material composition characteristic

The low rank coal is in the primary stage of coalification, the results of coal proximate analys were shown that there are some differences in material composition between vitrain and durain (Table 1). The volatile yield of coal sample is high (22.28–35.57%), in which volatile yield of vitrain is higher than that of durain. However, the fixed carbon and ash yield of durain are greater than that of vitrain, and the difference of fixed carbon is relatively small. The difference in material composition is the result of the evolution of coal-forming environment.

Maceral components characteristic

The maceral components test results of coal samples showed that vitrain is rich in vitrinite, and the content of vitrinite ranges from 64.5 to 78.6%, with an average of 71.05%. Durain is rich in inertinite, and the content of inertinite ranges from 54.1 to 74.6%, with an average of 67.37%. The content of liptinite in vitrain and durain generally low, about 1.2% on average (Table 2). The difference of maceral components between vitrain and durain is an important reason for determining pore development.

Micropore development characteristics of vitrain and durain

According to the pore classification standard of IUPAC48, micropores is pore size < 2 nm. Because of LP-N2 adsorption can only measure the pore size > 1.8 nm, so the micropore characterization result are not accurate. Compared with N2 molecules, CO2 molecules are smaller and can enter smaller pores, which can be reflected more objectively micropores (< 2 nm). The LP-CO2 absorption/desorption were analyzed by DFT model recommended by ISO and IUPAC48. The LP-CO2 absorption/desorption curves of vitrain and durain were shown in Fig. 1.

As shown in Table 3, BET pore specific surface area (SSA) of YZG-JM and YZG-AM are 150.737 m2/g and 114.937 m2/g, respectively, and those of HL-JM and HL-AM are 139.559 m2/g and 101.589 m2/g, respectively. The DFT pore SSA of YZG-JM and YZG-AM are 160.51 m2/g and 127.417 m2/g, respectively, while those of HL-JM and HL-AM are 117.623 m2/g and 113.924 m2/g, respectively. As a whole, the calculation results of the two models showed that the SSA of vitrain is larger than that of durain, and the calculation results of the two models have little difference, ranging from 6.25 to 15.8%. The BET mean pore size of YZG-JM and YZG-AM are 0.975 nm and 1.018 nm, respectively, and that of HL-JM and HL-AM are 0.752 nm and 1.023 nm, respectively. In other words, the mean pore size of durain is larger than that of vitrain.

Mesopore development characteristics of vitrain and durain

The analysis of pore development characteristics of LP-N2 adsorption still adopts the IUPAC standard48. According to the LP-N2 adsorption/desorption isotherms of coal samples in Fig. 2, the adsorption isotherms of YZG and HL rose slowly in the low pressure area (P/P0 < 0.10), and the curve was slightly convex upward, which corresponded to the single molecular layer adsorption of N2 in the pore. In the medium pressure area (0.10 < P/P0 < 0.80), the adsorption capacity increased slowly with the increase of relative pressure, corresponding to the multi-molecular layer adsorption. Subsequently, the isothermal adsorption curve show an inflection point, and the adsorption capacity increased sharply in the higher pressure area (0.80 < P/P0 < 1), and the adsorption curve still showed an upward trend until P/P0 = 1, corresponding to the capillary condensation.

The relationship between pore size and pore volume (PV) was shown in Fig. 3, the pore size is 1.8–145 nm, the PV curve of vitrain is higher than that of durain, and the PV increment of vitrain at each stage is greater than that of durain. The same pattern was observed between the pore SSA and the pore size (Fig. 4). The PV and pore SSA showed three stages of change. That is, increases slowly when the pore size is 4–145 nm. The PV and pore SSA increase significantly when the pore size is 3–4 nm. At pore size 1.8–3 nm, the slope of the curve slows down again. Comparing vitrain and durain in the same coal sample, it was found that the curve slope of vitrain was greater than that of durain, and the growth rate of vitrain was greater under the same pore size range. The PV and pore SSA growth curves 4–145 nm were analyzed, it was found that the PV curve could be approximated as a primary function, while the SSA curve was an exponential function.

Traditional BET and BJH models have certain deviation in the analysis of micropores materials. In addition to the BET and BJH models, the analysis of pore development characteristics was compared with the DFT model. It can be seen from Table 4, the pore SSA of DFT model was smaller than that of BET model, and the pore SSA of vitrain was obviously larger than that of durain in the same coal sample. The PV of the DFT model was smaller than that of the BJH model, and the PV of vitrain in the same coal sample was obviously larger than that of durain. The mean pore size of vitrain calculated by BET and BJH models was smaller than that of durain. Therefore, the analysis results of BET, BJH and DFT models were consistent for the pore characteristic parameters of vitrain and durain.

