Abstract

Space bioprocess engineering (SBE) is an emerging multi-disciplinary field to design, realize, and manage biologically-driven technologies specifically with the goal of supporting life on long term space missions. SBE considers synthetic biology and bioprocess engineering under the extreme constraints of the conditions of space. A coherent strategy for the long term development of this field is lacking. In this Perspective, we describe the need for an expanded mandate to explore biotechnological needs of the future missions. We then identify several key parameters—metrics, deployment, and training—which together form a pathway towards the successful development and implementation of SBE technologies of the future.

Similar content being viewed by others

Introduction

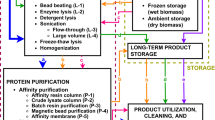

Biotechnologies may have mass, power, and volume advantages compared to abiotic approaches for critical mission elements for long-term crewed space exploration1,2. While there has been progress in the demonstration and evaluation of these benefits for specific examples in this field such as for food production, and waste recycling, there is only just emerging possible consensus on the scope of the application of biosynthetic and biotransformative technologies to space exploration. Additionally, there is almost no formal definition of the scope, performance needs and metrics, and technology development cycle for these systems. It is time to formally establish the field of space bioprocess engineering (SBE) to build this nascent community, train the workforce and develop the critical technologies for planned deep-space missions. SBE (Fig. 1a) borrows elements from a number of related fields such as the synthetic biology design process from Bioengineering, astronaut sustainability3,4 and mission design from Astronautics5,6, environmental-context, and constraints from the Space Sciences, and living systems habitability and distribution concepts from Astrobiology7. SBE represents an extension of the standard astronautics paradigm in meeting NASA’s Space Technology Grand Challenges (STGCs) for expanding the human presence in space, managing resources in space, and enabling transformative space exploration and scientific discovery8,9 (Fig. 1b). Aspirational realizations of SBE would feature prominently in establishment of in-orbit test-facilities, interplanetary waystations, lunar habitats, and a biomanufactory on the surface of Mars10. Differentiated from traditional efforts in space systems engineering, these SBE systems would encapsulate elements from in situ resource utilization (ISRU) for the production of biological feedstocks such as fixed carbon and nitrogen for use as inputs for plant, fungal, and microbial production systems11,12, fertilizers for downstream use by plants13; in situ (bio)manufacturing (ISM) to produce materials requisite to forge useful tools and replacement parts14, food and pharmaceutical synthesis (FPS) via plant, fungal and microbial engineering for increased productivity and resilience in space conditions, production of nutrients and protective/therapeutic agents for sustaining healthy astronauts15,16; and life-support loop closure (LC) for minimizing waste and regenerating life-support functions and biomanufacturing. Maximizing the productivity of the biomanufacturing elements increases the delivery-independent operating time of a biofoundry in space while minimizing cost and risk17. (Fig. 1c). Ultimately, efforts must be mounted to: (1) update the mandate to include SBE as a tool for enabling human exploration; (2) specialize the metrics and methods that guide SBE technology life-cycle and development; (3) further develop the means by which SBE technologies are designed for ground-based testing and matured on offworld platforms (Fig. 1d); and (4) train the minds entering the spacefaring workforce to better understand the leverage the SBE advantages and capabilities.

a Venn Diagram-based definition of Space Bioprocess Engineering (SBE) as an interdisciplinary field. b NASA's space technology grand challenges8 key by shape and colored by group. c Possible SBE components separated by colors for in situ resource utilization (ISRU), food and pharmaceutical synthesis (FPS), in situ manufacturing (ISM), and loop closure (LC), with the biological processes inherent to each represented below in circles. d Platform evolution for biological experiments starting with Earth-orbit CubeSats and proceeding through the ISS, Mars-and-Luna-based rovers, to Lunar and cis-Lunar based human and autonomous systems via the Artemis program.

An inclusive mandate to leverage SBE

While previous strategic surveys such as NASA’s Journey to Mars program18 and the 2018 Biological and Physical Sciences (BPS) Decadal Survey19 have acknowledged that plants and microbes may be integral parts of life support and recycling systems, but can present challenges to the environmental operation of engineering systems in space due to contamination and other inherent drawbacks. However, no such survey has coherently called for the development of science and technology to engineer these organisms and their biotransformative processes in support of space exploration. The SBE community requires a mandate that identifies mission designs and elements for which engineering biosystems would be most appropriate, and defines the productivity, risk, and efficiency targets for these systems in an integrated context with other mission elements and in fair comparison to abiotic approaches. This will require integration of SBE resources and knowledge across government, industry, and academia. Previous biological strategies should now specifically call for (1) definition of the physical engineering constraints on the production systems and development of optimized reactor/processing systems for these elements; (2) quantitative assessment of the bioengineering required to meet performance goals in space given the special physiology required in an offworld environment; and (3) development of efficient tooling for offworld genetic engineering along with the proper containment and clean-up protocols.

