Abstract

A series of arecoline derivatives with amino acid moieties were designed and synthesised using an acylamide condensation strategy, taking arecoline as the foundational structure. The insecticidal efficacy of these compounds against Aphis craccivora and Tetranychus cinnabarinus was evaluated. Notably, derivatives 3h and 3i demonstrated superior insecticidal activity compared with arecoline. Additionally, 3h and 3i showed good fungicidal effectiveness against two types of plant fungi. Moreover, molecular docking analyses suggested that 3h and 3i could affect the nervous systems of A. craccivora and T. cinnabarinus by binding to neuronal nicotinic acetylcholine receptors. These findings suggest that compounds 3h and 3i represent promising leads for further development in insecticide and fungicide research.

Similar content being viewed by others

Introduction

The long-term and indiscriminate use of synthetic agrochemicals has led to increasingly severe issues with pesticide residues and resistance. Pesticides persist and accumulate in the environment and can enter the human body through various pathways, posing potential threats to human health and life. Moreover, the problem of pesticide resistance intensifies the emergence of super pests, directly disrupting ecosystem balance1,2,3. Despite the critical role of pesticides in securing agricultural production and product quality, the challenges posed by residues, pest resistance, and regrowth have become significant concerns for the global agricultural sector4,5,6. Addressing these challenges calls for the exploration and development of novel insecticides featuring new targets and modes of action. Natural products, known for their broad-spectrum insecticidal and fungicidal activities, serve as valuable resources for creating innovative pesticides in agriculture7,8,9,10. Alkaloids, a notable class of natural insecticides, exemplified by matrine11 and nicotine12, have found success in the development and application of novel botanical pesticides.

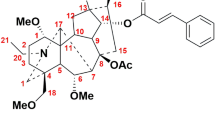

Arecoline, an alkaloid derived from the areca nut, exhibits diverse biological activities, including antimicrobial13, anti-inflammatory14, antiparasitic, and anthelmintic effects15. Research16 has shown that arecoline has certain insecticidal activity against Plutella xylostell. Additionally, arecoline has a certain acetylcholinesterase (AChE) inhibitory activity16, which is similar to the main insecticidal mechanism of organophosphates and carbamates pesticides. Also, some research studies17,18 have shown that arecoline is a muscarinic acetylcholine receptor agonist, with cholinergic effects. However, research on arecoline has predominantly focused on medical applications19,20,21, with limited exploration in agriculture. Thus, a thorough investigation into arecoline’s insecticidal potential is crucial for fully leveraging arecoline plant resources and discovering new lead compounds for botanical insecticides.

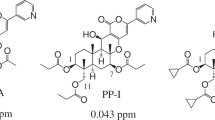

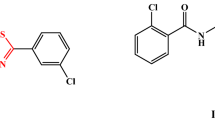

Amino acids, known for their special permeability, low toxicity, enzyme catalytic specificity, participate in multiple chemical reactions22, and are promising for developing lead compounds with ideal biological activity when introduced into natural product precursors23,24. Notably, various agricultural chemicals, including insecticides, fungicides, and herbicides, incorporate amino acids and their derivatives, such as fluoroacetamide, chlorobenzamide, glyphosate25, and bromoxynil26. Structure–activity relationship studies have highlighted the critical role of unique amino acid structural fragments in exerting insecticidal activities. For instance, the interaction between amino acid residues and the AChR target of pests can significantly enhance insecticidal activity27. Recent modifications of monomers with amino acids and their derivatives as functional fragments have led to pesticides with enhanced insecticidal activity25,28,29,30. For example, Zhou et al.28 designed 18 novel N-phenylacetamide derivatives by incorporating alanine and serine, demonstrating significant insecticidal activity against Plutella xylostella. Mao et al.29 designed and synthesised novel N-pyridylpyrazolecarboxamide derivatives containing amino acid esters, based on the commercial insecticide, chlorfenapyr. The target derivatives with the methacrylic acid substructure exhibited strong insecticidal activity against diamondback and oriental fruit moths. Zhu et al.30 synthesised 69 amino acid-substituted 4-ethynylphenylsulfonyl amide derivatives and evaluated their insecticidal activities against third-instar S. litura and Chilo suppressalis. Derivatives D16, D18, and D19 showed more than 14-fold higher insecticidal activity than the commercial insecticide avermectin V. These findings preliminarily confirm the potential of amino acids and their derivatives to enhance the insecticidal activity of monomeric compounds.

