Abstract

Seawater intrusion is a worldwide increasing challenge, which lowers the freshwater availability by salination of fresh groundwater resources in coastal areas. The abstraction-desalination-recharge (ADR) methodology can combat seawater intrusion, whereby desalination is hereby the key factor for the overall efficiency of aquifer remediation. Which desalination technique is suitable within ADR depends on several factors and was not discussed before. We use a multi-criteria decision analysis and cost analysis to compare nanofiltration, reverse osmosis, electrodialysis, and (membrane) capacitive deionization and show for three case scenarios which desalination technique is most suitable within ADR. Overall, electrodialysis, nanofiltration, and reverse osmosis have shown the best utility value for saline groundwater salinity of 1–10 g L−1, whereby electrodialysis is more suitable for lower salinities. The lowest desalination costs are calculated for nanofiltration and reverse osmosis with 0.3–0.6 € m−3 depending on specific energy costs. Even capacitive deionisation can be a suitable alternative for low, slightly saline groundwater (1 g L−1) if the technology readiness level and a lifetime of electrodes increase and material costs decrease. These new insights provide a data analysis, costs, and decision support for desalination which are needed for the holistic approach to counteract seawater intrusion.

Similar content being viewed by others

Introduction

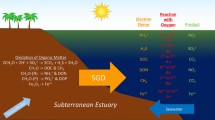

Groundwater salination describes the process of increasing the salinity of fresh groundwater resources. This process is driven by inland geogenic salt deposits, saline (waste) waters, or the inland drift of seawater into fresh groundwater aquifers1. The latter—often published with the term seawater intrusion—occurs due to increasing groundwater abstraction at coastal areas and rising sea levels decreasing freshwater availability2,3. In order to satisfy the need for water for drinking water, irrigation, and industrial purposes, sustainable management of the groundwater aquifer is needed. Reducing fresh groundwater abstraction and increasing natural groundwater recharge would remediate the aquifer but is often impossible to implement due to the growth of population and water needs in coastal sites. Abrupt reduction of pumping rates would rather lead to an increased seawater intrusion and long recovery periods4,5. Managed aquifer recharge is recommended to overcome the seawater intrusion problematic, whereby water-scarce regions show a lack of adequate water resources for recharge6,7. Therefore, desalination would be a key process to reduce the saline water amount in the aquifer and to ensure simultaneously water in adequate quality and quantity for recharge. A so called mixed hydraulic barrier system provides a negative barrier for the abstraction of saline groundwater (SGW) and a positive barrier as recharge to drive the saltwater interface towards the sea and remediate the aquifer8. The abstraction-desalination-recharge (ADR) methodology can be extended by using the desalinated water for domestic use and recharging treated wastewater7 (Fig. 1).

A practical application of ADR is not known to the authors. However, publications by Abd-Elhamid & Javadi8, Ebeling, Händel & Walther9, and Saad et al.10 proved the effective remediation of ADR by groundwater flow models. Remediation costs will thereby depend on site-specific costs for the abstraction, desalination, and recharge processes. The quantitative and qualitative requirements for desalination within ADR depend on regional conditions and are summarised according to the literature as follows.

Results of simulated ADR scenarios of Ebeling, Händel & Walther9, Sadjad Mehdizadeh, Badaruddin & Khatibi11 and Abd-Elaty, Abd-Elhamid & Qahman12 show that the remediation duration of a saline aquifer can be reduced by increasing the recharge rate. According to these studies, depending on the specific hydraulic characteristics of the aquifer, >100 m3 desalinated water per day and coast kilometer are needed for recharge, achieving a remediation duration of 3–100 years.

Saline groundwater effected by seawater intrusion usually show a sodium chloride concentration exceeding the drinking water and irrigation limit values13,14. SGW is classified in slightly, moderately, highly and very highly SGW due to their electrical conductivity or chloride concentration15,16 (Table 1).

The time and location-dependent specific composition of SGW depends thereby on the chemical, physical, and biological processes in the aquifer14. Seawater intrusion indicated processes, as cation exchange, calcite dissolution and sulphate reduction lead to mineralisation of the groundwater with calcium, magnesium, bicarbonate, dissolved nutrients, inorganic carbon, organic carbon, sulphide and metals3,17 which trigger scaling and fouling within desalination18. However, high nitrate concentrations in SGW often result from agriculture19,20.

Referring to Escalante et al.21, so far there exists no general guidelines or fixed limit concentrations for sodium and chloride concentrations for managed aquifer recharge. According to this publication and van der Bruggen22, the target concentration produced by desalination should meet regional conditions for optimal recharge and final use as the limit quality for drinking water23 and irrigation13,24 (Table 2). According to Martin25, the concentration for recharge water should equal the natural composition of the initial present freshwater concentration to reduce swelling, dissolution, precipitation, and clogging processes, which results in reduction of hydraulic conductivity of the aquifer. No complete desalination of the SGW is needed for managed aquifer recharge. The sodium chloride proportion of the total suspended solids (TDS) in SGW is usually 25% up to 90%14, therefore the rejection of sodium chloride (RNaCl) needs usually to be lower than 90%. The salt rejection by desalination is defined by the SGW concentration (cSGW) and the target recharge water concentration (crecharge).