Pore fractal characteristics of vitrain and durain with LP-N 2 adsorption

According to the LP-N2 adsorption/desorption curve, there is an obvious hysteresis loop in the adsorption/desorption curve when the relative pressure P/P0 = 0.5, and the adsorption/desorption curves tend to coincide when P/P0 < 0.5. According to the principle of N2 adsorption in coal pores, when the relative pressure is low (P/P0 < 0.5), N2 molecules are mainly affected by the Vander Waals force on the surface of coal as monolayer adsorption. The fractal dimension at this stage represents the roughness of the pore surface, and the fractal dimension D1 is recorded. With the gradual increase of relative pressure (P/P0 > 0.5), N2 molecules adsorbed from single molecular layer to multi-molecular layer, from micropores to mesoporous and macropores, and the adsorption force gradually evolved from Vander Waals force to capillary condensation. The fractal dimension at this stage represents the complexity inside the pores, and as the fractal dimension D2. Therefore, the N2 adsorption/desorption curve is segmented, and the general pore fractal dimension is 2–3. The more tends to 2, the smoother and more simple it is, and the more tends to 3, the coarser and more complex it is.

The fractal dimension for LP-N2 adsorption/desorption were shown in Fig. 5. The fractal dimension D1 of YZG-JM and YZG-AM are 2.614 and 2.542, respectively, and the fractal dimension D1 of HL-JM and HL-AM are 2.889 and 2.566, respectively. The fractal dimension D1 of vitrain is greater than that of durain, indicating that the pore surface of vitrain is coarser than that of durain at the single molecular layer adsorption. When P/P0 > 0.5 is used for multilayer adsorption and capillary condensation, the fractal dimensions D2 of YZG-JM and YZG-AM are 2.833 and 2.795, and the fractal dimensions D2 of HL-JM and HL-AM are 2.554 and 2.688, respectively. The fractal dimension D2 of YZG-JM is larger than YZG-AM, while the fractal dimension D2 of HL-JM is smaller than HL-AM. On average, the fractal dimension D2 of durain is larger than vitrain, indicating that the pore structure of durain is more complex than vitrain.

Macropore development characteristics of vitrain and durain

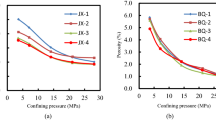

As shown in Fig. 6, The pressure-mercury saturation curves of coal samples from YZG and HL showed obvious difference. The mercury intrusion curve of YZG can be divided into two section, pore size < 1000 nm is more developed, but there is little difference between vitrain and durain overall. HL coal sample can be divided into three section, the fracture (> 100,000 nm) and pore (< 100 nm) developed in vitrain and durain. Comparatively speaking, the fracture of vitrain is more developed.

The MIP range is limited (0.005–1000 μm), and the MIP could not characterize the pores with pore size < 2 nm, so the MIP adopted the pore size classification standard of B.B.Xoдoт. According to the results of MIP, the PV proportion of macropore and mesopore (> 100 nm) in YZG-JM are 38.94% and that of YZG-AM are 24.25%. HL-JM and HL-AM are 43.60% and 32.03%, respectively (Fig. 7). It is particularly noted that the macropore (micro-fractures) of HL-JM account for 41.42%, mainly because HL-JM is brittle and the fractures are very developed. The PV proportion of transition pore in durain is 51.94% (YZG-AM) and 44.97% (HL-AM), which is larger than that of vitrain 32.93% (YZG-JM) and 26.70% (HL-JM). The micropore development of vitrain is higher than that of durain in the same coal sample. In terms of SSA, micropores are still the first contributor of SSA, accounting for more than 60%. It is found that the micropore SSA of vitrain is 70.03% (YZG-JM) and 75.92% (HL-JM) than that of durain is 60.54% (YZG-AM) and 62.85% (HL-AM), and the transition pore SSA of durain is greater than that of vitrain (Fig. 8). The SSA of mesopore and macropore are so small that they are almost negligible.