Building on this theoretical and research foundation, the current study introduced nine amino acids into the molecular structure of arecoline using acylation condensation reaction, with hexafluorophosphate azabenzotriazole tetramethyl uronium (HATU) as the condensing agent, to design and synthesise a series of novel arecoline derivatives with amino acid bonds. This synthetic strategy allows for the production of high-purity target derivatives through simple solvent extraction and recrystallisation, effectively bypassing the laborious and time-consuming processes typically associated with conventional and column chromatography. The insecticidal and fungicidal activities of these target derivatives were evaluated, and molecular docking was employed to explore the preliminary mechanisms of action of compounds 3h and 3i. This work not only diversifies and expands the chemical structure of arecoline but also offers new insights and viable candidates for developing novel arecoline-based insecticides and fungicides.

Results and discussion

Chemistry

The synthesis pathway for the target compounds is depicted in Fig. 1. Scheme A illustrates that compound 1 was derived from arecoline through a hydrolysis reaction. The essential intermediates 2a–2l were synthesised following a method previously described in the literature31, utilising sulfifinyl chloride as detailed in Scheme B. These intermediates, 2a–2l, underwent purification via recrystallisation in methanol and anhydrous ether, effectively preserving the amino acid carboxyl terminal with a methyl ester.

In conditions maintained under an ice bath, employing HATU as the condensing agent, DIEA as the base, and DCM as the solvent, compounds 1 and 2 underwent amide coupling to yield their respective crude products. Subsequently, these crude products were hydrolysed with NaOH at room temperature to generate the corresponding sodium salts, and the final target compounds 3a–3l of enhanced purity were acquired through recrystallisation in a water–acetone mixture (Scheme C). Notably, this synthesis process allows for the attainment of target compounds with superior purity by adeptly conducting solvent extraction, hydrolysis, and recrystallisation, tailored to the specific chemical properties of the substrates and products. As shown in Fig. S1, the 1H-NMR spectrum results of 3h showed that some impurities can be significantly removed after recrystallization treatment to achieve the purpose of improving purity. This strategy effectively circumvents the labour intensive and time-consuming purification methods, such as column chromatography.

The 1H-NMR, 13C-NMR, and high-resolution mass spectra for the target compounds 3a–3i are meticulously detailed in the Supporting Information.

Insecticidal biological activity

The insecticidal efficacy of the target compounds against A. craccivora and T. cinnabarinus is presented in Tables 1, 2 and 3. Imidacloprid and avermectin served as the reference standards. As indicated in Table 1, only compounds 3h and 3i achieved more that 50% mortality against A. craccivora and T. cinnabarinus at a concentration of 400 mg/L, with efficacy diminishing at reduced concentrations (200 mg/L). Furthermore, compounds 3h and 3i exhibited mortality rates surpassing that of the precursor compound, arecoline, at 400 mg/L. Compounds 3h (R = sodium phenolate) and 3i (R = sodium propionate), characterised by their strong electronegativity, demonstrated notable insecticidal potency. Hence, we tentatively propose that the inclusion of highly electronegative groups is beneficial for enhancing insecticidal activity. Furthermore, the LC50 values of compounds 3h and 3i against A. craccivora and T. cinnabarinus were determined (Tables 2, 3), revealing LC50 values of 394.66 mg/L and 208.01 mg/L for 3h and 275.28 mg/L and 257.46 mg/L for 3i, respectively. Overall, The LC50 values of 3h and 3i were lower than those for the parent compound, arecoline (634.19/315.35 mg/L), yet higher than those for imidacloprid and avermectin (7.75/3.88 mg/L).

Fungicidal activity

The fungicidal activities of the target compounds 3a–3i, alongside standard controls (arecoline and chlorothalonil) against five types of plant fungi were evaluated and are summarised in Table 4. Among the compounds tested, 3e demonstrated inhibitory rates of 39% against Colletotrichum gloeosporioides and 49% against Botrytis cinerea, and its activity level is equivalent to that of arecoline (41% and 48%, respectively). Compounds 3h and 3i exhibited enhanced inhibitory activity against C. gloeosporioides (54%/48%) and B. cinerea (70%/64%) compared with arecoline (41%/48%). On the whole, the antifungal activities of compounds 3e, 3h and 3i against against C. gloeosporioides and B. cinerea were outstanding, warranting further investigation as potential fungicide candidates.