If SGW contains organic carbon26, retention of organic matter is recommended to circumvent clogging problems during recharge25. Since the aquifer is prone to dissolved oxygen and pH changes as well27,28, aeration and intensive pH drifts during desalination should be avoided. Further, chemical use and temperature changes should be kept at a minimum since the brine, which consists of concentrated salts, is usually disposed into the sea29,30.

Since desalination is an energy consuming process, the specific energy consumption (SEC) for desalination will define the economic and ecologic feasibility of ADR. In anthropogenic-caused seawater intrusion-affected areas electric energy is usually available whereby these areas correlate with high solar radiation or wind power31,32,33, which makes desalination techniques powered by renewable energy more attractive for ADR. Since the theoretical minimum desalination energy needed for brackish water is lower than for seawater34, SEC for SGW desalination within ADR should be lower than the minimum SEC of seawater with 2.5 kWh m−335,36 in order to compete with managed aquifer recharge by seawater desalination.

Since several factors, as water quality and water quantity as well as the energy supply by renewable energy, are variable in time, flexible desalination technologies are favoured within ADR methodology. Further, adequate pre-treatment and post-treatment needs to be maintained as for other desalination applications according to the used desalination techniques37 to maintain an energy efficient treatment process.

Classic pressure-driven desalination techniques, as nanofiltration (NF) and reverse osmosis (RO), and electrochemical desalination techniques, as electrodialysis (ED), comply with the above-described requirements and show according to Wang et al.34 and Patel, Biesheuvel & Elimelech38 the lowest SEC for brackish water desalination. Contrary, thermal large-scale-desalination techniques as multiple effect distillation, multistage flash distillation, and mechanical vapour compression show a higher SEC and are more applicable for brines30. Desalination techniques, such as membrane distillation, solar distillation, humidification-dehumidification, and microbiological desalination, show a high energy consumption, are up to now not suitable for commercial large-scale applications or are less investigated for brackish water desalination39,40,41.

RO is the most often used desalination technique regarding seawater and brackish water desalination30. Within this technology, hydrostatic pressure greater than the osmotic pressure of the saline solution is used to drive the liquid through a membrane against the natural direction of osmosis, producing a permeate stream on the effluent site and a concentrate stream (brine) on the influent site of the membrane. RO membranes are usually constructed as spiral-wound modules42. The solution diffusion model was mostly used to describe the transport mechanisms within RO before Wang et al.43 emphasised that the water transport is driven by a pressure gradient and should be described by pore flow. Steric exclusion, Donnan effect, and dielectric exclusion of semipermeable membranes affect the specific salt rejection. RO is classified by the rising rejection rate of the membrane and rising feed pressure in: brackish water reverse osmosis (BWRO) and seawater reverse osmosis (SWRO). In addition, NF membranes, which are generally characterized by an even higher water and salt flux than BWRO, are often applied for low brackish water concentrations44.

In contrast to NF and RO, where the solvent as liquid is separated from the feed, electrochemical desalination technologies separate the ions of the feed, making these technologies, especially for lower salt rejections more advantageous45. Electrodialysis (ED) uses an electric potential difference to transport charged anions and cations through an ion exchange membrane (IEM) to produce a low-saline solution in diluate chambers and a high-saline solution in concentrate chambers, which are stacked in parallel. The salt rejection is described by electromigration, convection and diffusion46. Most of the ED processes are operated as ED reversal, whereby the concentration polarisation on the membranes can be reduced by reversing the electric potential. ED is usually used for concentrate recovery or for brackish water desalination if no total desalinated product is needed47.

Similar to ED, capacitive deioniation (CDI) is an electrochemical membrane technology, whereby charged ions can adsorb in the electric double layer of a positively and a negatively charged electrode producing a low-saline solution48. If static electrodes are used, alternating desorption processes by short-circuiting or reversing the electrical current produce a concentrate solution49. Electrode coatings or the implementation of ions exchange membranes in CDI, called membrane capacitive deionisation (MCDI), improves the charge efficiency50,51. Further, flow electrode CDI can ensure continuous desalination even at higher concentrated brackish water concentrations and resource recovery but needs higher investments caused by the higher complexity of the system52,53,54.

Which desalination technique is suitable and how high the costs would be within ADR is rarely discussed in the literature. Therefore, the main research questions of this paper are: which desalination techniques should be used, and what are the costs within ADR? We use a multi-criteria decision analysis based on a literature review and a cost calculation in order to evaluate which pressure-driven desalination technique (NF/RO) or electrochemical desalination techniques (ED, CDI, and MCDI) are most suitable for three different case studies showing a TDS concentration in SGW of 1 g L−1 (A), 5 g L−1 (B) & 10 g L−1 (C) and site-specific parameters. Here, we include environmental, economical, technical, and social criteria. We distinguish between two different scenarios: a present scenario according to the current parameters and a future scenario according to predicted material improvements, including cost declines and lifespan. In this paper, we focus on the traditional ADR methodology without wastewater treatment, whereby desalination requirements of saline water are similar for both approaches.