Mercury intrusion/extrusion curve of YZG coal sample has a large opening and obvious hysteresis, which indicates that YZG is dominated by open pores and has good connectivity. The mercury extrusion efficiency of four coal samples ranges from 34.71 to 58.38% (Table 5), which does not exceed 60%, and is generally poor. The mercury extrusion curves are obviously different between HL-JM and HL-AM. The mercury extrusion efficiency of HL-JM is high (58.38%), reflecting that except for macropores (fracture), the other pores of HL-JM are mainly semi-open pores, and the connectivity is poor. HL-AM the mercury extrusion efficiency is 43.39%, and the mercury extrusion curve hysteresis is obvious at the middle and low pressure stage, indicating poor connectivity in the micropore-transition pore and good connectivity in the mesopore-macropore. In comparison, the mercury extrusion efficiency of HL-JM is maximum, mainly due to its fractures development, which is consistent with the research results of bright coal with rich fractures and good connectivity proposed by Qu et al49. According to the pore characteristics with MIP (Table 5), the threshold pressure and tortuosity of vitrain are greater than that of durain, but the mean pore size of vitrain is smaller than that of durain, and the pore structure of vitrain is more complex.

Pore fractal characteristics of vitrain and durain with MIP

Macropores are mainly used as diffusion and permeability channels in the process of desorption and migration of CBM. However, it is insufficient to reflect the complexity of pore structure only by direct results of MIP. Fractal theory can make up for this defect, that is, to quantitatively express the complex problem of pore structure characteristics. LP-N2 absorption/desorption is mainly targeted at < 50 nm pores, so it is feasible to calculate the fractal characteristics of > 50 nm pores by MIP data. The pores with pore size > 50 nm were divided into macropore with pore size 50–1000 nm and fractures with pore size > 1000 nm. The diffusion capacity and permeability capacity of the pores were characterized, and the fractal dimensions are Dk and Ds, respectively. According to the calculation results of fractal dimension (Fig. 9), the fractal dimension Dk of YZG-JM and YZG-AM are 2.712 and 2.611, respectively, and the fractal dimension Dk of HL-JM and HL-AM are 2.958 and 2.841, respectively, when the pore size is 50–1000 nm. The fractal dimension Dk of vitrain is larger than that of durain, indicating that the diffusion ability of macropore of vitrain is weak. In the range > 1000 nm, the fractal dimension Ds of YZG-JM and YZG-AM are 2.738 and 2.864, respectively, and the fractal dimension Ds of HL-JM and HL-AM are 2.973 and 2.959, respectively. The mean fractal dimension Ds of vitrain is smaller than that of durain, it indicates that vitrain has stronger seepage capacity, which is closely related to the fractures development of vitrain.

According to the above analysis results, it can be believed that there are obvious differences in pore development and pore structure of macro petrographic composition represented by vitrain and durain in low-rank coal reservoirs. Under the influence of coal-forming environment, vitrain is formed in water-covered sedimentary environment, and micropores develop. Later, due to the action of tectonic stress, vitrain brittleness leads to its fracture development. The durain is formed in dry oxidizing environment, transition pore development, the type of pore is mainly plant cell pore. Coalbed methane is stored in pores-fracture. Since the pore volume and specific surface area of vitrain are larger than that of durain and the micropore surface is rough, it is more favorable for methane adsorption and enrichment. The mean pore size of durain is larger than that of vitrain and the transition pore are develop and well connected, and the methane diffusion ability in macropores is strong, which is more conducive to the desorption and migration of methane.

Conclusion

-

(1)

The basic material composition of vitrain and durain is different in the same coal sample. Vitrain has a higher volatile yield than durain, but the ash yield and fixed carbon content of durain are higher than that of vitrain Vitrain is rich in vitrinite, durain is rich in inertinite, and the content of liptinite is generally low in low-rank coal.

-

(2)

The micropores developed in vitrain and transitional pores developed in durain. The SSA and PV of vitrain are larger than that of durain, in which the micropore SSA of vitrain being 35% higher than that of durain. Transition pores and micro-fractures are the main contributors to the PV, accounting for more than 50% of the total PV. The LP-N2 absorption results showed that the PV curve could be approximated as a primary function, while the SSA curve was an exponential function when the pore size is 4–145 nm.

-

(3)

The mercury extrusion efficiency of coal samples is between 34.71 and 58.38%, which does not exceed 60%. In comparison, the mercury extrusion efficiency of HL-JM is maximum at 41.42%, which is mainly due to the development of micro-fractures. The threshold pressure and tortuosity of vitrain are greater than that of durain, but the mean pore size of vitrain is smaller than that of durain at different pore sizes.