Docking simulation

Figure 2 illustrates the binding modes of target compounds 3h and 3i to AChBP, revealing similarities between them. Both compounds establish hydrogen bonds with TRP-143 and engage in four cation–π interactions with TRP-143, TRP-53, and TYR-192, in addition to forming two hydrogen bonds with ARG-55. Specifically, compound 3i formed two hydrogen bonds with SER-186 and CYS-187 and two salt bridges with ARG-55, whereas compound 3h formed only one salt bridge interaction with ARG-55 and an additional hydrogen bond with TYR-192. This correlates with the observed stronger biological effects of 3i compared to 3h. The reference molecule, imidacloprid (IMI) formed two hydrogen bonds and a salt bridge with ARG-55. In particular, imidacloprid shared a halogen bond with LEU112 and a water bridge with LEU102 and VAL114. These interactions between IMI molecules and AChBPs may be vital factors for the significant insecticidal activity of IMI.

Molecular docking results of different chemicals with AChBP. (A) 3h, (B) 3i and (C) Imidacloprid. The small molecules are shown in green sticks, while the residues within 5 Å of the ligand are shown in yellow lines. The hydrogen bond, cation-π, salt bridge and halogen bond are represented by red dash, light-magenta dash, blue dash and purple dash.

Conclusions

In summary, this research successfully designed and synthesised a series of novel arecoline derivatives containing amino acid functional groups. The insecticidal and fungicidal efficacy of these compounds were assessed. Compounds 3h and 3i exhibited higher insecticidal activities against A. craccivora (LC50: 394.66 and 275.28 mg/L) and T. cinnabarinus (LC50: 208.01 and 257.46 mg/L) as arecoline (LC50: 634.19 and 315.35 mg/L). Furthermore, compounds 3h and 3i showed excellent inhibitory activities against C. gloeosporioides (54% and 48%) and B. cinerea (70% and 64%). Molecular docking analyses suggest that 3h and 3i likely target neuronal nicotinic acetylcholine receptors. This study contributes valuable insights and introduces promising candidates for the development of new arecoline-based insecticides and fungicides. Future work will explore the acute toxicity and detailed mechanisms of action of these compounds in our laboratory.

Materials and methods

Chemical and instruments

All reagents and solvents were sourced from commercial suppliers and utilised as received, without further purification. Arecoline (98% purity) was purchased from Shanghai Maclean Biochemical Technology Co., Ltd. 2-(7-Azabenzotriazol-1-yl)-N, N, Nʹ, Nʹ-tetramethyluronium hexafluorophosphate (99% purity) (HATU), N, N-Diisopropylethylamine (99% purity) (DIEA) and amino acids were from Shanghai Aladdin Reagent Co Ltd. Solid reagents such as sodium hydroxide and sodium carbonate are analytically pure grade, produced by Tianjin City Zhiyuan Chemical Reagent Co., Ltd. Methanol, ethanol, anhydrous ether, dichloromethane and other liquid reagents are analytically pure grade, are purchased from Guangzhou Chemical Reagent Factory. Deionized water was obtained from laboratory preparation.

NMR spectra were obtained using a Bruker Advance spectrometer operating at 400 MHz, using MeOD with TMS as the internal standard. Melting points were determined using a Buchi melting point (B540) apparatus and were reported as observed. High-resolution mass spectra were obtained on a Triple TOF 5600 mass spectrometer (AB SCIEX, USA).

Synthesis

Synthesis of compound 1

Compound 1 was synthesised as previously described32. Initially, arecoline hydrobromide (5.90 g, 25 mmol) was dissolved in 30 mL of deionised water. The pH was adjusted to 10–11 using 30% Na2CO3, and the solution was stirred at room temperature for 1 h. Then, the mixture was extracted with DCM (5 × 10 mL). The DCM extracts were then concentrated under vacuum at 40 ℃. The residue was dissolved in 30 mL of water and refluxed overnight after heating. Finally, water was removed under vacuum and the crude product was purified by recrystallisation using a water-acetonitrile mixture, yielding compound 1.

Compound 1, white solid, yield 92%, mp. 225–226 °C; 1H-NMR (400 MHz, D2O) δ 6.70–6.72 (m, 1H), 3.98–4.02 (d, J = 16.0, 1H), 3.59–3.64 (d, J = 20.0, 1H), 3.44–3.46 (m, 1H), 3.04–3.11 (m, 1H), 2.89 (s, 3H), 2.41–2.60 (m, 2H). 13C NMR (400 MHz, D2O) δ 171.8, 131.9, 128.5, 52.1, 49.7, 42.2, 22.3.