Such a mandate would result in: (1) a deeper, more mechanistic understanding of the growth and phenotypic characteristics of organisms operating in space-based bioprocesses taking into account issues of differences in gravity, radiation, light, water quality; (2) new applications of these organisms off-planet; (3) new reactors, bioprocess control designs and product processing/delivery technologies accounting for these conditions and the specific constraints of scaling and operational simplicity in space. The development of open, publicly accessible data and tools would enable rigorous comparison among biotechnologies and abiotic (physical and chemical) approaches, and across mission-scenarios of higher-fidelity. Ideally, this should create interative sub-communities that may collaborate and compete on different approaches to meet bioengineering goals and metricize results against the mission specifications.

SBE is an emerging engineering discipline and there are long but feasible routes from discovery, through invention to application. Furthermore, SBE is multidisciplinary and its utility within the larger space community demands specialized cross-training of diverse teams. In such situations, agencies like the Department of Energy have found it effective to ensure there is specific funding to support longer-term team science to accomplish ambitious scientific and technical goals. The Industrial Assessment Centers (IACs) program is one of the longest-running Department of Energy programs (started in 1976) and has provided nearly 20,000 no-cost assessments for small- and medium-sized manufacturers and more than 147,000 recommendations in an effort to reduce greenhouse gas emissions without compromising U.S. manufacturing’s competitive edge globally20. Conversely, successful examples for demonstrating the effect of fostering multidisciplinary centers for space-based biotechnology can be found in NASA’s Center for the Utilization of Biological Engineering in Space (CUBES), or ESA’s Micro-Ecological Life Support System Alternative (MELiSSA) program—with the capabilities to design, prototype, and ultimately translate biological technologies to space while training the necessary workforce. Such centers are tasked with the development of initial concept trade studies; defining requirements; managing life-support interfaces; evaluating ground integration, operations, and maintenance; coordinating mission operations; and supporting and sustaining engineering and logistics21,22. However, these programs are generally restricted to shorter operation timelines—and would benefit from a longer horizon. This is especially true for SBE as biological developments generally require a longer timeframe for integration in industrial endeavors.

Specialization of SBE metrics and methods

Response to the proposed expanded mandate above requires careful consideration of the space-specific performance metrics that SBE must fulfill. Payload volume, mass, and power requirements are made as small as possible and are limited in envelope by their carrier system. One of the most compelling aspects of biotechnology is the ability of such systems to adapt to these constraints relative to certain industrial alternatives. To efficiently evaluate and deploy novel biotechnologies, SBE experiments should begin with standardized unit operations that clearly define the desired biological function. This allows for a standardized experimental framework to test modular biotechnologies not only within the system to be engineered, but also within and between research groups. To define the minimal basis set of unit operations for a given mission, test and optimize the biotechnologies for each unit operation, and integrate each unit operation into a stable system, we propose to adopt the methods from standard bioengineering in the form of a Design-Build-Test-Learn (DBTL) cycle23 (Fig. 2).

Performance metrics

The design phase of the DBTL cycle begins with the establishment of core constraints and engineering targets that can be explored by standardizing the high-priority performance metrics ({Modularity, Recyclability, Supportability, Autonomy, Sustainability})—which we argue gain special weight in space—from which downstream technoeconomic and life-cycle analysis decisions can be explored (Fig. 2a). The space-specific constraints on performance include: (1) an exceptionally strong weighting on a low mass/volume/power footprint for the integrated bioprocess; (2) limited logistic supply of materials and a narrow band of specifically chosen feedstocks; (3) added emphasis on simplicity of set-up, operation and autonomous function to free up astronaut time; (4) mission-context de-risking against cascading failure; (5) strong requirements for efficiency and closed-loop function to maximize efficient resource use and minimize waste products; (5) a critical need for modularity and ’maintainability’ so that parts can be swapped easily, new functions added easily, and repairs can be done without logistical support beyond the crew; (6) an increased dependence on other mission elements such as provision of water, gases, astronaut wastes, power, and other raw materials such a regolith which may vary in abundance, quality, and composition in unpredictable ways; (7) the need to design sustainable and supportable operation across long time horizons without logistical support beyond the bounds of the local mission; (8) increased ability to operate in more extreme environments including low gravity, high radiation, low nutrient input, and other stressors; (9) process compatibility among common media and operational modes to allow for easy process integration and risk-reduction through redundancy of systems; and (10) further consideration and development of biocontainment of engineered organisms to prevent (or at least mitigate) unexpected dispersal of unwanted living systems in pristine or tightly controlled environments24,25,26.