Results and discussion

Desalination costs and energy consumption

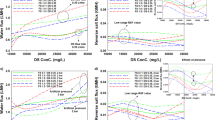

Costs and SEC for desalination are calculated for NF/RO, ED, CDI, and MCDI for SGW concentration of our case studies in Table 3: A - East Frisian Islands in Germany (1 g L−1)55,56,57; B—Kimje in South Korea (5 g L−1)58 and C - Nile Delta in Egypt (10 g L−1)59,60. Results for pressure-driven desalination costs are shown either for NF regarding case A, or for RO regarding case B and C considering which membranes are more efficient (Supplementary Table 1, Supplementary Fig. 1, Supplementary Methods). Figure 2 shows the specific capital expenditures per m3 (CAPEX), operational expenditures per m3 (OPEX), SEC and total costs per m3 in the present and future scenario. Costs and SEC for desalination increase with rising SGW concentrations regardless the desalination technology (Fig. 2a–e). The rise of costs and SEC with increasing SGW concentration is, however, steeper for the electrochemical technologies than for pressure-driven technologies, showing especially the advantage of RO, and disadvantage of ED, CDI and MCDI for higher SGW concentration and vice versa. The different case study-specific energy costs of Table 3 affect the costs but not these trends, since the influence of energy cost is superimposed by the SGW concentration in our study. The influence of the specific energy costs can be realised by differences between SEC (independent of energy price) in Fig. 2c and OPEX only for the SEC (OPEXenergy) in Fig. 2d. OPEXenergy for NF/RO and ED regarding case study A, B, and C does not variate much with 0.04–0.10 € m−3 compared to the SEC with 0.18–1.62 kWh m−3 due to the highest energy costs for case study A and the lowest energy costs for case study C. Detailed data can be found in Supplementary Table 2 and Supplementary Table 3. The calculated costs and SEC are generally in range with data given by literature (Supplementary Table 4). It should be noted that SEC and costs for CDI and MCDI for case C are only theoretically calculated and that these techniques are usually not suitable for a salinity of 10 g L−161.

a Capital expenditures (CAPEX), b operational expenditures without energy (OPEXwithout energy), c specific energy consumption (SEC), d energy costs (OPEXenergy), e total costs (Ctotal), and f total utility value for NF/RO, ED, CDI, and MCDI regarding case study A, B, and C. Costs of the future scenario are shown in a more glaring colour. Bars show comparative maximum and minimum values from other publications, which are listed in Supplementary Table 4. Pattern filling for CDI and MCDI show theoretical data since these technologies usually not used for SGW concentration of ≥10 g L−1.

The increase of CAPEX with the SGW concentration for electrochemical desalination techniques is higher than for pressure-driven desalination techniques (Fig. 2a). According to our calculations, CAPEX is the lowest for CDI with 0.05–0.25 € m−3 by assuming a high capacitance and a high module packing density of Liu et al.52. MCDI shows higher CAPEX with 0.07–0.56 € m−3 due to the IEM costs. Hand et al.62 and Bales et al.63 predict similar CAPEX, whereby in their publications, CAPEX can be up to 1.4 € m−3 depending on the assumed material characteristics. ED shows with 0.30–1.08 € m−3 higher CAPEX than CDI and MCDI and higher CAPEX than NF/RO with 0.20–0.35 € m−3. CAPEX of NF/RO and ED comply with real data by Wittholz et al.64 and Sajtar & Bagley65. Especially for higher SGW concentration, less or no data are published to validate the results for CDI and MCDI, compared to ED and NF/RO. CAPEX reduction in the future case scenario (Supplementary Table 3) by lower electrode costs and IEM costs (Supplementary Table 7) would further reduce CAPEX for CDI and MCDI, whereby CAPEX reduction for ED by lower IEM costs and for pressure-driven desalination techniques by a higher permeability is neglectable (Supplementary Methods, Supplementary Table 1). Increasing or decreasing the desalination capacity by factor 3 lowers and rises CAPEX for the specific desalination techniques, respectively, but does not impact the ratio between the specific techniques (Supplementary Fig. 2). Since CAPEX has the highest cost component in total costs of ED (details in Supplementary Table 2, Supplementary Fig. 1) the scale of the desalination plant influences this technique the most.

Regarding the SGW concentration of 1–10 g L−1, NF/RO shows the lowest OPEX without energy costs (OPEXwithout energy) due to low membrane costs, followed by ED (Fig. 2b). Note that NF membranes are considered for 1 g L−1 and RO membranes for 5–10 g L−1 SGW concentration (Supplementary Table 1, Supplementary Methods). OPEXwithout energy for CDI and MCDI is higher due to replacement of total module every half year up to 3 years for CDI and every 1 to 5 years for MCDI. According to the present scenario, CDI and MCDI are not cost-efficient for SGW concentration >1 g L−1 due to the needed membrane and electrode area, the specific material costs, and a low material lifetime. In the future scenario, the replacement costs for ED, CDI and MCDI can be reduced by the assumed reduced IEM costs and electrode costs as well as by an expanded electrode lifetime. Increasing the lifetime of NF/RO membranes does not lower OPEX due to the low membrane costs.

The lowest SEC and OPEXenergy is calculated for ED, whereby the difference to NF/RO decreases with higher SGW concentration (Fig. 2c, d). The SEC for CDI and MCDI is higher even though we considered energy recovery. In contrast to OPEXwithout energy, OPEXenergy is lower for MCDI than for CDI due to a higher charge efficiency and higher energy recovery of MCDI.