General procedure for compounds 2a–2l

The intermediate 2a–2l were synthesised following the methodology outlined in our previous study, as detailed in Scheme B31. In briefly, 16 mL (400 mmol) of methanol was added to a 50 mL round-bottom flask and placed in ice-salt bath conditions. Keep the temperature at − 5 °C, slowly add 1.9 mL (26 mmol) SOCl2 dropwise with a constant pressure dropping funnel, and control the addition to be completed within 30 min. After stirring at − 5 °C for 1 h, the system was allowed to stand at room temperature and 1.5 g (20 mmol) of l-alanine was added. After stirring at room temperature for 1 h, heat at 70 °C for 2 h at reflux. After the reaction was finished, the unreacted methanol and SOCl2 were removed by pressure reduction and concentration at 50 °C to obtain a crude product. Recrystallize with methanol (a little)-anhydrous ether (excess) in ice water bath, then an amount of white lump crystal was precipitated, the crystals were washed with anhydrous ether for 2–3 times, and the pure product compound 2d was obtained by vacuum drying. The synthetic procedures of compounds 2a–2c and 2e–2i were prepared similarly to 2d.

General procedure for target compounds 3a–3l

In a 50 mL flask, compound 1 (169 mg, 1.2 mmol), HATU (532 mg, 1.4 mmol), DIEA (0.8 mL), and DCM (10 mL) were combined and cooled to − 5 °C in an ice bath. The mixture was stirred at − 5 °C for 1 h before adding compound 2a (255 mg, 1 mmol), continuing the stirring at − 5 °C for 1 h. Completion of reaction was monitored by TLC. The mixture was then washed with deionised water (5 mL × 3), and the organic phase was dried under vacuum to yield a pale-yellow oil. This crude product was used directly in the next step without purification.

The crude oil was dissolved in a 3 mL mixture of water and tetrahydrofuran (H2O: THF = 1:2), to which NaOH (120 mg, 3 mmol) was added. The solution was stirred thoroughly for 2 h at room temperature. It was then transferred to a 60 mL separatory funnel and extracted with 2 mL of DCM. After layer separation, the organic layer was collected and concentrated under reduced pressure to yield crude product 3a. This product was further purified by recrystallisation (water/acetone, 1:15 v/v) to obtain the desired compound 3a. The synthesis of compounds 3b–3l followed a similar procedure.

Compound 3a

Sodium (1-methyl-1, 2, 5, 6-tetrahydropyridine-3-carbonyl) tryptophanate. Yellow powder, yield 35.4%, mp.107–108 °C; 1H NMR (400 MHz, MeOD) δ 7.50 (dt, J = 8.0, 1.2 Hz, 1H), 7.25 (dt, J = 8.0, 1.2 Hz, 1H), 7.04 (s, 1H), 7.01–6.92 (m, 2H), 6.40 (m, 1H), 4.58 (m, 1H), 3.39–3.20 (m, 2H), 3.08–2.86 (m, 2H), 2.48–2.40 (m, 2H), 2.28 (s, 3H), 2.24–2.19 (m, 2H). 13C NMR (400 MHz, MeOD) δ 177.3, 166.6, 136.5, 131.6, 130.5, 128.2, 123.1, 120.7, 118.3, 118.1, 110.7, 110.5, 55.8, 52.4, 50.3, 44.2, 27.4, 25.1. HRMS-ESI (m/z): calcd for C18H20N3NaO3 [M+H]+ 350.1475, found, 350.1482.

Compound 3b

Sodium (1-methyl-1,2,5,6-tetrahydropyridine-3-carbonyl) leucinate. Yellow oil, yield 36%; 1H NMR (400 MHz, MeOD) δ 6.63 (m, 1H), 4.38 (m, 1H), 3.23–3.08 (m, 2H), 2.55–2.49 (m, 2H), 2.37 (s, 3H), 2.35–2.30 (m, 2H), 1.67–1.60 (m, 2H), 1.59–1.55 (m, 1H), 0.92 (d, J = 1.6 Hz, 3H), 0.90 (d, J = 1.2 Hz, 3H). 13C NMR (400 MHz, MeOD) δ 178.8, 167.0, 131.8, 130.3, 53.5, 52.7, 50.4, 44.3, 42.0, 25.3, 24.9, 22.4, 21.0. HRMS-ESI (m/z): calcd for C13H21N2NaO3 [M+H]+ 277.1522, found, 277.1530.