Ideally, this combination of performance metrics provides informative constraints on biology and technology choices. Feedstock, loop-closure, environmental parameters and product needs will constrain the minimal set of organisms to develop and test for growth rate, optimal cultivation, robustness and resilience to space conditions and shelf-life, safety and genetic tractability, product yield, titer and rate, feedstock utilization, ease of biocontainment, streamlining of purification, and waste streams27. Once suitable chassis organisms have been evaluated and selected, the DBTL cycle can integrate staged co-design of the optimal process hardware (e.g., molecular biological set-ups, genetic engineering tools, bioreactors, and product post-processing systems) configuration, operating parameters, and process controllers. Aerobic organisms may be much more efficient but only viable in systems in which oxygen is available and easily obtainable. This in particular provides insight into the specific questions that require further study in terms of organism engineering. The question of anaerobic versus aerobic metabolism really depends on the product and the style of process—at small scale aerobics may have an advantage in terms of yield and rate, due to more energy being derived from the transfer of reducing equivalents to cellular metabolism—while at large scale, mass-transfer limitations are dominating these parameters (yield and rate), which gives anaerobics an advantage28. Additionally, bioproduct isolation and purification processes need to be considered beyond the Earth-centric means of fermentation. For example, cell-free bioproduction systems may prove critical in biotransformation and point-of-care biosensing as shown in recent space pharming techoeconomic analyses29. Operation of the cycle over increasing scale and ever more realistic deployment environments permits controlled traversal of the technology readiness levels for each technology and mission.

Design-build-test-learn

In the design phase, we argue that efforts must be made to (1) create a database of engineering targets (products, production rates, production yields, production titers, risk factors, waste/recyclability factors, material costs, operational costs, weight, power demand/generation) that set the core constraints for workflow and mission optimization; (2) leverage emerging pathway design software and knowledge bases30 to identify the key types of biological production workflows (i.e., metabolic engineering strategies31) that need to be modified for different space-based scenarios; (3) identify the supporting biomanufactory design elements within which these production workflows could be implemented32,33,34; and (4) identify the chassis organisms and other biological components35,36,37 that will be required to compose the complete set for downstream engineering specifications. Systems designed from a minimal set of reliable parts, standard interconnects, and common controller languages also offer the best possible chance of characterized reliability under changing environmental conditions. Therefore, control of hardware and wetware should be augmented through the design and operation of software support. We see a fundamental effort in SBE as the amalgamation of space-driven hardware, software, and wetware that follows a synthetic biology DBTL cycle38.

The foundation of new SBE performance metrics that guide the design phase of the DBTL cycle must be augmented with additional downstream efforts in the build and test phases to (1) develop a process design framework that takes in specific production needs in amounts/time over acceptable ranges under the constraints expected across different offworld scenarios; (2) create the biological, process, and mission design software platforms to allow sophisticated DBTL, risk assessment, and mission choice support; (3) create the sensor/controller sets that will allow real-time optimization of biological production workflows; and (4) develop the online process controller framework that coordinates reactor conditions and inter-reactor flows to optimize reliable production across all units within acceptable ranges with minimal power and risk. The realization of this SBE DBTL cycle depends on the integration of such benchmark models and modeling standards. These benchmarks describe the dynamics of all SBE processes and relate to the SBE metrics in the design phase from which optimization can be carried out in the learn phase.