Summarising OPEX and CAPEX of the present scenario, NF and RO show with 0.33 € m−3 and 0.45–0.55 € m−3 the lowest total costs (Ctotal) in Fig. 2e for case study A, B, and C, respectively, whereby material improvements will not significantly change the costs as earlier discussed by Werber, Deshmukh & Elimelech66. However, future material improvements can lower total costs for ED, CDI, and MCDI for case study C from 1.41 to 1.26 € m−3, from 2.49 to 1.08 € m−3 and from 4.71 to 0.70 € m−3, respectively (Supplementary Table 2 in comparison to Supplementary Table 3). According to Supplementary Fig. 3a, the general result would be similar assuming for all case studies the same energy consumption, showing total costs for NF/RO between 0.30 and 0.60 € m−3. If the theoretical cost assumptions for CDI and MCDI can be verified in big-scale long-term desalination, especially MCDI could be a cost efficient alternative. In total, the SGW salinity, material costs of membranes and electrodes have a high impact on the desalination costs. It needs to be noted, that a target concentration for recharge >0.45 g L−1 would result in a lower needed salt retention, resulting in lower OPEX and CAPEX, especially for electrochemical desalination technologies. Since all results for costs and SEC depend on the rejection of sodium chloride, experimental investigations would bring higher accuracy for specific feedwater compositions, especially for monovalent desalination45.

Multi-criteria decision analysis

The resulting total utility values for NF/RO, ED, CDI, and MCDI for case study A, B, and C of the multi-criteria decision analysis are shown in Fig. 2f. The utility value and weight for each criterion, desalination alternative and case study are shown inclusive references in Supplementary Table 5 and Supplementary Table 6. Criteria as water recovery, retention of sodium chloride, CAPEX, OPEXwithout energy, technology readiness level, and occupational safety for the desalination techniques are rated with a higher significance regarding the application within the ADR methodology, whereby criteria as the space requirement and flexibility & tolerance are rated with a lower significance (Fig. 3).

According to our multi-criteria decision analysis, ED and NF/RO show for all case studies in the present scenario, the highest total utility value due to a high water recovery, a high salt retention, a high material lifetime, a high occupational safety level, a high suitability to be coupled with renewable energy, low social requirements and the before mentioned results for CAPEX, OPEX and SEC. For a low SGW concentration as for case study A, especially the electrochemical technologies show a higher total utility value compared to case study B and C cause of their lower need of chemical application, a low SEC, the option of using monovalent desalination and a more flexible process. ED shows therefore the highest utility value for case A in the present and future scenarios. ED benefits in the future scenario by lower costs, improved material properties and higher monovalent ion selectivity of IEM as recently discussed by Patel et al.67, giving ED the highest utility value regarding case study B.

NF/RO has a higher total utility value regarding the criteria maintenance and lifetime of materials and shows lower total desalination costs as discussed before. Improvements of the permeability and durability of the membranes does here effectively increase the total utility value for NF/RO in the future scenario in comparison to the before discussed cost and energy results.

CDI and MCDI show in the present scenario a low technology readiness level and a low lifetime of the electrode. Without increasing the durability of the electrode or similar materials, these techniques cannot compete with ED and NF/RO. Due to the finite specific salt adsorption, high costs for IEM, and lower water recovery at higher SGW concentration, these desalination technologies are less suitable for higher SGW concentrations. The drawback of finite salt adsorption might be solved in the future by flow electrode CDI. For low SGW concentrations, CDI and MCDI can be an alternative for NF/RO and ED.

Weighting the criteria of case study A and C similar to case study B as in Supplementary Table 6—assuming that the case studies would only differ from their SGW concentration—surprisingly do not change the total utility value. Supplementary Fig. 3b shows approximately the same total utility value as in Fig. 2f, showing that in our study the SGW salinity mostly impacts the total utility value of the desalination techniques. The high energy price of Case A has according to our weighting not shown the full effect cause of the low SGW concentration. The energy price would have a higher impact in higher saline case studies because of their higher SEC. Including specific (monovalent) ion rejection, specific case-dependent material costs, and more specific details of a survey with different stakeholders can, however, result in more differentiated utility values.

ADR is a highly important methodology to remediate saline aquifers due to increasing seawater intrusion by climate change and sea level rise within the future. So far, the suitability and costs of different desalination techniques have not been evaluated before. We evaluate NF/RO, ED, CDI, and MCDI according to the specific requirements within ADR by a multi-criteria decision analysis. Based on the current literature, NF/RO and ED are the most suitable technologies within the application of ADR to remediate saline aquifers with a concentration of 1–10 g/L. Especially for slightly SGW, ED shows the highest total utility value according to the low chemical application, high flexibility, low SEC, moderate costs, and monovalent ions selective rejection. In the future scenario, ED would profit verifiably by reduced IEM costs and improved material properties. Regarding the total costs, NF/RO are for the chosen case studies with 0.3–0.6 € m−3 the most cost-effective desalination technology. Even though CDI and MCDI are not able to compete with NF/RO and ED yet, lots of research is currently focused on improving their material drawbacks. With the three site-specific case studies, we want to highlight that the multi-criteria decision analysis and cost analysis depend on the site-specific conditions, parameters, and targets. However, the SGW and product water quality have the highest influence on the evaluation. This analysis could be further extended to an abstraction-desalination-recharge by treated wastewater (ADRTWW) methodology (Fig. 1) in order to identify additional costs and possible synergies in water use. The cost and multi-criteria decision analysis of this paper can be coupled with a groundwater transport model to analyze the nexus of salinization, remediation duration, and desalination costs. This coupled model could be further used as decision help in a holistic comparison with alternative methodologies (e.g., the building of water retention and infiltration ponds) to counteract seawater intrusion.