Compound 3c

Methyl (1-methyl-1,2,5,6-tetrahydropyridine-3-carbonyl) valinate. Yellow oil, yield 38%; 1H NMR (400 MHz, MeOD) δ 6.64 (m, 1H), 4.20 (d, J = 5.6 Hz, 1H), 3.29–3.07 (m, 2H), 2.59–2.50 (m, 2H), 2.38 (s, 3H), 2.35–2.28 (m, 2H), 2.16–2.07 (m, 1H), 0.93 (d, J = 7.2Hz, 3H), 0.88 (d, J = 6.8 Hz, 3H). 13C NMR (400 MHz, MeOD) δ 177.3, 167.1, 131.8, 130.4, 60.0, 52.7, 50.4, 44.3, 31.5, 25.3, 18.8, 17.2. HRMS-ESI (m/z): calcd for C13H22N2O3 [M+H]+ 255.1703 found, 255.1712.

Compound 3d

Sodium (1-methyl-1, 2, 5, 6-tetrahydropyridine-3-carbonyl) alaninate. Yellow oil, yield 30%; 1H NMR (400 MHz, MeOD) δ 6.69 (m, 1H), 4.27 (q, J = 6.0 Hz, 1H), 3.20 (m, 2H), 2.57 (m, 2H), 2.42 (s, 3H), 2.39 (m, 2H). 13C NMR (400 MHz, MeOD) δ 178.3, 166.4, 131.7, 130.3, 52.5, 50.5, 50.4, 44.2, 25.2, 18.0. HRMS-ESI (m/z): calcd for C10H15N2NaO3 [M+H]+ 235.1053 found, 235.1062.

Compound 3e

Sodium (1-methyl-1, 2, 5, 6-tetrahydropyridine-3-carbonyl) methioninate. Yellow oil, yield 33%; 1H NMR (400 MHz, MeOD) δ 6.70 (m, 1H), 4.38 (dd, J = 6.0, 4.0 Hz, 1H), 3.22 (m, 2H), 2.58 (m, 2H), 2.52 (m, 2H), 2.42 (s, 3H), 2.39 (m, 2H), 2.15 (m, 2H), 2.08 (s, 3H), 2.00 (m, 2H). 13C NMR (400 MHz, MeOD) δ 176.9, 166.8, 131.6, 130.6, 54.3, 50.4, 50.1, 44.2, 32.4, 30.0, 25.2, 13.9. HRMS-ESI (m/z): calcd for C12H19N2NaO3S [M+H]+ 295.1086, found, 295.1092.

Compound 3f

Sodium (1-methyl-1,2,5,6-tetrahydropyridine-3-carbonyl) phenylalaninate. Yellow oil, yield 40%; 1H NMR (400 MHz, MeOD) δ 7.25–7.15 (m, 5H), 6.54 (m, 1H), 4.56 (dd, J = 5.6, 4.0 Hz, 1H), 3.25 (dd, J = 10.8, 4.0 Hz, 2H), 3.16 (dd, J = 12.8, 1.2 Hz, 2H), 3.05 (m, 2H), 2.25 (m, 2H), 2.38 (s, 3H), 2.33 (m, 2H). 13C NMR (400 MHz, MeOD) δ 176.6, 166.6, 138.0, 131.7, 130.3, 129.2, 127.7, 125.9, 55.7, 52.5, 50.3, 44.2, 37.6, 25.1. HRMS-ESI (m/z): calcd for C16H19N2NaO3 [M+H]+ 311.1366, found, 311.1375.

Compound 3g

Sodium (1-methyl-1, 2, 5, 6-tetrahydropyridine-3-carbonyl) aspartate. Yellow solid, yield 35%, mp. 235–236 °C; 1H NMR (400 MHz, MeOD) δ 6.72 (m, 1H), 4.53(t, J = 4.0 Hz, 1H), 3.22(dd, J = 24.4, 12.8 Hz, 2H), 2.69 (m, 2H), 2.56 (m, 2H), 2.41(s, 3H), 2.38 (m, 2H). 13C NMR (400 MHz, MeOD) δ 178.8, 178.3, 131.6, 130.6, 52.6(2C), 50.4, 44.3, 40.5, 25.2. HRMS-ESI (m/z): calcd for C11H14N2Na2O5 [M+H]+ 301.0770, found, 301.0779.