DBTL cycles within the scope of SBE must prepare for both ground- and flight-based system operations. Ground-based developments must prioritize designs that meet the requirements for flight-based testing, during which system behaviors may be better characterized in unique environments such as those offered in micro- and zero-gravity. For instance, a biological nitrogen-fixing system on Earth must at least be designed to meet the mass and volumetric constraints required for validated ground-based simulators of microgravity, galactic cosmic radiation, and other physical stressors. Meeting certain requirements for time, power, and substrate usage is essential for any degree of long-term operation. This allows for the in-flight testing of bioreactors previously evaluated on Earth that can more directly measure the effects micro-gravity, radiation, and other stressors on the bioprocessing system. A combination of ground- and flight-based tests are required for the development of functional and robust space biosystems.

Development of means for SBE flight

Deployment of SBE platforms as mission critical elements will likely be reserved for longer duration human exploration missions such as those in the Artemis or Mars programs10. These future programs are still in the concept and planning stage in development, but will certainly be composed of a myriad of technologies that range in degree of flight-readiness as standardized by NASA’s Technology Readiness Level39 (TRL, used to rate the maturity of a given technology during the acquisition phase of a program). Recent updates in NASA’s definitions of and best-practices for applying the TRL paradigm led to the standardization and merging of exit criteria between hardware and software systems40. However, the TRL concept as it relates to SBE must be further expanded to include definitions and exit criteria for ‘wetware’ in addition and in relationship to hardware and software elements.

Deployment of SBE in space requires a level of rigor in technology acceptance that is of a different order than most Earth-based systems because mission failures are exceptionally costly and difficult to recover from. The missions into which SBE processes will integrate are hugely complicated and as noted above will be interdependent in complex ways. Thus while low levels TRLs can be reached through unit testing in modest formats both on Earth and in limited flight experiments, the integrated nature of the bioprocess control and engineering will require integration testing even at the TRL 4 and 5 levels40. To meet acceptance at TRL 6 and beyond will require long term planning realistic integration and deployment testing with actual sophisticated space missions and their logistics.

Even at low TRLs, research on the timescales needed to validate extended-use systems as would be leveraged on extended-stay forward deployment such as Martian or lunar missions are not possible given the current ISS capabilities and constraints. Constraints in astronaut time and limitations in hardware designed for shorter experiments prevent testing times comparable to long duration missions. Table 1 outlines a number of constraints on past and current experimental platforms and provides some basis for constraints of future systems (Fig. 1d). Here we note that extended multigenerational studies, especially in microbiology, can be difficult with some of the operational lifetimes41. Volume is also constrained, and available space is broken up into segmented rack testbeds and independent machines, which can prevent aspects of a system from interacting with each other (Table 1). Much of the testing hardware on the ISS is designed for front-end processing and basic science. Experiments in microbial observation42,43, hybrid life support44, and antibiotic response45 require returning samples to Earth for efficient processing, limiting the end-product downstream analysis and use as feedstocks for other integrated processes, as is needed to advance TRL beyond 6. This also cuts down on the ability to run DBTL diagnostics and SBE performance metrics on the system in toto as recyclability and sustainability are reliant on those end-products, and supportability if the processing is often reliant on Earth resources. Though much of the potential testing: polymerase chain reaction46, imaging, and DNA sequencing47,48 is possible with current miniaturized ISS modules, it may not all be at the scale needed for future experiments, and there may be gaps in capability as the field matures. Improved in situ data analysis through the development of new, high-throughput instruments could help close those gaps49 and allow better metricization of whole systems under these new performance paradigms.

Lunar and Martian gravity is likely to have distinct biological effects compared to Earth gravity, resource composition, and radiation profile—and the ISS has only a limited volume in which to simulate them50. Additionally, both ambient environmental and target temperature windows span an extensive range across extraterrestrial environments, as do gas compositions, making representative testing more difficult in growth and testing chambers (plant, animal, and microbial) without full environmental control (Table 1). Environmental Control and Life Support System (ECLSS) systems for large-scale plant science requisite for advancing TRL for downstream lunar and Martian missions also require larger volume bounding boxes than is currently provided on the ISS51. Here we note the trade-offs with the tight volume and power stores on board. Smaller satellite modules can get technologies off the ground to advance TRL52,53,54, but feature even greater size handicaps, and may prevent testing at the integrated, factory level in the DBTL cycle55,56. Scientific instruments and modules on rovers have been geared primarily for exploration and observation, not technology validation. Dedicated rovers or simply landing SBE payloads onto extraterrestrial sites, SBE-ready orbiters, and Artemis operations as a stepping-stone to Mars can all demonstrate technology within a representative context and stand as some of the premier testbeds to flight qualify SBE prototypes39. In situ testing is key to the proposed SBE performance metrics: it forces technology and bioprocesses into accurate, integrated environments, and provides better confidence under radiation, microgravity, and isolation.