Methods

Comparative desalination techniques and case studies

NF, RO, and ED are standard brackish water desalination technologies and are therefore included in our comparative analysis. Even though, CDI is examined mostly in laboratory scale and is controversy discussed in the literature61,68,69,70, we included CDI and MCDI as potentially suitable technology in our study due to a high retention of sodium chloride13,71,72, recent economic analyses52,62,63 and increasing interest in this technology73. A literature study for costs and SEC for brackish water desalination demonstrate the suitability of the preselected desalination technologies according to the before described requirements according quantity (>100 L d−1), quality (25% < RNaCl < 90%) and SEC (generally <2.5 kWh m−3). CDI and MCDI are usually not applied for feed concentrations of 5–10 g L−161. However, CDI is included for these concentrations to demonstrate the trend with increasing concentrations. Flow electrode CDI, which shows a higher desalination capacity is not included in our study due to less experiences and data at treatment capacities >100 L d−153,54.

The suitability of the desalination techniques and the costs depends on the site-specific conditions, therefore a multi-criteria decision analysis and costs analysis for three different SWI affected cases (Table 3) is conducted. The East Frisian Islands in Germany, Kimje in South Korea, and the Nile Delta in Egypt were chosen as examples with different SGW concentrations and different economic, social, and environmental characteristics.

Cost and energy calculation

CAPEX, OPEX, and SEC variate according to the SGW concentration and process parameters. In order give a fair comparison in this paper, costs and SEC are calculated for 600 m³/d recharge per kilometres of coastline and a remediation duration of 4 and 50 years according to the simulation of Ebeling, Händel & Walther9. The assumed water recovery was 75% with a water abstraction rate of 800 m3 d−1. Since CAPEX per produced flow rate are lower at higher capacities up to a limit capacity of 200,000 m3 d−136, we set the production rate per day to remediate 100 km coastline to 60,000 m3 d−1, which corresponds with the recharge rate of 600 m3 d−1 km−1. This production capacity is classified as a medium size desalination plant36. The capacity is increased and decreased by a factor of 3 in order to check, if this would have a major influence on the costs.

Total desalination costs (\({C}_{{\rm{total}}}\)) are divided into capital expenditures and operational expenditures. CAPEX include expenditures as conception, design, construction, while OPEX include regularly operation and maintenance costs associated with the plant as membrane replacement, energy costs, labour and maintenance costs. Since the energy price differs for the case studies (Table 3), we differentiate between OPEX without energy (OPEXwithout energy), energy costs (OPEXenergy) and SEC.

CAPEX and OPEX for NF, RO and ED are well known due to their large-scale desalination application over decades. The costs for these techniques are calculated similar to Wittholz et al.64, Sajtar & Bagley65, Abdulbaki et al.74 and Wreyford et al.75 based on real large-scale data. Data of large-scale CDI costs are not published even though CDI plants up to 60,000 m3 d−1 are already in use76. The cost calculation for CDI bases therefore on economic analysis of Liu et al.52 for CDI and MCDI. Suitable NF and RO membranes are chosen regarding the feed concentration and needed retention rates in case A (NF membrane), B (BWRO membrane) and C (SWRO membrane) as pressure and flux and therefore costs changes. This gives a fairer comparison to electrochemical technologies which can be easily adjusted by the applied electric current and voltage.

The total costs per m3 partial desalinated water are calculated for each desalination technology depending on the specific SGW concentration of case study A, B, and C (1–10 g L−1, Table 3) and a target concentration of 0.45 g/L for the present and future scenario. The target concentration is chosen according to the recommended concentration in Table 2, which fulfils the recommendation of Escalante et al.21 and van der Bruggen et al.22. Detailed characteristics as feedwater-specific chemical cleaning, specific labour costs and monovalent selective rejection was not included in the cost and energy calculation. However, these characteristics are included in the multi-criteria decision analysis. A detailed description about the cost calculation is shown in Supplementary Methods.

Multi-criteria decision analysis

In this paper, the multi-criteria decision analysis is used as decision help method to choose site-specific desalination techniques according to their weights of various criteria. This method gives a flexible transparently evaluation, the possibility to consider even seemingly non-related factors due to the broad criteria composition77 and is adaptable to before-mentioned requirements. Further, a multi-criteria decision analysis was recently used to evaluate water treatment processes as in AbdulBaki et al.78 and Wencki et al.79. We analysed NF/RO, ED and CDI for 17 criteria, which were divided into four categories: environmental, economical, technical and social (Fig. 3).

The desalination alternatives were evaluated according to a fast sustainable remediation of saline aquifers within ADR. A specific utility value (v) is given for each criteria (r) depending on the specific case (x) and desalination technique (a).

Here, m is the number of criteria and \(w\) the weight which define how important the criteria is according to the remediation of the aquifer (Table 4). Thereby, the sum of all weights has to be 1. The variable t represents the time scenario. We analysed the suitability of the technologies according to current knowledge in the literature for a present scenario (2023) and a future scenario (2043) due to predicted technical and material improvements (Supplementary Methods). As shown in the Supplementary References, 160 references were used in order to represent a transparent and non-subjective evaluation. The values and weights are given according to the evaluation standard for three case studies to rate the suitability of the technologies according to their specific conditions.

Data availability

The datasets used and/or analysed during the current study are available in the Supplementary information. Further data are available from the corresponding author on reasonable request.