-

(4)

Based on the calculation of the fractal dimension of pores with LP-N2 adsorption, it was found that at P/P0 < 0.5, the fractal dimension D1 of vitrain is larger than that of durain, indicating that the pore surface of vitrain is coarser than that of durain. when P/P0 > 0.5, the fractal dimension D2 of durain is larger than that of vitrain indicating that the pore structure of durain is more complex than that of vitrain. According to the results of MIP, in the range of pore size 50–1000 nm, the fractal dimension Dk of vitrain is larger than that of durain, it indicates that the diffusion ability of vitrain is weak. At the pore size > 1000 nm, the mean fractal dimension Ds of vitrain is smaller than that of durain, indicating that vitrain has developed fractures and strong seepage capacity.

Data availability

All data generated or analysed during this study are included in this published article.

References

Moore, T. A. Coalbed methane: A review. Int. J. Coal Geol. 101, 36–81. https://doi.org/10.1016/j.coal.2012.05.011 (2012).

Mastalerz, M. & Drobniak, A. Coalbed methane: Reserves, production, and future outlook. Future Energy https://doi.org/10.1016/b978-0-08-102886-5.00005-0 (2020).

Li, Y., Wang, Z., Tang, S. & Elsworth, D. Re-evaluating adsorbed and free methane content in coal and its ad- and desorption processes analysis. Chem. Eng. J. https://doi.org/10.1016/j.cej.2021.131946 (2022).

Liu, X. et al. Nanopore structure of deep-burial coals explored by AFM. Fuel 246, 9–17. https://doi.org/10.1016/j.fuel.2019.02.090 (2019).

Mou, P. et al. Coal pores: Methods, types, and characteristics. Energy Fuel 35, 7467–7484. https://doi.org/10.1021/acs.energyfuels.1c00344 (2021).

Xiong, Q. et al. Characterizing coal pore space by gas adsorption, mercury intrusion, FIB–SEM and µ-CT. Environ. Earth Sci. https://doi.org/10.1007/s12665-020-08950-3 (2020).

Li, Z. et al. Full-scale pore structure characterization of different rank coals and its impact on gas adsorption capacity: A theoretical model and experimental study. Energy https://doi.org/10.1016/j.energy.2023.127621 (2023).

Xu, S., Hu, E., Li, X. & Xu, Y. Quantitative analysis of pore structure and its impact on methane adsorption capacity of coal. Natl. Resources Res. 30, 605–620. https://doi.org/10.1007/s11053-020-09723-2 (2020).

Zhang, M. & Fu, X. Characterization of pore structure and its impact on methane adsorption capacity for semi-anthracite in Shizhuangnan Block, Qinshui Basin. J. Natl. Gas Sci. Eng. 60, 49–62. https://doi.org/10.1016/j.jngse.2018.10.001 (2018).

Tao, S. et al. Material composition, pore structure and adsorption capacity of low-rank coals around the first coalification jump: A case of eastern Junggar Basin, China. Fuel 211, 804–815. https://doi.org/10.1016/j.fuel.2017.09.087 (2018).

Jiang, J., Yang, W., Cheng, Y., Zhao, K. & Zheng, S. Pore structure characterization of coal particles via MIP, N2 and CO2 adsorption: Effect of coalification on nanopores evolution. Powder Technol. 354, 136–148. https://doi.org/10.1016/j.powtec.2019.05.080 (2019).

Li, X., Kang, Y. & Haghighi, M. Investigation of pore size distributions of coals with different structures by nuclear magnetic resonance (NMR) and mercury intrusion porosimetry (MIP). Measurement 116, 122–128. https://doi.org/10.1016/j.measurement.2017.10.059 (2018).

Liu, W., Wang, G., Han, D., Xu, H. & Chu, X. Accurate characterization of coal pore and fissure structure based on CT 3D reconstruction and NMR. J. Natl. Gas Sci. Eng. https://doi.org/10.1016/j.jngse.2021.104242 (2021).

Sun, L., Zhang, C., Wang, G., Huang, Q. & Shi, Q. Research on the evolution of pore and fracture structures during spontaneous combustion of coal based on CT 3D reconstruction. Energy https://doi.org/10.1016/j.energy.2022.125033 (2022).

Li, R., Hou, X., Chen, L., Fang, H. & Zheng, C. Multifractal investigation on multi-scale pore structure heterogeneity of high rank coal reservoirs. Natl. Resources Res. 31, 1665–1685. https://doi.org/10.1007/s11053-022-10046-7 (2022).