Training of SBE minds

Maturation of space bioprocess engineering requires specialization of the training needed to produce the next generation of spacefaring scientists, engineers, astronauts, policy makers, and support staff57. Lessons learned from the Space Transportation System era led to calls for an increase in Science-Technology-Engineering-Mathematics (STEM) educational programs58 beginning in secondary schools59 and propagating to novel astronautics-based undergraduate60 and graduate programs, and to the establishment of specialty space research centers focused on technology transfer61. The calls for workforce development were repeated just prior to the collapse of the Space Transportation System program, noting the dangers likely to arise from the lack of educational and training resources for those entering the space industry.62. Such a risk as described is especially poignant in the case of space-based biotechnologies given that mature technologies are far fewer, the new applications more futuristic, and the disciplines are not well represented in the traditional physics and engineering curricula. The Universities Space Research Association (USRA) lists 114 institutions with Space Technologies/Science academic programs while recent accounting of bioastronautics programs numbers 3663. However, the intersection between these lists yields only 22 schools. Given that US News names 250 world schools that have tagged themselves with Space Science programs, only ~8% of these are currently offering bioastronautics specialization—demonstrating that efforts that integrate human performance, life support, and bioengineering are under-served. Furthermore, the bioastronautics programs such as those offered by schools like Harvard-MIT, University of Colorado Boulder, and Baylor University are not focused on biomanufacturing aspects that underlie SBE64.

Academia must be prepared to capitalize on the opportunities of future SBE applications starting with either the creation of new and interdisciplinary programs or by assembling those from related disciplines (Fig. 1a). Because scientific and mathematical core courses are relatively standard across SBE-related disciplines, an effective foundation of technical skills could be easily constructed from the shared curriculum (Fig. 3). From there, specific SBE-driven training can be offered in (1) effects of space on plant and microbes; (2) process design for low gravity/high radiation; (3) management and storage of biological materials in space-based operations; (4) low energy/low mass bioreactor/bioprocessor design; (5) integrated biological systems engineering; (6) biological mission planning and logistics; (7) risk and uncertainty management; (8) containment and environmental impact of biological escape, films, corrosion, and cleanup; (9) policy awareness/development; and (10) ethics of cultivation and deployment. While the logistics for organizing such pathways for formal SBE training are non-trivial within the academic machine, we note that nearly all schools listed by USRA offer the component programs in bioengineering, planetary science or astronomy, and electrical or systems engineering. Since the courses for such engineering programs are standardized65, it stands to reason that establishing focused SBE programs can begin by collecting and highlighting course combinations. As programs grow, additional faculty with SBE-driven research can be sourced. Such openings offer a much-needed opportunity to address systemic issues of diversity, equity, and inclusion both within SBE-based academia and the industrial space community at large66.

Moving forward

Making progress on the program above requires scientists, engineers, and policy experts to work together to verify, open, and update campaign specifications. The science requires scientists from multiple disciplines spanning biological and space systems engineering that require a degree of modularity, small footprints, and robustness not found elsewhere. Additionally, bioprocess and biological engineering must be applied to the building of cross-compatible and scalable processing systems and optimized organisms within the confines of space reactor and product. Finally, coordination mission specialists are critical to deploy tests into space during the run-up and through crewed missions. We argue that such groundwork requires multidisciplinary centers that can build long term partnerships and understanding; train the workforce in this unique application space; and perform the large-scale, long-term science necessary to succeed.

References

Menezes, A. A., Cumbers, J., Hogan, J. A. & Arkin, A. P. Towards synthetic biological approaches to resource utilization on space missions. J. R. Soc. Interface 12, 20140715 (2015).

Nangle, S. N. et al. The case for biotech on Mars. Nat. Biotechnol. 38, 401–407 (2020).

Young, L. R. & Sutton, J. P. Handbook of Bioastronautics 1 edn (Springer, 2020).

Whitmore, M., Boyer, J. & Holubec, K. NASA-STD-3001, space flight human-system standard and the human integration design handbook. In Industrial and Systems Engineering Research Conference (International Council on Systems Engineering (INCOSE), 2012).