References

UN Water. The United Nations World Water Development Report 2022 - groundwater making the invisible visible. (2022).

Bear, J. & Cheng, A. H.-D. Introduction. In: Seawater Intrusion in Coastal Aquifers — concepts, methods and practices (eds. Bear, J., Cheng, A. H.-D., Sorek, S., Ouazar, D. & Herrera, I.) 1–8 (Springer Netherlands, 1999).

Werner, A. D. et al. Seawater intrusion processes, investigation and management: recent advances and future challenges. Adv. Water Resour. 51, 3–26 (2013).

Walther, M. et al. Assessing the saltwater remediation potential of a three-dimensional, heterogeneous, coastal aquifer system: Model verification, application and visualization for transient density-driven seawater intrusion. Environ. Earth Sci. 72, 3827–3837 (2014).

Walther, M., Stoeckl, L. & Morgan, L. K. Post-pumping seawater intrusion at the field scale: Implications for coastal aquifer management. Adv. Water Resour. 138, 103561 (2020).

Casanova, J., Devau, N. & Pettenati, M. Managed aquifer recharge: an overview of issues and options. In: Integrated groundwater management: concepts, approaches and challenges (eds. Jakeman, A. J., Barreteau, O., Hunt, R. J., Rinaudo, J.-D. & Ross, A.) 413–434 (Springer International Publishing, 2016).

Hussain, M. S., Abd-Elhamid, H. F., Javadi, A. A. & Sherif, M. M. Management of seawater intrusion in Ccoastal aquifers: a review. Water 11, 2467 (2019).

Abd-Elhamid, H. F. & Javadi, A. A. A cost-effective method to control seawater intrusion in coastal aquifers. Water Resour. Manag. 25, 2755–2780 (2011).

Ebeling, P., Händel, F. & Walther, M. Potential of mixed hydraulic barriers to remediate seawater intrusion. Sci. Total Environ. 693, 133478 (2019).

Saad, S., Javadi, A. A., Chugh, T. & Farmani, R. Optimal management of mixed hydraulic barriers in coastal aquifers using multi-objective Bayesian optimization. J. Hydrol. 612, 128021 (2022).

Sadjad Mehdizadeh, S., Badaruddin, S. & Khatibi, S. Abstraction, desalination and recharge method to control seawater intrusion into unconfined coastal aquifers. GJESM 5, 107–118 (2019).

Abd-Elaty, I., Abd-Elhamid, H. F. & Qahman, K. Coastal aquifer protection from saltwater intrusion using abstraction of brackish water and recharge of treated wastewater: case study of the gaza aquifer. J. Hydrol. Eng. 25, 05020012 (2020).

Rosentreter, H., Walther, M. & Lerch, A. Partial desalination of saline groundwater: comparison of nanofiltration, reverse osmosis and membrane capacitive deionisation. Membranes 11, 126 (2021).

Tomaszkiewicz, M., Abou Najm, M. & El-Fadel, M. Development of a groundwater quality index for seawater intrusion in coastal aquifers. Environ. Model. Softw. 57, 13–26 (2014).

Rhoades, J. D., Kandiah, A. & Mashali, A. M. The use of saline waters for crop production. (Food and Agriculture Organization of the United Nations, Rome, 1992).

Konikow, L. F. & Reilly, T. E. Seawater Intrusion in the United States. In: Seawater intrusion in coastal aquifers — concepts, methods and practices (eds. Bear, J., Cheng, A. H.-D., Sorek, S., Ouazar, D. & Herrera, I.) 463–506 (Springer Netherlands, 1999).

Moore, W. S. & Joye, S. B. Saltwater intrusion and submarine groundwater discharge: acceleration of biogeochemical reactions in changing coastal aquifers. Front. Earth Sci. 9, 600710 (2021).

Honarparvar, S. et al. Frontiers of membrane desalination processes for brackish water treatment: a review. Membranes 11, 246 (2021).

Libutti, A. & Monteleone, M. Soil vs. groundwater: the quality dilemma. Managing nitrogen leaching and salinity control under irrigated agriculture in Mediterranean conditions. Agric. Water Manag. 186, 40–50 (2017).

Weissman, G. et al. Increased irrigation water salinity enhances nitrate transport to deep unsaturated soil. VZJ 19, e20041 (2020).

Escalante, E. F., Casas, J. D. H., Medeiros, A. M. V. & Sauto, J. S. S. Regulations and guidelines on water quality requirements for Managed Aquifer Recharge. International comparison. AS/IT JGW 9, 2 (2020).

Van der Bruggen, B. et al. Electrodialysis and nanofiltration of surface water for subsequent use as infiltration water. Water Res, 37, 3867–3874 (2003).

WHO Press. Guidelines for drinking-water quality. (Gutenberg, Genf, 2011).

Bloetscher, F., Sham, C. H., Danko III, J. J. & Ratick, S. Lessons learned from aquifer storage and recovery (ASR) systems in the United States. JWARP 06, 1603–1629 (2014).

Martin, R. Clogging issues associated with managed aquifer recharge methods. IAH commission on managing aquifer recharge 214 (2013).

McDonough, L. K. et al. A new conceptual framework for the transformation of groundwater dissolved organic matter. Nat. Commun. 13, 2153 (2022).

Dillon, P. et al. Sixty years of global progress in managed aquifer recharge. Hydrogeol. J. https://doi.org/10.1007/s10040-018-1841-z (2018).