Compound 3h

Sodium 3-(1-methyl-1, 2, 5, 6-tetrahydropyridine-3-carboxamido)-3-(4-oxidophenyl) propanoate. Yellow solid, yield 40%, mp. 127–129 °C; 1H NMR (400 MHz, MeOD) δ 6.89–6.85 (d, J = 4.0 Hz, 2H), 6.54–6.52(d, J = 8.0 Hz, 2H), 6.52 (m, 1H), 4.43(t, J = 4.0 Hz, 1H), 3.20–3.17(m, 2H), 3.07–3.03 (m, 2H), 2.57–2.50(m, 2H), 2.38(s, 3H), 2.33(m, 2H). 13C NMR (400 MHz, MeOD) δ 177.7, 166.7, 165.2, 131.8, 130.2, 129.7, 122.4, 118.2, 56.3, 52.5, 50.4, 44.2, 36.8, 25.1. HRMS-ESI (m/z): calcd for C16H18N2Na2O4 [M+H]+ 349.1134, found, 349.1149.

Compound 3i

Sodium (1-methyl-1, 2, 5, 6-tetrahydropyridine-3-carbonyl) glutamate. Yellow solid, yield 42%, mp. 268–270 °C; 1H NMR (400 MHz, MeOD) δ 6.73 (m, 1H), 4.26 (m, 1H), 3.27–3.18 (dd, J = 24, 16 Hz, 2H), 2.58 (m, 2H), 2.42 (s, 3H), 2.39 (m, 2H), 2.13 (m, 2H), 2.03 (m, 2H). 13C NMR (400 MHz, MeOD) δ 181.0, 177.9, 166.9, 131.7, 130.2, 55.5, 52.6, 50.4, 44.2, 34.2, 29.0, 25.2. HRMS-ESI (m/z): calcd for C12H16N2Na2O5 [M+H]+ 315.0927, found, 315.0938.

Statistical analysis

Statistical analysis was performed using GraphPad Prism (ver. 8.3; GraphPad Software, San Diego, CA, USA). The Duncan’s multiple range test (p < 0.05) was used for data analysis, and the experimental data were expressed as the mean ± standard deviation (SD).

Biological assay

Detailed bioassay procedures for antifungal and insecticidal activities are referenced from published literature11,33,34. The relevant insect sources and strains employed in the experiment were sourced from the Institute of Plant and Environmental Protection of the Chinese Academy of Tropical Agricultural Sciences and the Institute of Tropical Biotechnology, respectively. Each bioassay is repeated at least 3 times to meet statistical requirements.

Insecticidal activities

Prepare a stock solution of each tested compound with methanol at a concentration of 3200 mg/L, and then dilute it to the desired concentration (50,100, 200, 400, 800, 1600 and 3200 mg/L) with deionized water. Deionized water (or methanol) and Imidacloprid (concentrations ranging from 2 to 32 mg/L) were used as blank and positive controls, respectively. Leaf-dip method was executed. Cut a leaf disc measuring 5 cm × 3 cm from fresh cowpea leaves, and then immerse it in the test solution for 10 s. After air-drying, the petioles were moisturized with skimmed cotton dipped in water, and the processed leaf discs were placed separately in a constant temperature chamber and inoculated with 30 aphids (wingless adults and larger wingless nymphs of aphids). During the examination, the aphids were gently flicked with a brush, and if they could not stand up after falling down, they were considered dead. Experimental conditions: temperature (25 ± 1) °C, relative humidity of about 75%, light cycle L:D = 16:8. Mortality rates were recorded over 48 h and toxicity of the corresponding compounds were determined by further determination of median lethal concentrations with mortality exceeding 50% (LC50).

The insecticidal activity of title compounds against T. cinnabarinus was tested according to our previously reported procedures35.

Antifungal activities

The antifungal activity of the test compound against the selected five phytopathogenic fungi was evaluated using an agar well diffusion method36. Briefly, dissolve the test compound in an appropriate amount of methanol, and then use a solution containing prepare a 0.1% TW-80 aqueous solution to obtain a stock solution with a concentration of 500 mg/L. One milliliters of stock solution were added to the sterilized PDA medium. The final concentrations were 50 mg/L. Subsequently, a Foc TR4 disc (4 mm) was placed on the PDA plate and incubated at 24 ± 1 °C for 48 h. sterilized water treatment was used as a control. The mycelial growth diameter was measured and the percentage inhibition was calculated.

Docking simulation

Molecular docking analysis was performed using Schrodinger Suite 2023.4. The structure of Lymnaea stagnalis AChBP with a Gln55Arg mutation (PDB Entry: 7PDR) was selected as the receptor in our docking37,38. Both the receptor and the small molecules underwent preparation processes using the Protein Preparation Workflow and LigPrep within the OPLS4 force field, separately. The receptor grid was then generated using Receptor Grid Generation. Finally, our small molecules were docked into the receptor at the reference pocket with extra precision using the default parameters by Ligand Docking.