Hoffman, S. J. & Kaplan, D. I. Human Exploration of Mars: The Reference Mission of the NASA Mars Exploration Study Team Vol. 6107 (National Aeronautics and Space Administration, Lyndon B. Johnson Space Center, 1997).

Drake, B. G., Hoffman, S. J. & Beaty, D. W. Human exploration of Mars, design reference architecture 5.0. In Aerospace Conference, 2010 IEEE 1–24 (IEEE, 2010).

Fridlund, M. & Lammer, H. The astrobiology habitability primer. Astrobiology 10, 1–4 (2010).

Talbert, T. & Green, M. Space Technology Grand Challenges (National Aeronautics and Space Administration, 2010).

Menezes, A. A., Montague, M. G., Cumbers, J., Hogan, J. A. & Arkin, A. P. Grand challenges in space synthetic biology. J. R. Soc. Interface 12, 20150803 (2015).

Berliner, A. J. et al. Towards a biomanufactory on mars. Front. Astron. Space Sci. 8, 120 (2021).

Cestellos-Blanco, S. et al. Production of PHB from CO2-derived acetate with minimal processing assessed for space biomanufacturing. Front. Microbiol. 12, 2126 (2021).

Langenfeld, N. J. et al. Optimizing nitrogen fixation and recycling for food production in regenerative life support systems. Front. Astron. Space Sci. 8, 105 (2021).

Rapp, D. Use of Extraterrestrial Resources for Human Space Missions to Moon or Mars 31–90 (Springer, 2013).

Werkheiser, N. In-Space Manufacturing: Pioneering a Sustainable Path to Mars Tech. Rep., N, Washington DC. https://ntrs.nasa.gov/citations/20150022327 (2015).

Cannon, K. M. & Britt, D. T. Feeding one million people on Mars. New Space 7, 245–254 (2019).

McNulty, M. J. et al. Molecular pharming to support human life on the Moon, Mars, and beyond. Crit. Rev. Biotechnol. 0, 1–16 (2020).

Poughon, L., Farges, B., Dussap, C. G., Godia, F. & Lasseur, C. Simulation of the MELiSSA closed loop system as a tool to define its integration strategy. Adv. Space Res. 44, 1392–1403 (2009).

NASA’s Journey to Mars: Pioneering Next Steps in Space Exploration. Tech. Rep., National Aeronautics and Space Administration, Washington DC. https://www.lpi.usra.edu/lunar/strategies/NP-2015-08-2018-HQ (2015).

A Midterm Assessment of Implementation of the Decadal Survey on Life and Physical Sciences Research at NASA. Tech. Rep., National Academy of Sciences, Washington, DC. https://nap.nationalacademies.org/catalog/24966/a-midterm-assessment-of-implementation-of-the-decadal-survey-on-life-and-physical-sciences-research-at-nasa (2018).

DOE Announces New $ 60 Million Investment to Increase Energy Efficiency in Manufacturing. https://www.energy.gov/articles/doe-announces-new-60-million-investment-increase-energy-efficiency-manufacturing (2021).

Marshall Space Flight Center Space Systems. Tech. Rep., National Aeronautics and Space Administration, Marshall Space Flight Center, Huntsville, AL. https://www.nasa.gov/sites/default/files/atoms/files/space_systems.pdf (2011).

Chapline, G. & Sullivan, S. Systems Engineering for Lifecycle of Complex Systems (Engineering Innovations (NASA), 2010).

Cohen, J. The crucial role of CS in systems and synthetic biology. Commun. ACM 51, 15–18 (2008).

Mandell, D. J. et al. Biocontainment of genetically modified organisms by synthetic protein design. Nature 518, 55–60 (2015).

Tian, R. et al. Titrating bacterial growth and chemical biosynthesis for efficient N-acetylglucosamine and N-acetylneuraminic acid bioproduction. Nat. Commun.11, 5078 (2020).

Lee, H. J., Choi, J.-I. & Woo, H. M. Biocontainment of engineered Synechococcus elongatus PCC 7942 for photosynthetic production of α-Farnesene from CO(2). J. Agric. Food Chem. 69, 698–703 (2021).

Averesch, N. J. H. Choice of microbial system for in-situ resource utilization on Mars. Front. Astron. Space Sci. 8, 116 (2021).

Weusthuis, R. A., Lamot, I., van der Oost, J. & Sanders, J. P. M. Microbial production of bulk chemicals: Development of anaerobic processes. Trends Biotechnol. 29, 153–158 (2011).