Zhang, H., Xu, Y. & Kanyerere, T. A review of the managed aquifer recharge: historical development, current situation and perspectives. Phys. Chem. Earth 118–119, 102887 (2020).

Bellona, C. Brine management. In: a multidisciplinary introduction to desalination (River Publishers, 2018).

Jones, E., Qadir, M., van Vliet, M. T. H., Smakhtin, V. & Kang, S. The state of desalination and brine production: a global outlook. Sci. Total Environ. 657, 1343–1356 (2019).

Cao, T., Han, D. & Song, X. Past, present, and future of global seawater intrusion research: a bibliometric analysis. J. Hydrol. 603, 126844 (2021).

Global Solar Atlas 2.0. https://globalsolaratlas.info/map (2023).

Global Wind Atlas 3.0. https://globalwindatlas.info (2023).

Wang, L., Violet, C., DuChanois, R. M. & Elimelech, M. Derivation of the theoretical minimum energy of separation of desalination processes. J. Chem. Educ. 97, 4361–4369 (2020).

Plakas, K., Sioutopoulos, D. & Karabelas, A. Energy consumption and minimization. In: A multidisciplinary introduction to desalination (River Publishers, 2018).

Voutchkov, N. Desalination project cost estimating and management. (CRC Press, 2019).

Voutchkov, N. Pretreatment. In: A multidisciplinary introduction to desalination (River Publishers, 2018).

Patel, S. K., Biesheuvel, P. M. & Elimelech, M. Energy consumption of brackish water desalination: identifying the sweet spots for electrodialysis and reverse osmosis. ACS EST Eng. 1, 851–864 (2021).

Aboutalebi, S. H., Yfantis, A. & Yfantis, N. State-of-the-art desalination research. In: A Multidisciplinary Introduction to Desalination (River Publishers, 2018).

Bazargan, A. & Salgado, B. Fundamentals of desalination technology. In: A multidisciplinary introduction to desalination (ed. Bazargan, A.) 41–92 (IWA Publishing, London, 2018).

Al-Mutaz, I. S. Thermal processes. In: A multidisciplinary introduction to desalination (River Publishers, 2018).

Greenlee, L. F., Lawler, D. F., Freeman, B. D., Marrot, B. & Moulin, P. Reverse osmosis desalination: water sources, technology, and today’s challenges. Water Res. 43, 2317–2348 (2009).

Wang, L. et al. Water transport in reverse osmosis membranes is governed by pore flow, not a solution-diffusion mechanism. Sci. Adv. 9, eadf8488 (2023).

Dach, H. Comparison of nanofiltration and reverse osmosis processes for a selective desalination of brackish water feeds. (Université d’Angers, 2008).

Alkhadra, M. A. et al. Electrochemical methods for water purification, ion separations, and energy conversion. Chem. Rev. 122, 13547–13635 (2022).

Strathmann, H. Electrodialysis, a mature technology with a multitude of new applications. Desalination 264, 268–288 (2010).

Al-Amshawee, S. et al. Electrodialysis desalination for water and wastewater: a review. J. Chem. Eng. 380, 122231 (2020).

Oren, Y. Capacitive deionization (CDI) for desalination and water treatment — past, present and future (a review). Desalination 228, 10–29 (2008).

Zhao, R., Porada, S., Biesheuvel, P. M. & van der Wal, A. Energy consumption in membrane capacitive deionization for different water recoveries and flow rates, and comparison with reverse osmosis. Desalination 330, 35–41 (2013).

Biesheuvel, P. M. & van der Wal, A. Membrane capacitive deionization. J. Membr. Sci. 346, 256–262 (2010).

Porada, S., Zhao, R., van der Wal, A., Presser, V. & Biesheuvel, P. M. Review on the science and technology of water desalination by capacitive deionization. Prog. Mater. Sci. 58, 1388–1442 (2013).

Liu, X., Shanbhag, S., Bartholomew, T. V., Whitacre, J. F. & Mauter, M. S. Cost comparison of capacitive deionization and reverse osmosis for brackish water desalination. ACS EST Eng. 1, 261–273 (2021).

Shin, Y.-U., Lim, J., Boo, C. & Hong, S. Improving the feasibility and applicability of flow-electrode capacitive deionization (FCDI): Review of process optimization and energy efficiency. Desalination 502, 114930 (2021).

Zhang, C. et al. Flow electrode capacitive deionization (FCDI): recent developments, environmental applications, and future perspectives. Environ. Sci. Technol. 55, 4243–4267 (2021).

Houben, G. J., Koeniger, P. & Sültenfuß, J. Freshwater lenses as archive of climate, groundwater recharge, and hydrochemical evolution: Insights from depth-specific water isotope analysis and age determination on the island of Langeoog. Ger. Water Resour. Res. 50, 8227–8239 (2014).

Costabel, S., Siemon, B., Houben, G. & Günther, T. Geophysical investigation of a freshwater lens on the island of Langeoog, Germany—Insights from combined HEM, TEM and MRS data. Appl. Geophys. 136, 231–245 (2017).

González, E. et al. Modellierung der küstennahen Grundwasserversalzung in Niedersachsen abgeleitet aus aeroelektromagnetischen Daten. Grundwasser 26, 73–85 (2021).