Liu, X. et al. Role of pore irregularity in methane desorption capacity of coking coal. Fuel https://doi.org/10.1016/j.fuel.2021.123037 (2022).

Nie, B. et al. Insights into the nanoscale microstructure diversity of different rank coals. Energy Fuel 36, 10899–10909. https://doi.org/10.1021/acs.energyfuels.2c02093 (2022).

Wang, T., Tian, F., Deng, Z. & Hu, H. The characteristic development of micropores in deep coal and its relationship with adsorption capacity on the eastern margin of the ordos basin, China. Minerals https://doi.org/10.3390/min13030302 (2023).

Wang, Z. et al. Experimental study of pore structure and fractal characteristics of pulverized intact coal and tectonic coal by low temperature nitrogen adsorption. Powder Technol. 350, 15–25. https://doi.org/10.1016/j.powtec.2019.03.030 (2019).

Zhao, J. et al. Effects of pore structures of different maceral compositions on methane adsorption and diffusion in anthracite. Appl. Sci. 9, 5130. https://doi.org/10.3390/app9235130 (2019).

Hazra, B. et al. Structural and thermal properties of vitrain lithotype in coal-inferences from TG-DTG-DSC, Rock-Eval and X-ray diffraction. J. Earth Syst. Sci. https://doi.org/10.1007/s12040-022-01849-6 (2022).

Ren, J. et al. Structure feature and evolution mechanism of pores in different metamorphism and deformation coals. Fuel https://doi.org/10.1016/j.fuel.2020.119292 (2021).

Xin, F. et al. Pore structure evolution of low-rank coal in China. Int. J. Coal Geol. 205, 126–139. https://doi.org/10.1016/j.coal.2019.02.013 (2019).

Teng, J., Mastalerz, M. & Hampton, L. Maceral controls on porosity characteristics of lithotypes of Pennsylvanian high volatile bituminous coal: Example from the Illinois Basin. Int. J. Coal Geol. 172, 80–94. https://doi.org/10.1016/j.coal.2017.02.001 (2017).

Liu, L. et al. Coalbed methane adsorption capacity related to maceral compositions. Energy Explor. Exploit. 38, 79–91. https://doi.org/10.1177/0144598719870325 (2019).

Feng, C. et al. Microstructure characteristics of tectonic coal and primary coal: A case study of Guizhou, China. Natl. Resources Res. https://doi.org/10.1007/s11053-023-10274-5 (2023).

Hu, B., Cheng, Y. & Pan, Z. Classification methods of pore structures in coal: A review and new insight. Gas Sci. Eng. 110, 204876. https://doi.org/10.1016/j.jgsce.2023.204876 (2023).

Du, Z., Huang, Q., Guo, J., Gao, F. & Du, Y. The occurrence of nano- and micro-scale pores and their controls on the selective migration of gases in the coals of different ranks. Fuel 264, 116748. https://doi.org/10.1016/j.fuel.2019.116748 (2020).

Guo, D., Guo, X. & Li, D. Effects of tectonic deformation on micropore-mesopore of bituminous deformed coal. J. China Coal Soc. 44, 3135–3144. https://doi.org/10.13225/j.cnki.jccs.2019.0304 (2019) (in Chinese).

Hao, J. & Li, Y. Research on multi-scale fractal characteristics of pore structure in tectonic coal and analysis of its influence factors. Coal Sci. Technol. 48, 164–174. https://doi.org/10.13199/j.cnki.cst.2020.08.021 (2020) (in Chinese).

Wei, J., Dai, S., Wen, Z., Ren, X. & Li, M. Research on comprehensive characterization method of different rank coal porosity. J. Henan Poly. Univ. 34, 305–310. https://doi.org/10.16186/j.cnki.1673-9787.2015.03.002 (2015) (in Chinese).

Zhang, S., Tang, S., Tang, D., Huang, W. & Pan, Z. Determining fractal dimensions of coal pores by FHH model: Problems and effects. J. Natl. Gas Sci. Eng. 21, 929–939. https://doi.org/10.1016/j.jngse.2014.10.018 (2014).

Lai, J. et al. Fractal analysis of tight shaly sandstones using nuclear magnetic resonance measurements. AAPG Bull. 102, 175–193. https://doi.org/10.1306/0425171609817007 (2018).