McNulty, M. J. et al. Evaluating the cost of pharmaceutical purification for a long-duration space exploration medical foundry. Front. Microbiol. 12, 700863 (2021).

Arkin, A. P. et al. KBase: The United States department of energy systems biology knowledgebase. Nat. Biotechnol. 36, 566–569 (2018).

Lucks, J. B., Qi, L., Whitaker, W. R. & Arkin, A. P. Toward scalable parts families for predictable design of biological circuits. Curr. Opin. Microbiol. 11, 567–573 (2008).

Carbonell, P. Metabolic Pathway Design 3–10 (Springer, 2019).

Appleton, E., Madsen, C., Roehner, N. & Densmore, D. Design automation in synthetic biology. Cold Spring Harbor Perspect. Biol. 9, a023978 (2017).

Goñi-Moreno, A. et al. An implementation-focused bio/algorithmic workflow for synthetic biology. ACS Synthetic Biol. 5, 1127–1135 (2016).

Shetty, R. P., Endy, D. & Knight, T. F. Engineering BioBrick vectors from BioBrick parts. J. Biol. Eng. 2, 1–12 (2008).

Canton, B., Labno, A. & Endy, D. Refinement and standardization of synthetic biological parts and devices. Nat. Biotechnol. 26, 787–793 (2008).

Cox, R. S. et al. Synthetic biology open language (SBOL) version 2.2. 0. J. Integrative Bioinform. 15, 20180001 (2018).

Cheng, A. A. & Lu, T. K. Synthetic biology: An emerging engineering discipline. Annu. Rev. Biomed. Eng. 14, 155–178 (2012).

Mankins, J. C. Technology readiness assessments: A retrospective. Acta Astronautica 65, 1216–1223 (2009).

Hirshorn, S. & Jefferies, S. Final report of the NASA Technology Readiness Assessment (TRA) study team Tech. Rep., National Aeronautics and Space Administration. https://ntrs.nasa.gov/citations/20170005794 (2016).

Castro, S. L, Smith, D. J & Ott, M. Researcher’s Guide to: International Space Station Microbial Research (Government Printing Office, 2014).

Khodadad, C. L. M. et al. Microbiological and nutritional analysis of lettuce crops grown on the International Space Station. Front. Plant Sci. 11, 199 (2020).

Burton, A. S. et al. Off earth identification of bacterial populations using 16S rDNA nanopore sequencing. Genes 11, 76 (2020).

Keppler, J. et al. The final configuration of the algae-based ISS experiment PBR@ LSR. In 48th International Conference on Environmental Systems (Institute of Space Systems, University of Stuttgart, Germany, Albuquerque, NM, 2018).

Aunins, T. R. et al. Spaceflight modifies Escherichia coli gene expression in response to antibiotic exposure and reveals role of oxidative stress response. Fronti. Microbiol. 9, 310 (2018).

Boguraev, A.-S. et al. Successful amplification of DNA aboard the International Space Station. npj Microgravity 3, 26 (2017).

McIntyre, A. B. R. et al. Nanopore sequencing in microgravity. npj Microgravity 2, 1–9 (2016).

Joannès, J. Feasibility study of a DNA-sequencing cubesat satellite. J. British Interplanet. Soc. 70, 287–299 (2017).

Karouia, F., Peyvan, K. & Pohorille, A. Toward biotechnology in space: High-throughput instruments for in situ biological research beyond earth. Biotechnology Adv. 35, 905–932 (2017).

Zavaleta, J., Iyer, J., Mhatre, S., Dolling-Boreham, R. & Bhattacharya, S. An automated behavioral analysis of Drosophila melanogaster. In Annual Meeting of the American Society for Gravitational and Space Research. https://ntrs.nasa.gov/citations/20190033964 (2019).

Suffredini, M. T. Reference Guide to the International Space Station. Tech. Rep., National Aeronautics and Space Administration, Johnson Space Center, Houston, TX (2014).

Marzioli, P. et al. CultCube: Experiments in autonomous in-orbit cultivation on-board a 12-Units CubeSat platform. Life Scie. Space Res. 25, 42–52 (2020).

Luna, A., Meisel, J., Hsu, K., Russi, S. & Fernandez, D. Protein structural changes on a CubeSat under rocket acceleration profile. npj Microgravity 6, 12 (2020).