Kim, J.-H. et al. Application of cluster analysis for the hydrogeochemical factors of saline groundwater in Kimje, Korea. Geosci. J. 7, 313–322 (2003).

Ahmed, M. A., Abdel Samie, S. G. & Badawy, H. A. Factors controlling mechanisms of groundwater salinization and hydrogeochemical processes in the quaternary aquifer of the Eastern Nile Delta, Egypt. Environ. Earth Sci. 68, 369–394 (2013).

Elewa, H. H., Shohaib, R. E., Qaddah, A. A. & Nousir, A. M. Determining groundwater protection zones for the Quaternary aquifer of northeastern Nile delta using GIS-based vulnerability mapping. Environ. Earth Sci. 68, 313–331 (2013).

Patel, S. K., Qin, M., Walker, W. S. & Elimelech, M. Energy efficiency of electro-driven brackish water desalination: electrodialysis significantly outperforms membrane capacitive deionization. Environ. Sci. Technol. 54, 3663–3677 (2020).

Hand, S., Guest, J. S. & Cusick, R. D. Technoeconomic analysis of brackish water capacitive deionization: navigating tradeoffs between performance, lifetime, and material costs. Environ. Sci. Technol. 53, 13353–13363 (2019).

Bales, C. et al. Predictive performance and costing model for Membrane Capacitive Deionization (MCDI) at operational scale. Desalination 557, 116595 (2023).

Wittholz, M. K., O’Neill, B. K., Colby, C. B. & Lewis, D. Estimating the cost of desalination plants using a cost database. Desalination 229, 10–20 (2008).

Sajtar, E. T. & Bagley, D. M. Electrodialysis reversal: process and cost approximations for treating coal-bed methane waters. Desalin. Water Treat. 2, 284–294 (2009).

Werber, J. R., Deshmukh, A. & Elimelech, M. The critical need for increased selectivity, not increased water permeability, for desalination membranes. Environ. Sci. Technol. Lett. 3, 112–120 (2016).

Patel, S. K., Lee, B., Westerhoff, P. & Elimelech, M. The potential of electrodialysis as a cost-effective alternative to reverse osmosis for brackish water desalination. Water Res. 250, 121009 (2024).

Qin, M. et al. Comparison of energy consumption in desalination by capacitive deionization and reverse osmosis. Desalination 455, 100–114 (2019).

Qin, M. et al. Response to comments on “comparison of energy consumption in desalination by capacitive deionization and reverse osmosis”. Desalination 462, 48–55 (2019).

Ramachandran, A. et al. Comments on “Comparison of energy consumption in desalination by capacitive deionization and reverse osmosis”. Desalination 461, 30–36 (2019).

Guyes, E. N., Shocron, A. N., Chen, Y., Diesendruck, C. E. & Suss, M. E. Long-lasting, monovalent-selective capacitive deionization electrodes. npj Clean. Water 4, 1–11 (2021).

Shocron, A. N., Roth, R. S., Guyes, E. N., Epsztein, R. & Suss, M. E. Comparison of ion selectivity in electrodialysis and capacitive deionization. Environ. Sci. Technol. Lett. 9, 889–899 (2022).

Ma, J., Zhou, R. & Yu, F. Hotspots and future trends of capacitive deionization technology: a bibliometric review. Desalination 571, 117107 (2024).

Abdulbaki, D., Al-Hindi, M., Yassine, A. & Abou Najm, M. An optimization model for the allocation of water resources. J. Clean. Prod. 164, 994–1006 (2017).

Wreyford, J. M., Dykstra, J. E., Wetser, K., Bruning, H. & Rijnaarts, H. H. M. Modelling framework for desalination treatment train comparison applied to brackish water sources. Desalination 494, 114632 (2020).

Suss, M. E. et al. Water desalination via capacitive deionization: what is it and what can we expect from it? Energy Environ. Sci. 8, 2296–2319 (2015).

Ishizaka, A. & Nemery, P. Multi‐criteria decision analysis: methods and software. (Wiley, 2013). https://doi.org/10.1002/9781118644898.

AbdulBaki, D., Mansour, F., Yassine, A., Al-Hindi, M. & Abou Najm, M. Multi-criteria decision making for the selection of best practice seawater desalination technologies. In: Frontiers in water-energy-nexus—nature-based solutions, advanced technologies and best practices for environmental sustainability (eds. Naddeo, V., Balakrishnan, M. & Choo, K.-H.) 489–492 (Springer International Publishing, Cham, 2020). https://doi.org/10.1007/978-3-030-13068-8_122.

Wencki, K. et al. Approaches for the evaluation of future-oriented technologies and concepts in the field of water reuse and desalination. J. Water Reuse Desalin. 10, 269–283 (2020).

Acknowledgements

This research was funded by a European Social Fund (ESF-doctoral scholarship) from the free-state of Saxony, Germany. Further, we acknowledge support by the Open Access Publication Funds of the SLUB/Technische Universität Dresden. The funders played no role in study design, data collection, analysis and interpretation of data, or the writing of this manuscript.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

Conceptualisation by M.W., A.L., and H.R. H.R. prepared the literature research, calculations and analysed the data. H.R. wrote the manuscript. M.W. and A.L. reviewed and edited the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rosentreter, H., Walther, M. & Lerch, A. Assessing the suitability of desalination techniques for hydraulic barriers. npj Clean Water 7, 40 (2024). https://doi.org/10.1038/s41545-024-00331-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41545-024-00331-8