Data availability

The data that support the findings of this study are available in the Supplementary Material of this article.

References

Huang, W. et al. Risk of breast cancer and adipose tissue concentrations of polychlorinated biphenyls and organochlorine pesticides: A hospital-based case-control study in Chinese women. Environ. Sci. Pollut. Res. 26, 32128–32136 (2019).

Schneider Medeiros, M., Reddy, P. S., Socal, P. M., Schumacher-Schuh, A. F. & Mello Rieder, C. R. Occupational pesticide exposure and the risk of death in patients with Parkinson’s disease: An observational study in southern Brazil. Environ. Health A Glob. Access. Sci. Source 19, 1–8 (2020).

Kim, K. H., Kabir, E. & Jahan, S. A. Exposure to pesticides and the associated human health effects. Sci. Total Environ. 575, 525–535 (2017).

Network, R. P. Trends and challenges in pesticide resistance detection. Trends Plant Sci. 21, 834–853 (2016).

El-Nahhal, Y. Pesticide residues in honey and their potential reproductive toxicity. Sci. Total Environ. 741, 139953 (2020).

Wu, J., Ge, L., Liu, F., Song, Q. & Stanley, D. Pesticide-induced planthopper population resurgence in rice cropping systems. Annu. Rev. Entomol. 65, 409–429 (2020).

Cantrell, C. L., Dayan, F. E. & Duke, S. O. Natural products as sources for new pesticides. J. Nat. Prod. 75, 1231–1242 (2012).

Marrone, P. G. Pesticidal natural products—Status and future potential. Pest Manag. Sci. 75, 2325–2340 (2019).

Yang, R. et al. Natural products-based pesticides: Design, synthesis and pesticidal activities of novel fraxinellone derivatives containing N-phenylpyrazole moiety. Ind. Crops Prod. 117, 50–57 (2018).

Zhi, X. et al. Natural product-based semisynthesis and biological evaluation of thiol/amino-Michael adducts of xanthatin derived from Xanthium strumarium as potential pesticidal agents. Bioorg. Chem. 97, 103696 (2020).

Cheng, X. et al. Semi-synthesis and characterization of some new matrine derivatives as insecticidal agents. Pest Manag. Sci. 76, 2711–2719 (2020).

Stehle, S. et al. Neonicotinoid insecticides in global agricultural surface waters—Exposure, risks and regulatory challenges. Sci. Total Environ. 867, 161383 (2023).

Boniface, P., Verma, S. K., Cheema, H. S., Darokar, M. P. & Pal, A. Evaluation of antimalarial and antimicrobial activites of extract and fractions from Areca catechu. Int. J. Infect. Dis. 21, 228–229 (2014).

Papke, R. L., Horenstein, N. A. & Stokes, C. Nicotinic activity of arecoline, the psychoactive element of ‘betel nuts’, suggests a basis for habitual use and anti-inflammatory activity. PLoS ONE 10, 1–18 (2015).

Yi, P. et al. Research progress on chemical constituents and pharmacological activities of Areca catechu. Chin. Tradit. Herb. Drugs 50, 2498–2504 (2019).

Liu, R. et al. Determination of the main alkaloids and their insecticidal activity of extract of Areca catechu nuts against Plutella xylostella. Int. J. Trop. Insect Sci. 42, 3563–3570 (2022).

Siregar, P. et al. Pharmaceutical assessment suggests locomotion hyperactivity in zebrafish triggered by arecoline might be associated with multiple muscarinic acetylcholine receptors activation. Toxins 13, 259 (2021).

Horenstein, N. A., Quadri, M., Stokes, C., Shoaib, M. & Papke, R. L. Cracking the betel nut: Cholinergic activity of areca alkaloids and related compounds. Nicotine Tob. Res. 21, 805–812 (2018).

Chan, Y. H. et al. Consumption of betel quid contributes to sensorineural hearing impairment through arecoline-induced oxidative stress. Sci. Rep. 9, 1–11 (2019).

Dasgupta, R. et al. Arecoline plays dual role on adrenal function and glucose–glycogen homeostasis under thermal stress in mice. Arch. Physiol. Biochem. 126, 214–224 (2020).

Xu, M. et al. Arecoline alleviated loperamide induced constipation by regulating gut microbes and the expression of colonic genome. Ecotoxicol. Environ. Saf. 264, 115423 (2023).

Blaskovich, M. A. T. Unusual amino acids in medicinal chemistry. J. Med. Chem. 59, 10807–10836 (2016).