Santoni, F. et al. GreenCube: Microgreens cultivation and growth monitoring on-board a 3U CubeSat. In 2020 IEEE 7th International Workshop on Metrology for AeroSpace (MetroAeroSpace) 130–135 (Institute of Electrical and Electronics Engineers (IEEE), 2020).

Cubesat 101: Basic Concepts and Processes for First-Time CubeSat Developers. Tech. Rep., National Aeronautics and Space Administration, Washington DC. https://www.nasa.gov/sites/default/files/atoms/files/nasa_csli_cubesat_101_508.pdf (2017).

Johnstone, A. CubeSat design specification (1U-12U) rev 14 CP-CDS-R14. Tech. Rep., (California Polytechnic State University, San Luis Obispo, CA, 2020).

Hurlbert, K. et al. Human Health, Life Support and Habitation Systems Technology Area 06. Tech. Rep., National Research Council, Washington DC. https://nap.nationalacademies.org/catalog/13354/nasa-space-technology-roadmaps-and-priorities-restoring-nasas-technological-edge (2012).

Farmer, T. A STEM Brainstorm at NASA. Techniques: Connecting Education Careers 84, 42–43 (2009).

Engle, H. A. & Christensen, D. L. Identification and evaluation of educational uses and users for the STS. Educational planning for utilization of space shuttle ED-PLUSS. Tech. Rep., Washington DC. https://ntrs.nasa.gov/citations/19740027152 (1974).

Brodsky, R. F. The time has come for the BS in astronautical engineering. Eng. Education 76, 149–152 (1985).

Fletcher, L. S. & Page, R. H. Technology transfer: The key to successful space engineering education. Acta Astronautica 29, 141–146 (1993).

Gruntman, M. The time for academic departments in astronautical engineering. In AIAA SPACE 2007 Conference & Exposition https://doi.org/10.2514/6.2007-6042 (2007).

Young, L. R. & Natapoff, A. The Harvard-MIT PHD program in bioastronautics. Life Space for Life on Earth 553, 90 (2008).

Klaus, D. M. Incorporating bioastronautics into an engineering curriculum. In 44th International Conference on Environmental Systems (Tucson, AZ, 2014).

Criteria for Accrediting Engineering Programs, 2020–2021 ∣ ABET https://www.abet.org/accreditation/accreditation-criteria/criteria-for-accrediting-engineering-programs-2020-2021/ (2021).

National Aeronautics And Space Administration (NASA) Model Equal Employment Opportunity Program Status Report: FY 2019. Tech. Rep., National Aeronautics and Space Administration, Washington DC. https://www.nasa.gov/sites/default/files/atoms/files/fy2020_md_715_report_signed_tagged.pdf (2020).

Acknowledgements

This work is supported by the grant from the National Aeronautics and Space Administration (NASA, award number NNX17AJ31G).

Author information

Authors and Affiliations

Contributions

A.J.B., A.M., J.M.H., and A.P.A. conceived the concept based on the Center for the Utilization of Biological Engineering in Space (CUBES). D.H. led the graphics effort with assistance from A.J.B. G.M., I.L., N.J.H.A., A.A.M., A.M., and A.P.A. contributed to research and analyses. All authors (A.J.B., I.L., D.H., J.M.H., G.V., G.M., M.J.M., K.Y., N.J.H.A., C.S.C., T.W., L.C.S., C.S.C., S.M., K.A.M., A.A.M., A.M., and A.P.A.) wrote and edited the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Engineering thanks Yanfeng Liu, Matthew Gilliham, and the other, anonymous, reviewer for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Berliner, A.J., Lipsky, I., Ho, D. et al. Space bioprocess engineering on the horizon. Commun Eng 1, 13 (2022). https://doi.org/10.1038/s44172-022-00012-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s44172-022-00012-9

This article is cited by

-

Space bioprocess engineering as a potential catalyst for sustainability

Nature Sustainability (2024)

-

Domains of life sciences in spacefaring: what, where, and how to get involved

npj Microgravity (2024)

-

Microbial biomanufacturing for space-exploration—what to take and when to make

Nature Communications (2023)

-

Toward sustainable space exploration: a roadmap for harnessing the power of microorganisms

Nature Communications (2023)

-

Theoretical design of a space bioprocessing system to produce recombinant proteins

npj Microgravity (2023)