Fu, H. et al. Characteristics of pore structure and fractal dimension of low-rank coal: A case study of Lower Jurassic Xishanyao coal in the southern Junggar Basin, NW China. Fuel 193, 254–264. https://doi.org/10.1016/j.fuel.2016.11.069 (2017).

Hazra, B. et al. Porosity controls and fractal disposition of organic-rich Permian shales using low-pressure adsorption techniques. Fuel 220, 837–848. https://doi.org/10.1016/j.fuel.2018.02.023 (2018).

Mu, G. et al. Fractal characterization of pore structure and its influence on CH4 adsorption and seepage capacity of low-rank coals. Front. Earth Sci. 16, 916–933. https://doi.org/10.1007/s11707-022-0969-2 (2022).

Liu, X. & Nie, B. Fractal characteristics of coal samples utilizing image analysis and gas adsorption. Fuel 182, 314–322. https://doi.org/10.1016/j.fuel.2016.05.110 (2016).

Guo, H., Yuan, L., Cheng, Y., Wang, K. & Xu, C. Experimental investigation on coal pore and fracture characteristics based on fractal theory. Powder Technol. 346, 341–349. https://doi.org/10.1016/j.powtec.2019.02.026 (2019).

Li, G., Qin, Y., Zhou, X., Zhang, Y. & Hu, W. Comparative analysis of the pore structure of fusain in lignite and high-volatile bituminous coal. J. Natl. Gas Sci. Eng. https://doi.org/10.1016/j.jngse.2021.103955 (2021).

Lin, Y., Qin, Y., Qiao, J., Li, G. & Zhang, H. Effect of coalification and maceration on pore differential development characteristics of high-volatile bituminous coal. Fuel 318, 118248. https://doi.org/10.1016/j.fuel.2022.123634 (2022).

Ma, Z. et al. Pore fractal characteristics of different macro-coal components and influence on adsorption/desorption: A case study in the Huanglong Jurassic coalfield. ACS Omega 7, 43770–43783. https://doi.org/10.1021/acsomega.2c04793 (2022).

Zheng, C., Ma, D., Chen, Y., Gao, Z. & Teng, J. Pore structure of different macroscopically distinguished components within low-rank coals and its methane desorption characteristics. Fuel 293, 120465. https://doi.org/10.1016/j.fuel.2021.120465 (2021).

Chalmers, G. R. L. & Marc Bustin, R. On the effects of petrographic composition on coalbed methane sorption. Int. J. Coal Geol. 69, 288–304. https://doi.org/10.1016/j.coal.2006.06.002 (2007).

Czerw, K., Dudzińska, A., Baran, P. & Zarębska, K. Sorption of carbon dioxide on the lithotypes of low rank coal. Adsorption 25, 965–972. https://doi.org/10.1007/s10450-019-00122-5 (2019).

Jia, T., Wang, M., Gao, X., Zhao, J. & Hu, J. Pore structure characteristics of low-rank coal reservoirs and evaluation of fractal models. Natl. Gas Geosci. 32, 423–436. https://doi.org/10.11764/j.issn.1672-1926.2020.12.010 (2021).

Avnir, D., Farin, D. & Pfeifer, P. Chemistry in noninteger dimensions between two and three: II: Fractal surfaces of adsorbents. J. Chem. Phys. 79, 3566–3571. https://doi.org/10.1063/1.446211 (1983).

Zhang, B. & Li, S. Determination of the surface fractal dimension for porous media by mercury porosimetry. Am. Chem. Soc. 34, 1383–1386 (1995).

Thommes, M. et al. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 87, 1051–1069. https://doi.org/10.1515/pac-2014-1117 (2015).

Qu, J., Shen, J., Han, L., Ji, C. & Cheng, H. Characteristics of fractures in different macro-coal components in high-rank coal based on CT images. Natl. Gas Ind. 42, 76–86. https://doi.org/10.3787/j.issn.1000-0976.2022.06.007 (2022).

Acknowledgements

This work was supported by National Natural Science Foundation of China (52264007).

Author information

Authors and Affiliations

Contributions

C.Z.: Conceptualization, Writing—Original Draft. Y.C.: Writing-Review & Editing, Funding acquisition. L.Y.: Supervision. W.L.: Funding acquisition. X.D.: Data Curation. F.Y.: Resources.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zheng, C., Chen, Y., Yu, L. et al. Experimental investigation on pore characteristics of vitrain and durain in low rank coal based on fractal theory. Sci Rep 14, 5008 (2024). https://doi.org/10.1038/s41598-024-55668-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-55668-4

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.