Xu, Q., Deng, H., Li, X. & Quan, Z. S. Application of amino acids in the structural modification of natural products: A review. Front. Chem. 9, 650569 (2021).

Ting, C. P. et al. Use of a scaffold peptide in the biosynthesis of amino acid-derived natural products. Science 365, 280–284 (2019).

Chen, R. J. et al. Design, synthesis, and insecticidal activities of novel diamide derivatives with alpha-amino acid subunits. J. Heterocycl. Chem. 58, 1429–1436 (2021).

Katsuta, H. et al. Discovery of broflanilide, a novel insecticide. J. Pestic. Sci. 44, 120–128 (2019).

Zhao, Y. & Li, Y. Design of environmentally friendly neonicotinoid insecticides with bioconcentration tuning and Bi-directional selective toxic effects. J. Clean. Prod. 221, 113–121 (2019).

Zhou, S. et al. Synthesis, insecticidal activities and SAR studies of novel anthranilic diamides containing trifluoroethoxyl substituent and chiral amino acid moieties. Chin. Chem. Lett. 29, 1254–1256 (2018).

Mao, M. Z. et al. Synthesis and insecticidal evaluation of novel N-pyridylpyrazolecarboxamides containing an amino acid methyl ester and their analogues. J. Agric. Food Chem. 62, 1536–1542 (2014).

Zhu, X. Z. et al. Design, synthesis and insecticidal activities of 4-propargyloxybenzene sulfonamide derivatives substituted with amino acids. J. Asian Nat. Prod. Res. 25, 379–386 (2023).

Pang, C., Luo, J., Liu, C., Wu, X. & Wang, D. Synthesis and biological evaluation of a series of novel celastrol derivatives with amino acid chain. Chem. Biodivers. 15, e1800059 (2018).

Song, S., Zhu, S., Pu, L. & Zhou, Q. Iridium-catalyzed enantioselective hydrogenation of unsaturated heterocyclic acids. Angew. Chem. 125, 6188–6191 (2013).

Gang, F. et al. Synthesis and insecticidal activity evaluation of virtually screened phenylsulfonamides. J. Agric. Food Chem. 68, 11665–11671 (2020).

Zhang, X. et al. A pH-and enzymatic-responsive nanopesticide to control pea aphids and reduce toxicity for earthworms. Sci. Total Environ. 861, 160610 (2023).

Badalamenti, N., Bruno, M., Pavela, R., Maggi, F. & Benelli, G. Structural characterization of carboxyatractyloside and acaricidal activity of natural ent-kaurene diterpenoids isolated from Chamaeleon gummifer against Tetranychus urticae. J. Pest Sci. 97, 911–920 (2023).

Chen, Y. et al. Discovery of niphimycin C from Streptomyces yongxingensis sp. nov. as a promising agrochemical fungicide for controlling banana fusarium wilt by destroying the mitochondrial structure and function. J. Agric. Food Chem. 70, 12784–12795 (2022).

Ihara, M. et al. Studies on an acetylcholine binding protein identify a basic residue in loop G on the β1 strand as a new structural determinant of neonicotinoid actions. Mol. Pharmacol. 86, 736–746 (2014).

Wang, Y. et al. Design, synthesis, and insecticidal evaluation of neonicotinoids with conjugated diene. J. Agric. Food Chem. 71, 11332–11340 (2023).

Acknowledgements

The authors acknowledge the financial support from Innovational Fund for Scientific and Technological Personnel of Hainan Province (KJRC2023D26), Natural Science Foundation of Hainan Province (320QN302), Hainan Province “Nan Hai Xin Xing” Technology Innovation Talent Platform Project (NHXXRCXM202323) and Chinese Academy of Tropical Agricultural Sciences for Science and Technology Innovation Team of National Tropical Agricultural Science Center (NO. CATASCXTD202314).

Author information

Authors and Affiliations

Contributions

C.H. P., Y. X. and S.F. Z.: performed most of the experiments and analyzed the data; H. T. and X.H. M.: performed most of the bioactivity tests; C.H. P. and S.H. L.: wrote the manuscript; M.Y. W. and B.J.H.: provided research funding support. All authors approved the final version of the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Pang, C., Xu, Y., Ma, X. et al. Design, synthesis, and evaluation of novel arecoline-linked amino acid derivatives for insecticidal and antifungal activities. Sci Rep 14, 9392 (2024). https://doi.org/10.1038/s41598-024-60053-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-60053-2

Keywords

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.